Patents

Literature

64results about How to "Reduce output pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

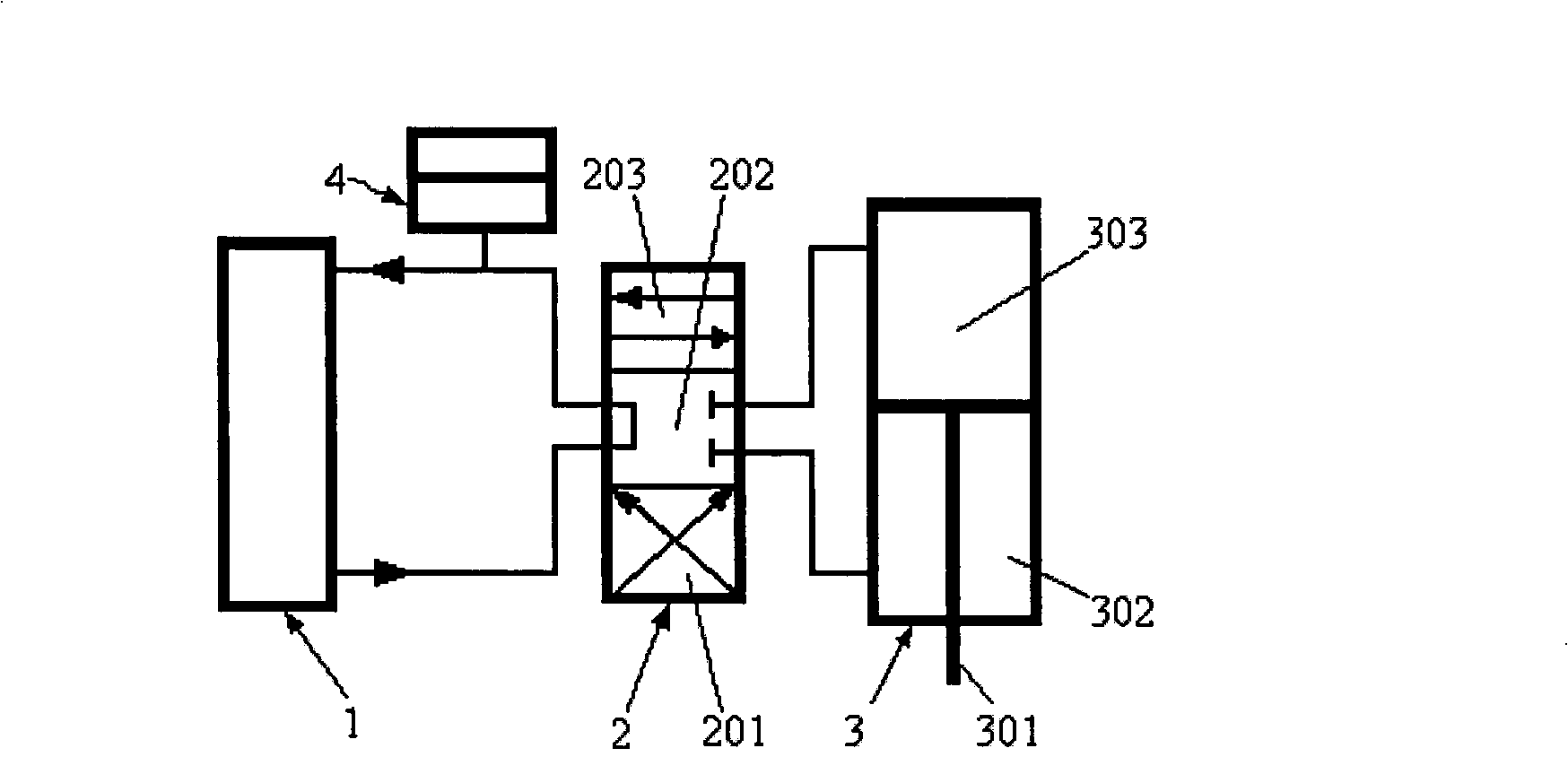

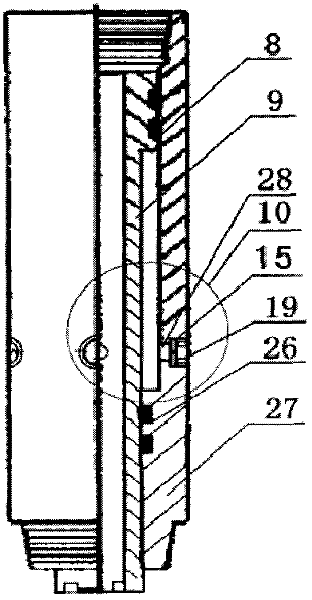

Piezoelectric hydraulic linear motor

InactiveCN101354052ASimple structureEasy to controlFlexible member pumpsFluid-pressure actuatorsPiezoelectric pumpPiston

The invention relates to a piezoelectric hydraulic linear motor which pertains to the field of mechanical-electrical-hydraulic integration. An inlet of a piezoelectric pump is connected with an accumulator by a pipeline; the accumulator is also connected with a reversing valve by the pipeline; the reversing valve is connected with an outlet of the piezoelectric pump by the pipeline; the reversing valve is also connected with a cavity body of a hydraulic cylinder. The piezoelectric hydraulic linear motor has the advantages of novel structure, being capable of effectively converting the micro-amplitude reciprocating vibration of piezoelectric ceramic to the micro liner motion of a piston of the hydraulic cylinder by utilizing fluid media to transmit power, obtaining relatively large driving power and motion displacement and realizing precise driving and control by a method of accumulating a liquid drop for one time; meanwhile, the piezoelectric hydraulic motor has simple structure and control, small volume and good sealing property and can be applied to marking parts.

Owner:JILIN UNIV

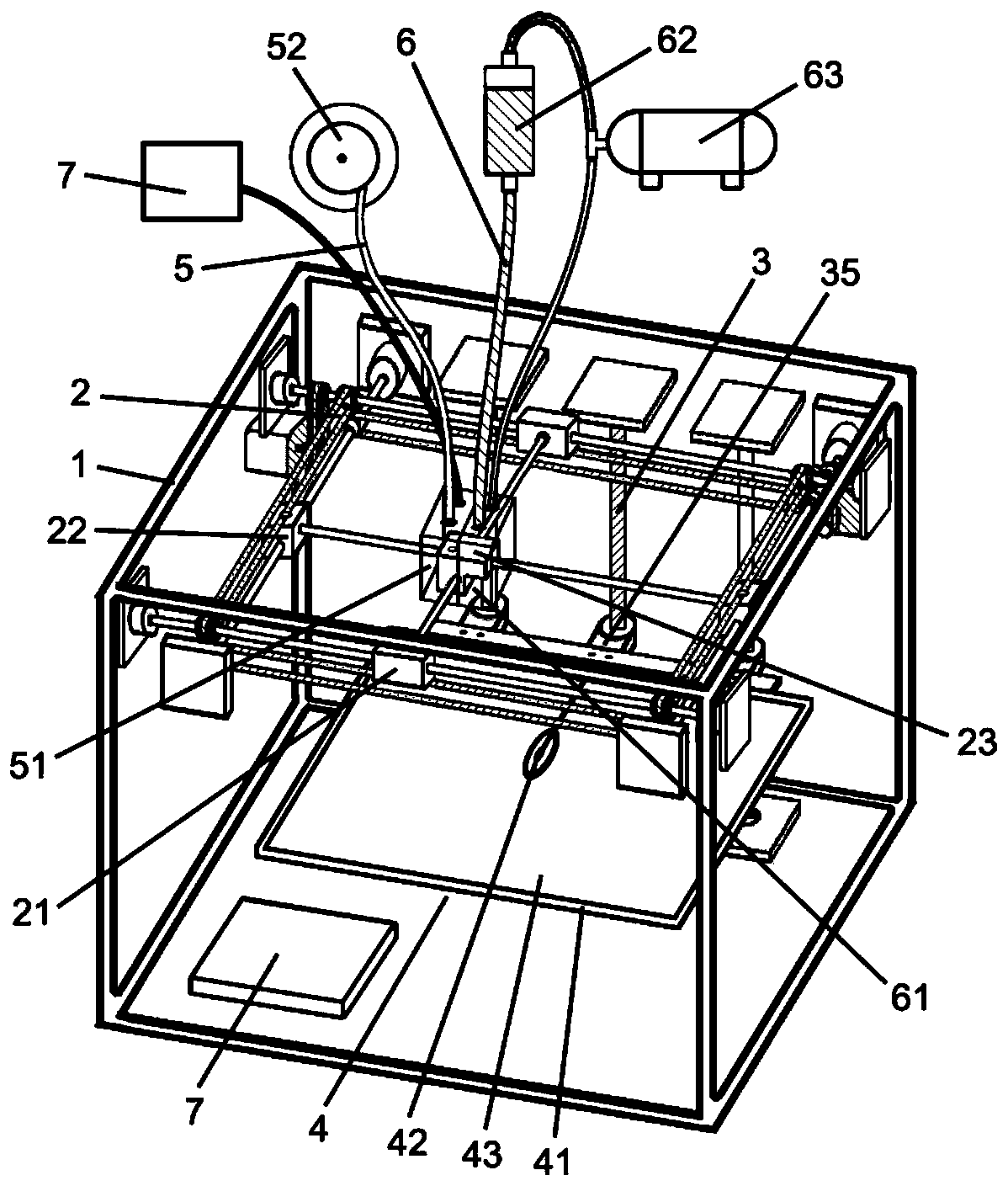

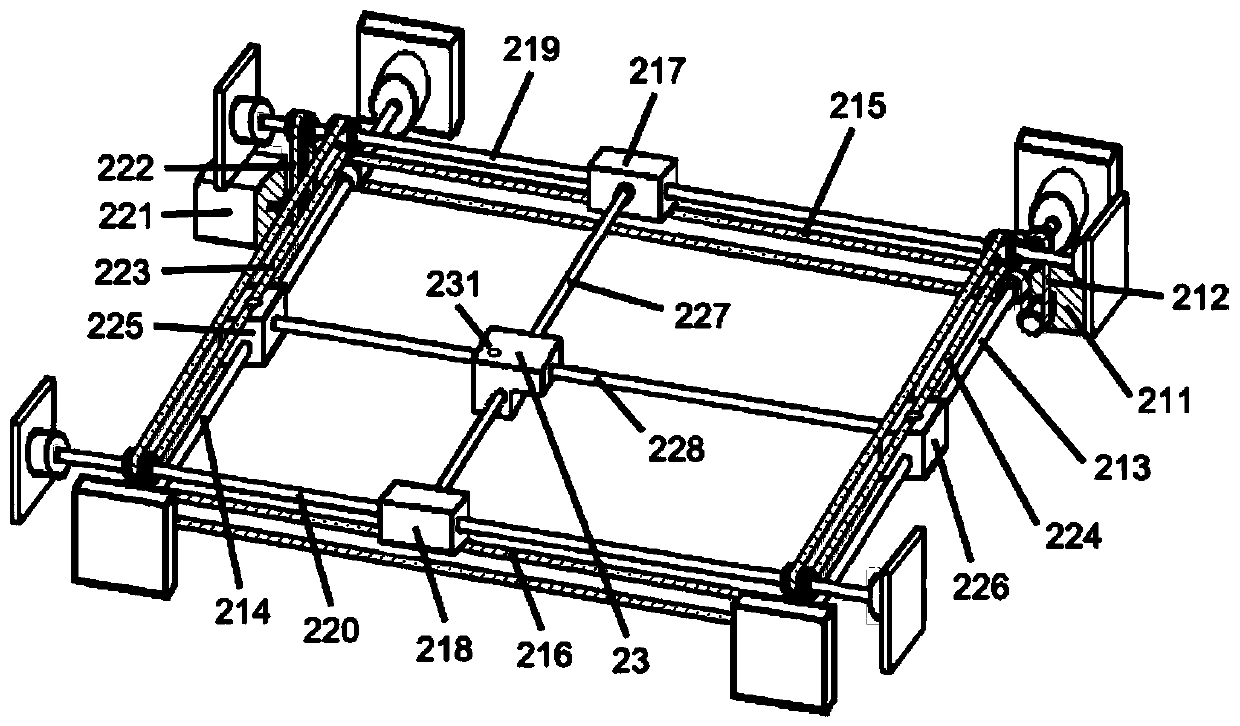

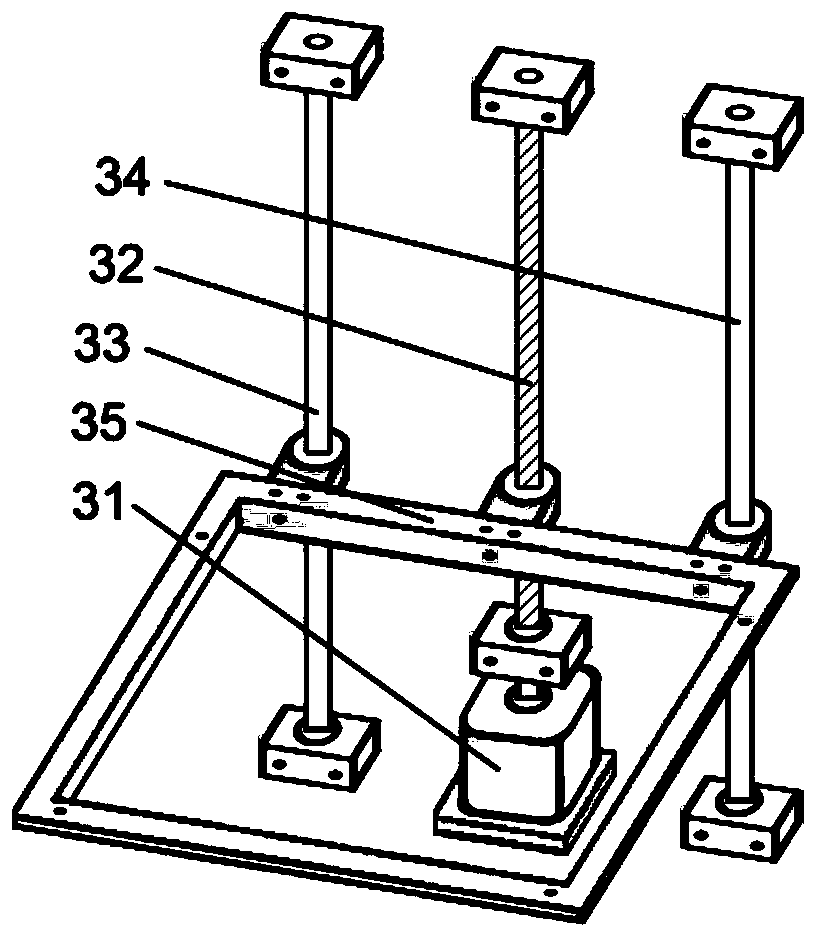

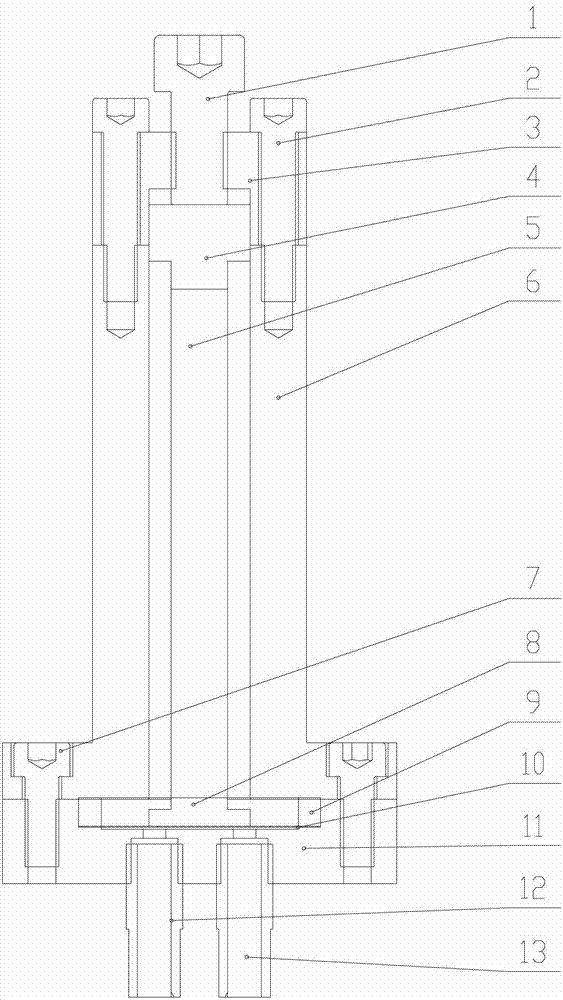

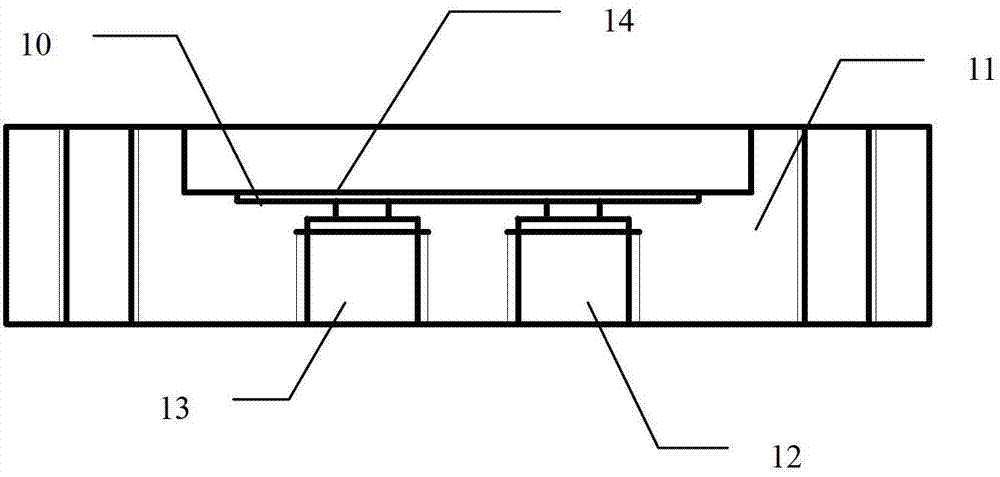

Solid material and liquid material combined dual-nozzle 3D printer and printing method thereof

PendingCN110614767A3D printing realizedRealize one machine with multiple functionsAdditive manufacturing apparatusIncreasing energy efficiencyThroatEngineering

The invention discloses a solid material and liquid material combined dual-nozzle 3D printer and a printing method thereof. The dual-nozzle 3D printer comprises a frame, an XY side moving module, a Zaxis moving module, a carrying plate, a solid material printing unit, a liquid material printing unit and a master control module, wherein the solid material printing unit comprises a solid printing head module and a wire feeding module; the upper end of a wire feeding throat pipe of the solid printing head module penetrates through a fixed plate of a cooling module to communicate with a wire feeding channel in the XY side moving module; and the lower end of the wire feeding throat pipe extends into a circular through hole of a metal heating block to communicate with a solid nozzle. An articlecombining the solid material with the liquid material can be printed, or a solid material article or a liquid material article is individually printed, and dual-component liquid materials are mixedlyprinted, a feeding module and a printing speed of the liquid material are flexibly controlled, and the combined dual-nozzle 3D printer and the printing method are suitable for performing 3D printingon multiple materials comprising a thermosensitive or thermoset liquid material.

Owner:SOUTH CHINA UNIV OF TECH

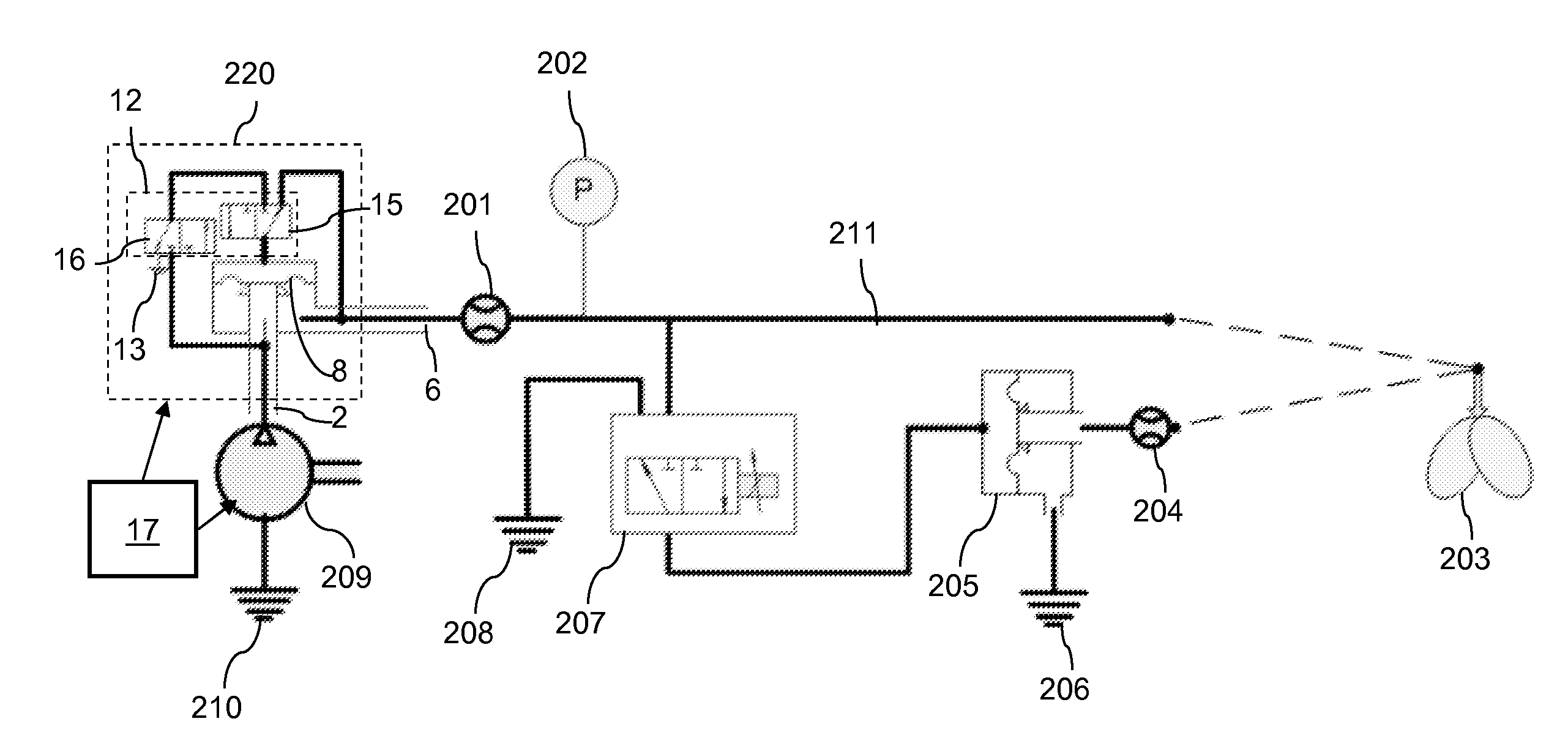

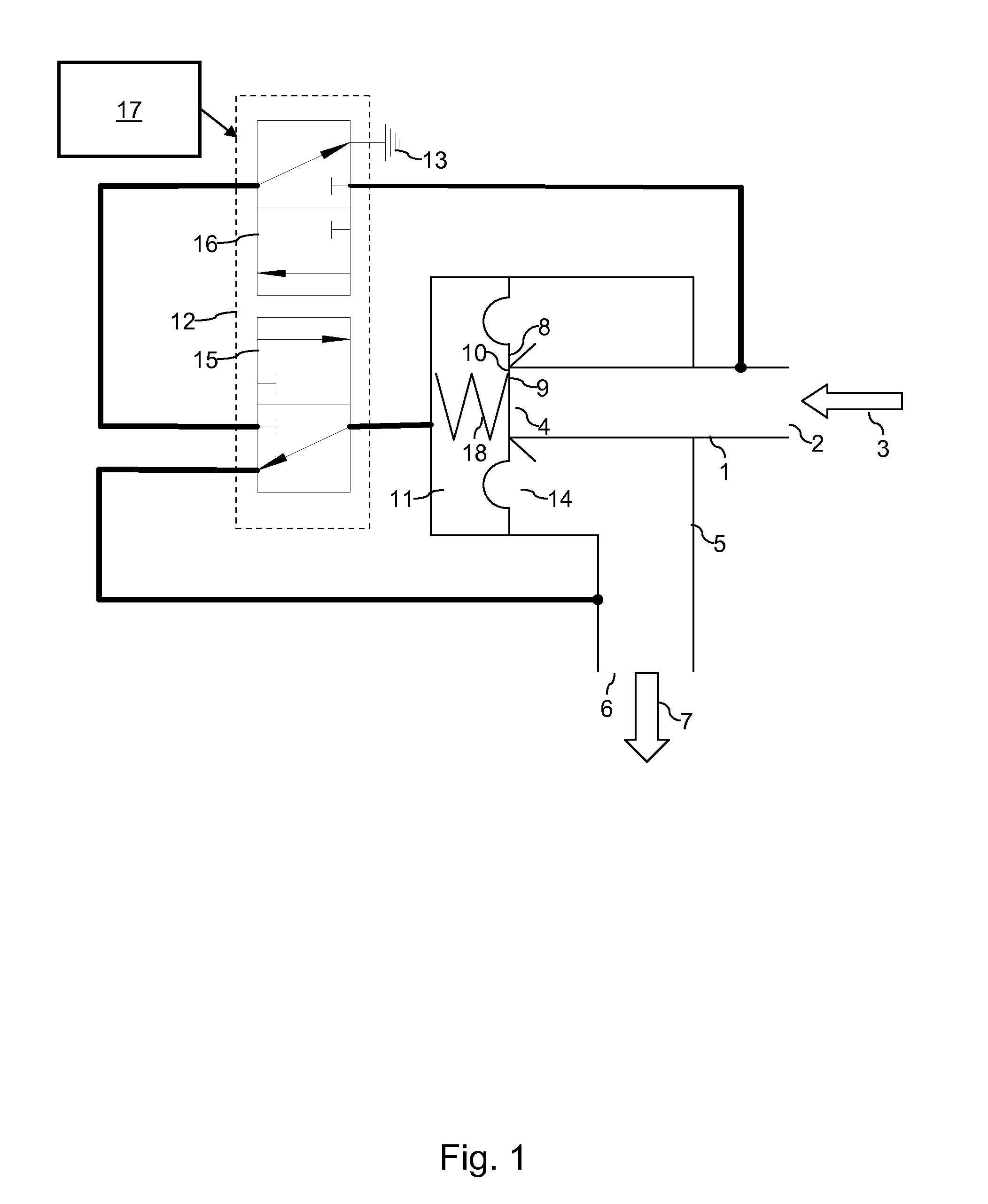

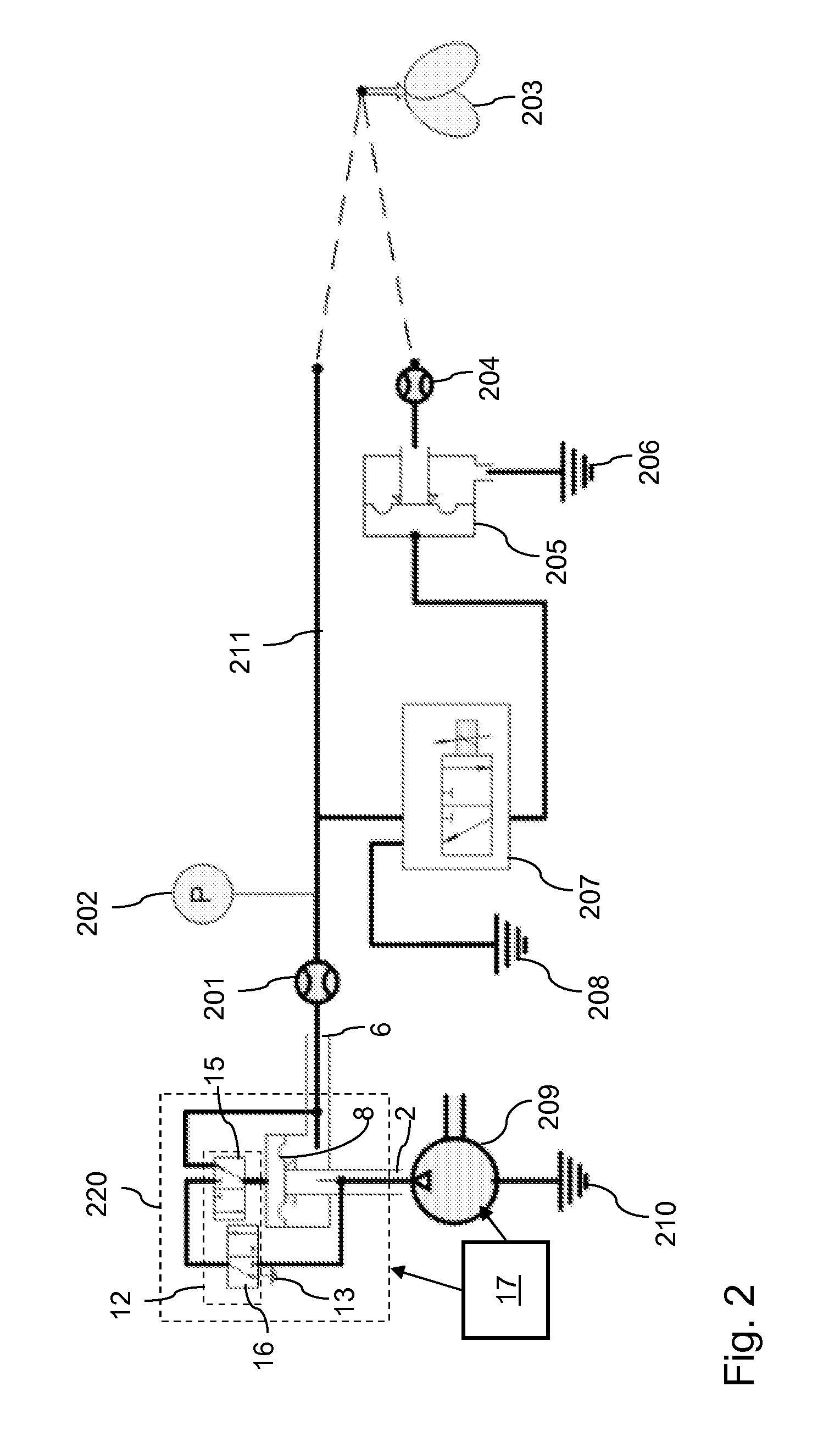

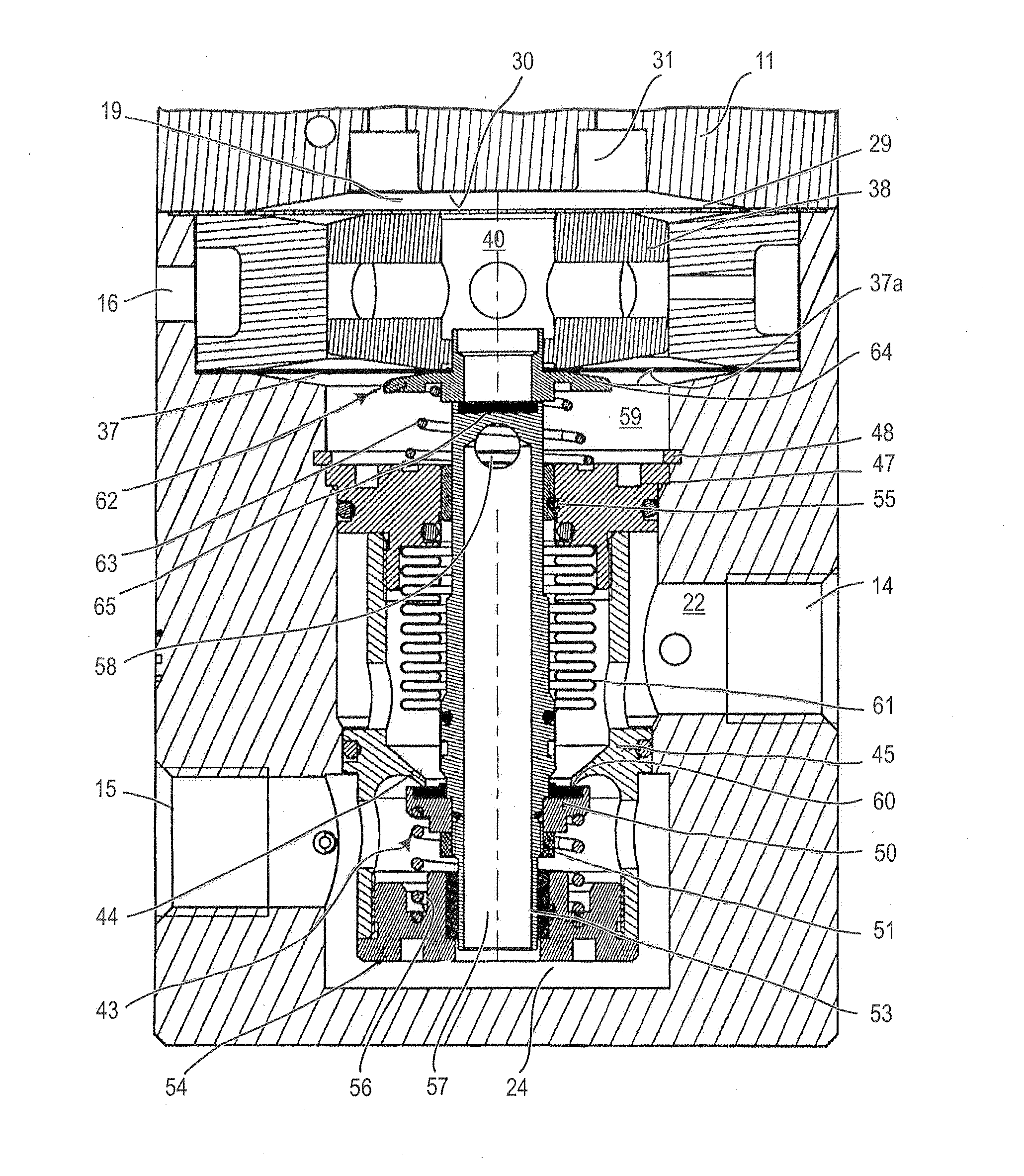

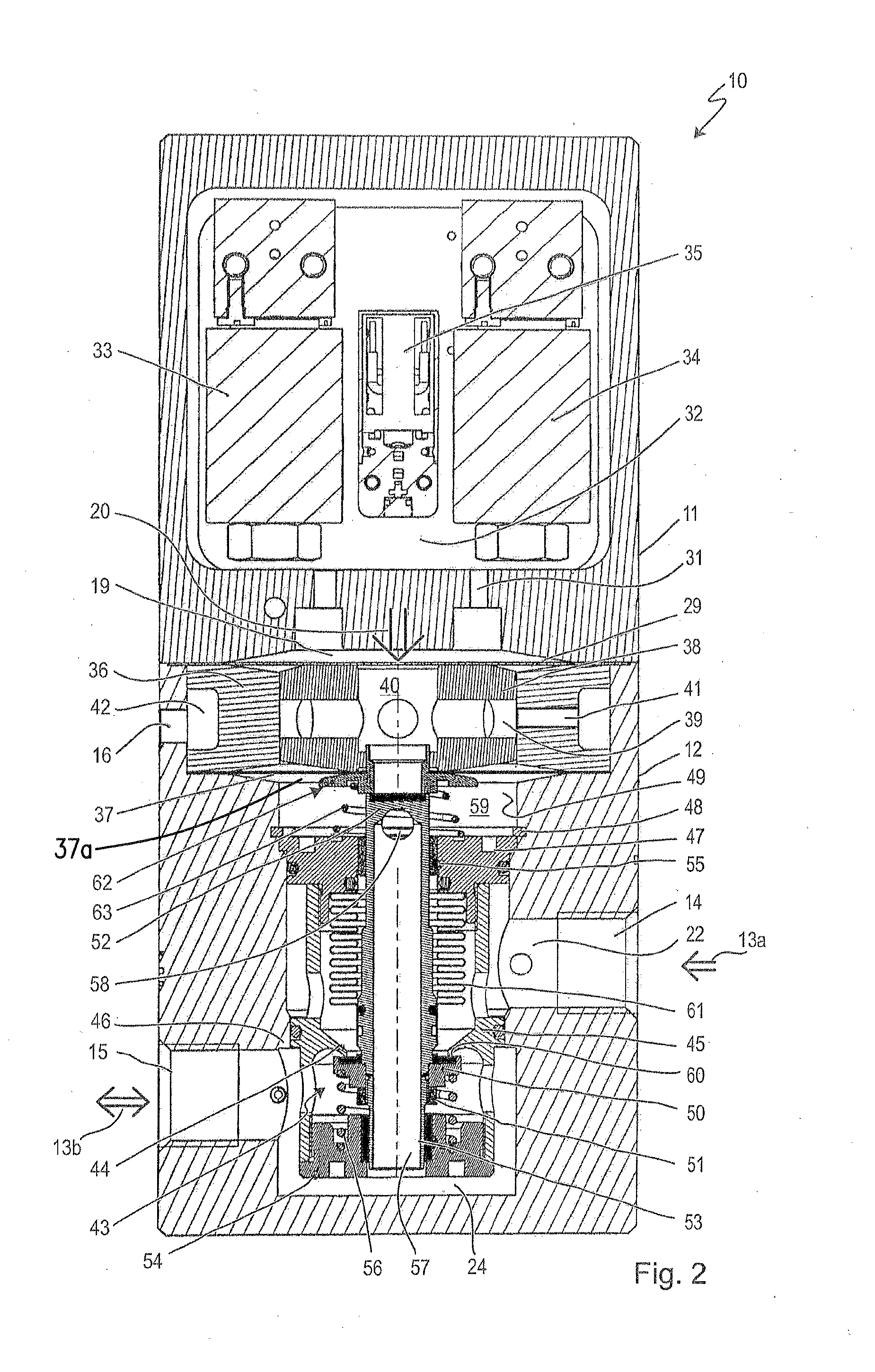

Combi-valve for a blower driven ventilator

InactiveUS20110232640A1Reduce resistanceAccurate flowRespiratorsOperating means/releasing devices for valvesEngineeringAmbient air

A valve assembly for a blower driven ventilator has a first conduit (1), an inlet (2) for receiving fluid from the blower (209) and a first orifice (4). A second conduit (5) is provided with an outlet (6) for forwarding fluid to a patient (203). A membrane (8) includes a front side (9) and a back side (10), wherein at least part of the membrane (8) is movable between a closed position and an open position. A switching circuit (12) enables the selective opening and closing of a fluid connection between the cavity (11) and the blower (209) via the fluid inlet (2), a fluid connection between the cavity (11) and the patient (203) via the fluid outlet (6), and a fluid connection between the cavity (11) and ambient air (13). A control system (17) controls the switching circuit (12) during a ventilation operation of the blower (209).

Owner:DRAGERWERK AG

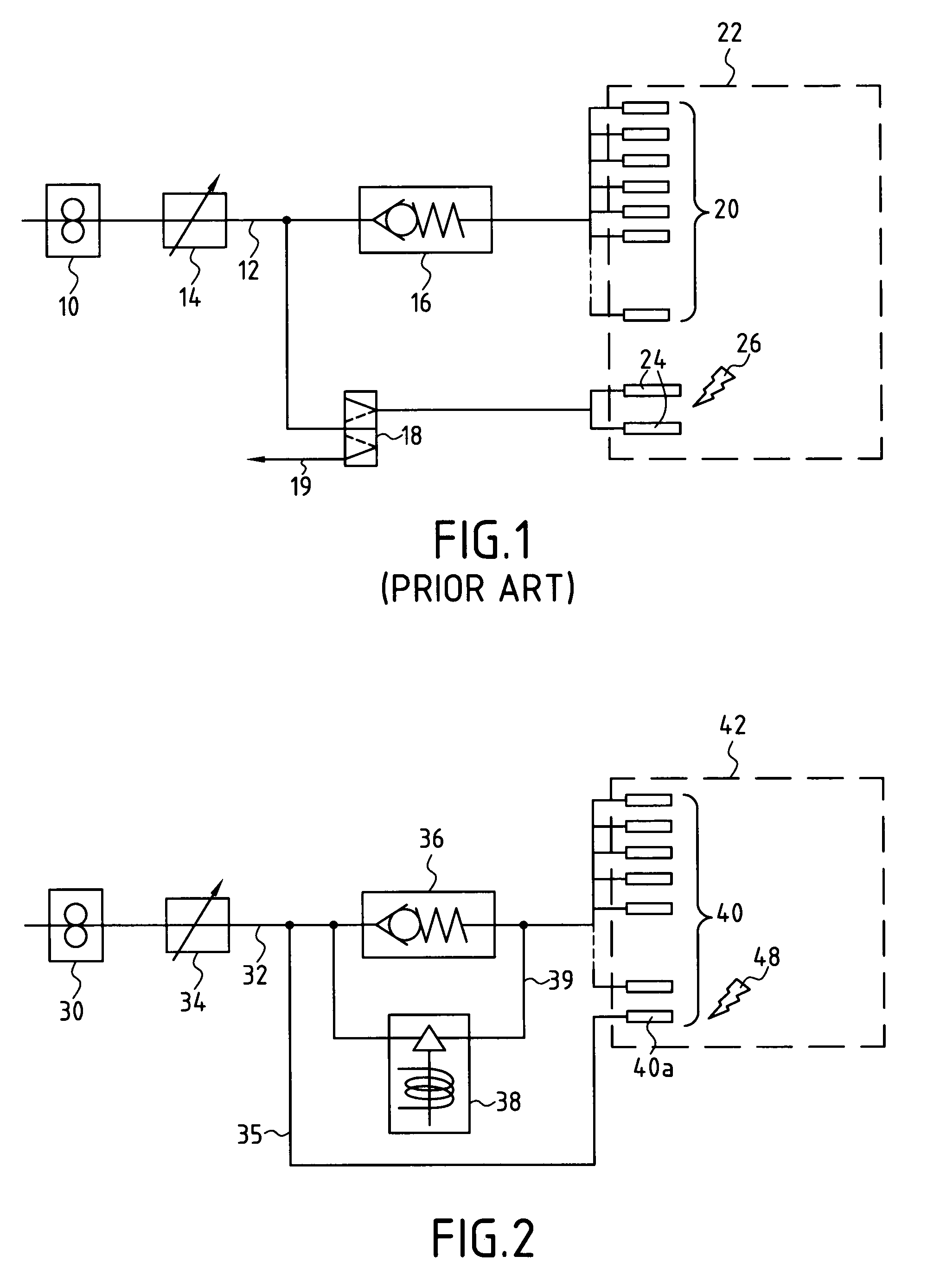

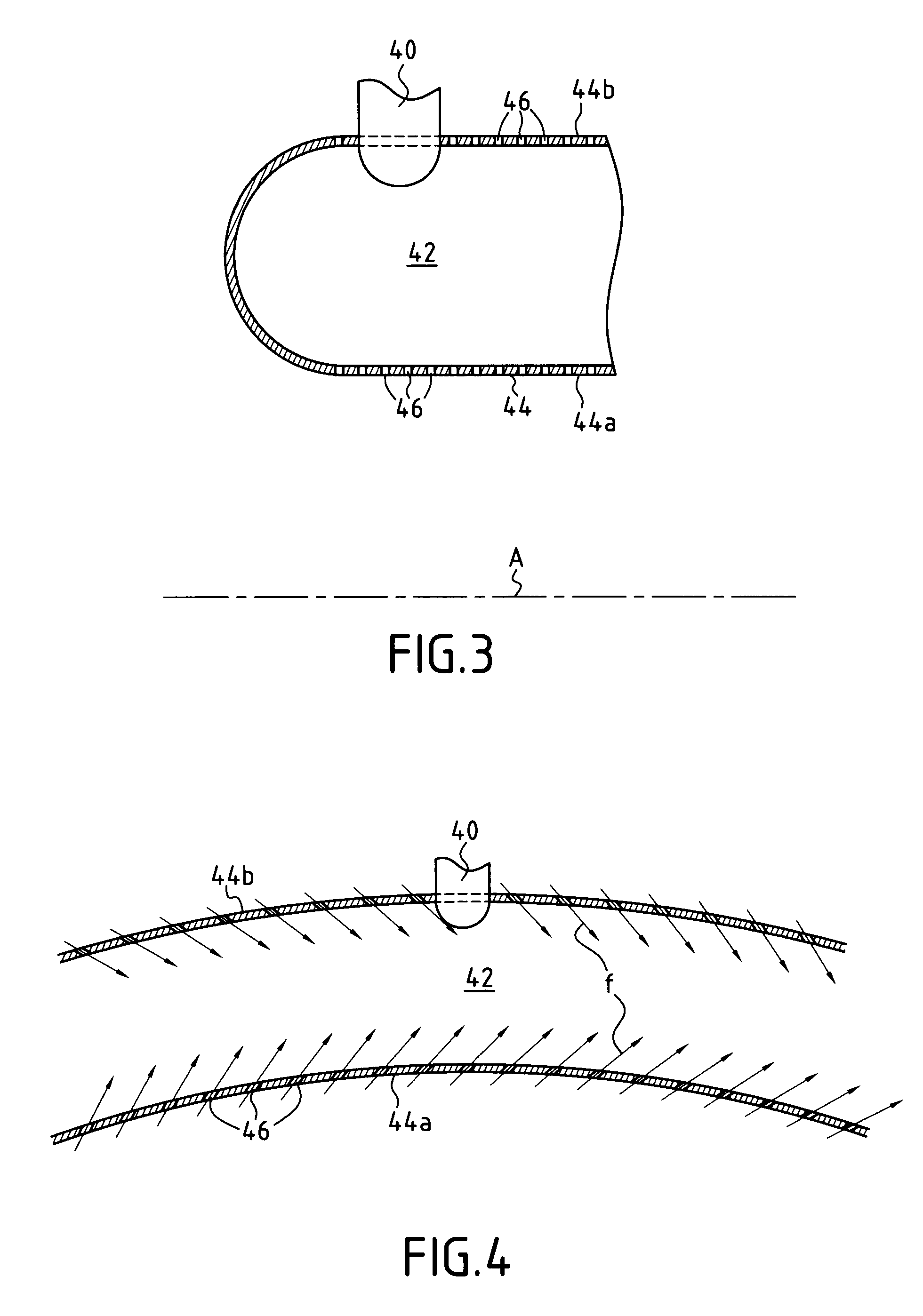

Method of starting a gas turbine helicopter engine, a fuel feed circuit for such an engine, and an engine having such a circuit

InactiveCN101255821AGood fuel injectionIncrease pressureContinuous combustion chamberTurbine/propulsion fuel supply systemsEngineeringTurbine

The present invention provides a method of starting a gas turbine helicopter engine. At least one of the main injectors of the engine, forming a starter main injector, is fed directly by the pressurized feed pipe, while a head loss is imposed between the pressurized feed pipe and the other main injectors. Ignition is caused to take place at the starter main injector, and after ignition, said head loss imposed between the feed pipe and the other main injectors is eliminated so that all of the main injectors are fed with fuel at substantially the same pressure, without any imposed head loss. The present invention also provides a fuel supply circuit for such an engine, and engine having such a circuit.

Owner:TURBOMECA SA

Braking device of wind power generation yaw bearing

ActiveCN102220939AExtended service lifeIncrease stiffnessWind motor controlBall bearingsTangential forceBrake lining

The invention relates to a braking device of a wind power generation yaw bearing; a yaw rotary bearing consists of an outer bearing ring and an inner bearing ring; the inner side surface of the lower part of the outer bearing ring is provided with an annular concave bearing braking surface; the lower end surface of the inner bearing ring is provided with more than one fan-shaped brake; two end surfaces of a fan-shaped brake surface part of a brake support are contacted and connected with the left contacting surface and / or the right contacting surface of a brake fan-shaped groove; and a brake lining pad is provided with a fan-shaped convex lining pad braking surface matched with the bearing brake surface. When in braking, damping moment force generates when the lining pad brake surface of the brake lining pad is contacted with the bearing brake surface, and the tangential force generated in the braking process acts on the left contact surface and / or the right contact surface where the brake support is connected with a brake base, so that braking abrasion of the brake lining pad is reduced. In the invention, a plurality of fan-shaped brakes arranged symmetrically are adopted for applying damping moment force on the bearing brake surface so that yaw braking of a wind power generation set can be realized.

Owner:JIANGSU NEW UNITED HEAVY IND SCI & TECH +1

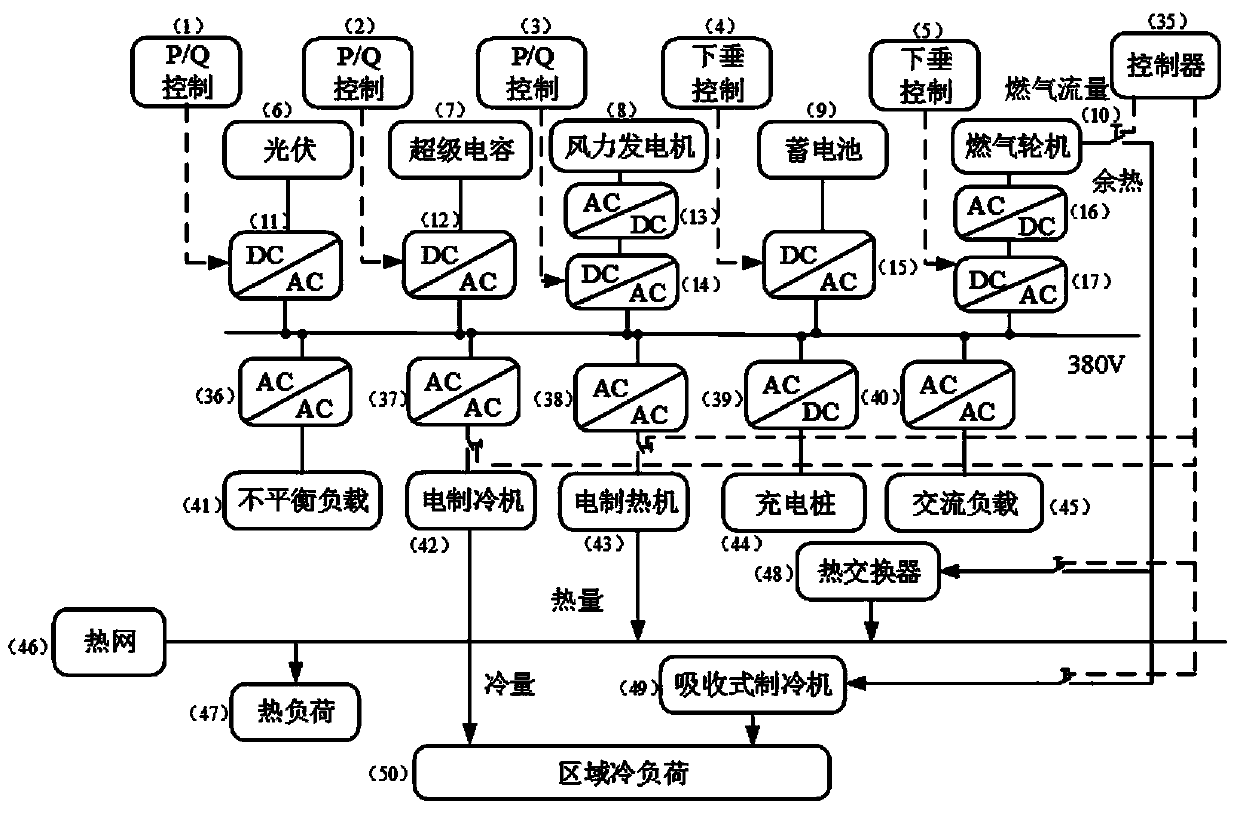

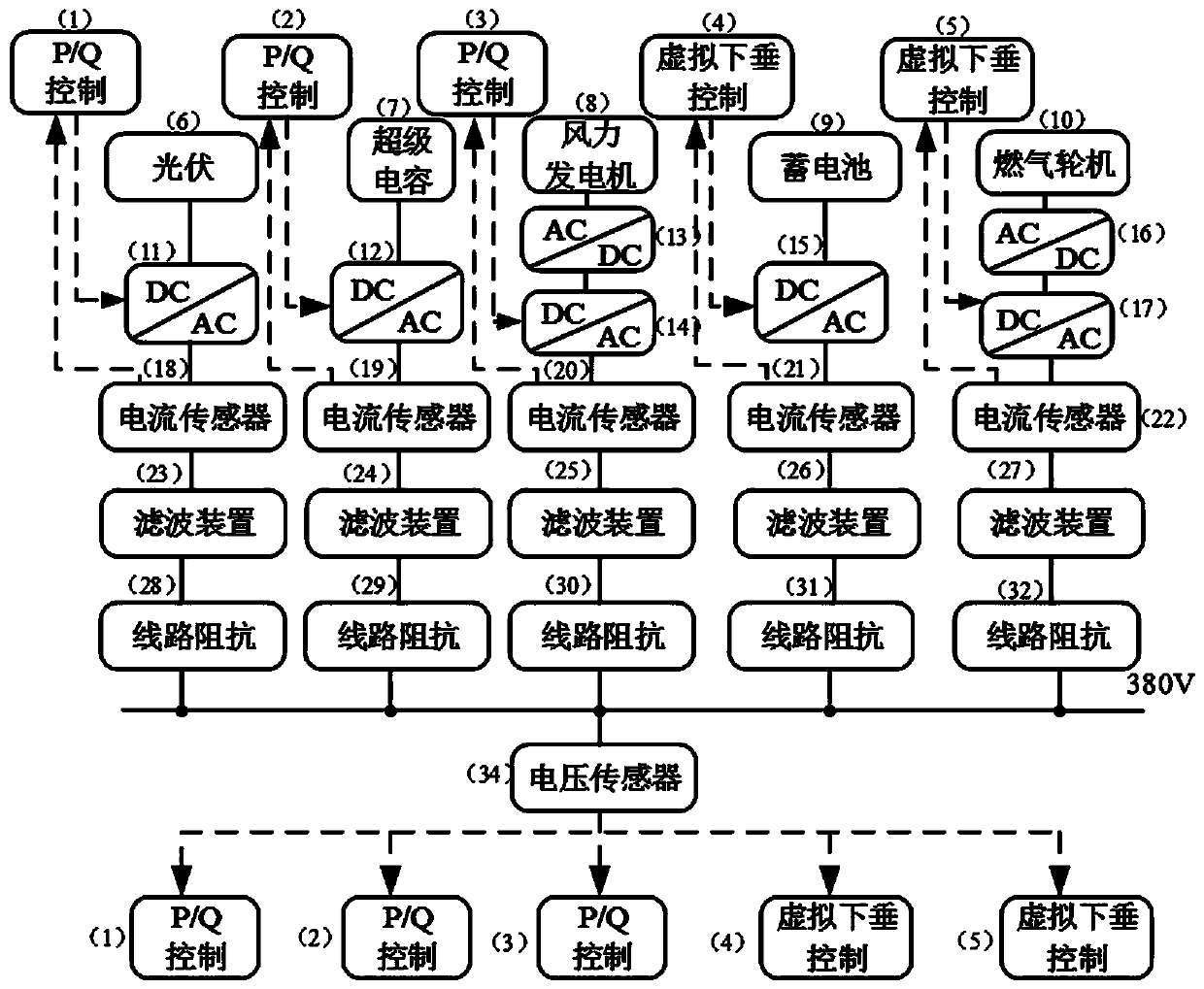

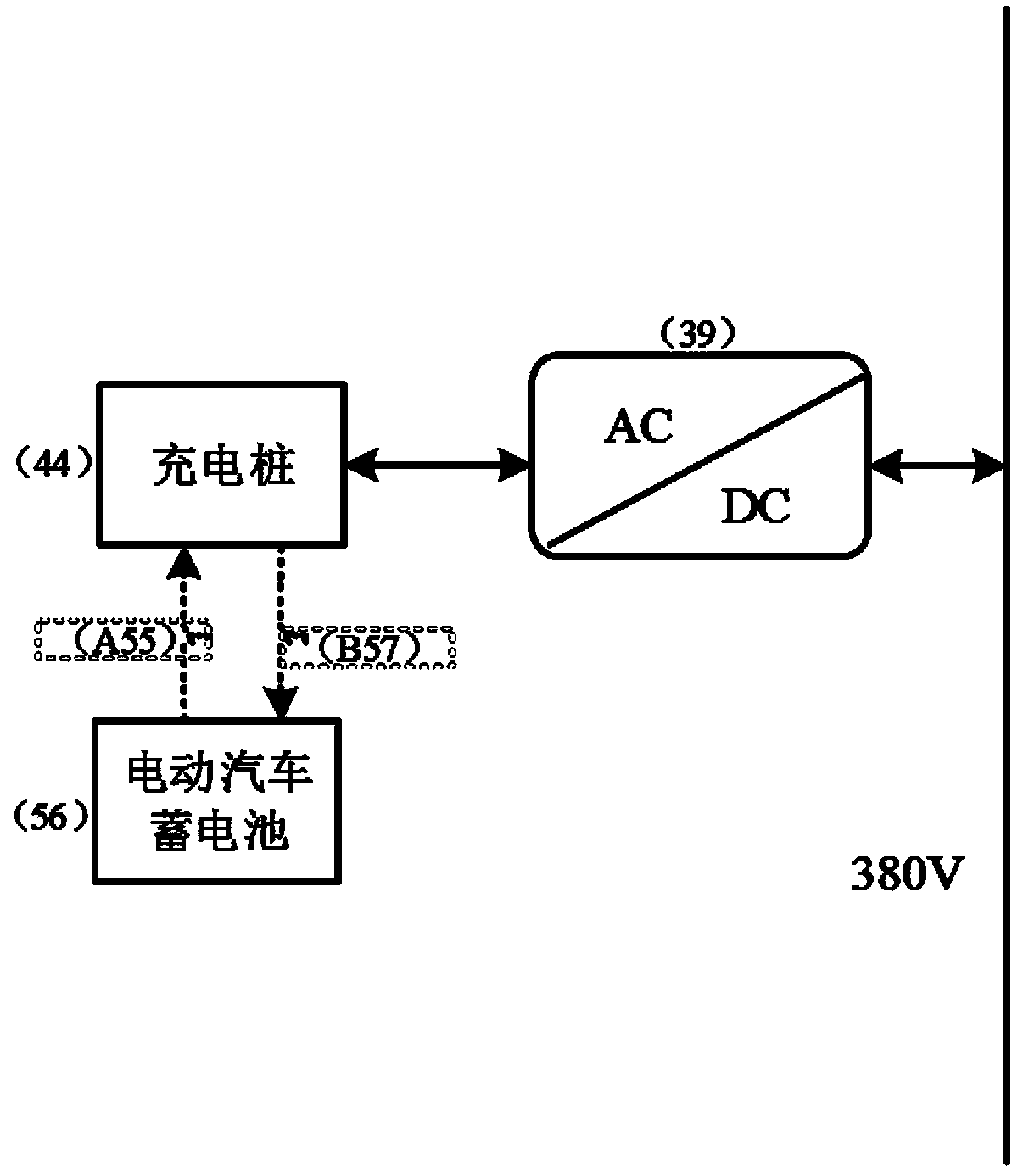

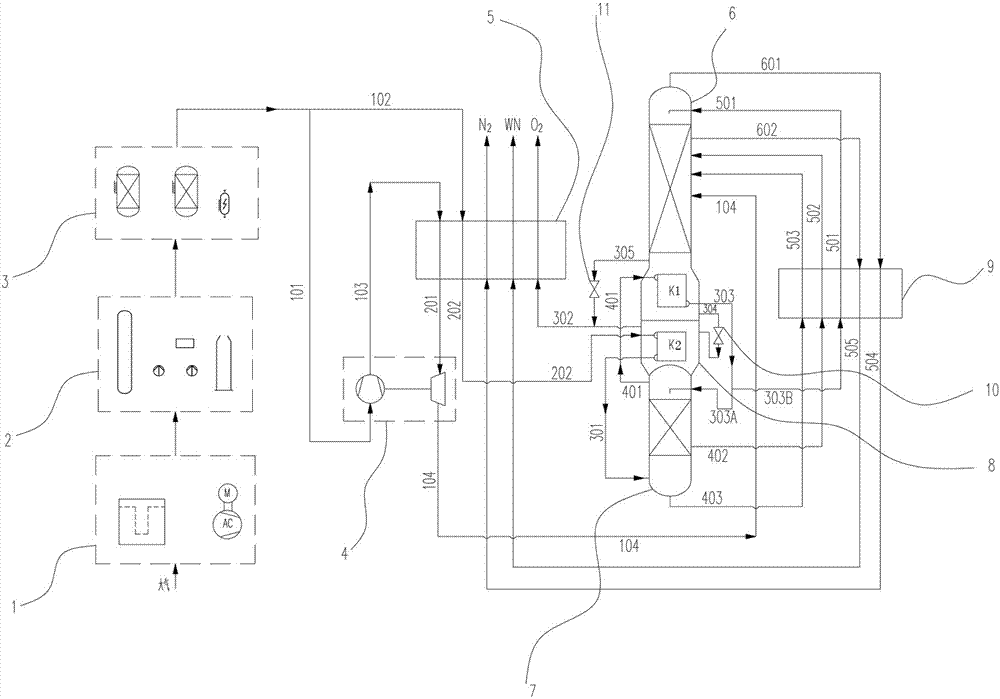

Multi-energy complementary microgrid multi-master-slave control structure and method based on micro-source and load cooperative support

PendingCN110535135AImprove power supply reliabilityImprove power qualitySingle network parallel feeding arrangementsEnergy storagePower qualityWind driven

The invention relates to the technical field of microgrids, in particular to a multi-energy complementary microgrid multi-master-slave control structure and method based on micro-source and load cooperative support. The structure comprises a photovoltaic system, a super capacitor, a wind driven generator, a battery, a gas turbine, a charging pile and a thermal load. All the micro-sources are provided with controllers, and each cold load and each heat load are also provided with controllers. When the demand is greater than the supply limit, a heat supply network converts heat energy back to electric energy, the heat supply network and the micro-source jointly provide energy for the load through a microgrid bus, the charging pile transmits the electric energy from an AC bus of the microgridto the electric vehicle battery in a bidirectional mode through bidirectional AC-DC, idle energy is fully utilized, and the output power pressure of the micro-source is reduced. And a virtual droop control strategy is adopted, so that the voltage and the frequency of the microgrid are always stabilized at the same value. Thus, the stability and the adaptability of the multi-energy complementary microgrid are improved, and the power quality of the system is improved.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +2

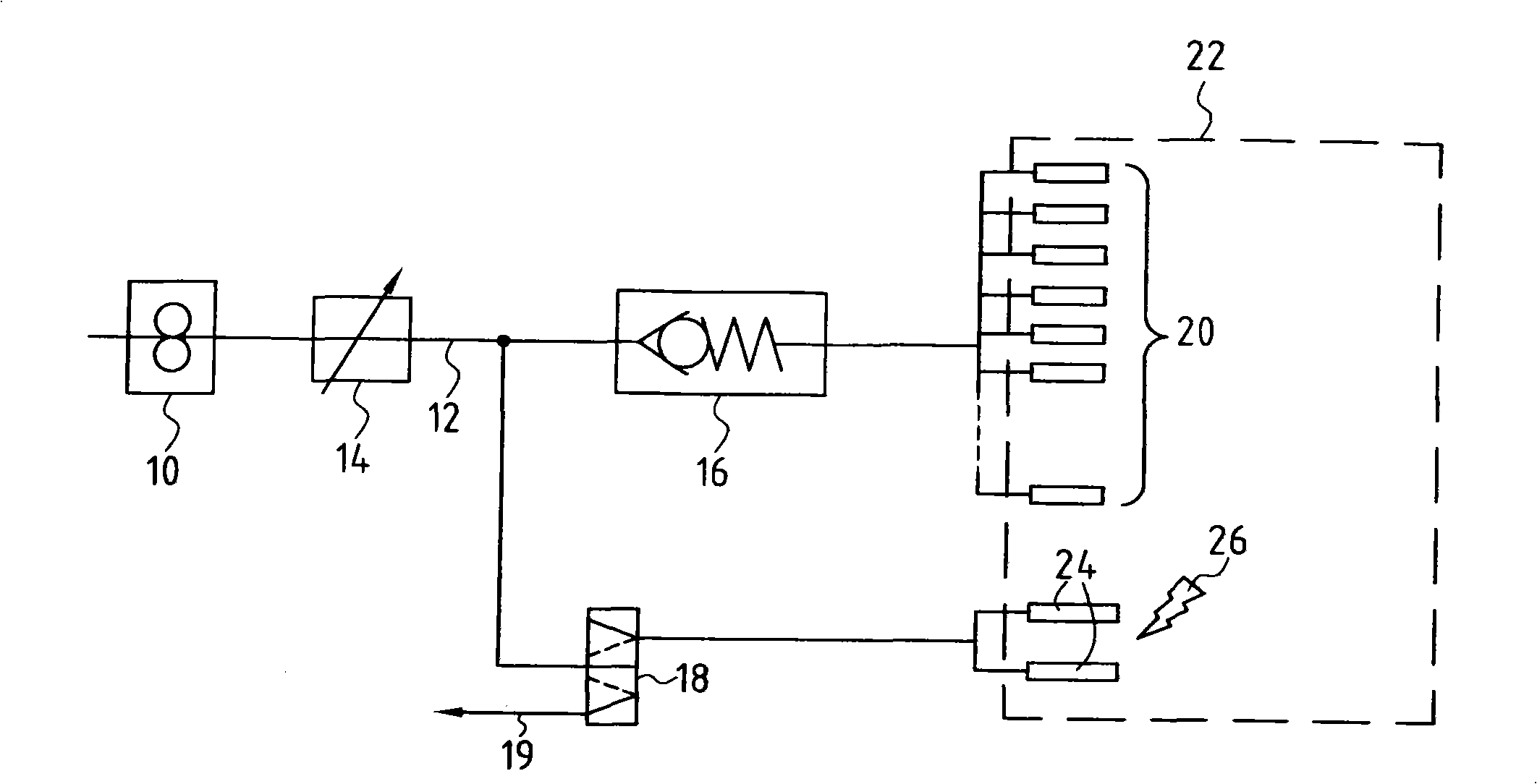

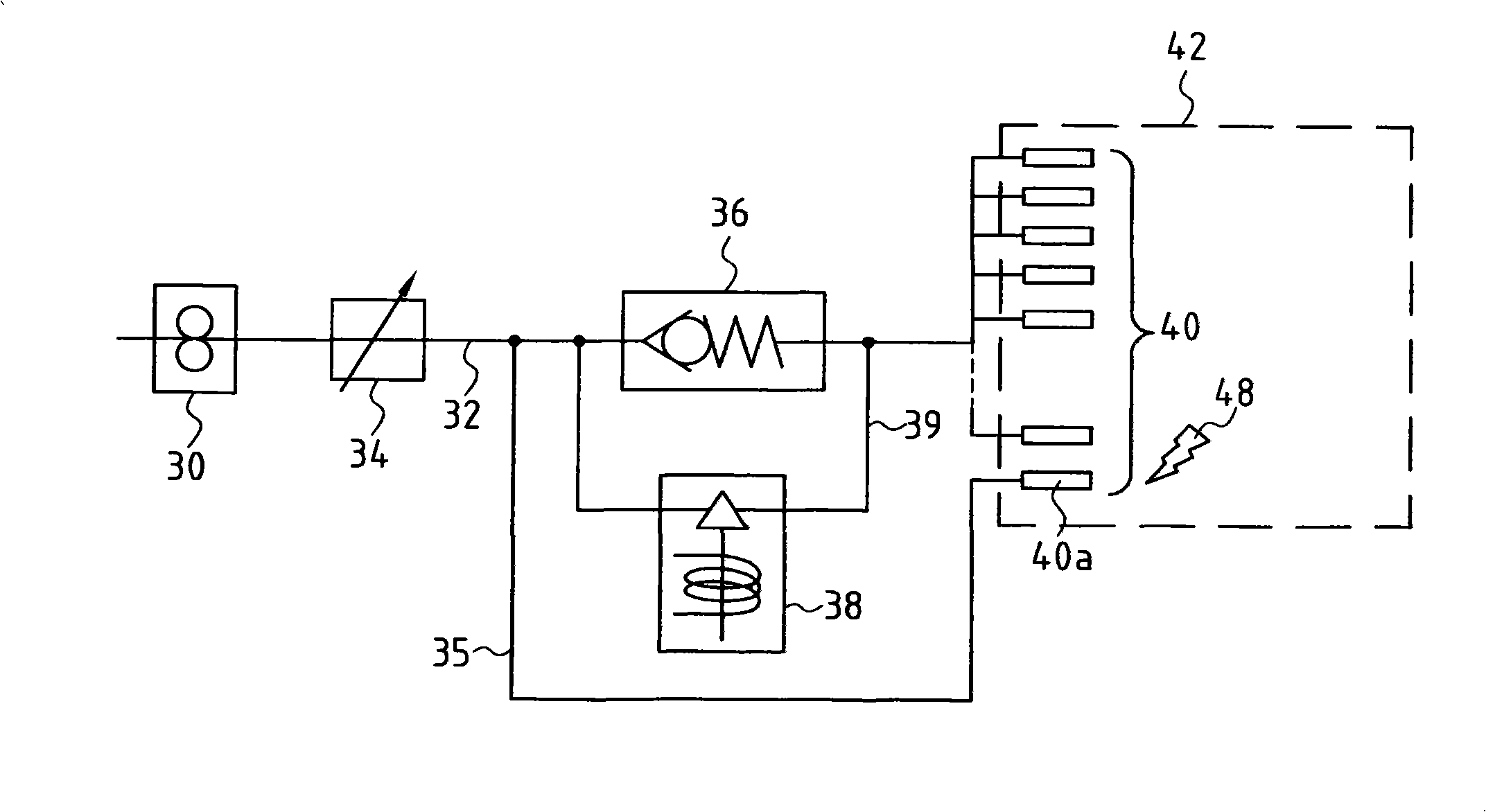

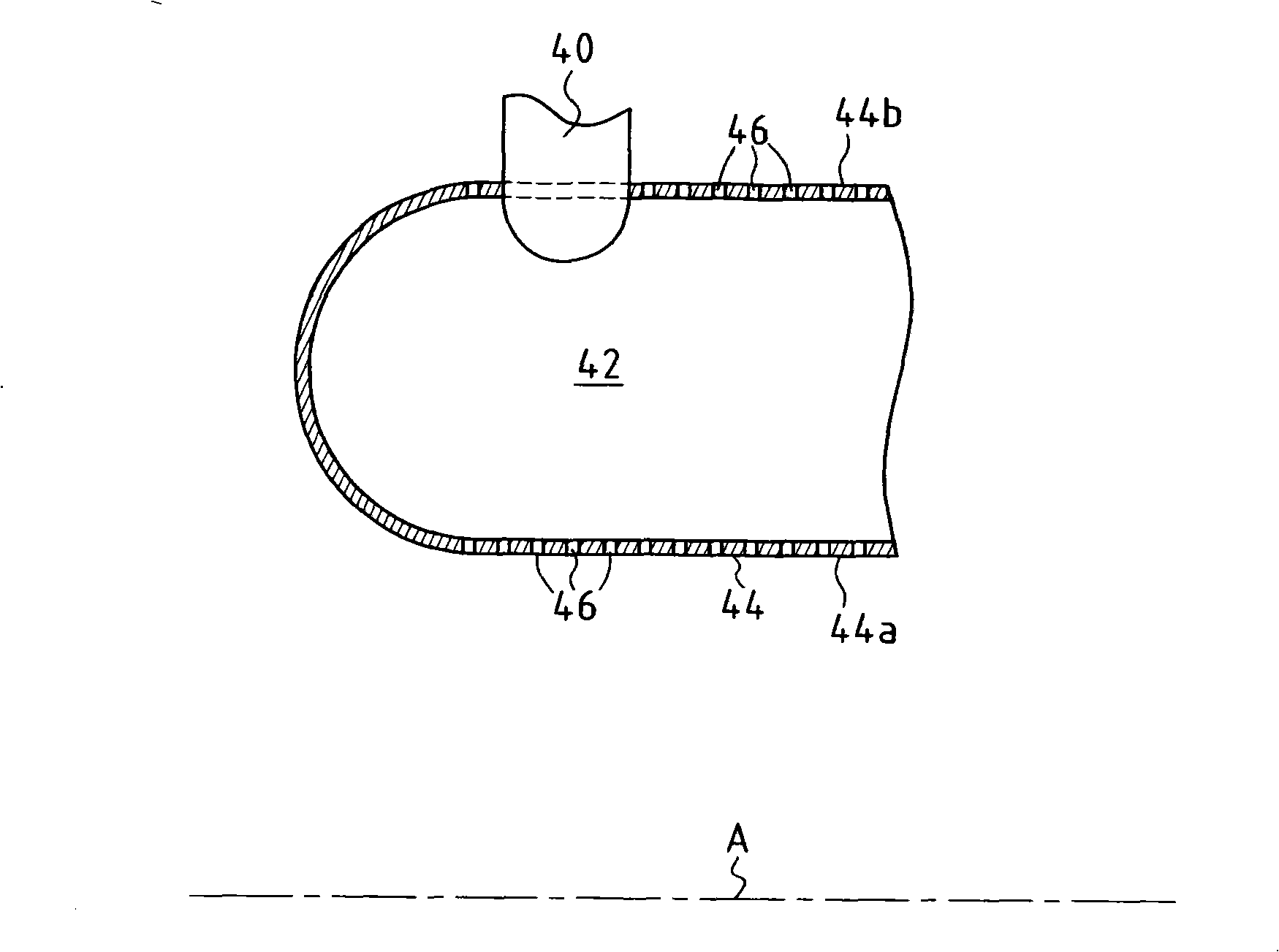

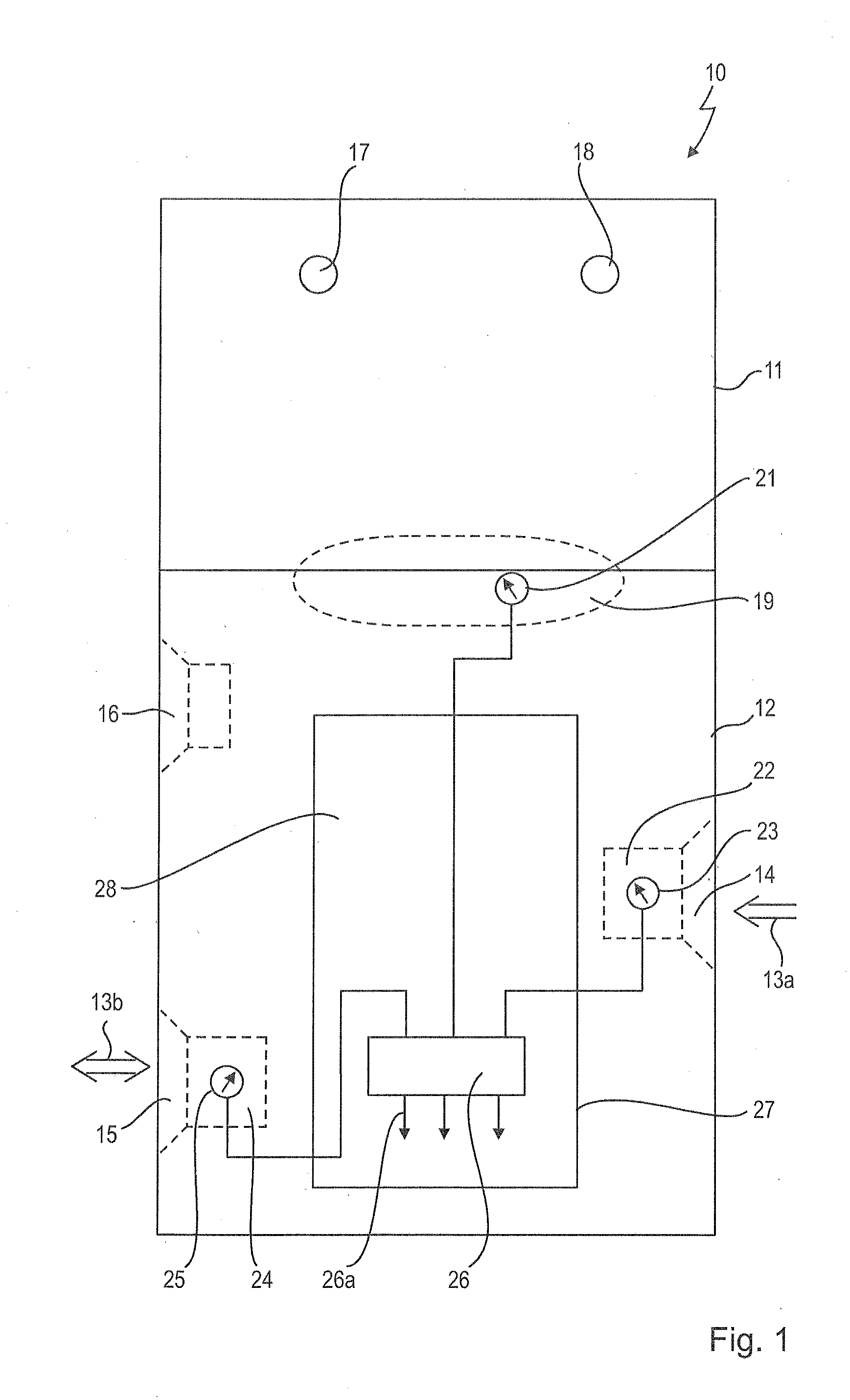

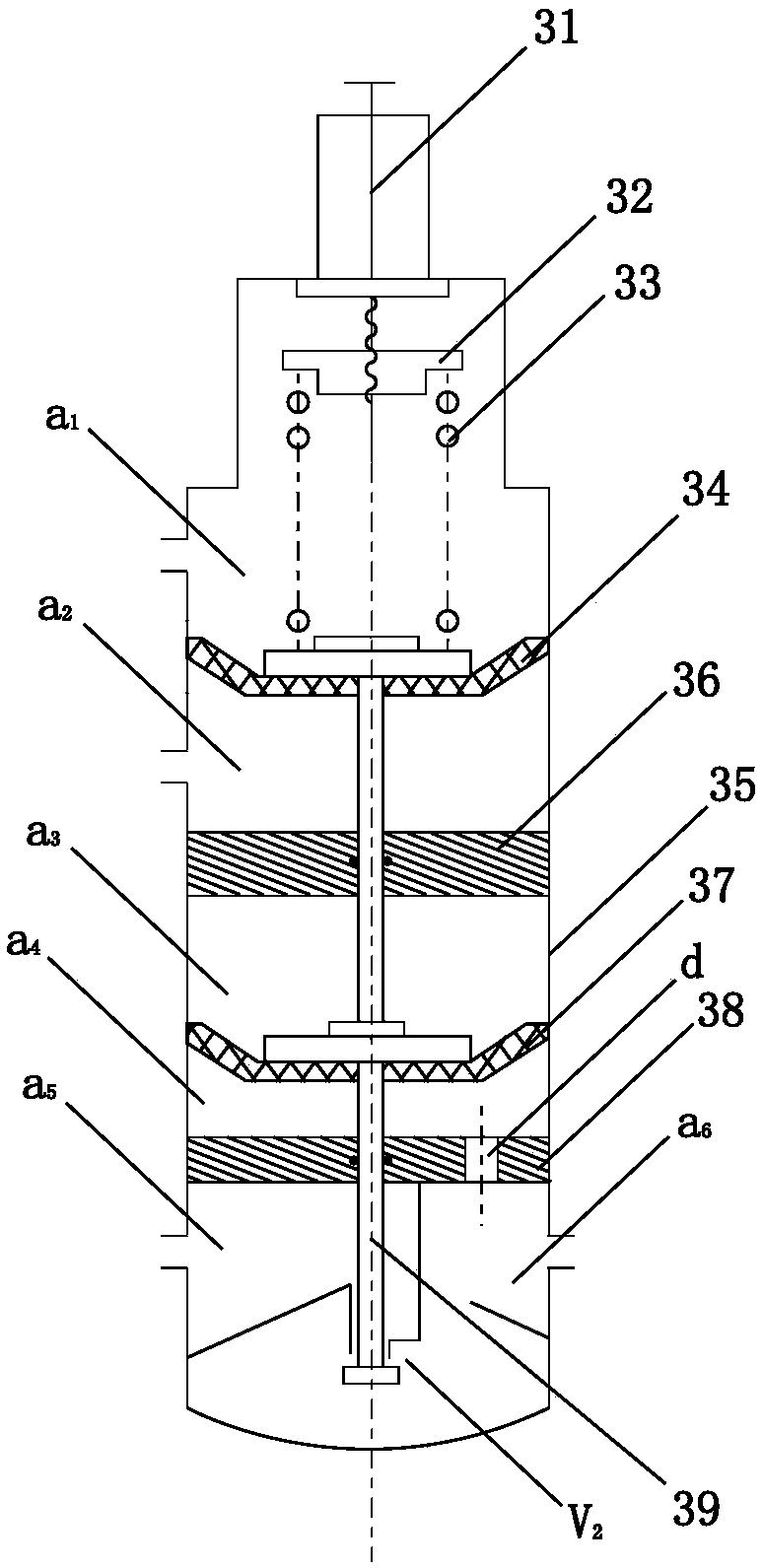

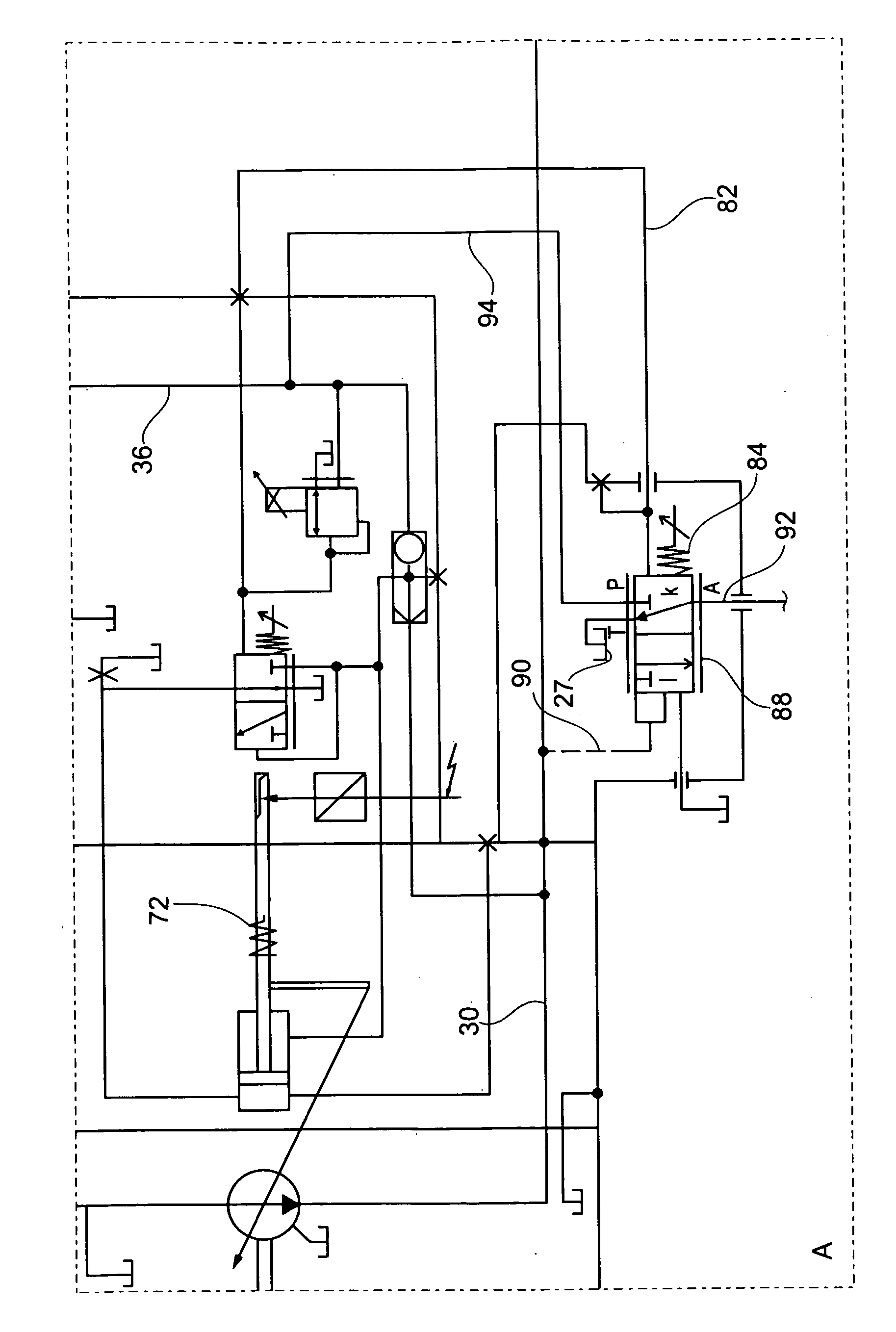

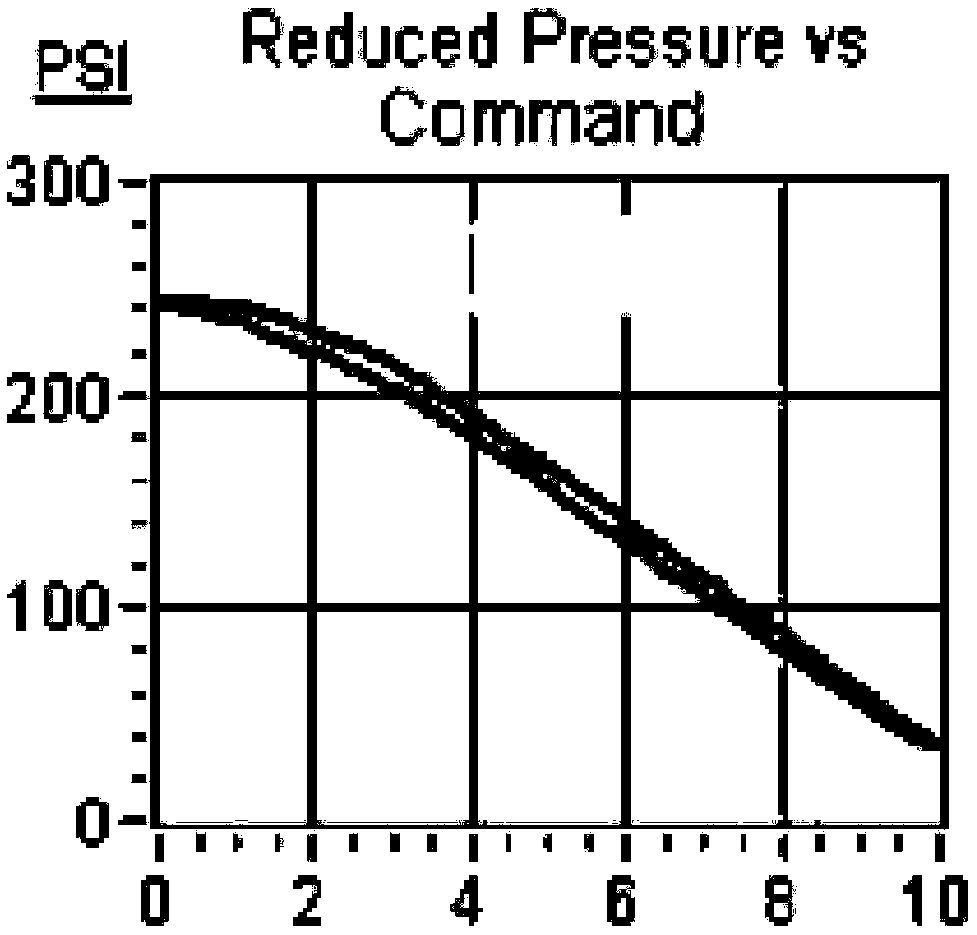

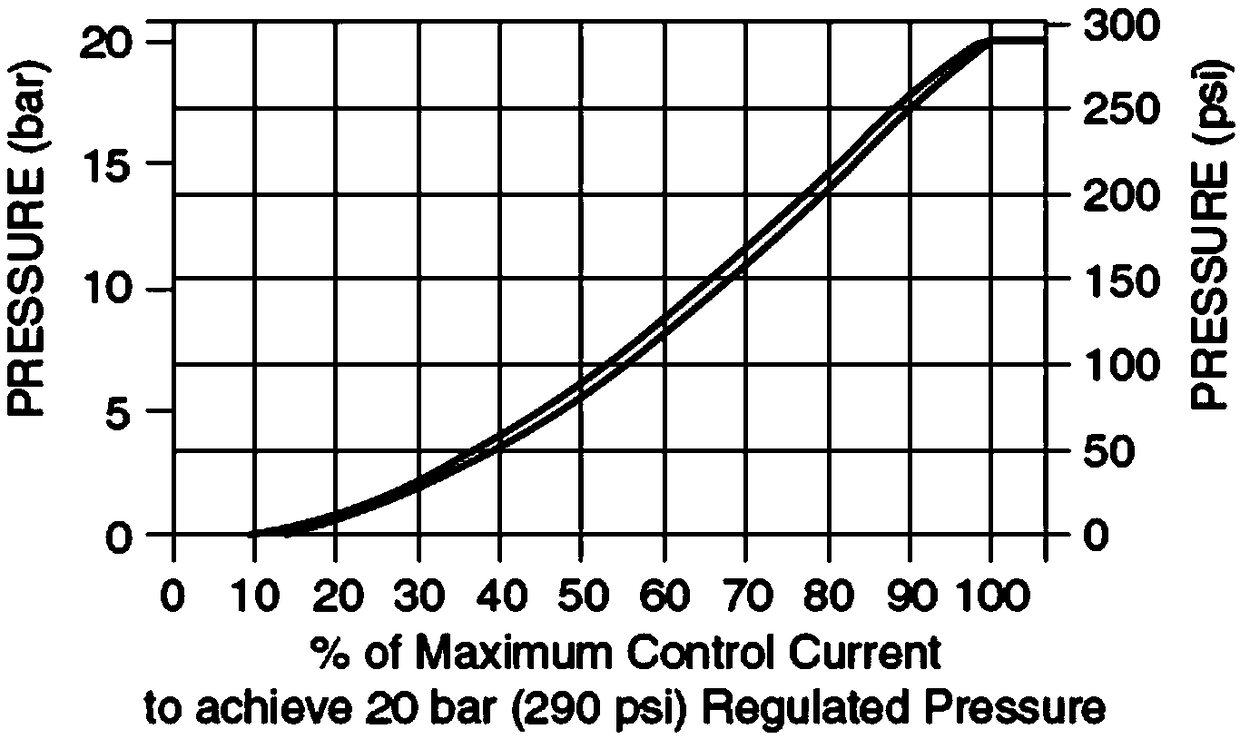

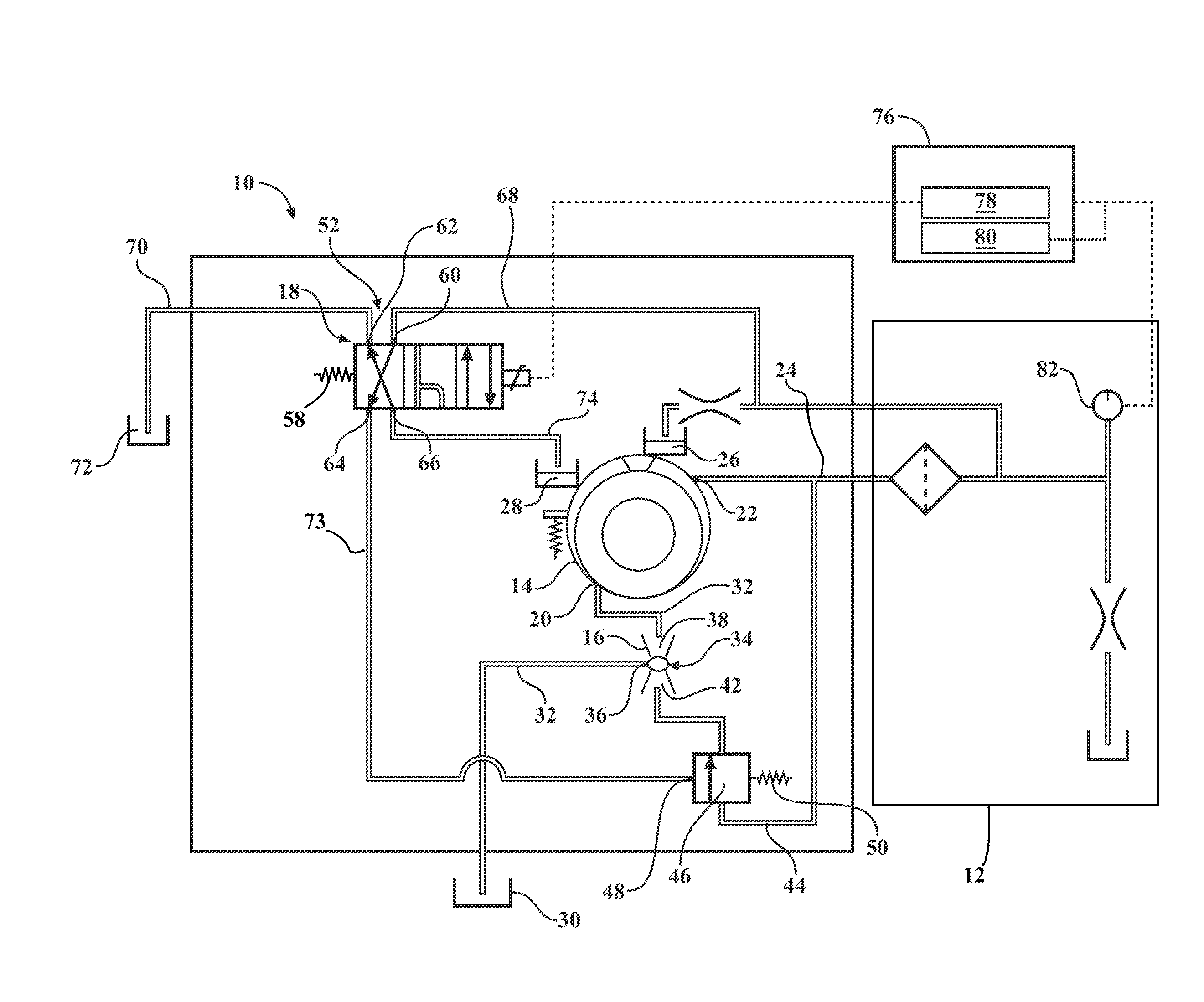

Device for providing a fluid having regulated output pressure

ActiveUS20150268669A1Simple designSlight mechanical frictionOperating means/releasing devices for valvesFlow control using electric meansControl theoryPressure controlled ventilation

A device for providing an output fluid at a regulated output pressure includes a pressure control unit controlled via a pilot control pressure and a pilot control unit that provides the pilot control pressure. The pressure control unit includes an inlet chamber for an input fluid having an input pressure, an outlet chamber for the output fluid having the regulated output pressure and a first valve unit that acts between the inlet chamber and the outlet chamber. A first diaphragm of the pressure control unit is acted upon by the pilot control pressure. A second diaphragm, which is mechanically coupled to the first diaphragm is acted upon by the output fluid having the output pressure acts. At least the second diaphragm mechanically acts on the first valve unit.

Owner:ASCO NUMATICS

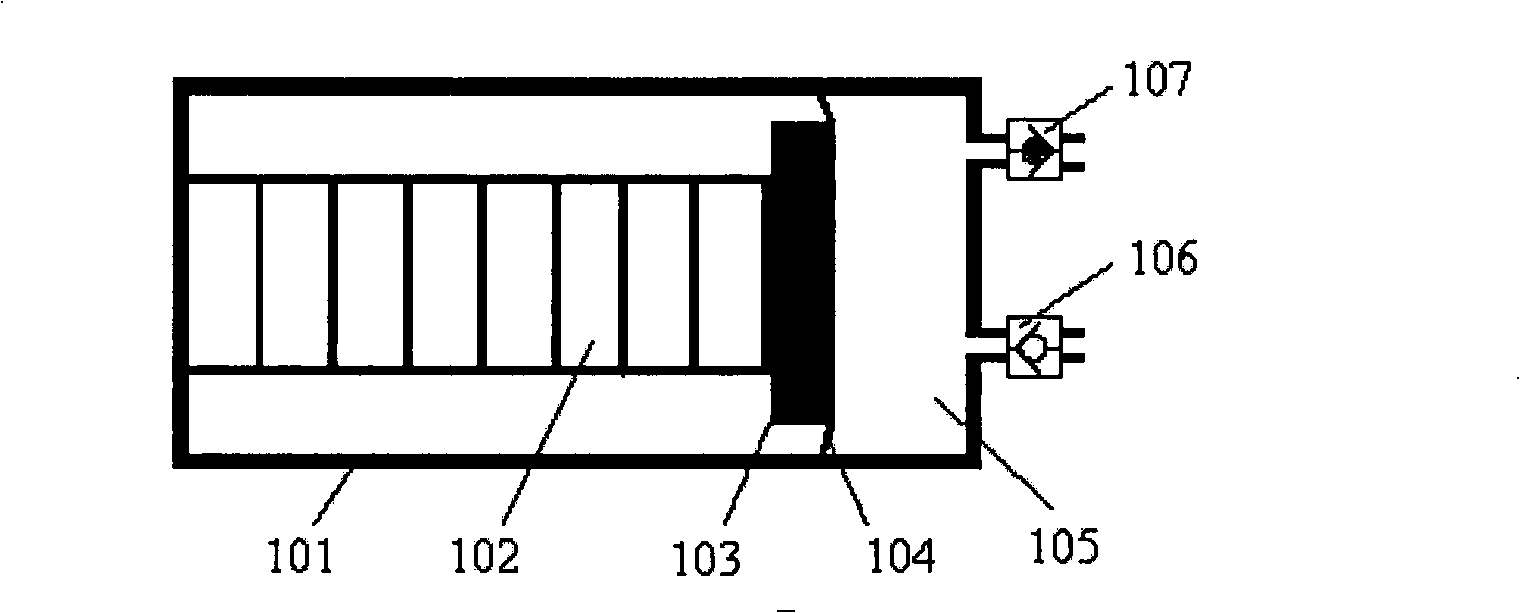

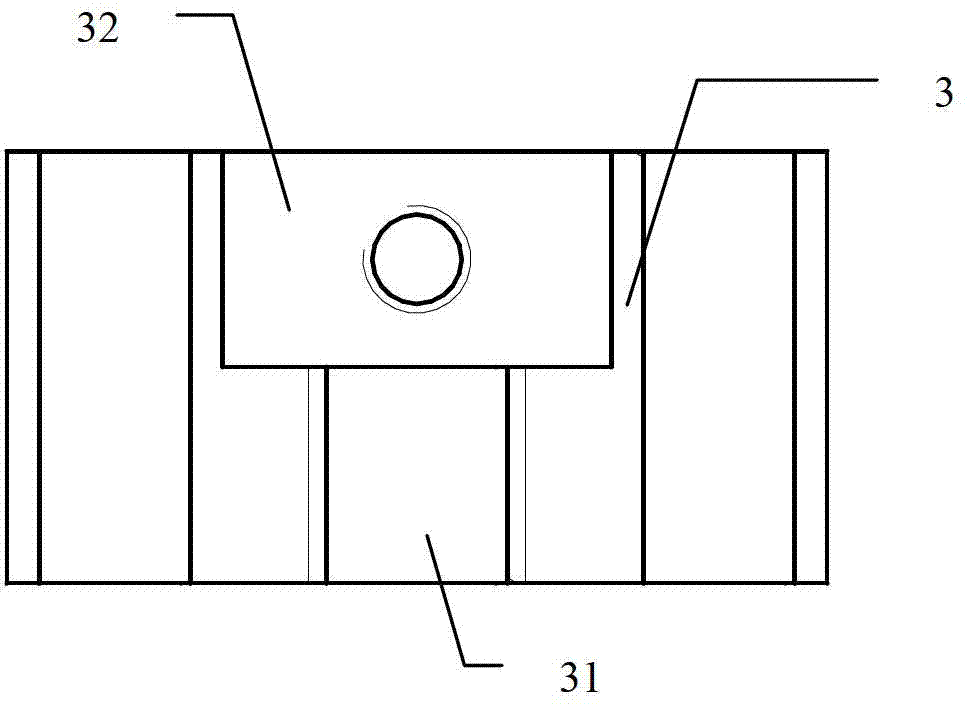

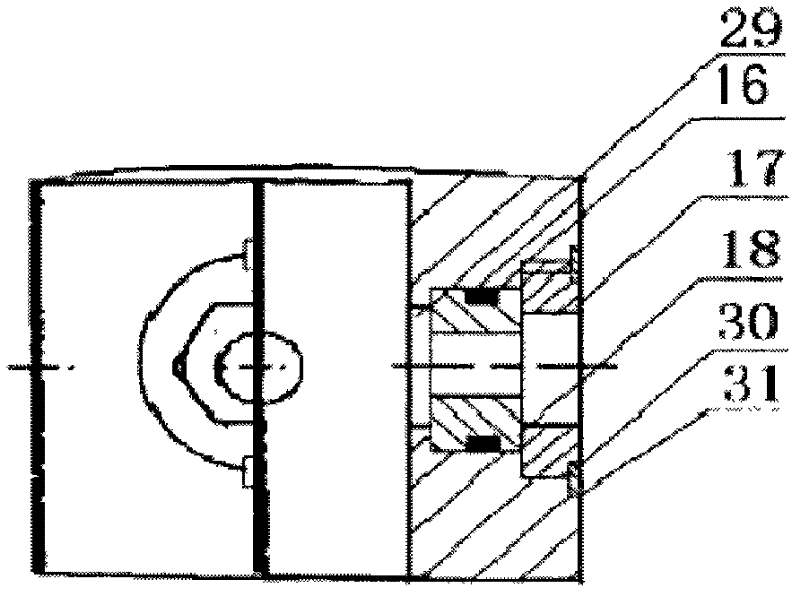

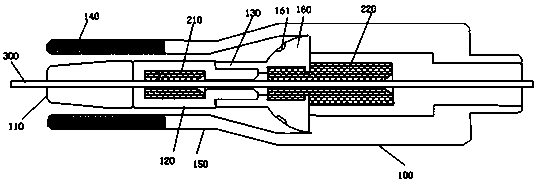

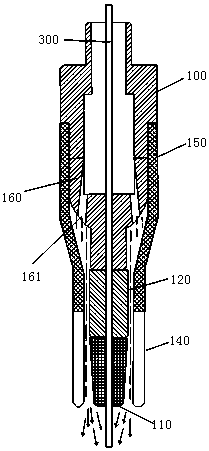

Piezo-stack pump

InactiveCN102817817AEasy to assembleReduce output pressureFlexible member pumpsPositive-displacement liquid enginesVibrating membraneWorking fluid

The invention discloses a piezo-stack pump, which comprises a pump base, a pump body, a top pump cap and a piezo-stack, the pump base is provided with a fluid inlet and a fluid outlet, the piezo-stack is contained in the pump body, a vibrating piston is arranged between one end of the piezo-stack and the pump base, and a pretightened piston is arranged between the other end of the piezo-stack and the top pump cap; the vibrating piston is stuck on a vibrating membrane, and a working fluid chamber is formed between the vibrating membrane and the pump base. All the parts in the piezo-stack pump are centralized in the pump body, so that space is saved, each part is convenient to assemble and easy to machine, the working fluid chamber is strictly closed, so that leakage is effectively prevented, and thereby the output power is increased. The piezo-stack pump can be widely applied in the fields of automobile engine fuel supply and robots.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

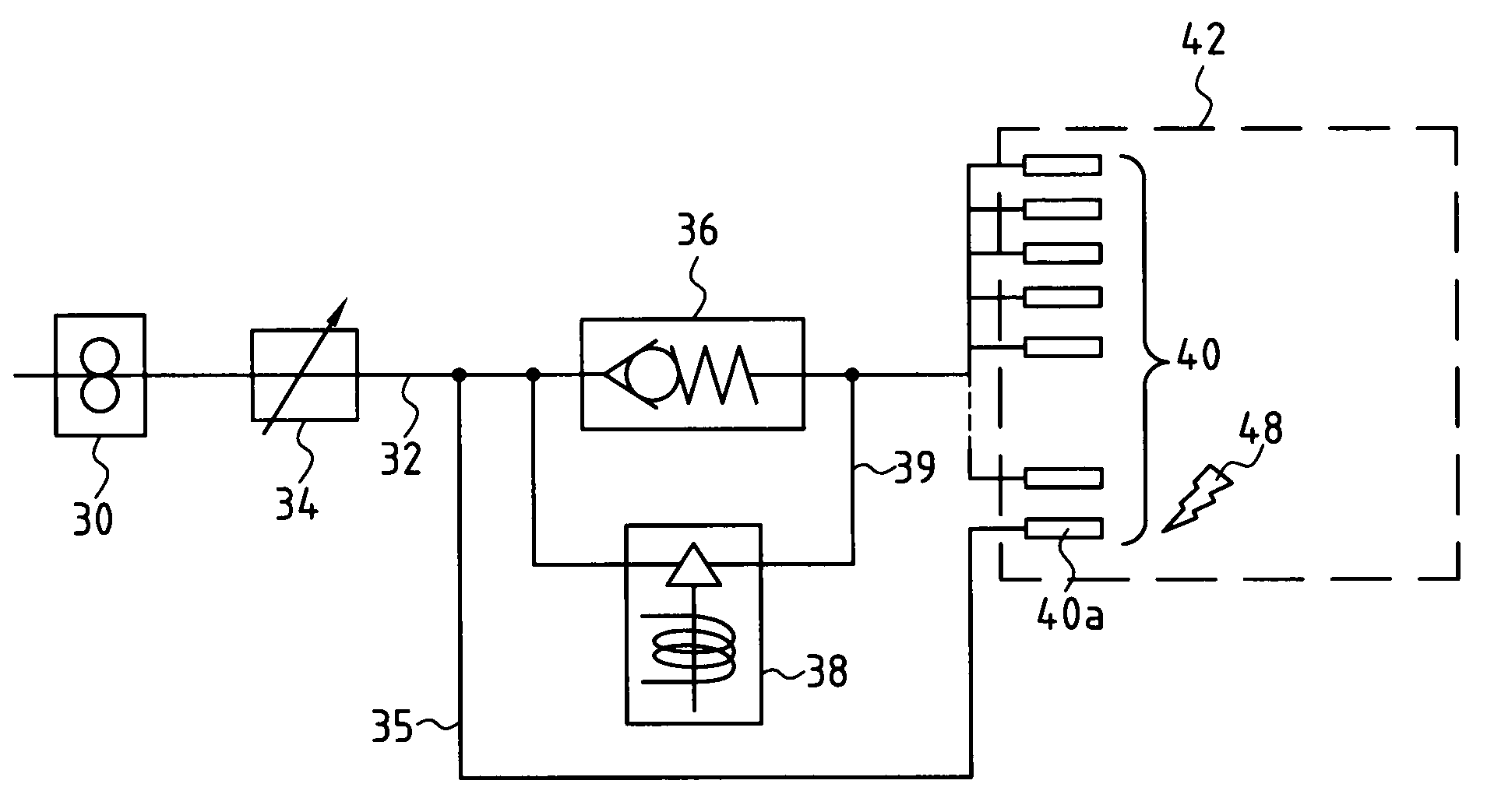

Method of starting a gas turbine helicopter engine, a fuel feed circuit for such an engine, and an engine having such a circuit

InactiveUS20080209910A1High pressureSpeed up sprayingTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionInjectorGas turbines

At least one of the main injectors of the engine, forming a starter main injector, is fed directly by the pressurized feed pipe, while a head loss is imposed between the pressurized feed pipe and the other main injectors. Ignition is caused to take place at the starter main injector, and after ignition, said head loss imposed between the feed pipe and the other main injectors is eliminated so that all of the main injectors are fed with fuel at substantially the same pressure, without any imposed head loss.

Owner:TURBOMECA SA

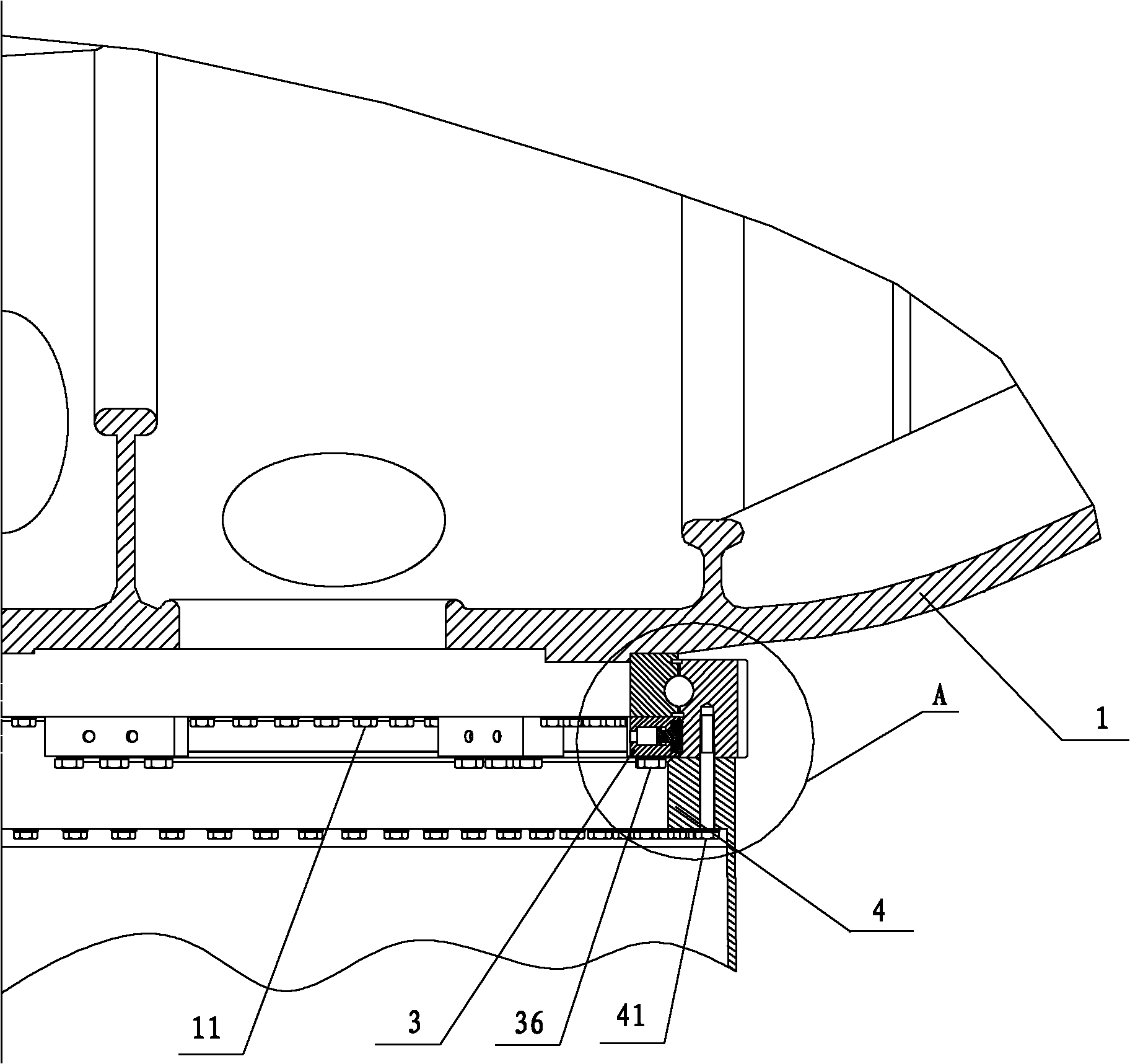

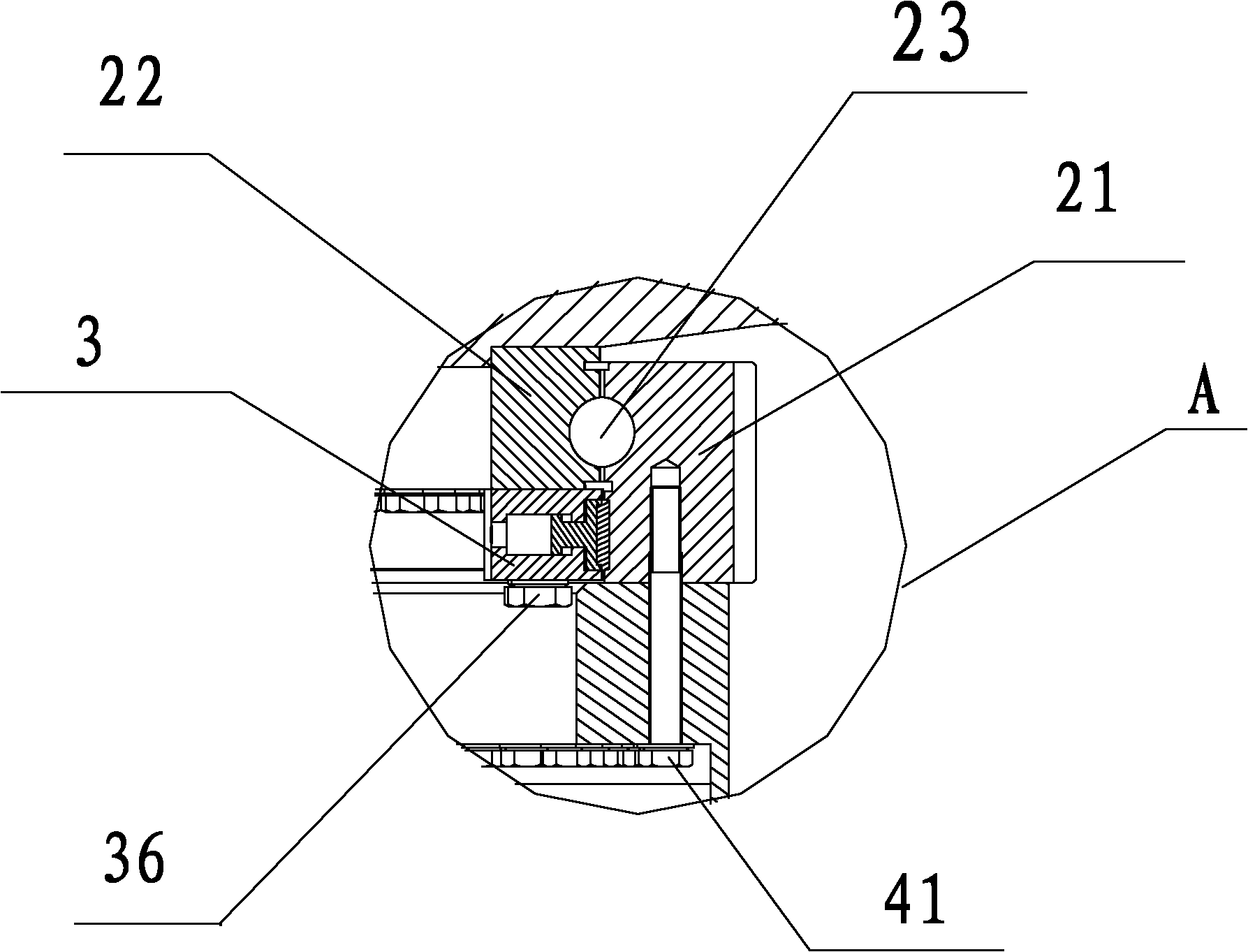

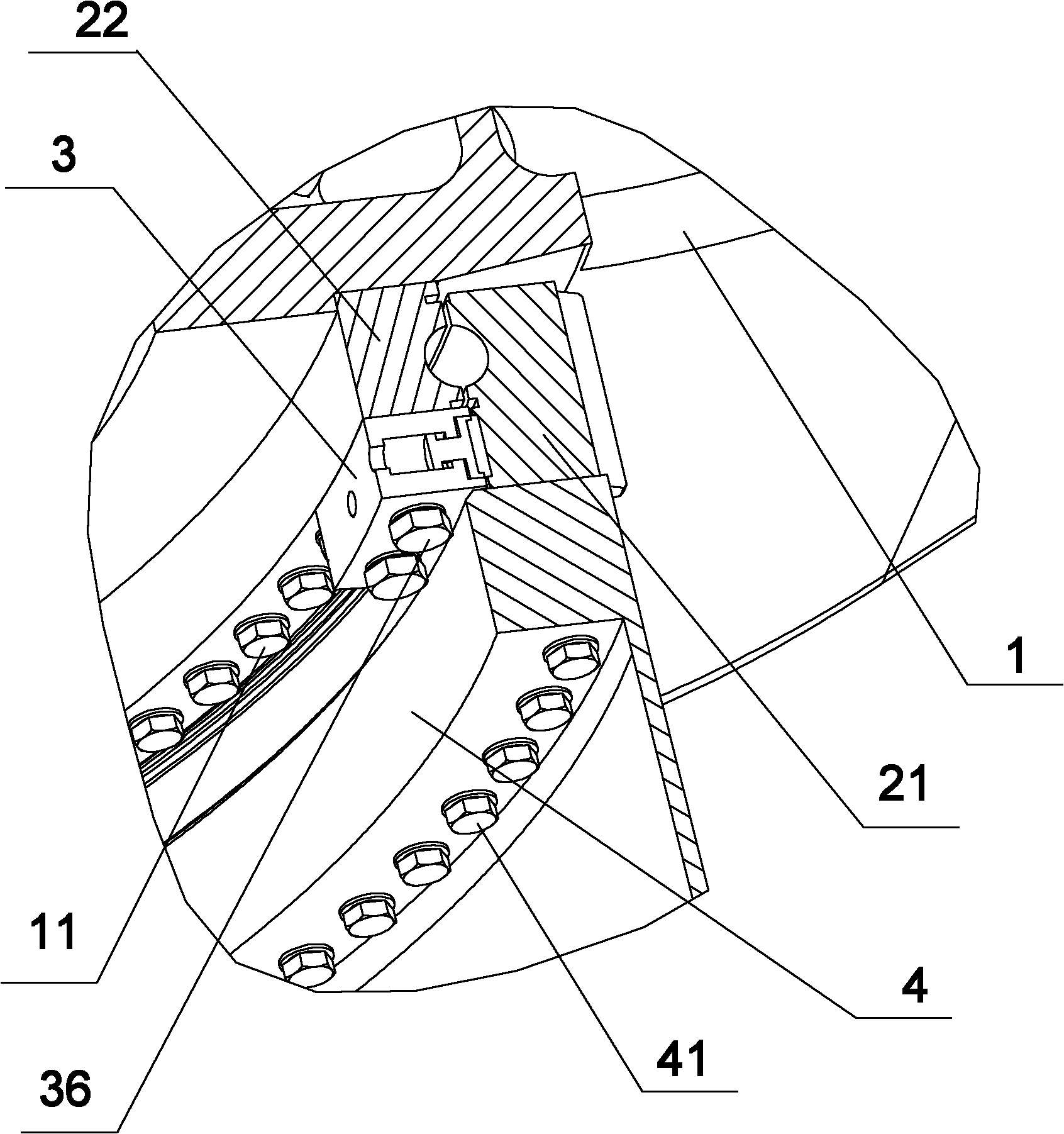

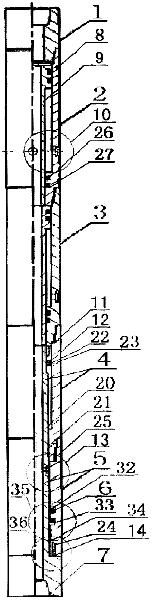

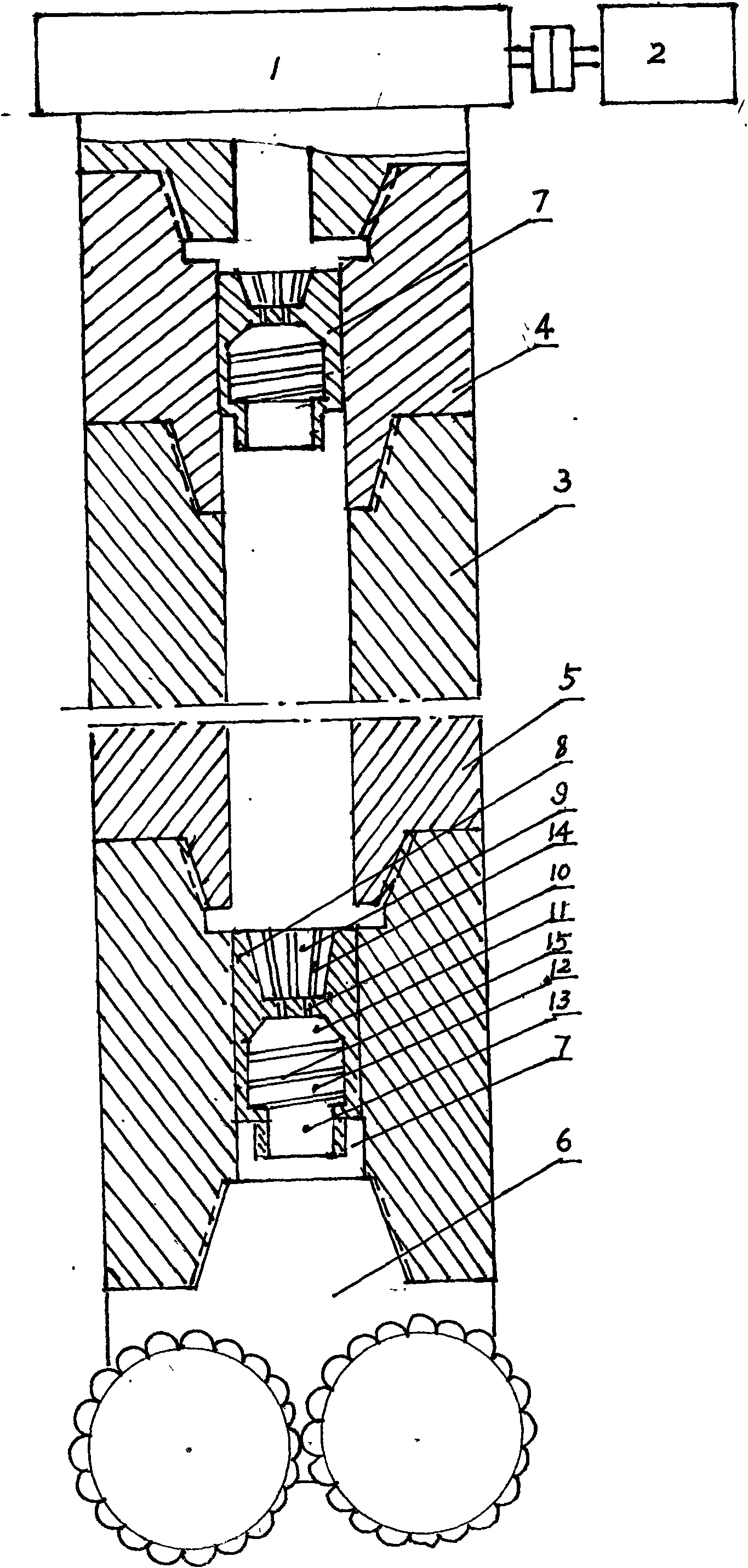

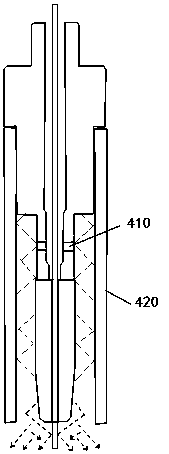

Hydraulic pressurizer

The invention relates to a hydraulic pressurizer, belonging to the technical field of slurry circulating equipment of bored wells. The pressurizer at least comprises an upper connector, a hydraulic pressurizing device, a torque transmission device and a bit pressure tracking early-alarming device that is connected with a drill bit. The hydraulic pressurizing device comprises a hydraulic cylinder, a hollow piston and a respirator; the torque transmission device comprises an external square shaft, an internal square sleeve, a retainer ring and a pressure balance mechanism; and the bit pressure tracking early-alarming device comprises a signal device, a seal cylinder, a central shaft, a seal mechanism and a liquid drainage mechanism. The pressurizer is connected between drilling tools. The bit pressure can be accurately applied to the drill bit by using the pressurizer. According to the pressurizer disclosed by the invention, pulse jet stream with sound harmonic resonance can be produced through a labial structure formed by a water course and a drill bit nozzle of the pressurizer, cavitation is induced in relatively static slurry, such that the bottom of a well produces transient low pressure to reduce 'hold-down effect' of a slurry liquid column. When the bit pressure is changed, the bit pressure tracking early-alarming device can send out a signal to indicate operation. The pressurizer has the capabilities of absorbing vibration of drilling tools and prolonging service life of the drill bit. Moreover, the pressurizer has the functions of inclining prevention, angle maintaining and speed acceleration.

Owner:刘白杨

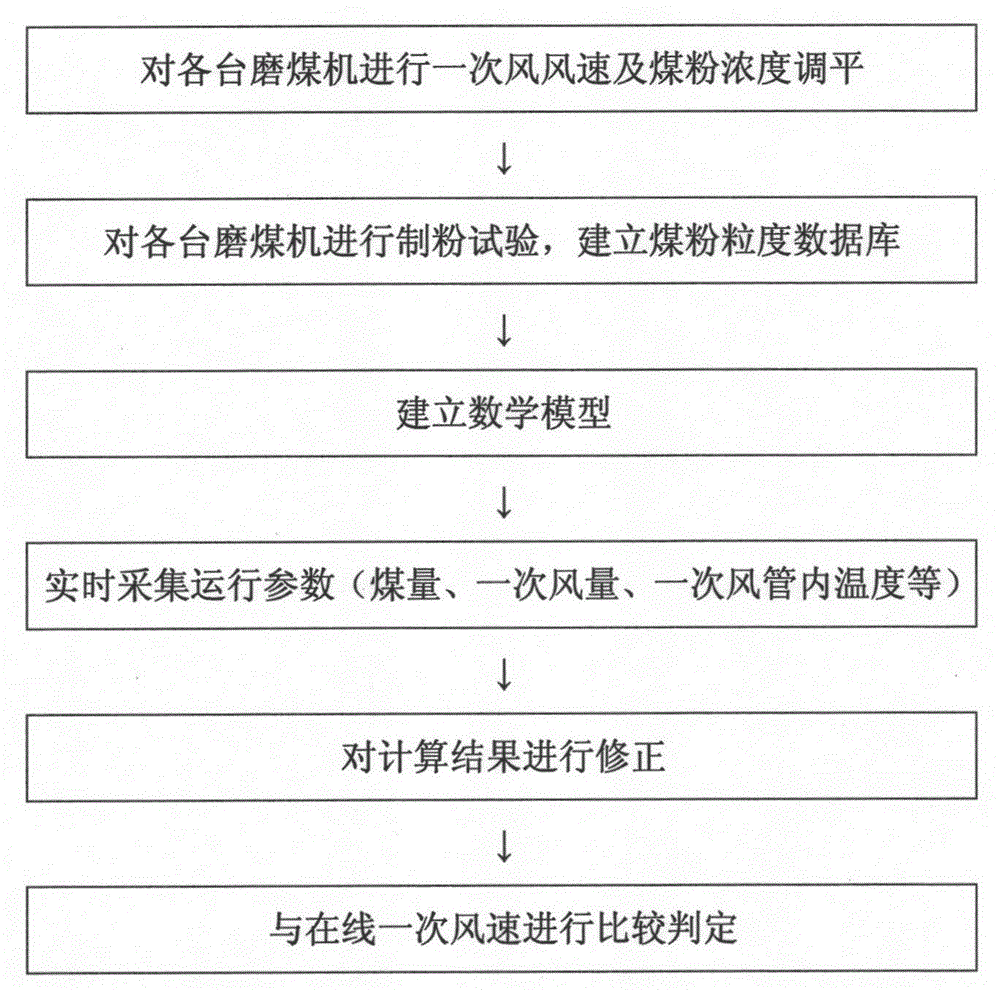

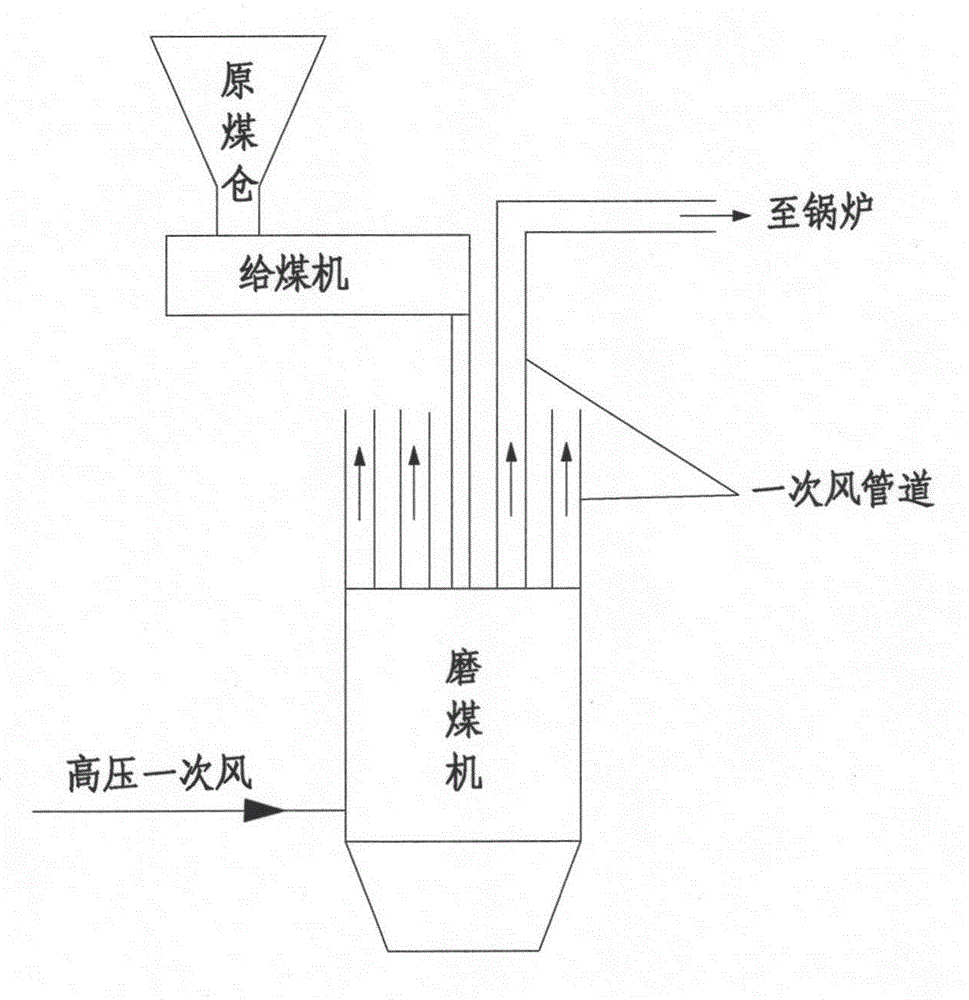

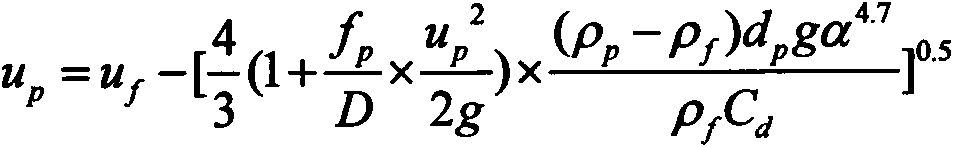

Online pipe anti-blocking method for utility boiler primary air pipe

The invention discloses an online pipe anti-blocking method for a utility boiler primary air pipe. The method comprises the steps that firstly, leveling is carried out on the air speed of primary air and pulverized coal concentration of each coal mill; secondly, a coal pulverizing system test is carried out on the coal mill, and a pulverized coal grain size database is established; thirdly, a mathematic model is established, according to parameters in operation collected in real time and the pulverized coal grain size database, the minimum fluidizing velocity of pulverized coal conveying under the theory state is calculated, a theoretical value is corrected according to the actual operation condition, the corrected minimum fluidizing air velocity is compared with the primary air speed measured online, and guiding opinions of the primary air speed are given. The online pipe anti-blocking method for the utility boiler primary air pipe can avoid the defects brought by too high primary air speed that pulverized coal ignition is delayed, the electric current of a primary air fan is too large, and air leakage of an air preheater is increased, and achieve energy saving and consumption reducing under the condition that the primary air pipe is not blocked.

Owner:SHANGHAI POWER EQUIP RES INST

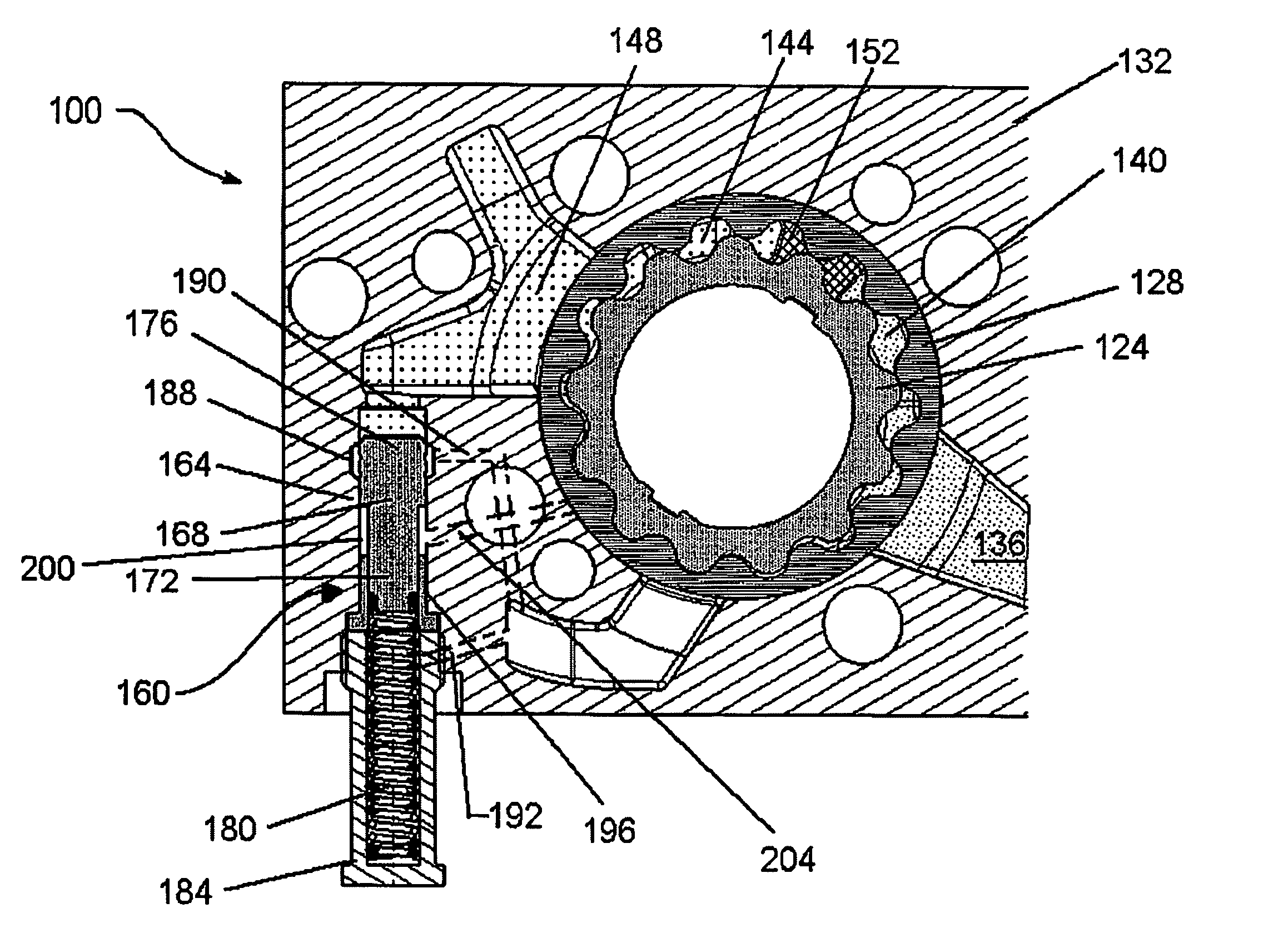

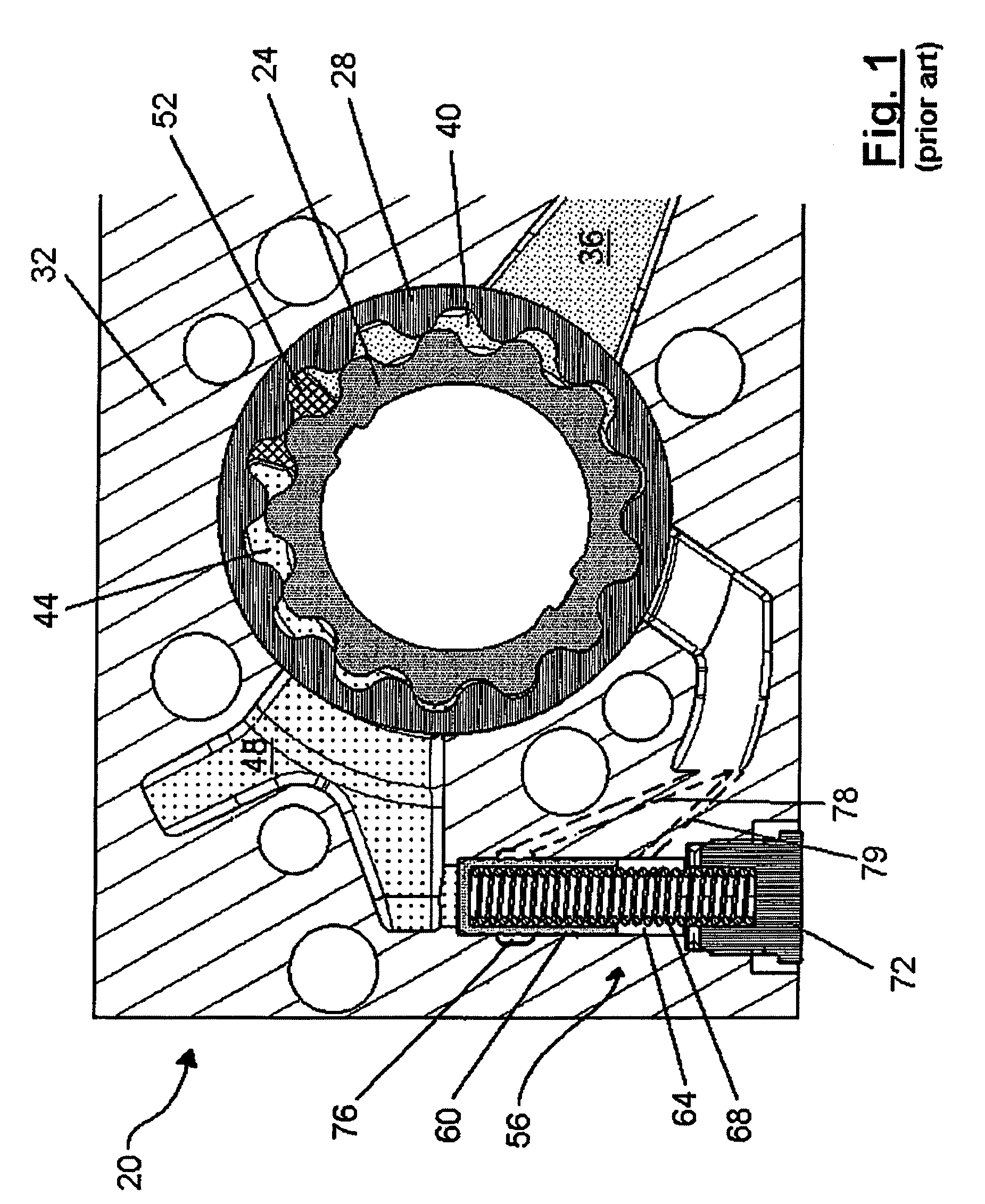

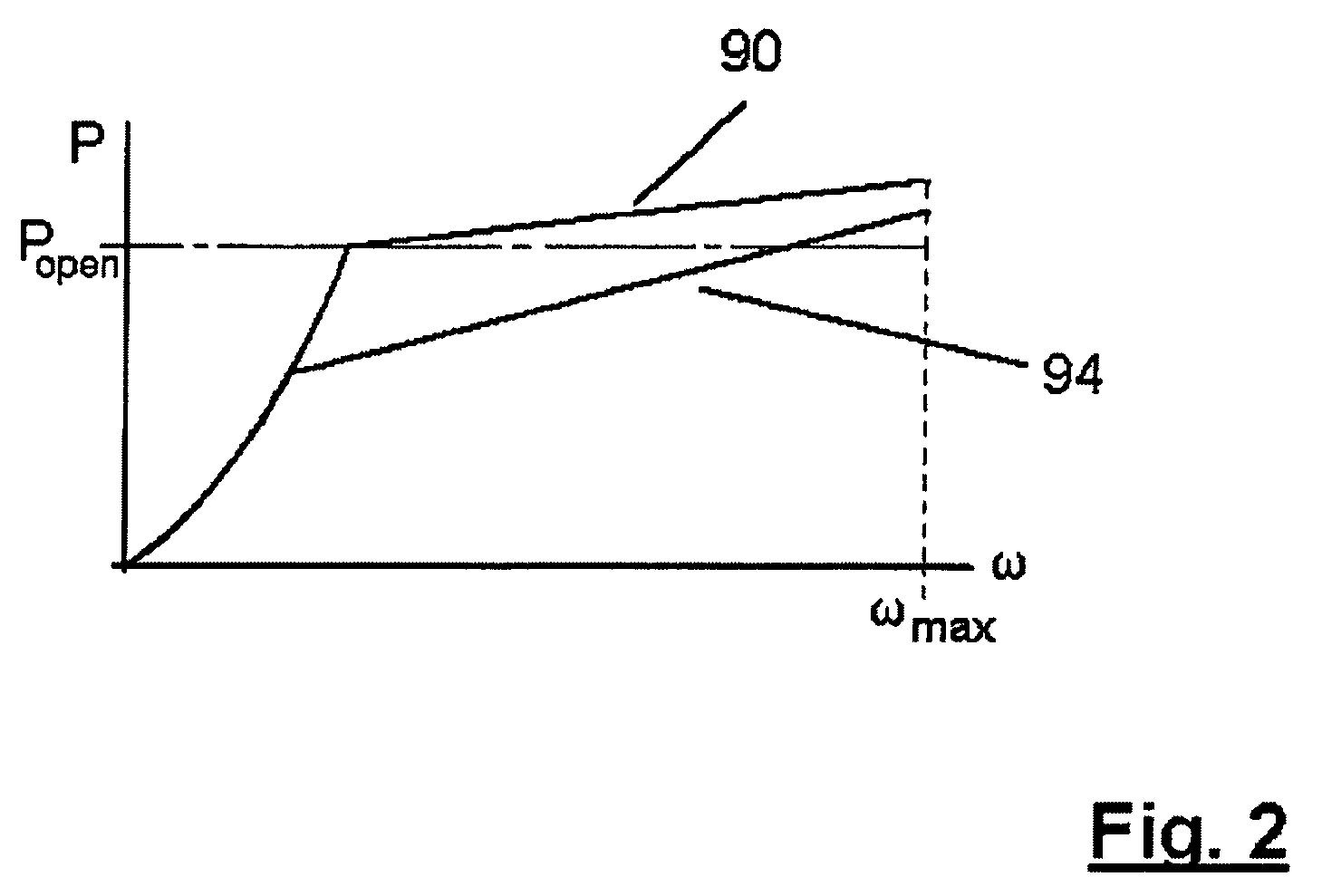

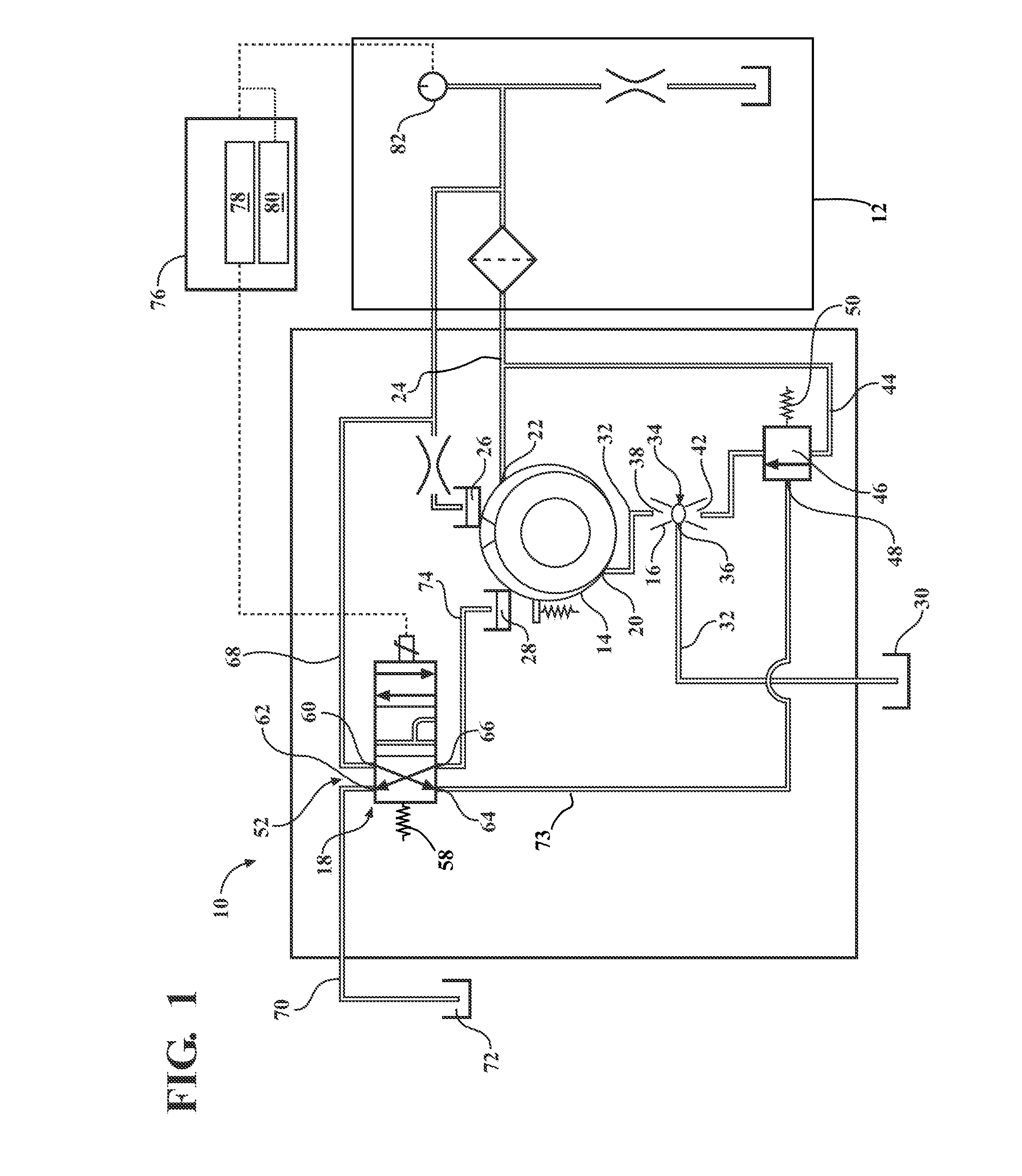

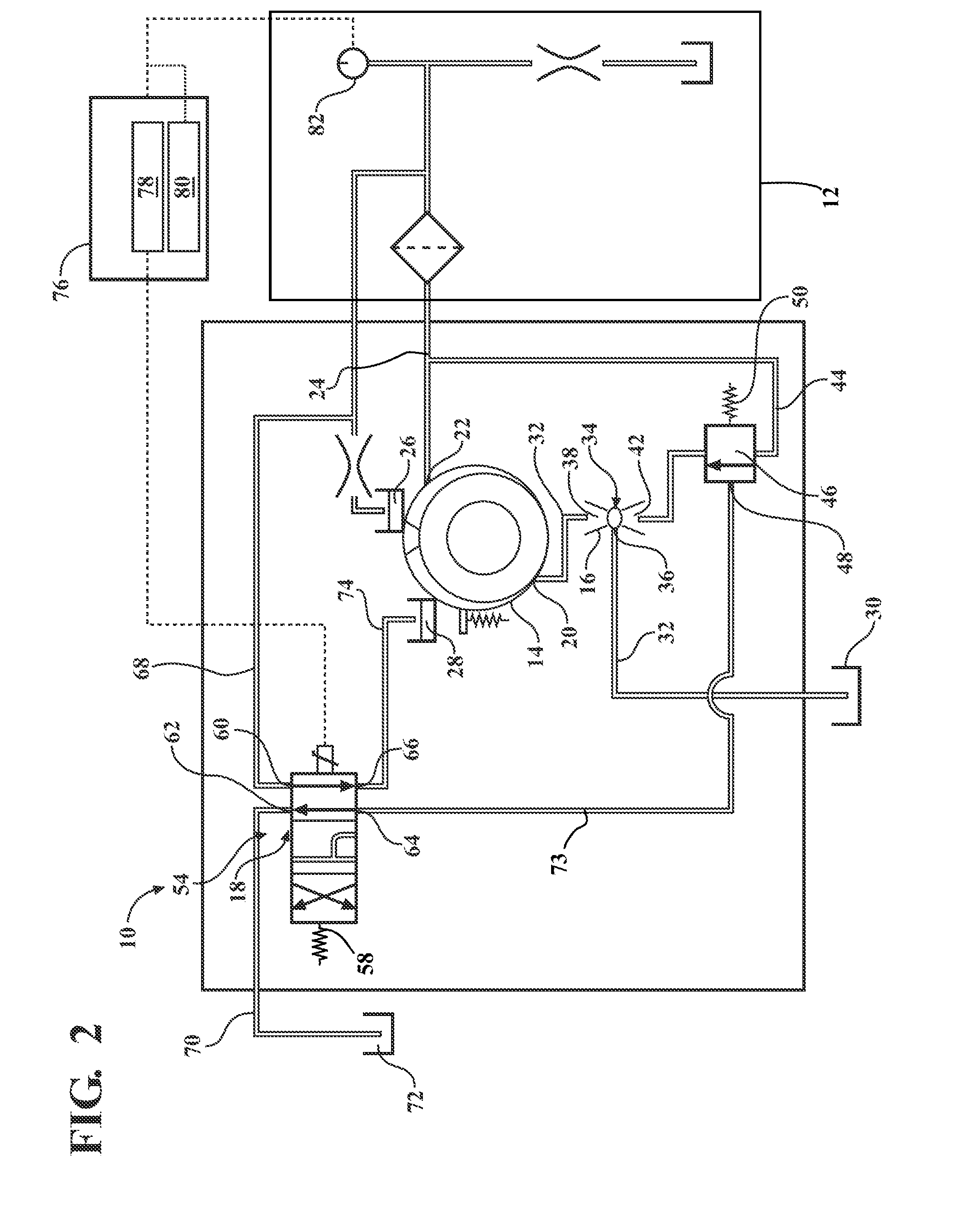

Pump control using overpressure source

ActiveUS8297943B2High strengthReduce output pressureCheck valvesEngine of intermeshing engagement typeWorking fluidControl system

A rotary positive displacement pump employs the higher pressure available at a region within the rotor chamber after the outlet port to augment the force of a biasing spring in a control system. A biasing spring with a lower spring force can thus be employed in the control system, resulting in a pump pressure output characteristic which can more closely match the operating speed varying working fluid requirements for devices supplied by the pump.

Owner:HANON SYST EFP CANADA LTD

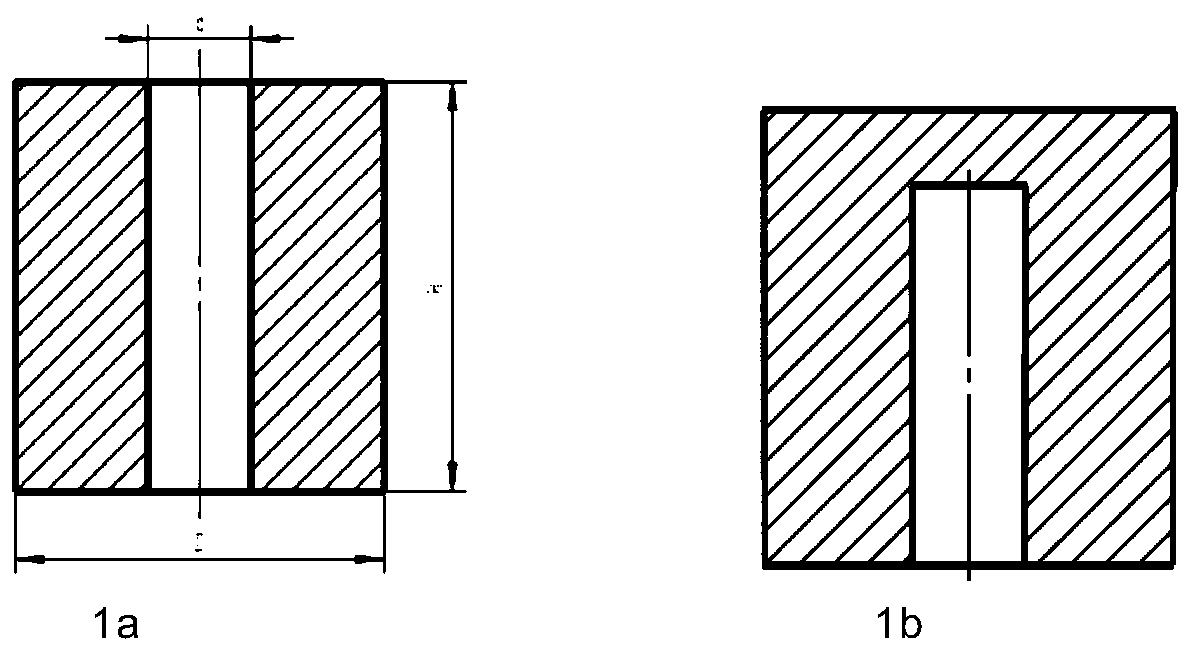

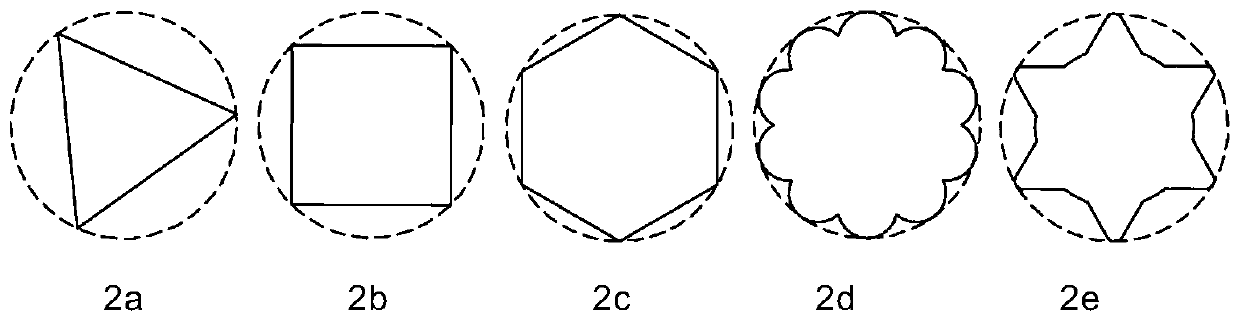

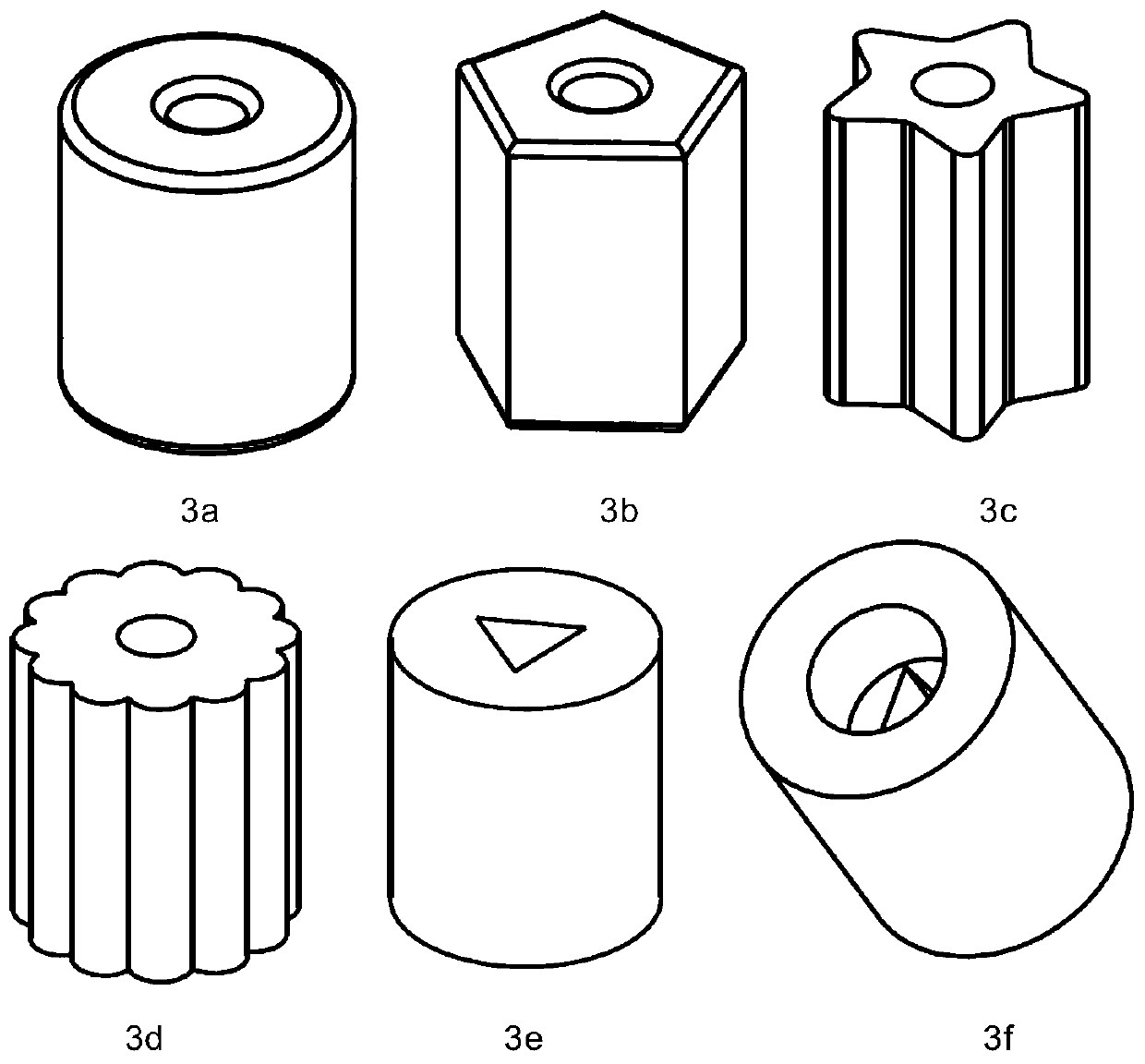

Perforated gas producing agent molding pressing product and preparation process thereof

PendingCN109809953AAdjust the burning surfaceSmall impactExplosivesPressure gas generationProcess engineeringIntermediate stage

The invention relates to a perforated gas producing agent molding pressing product and a preparation process thereof. The appearance of the perforated gas producing agent molding pressing product is acylinder body; a penetrated or non-penetrated hole is formed at the inside; the perforated gas producing agent can achieve the goals of reducing the surface combustion process, or realizing the equalsurface combustion or increased surface combustion in a period time in the combustion process, and thus realizing the low early stage pressure and slope of the gas generator; the impact on an airbagand the harm are small; an airbag is slowly unfolded; the middle stage pressure fast rises; the airbag is fast filled; the later stage pressure is slowly reduced; the airbag maintaining time is prolonged; the curve is similar to the S-shaped pressure-time curve. The initial combustion surface is reduced; the reduced surface combustion or equal surface combustion or increased surface combustion arereduced; the pressure inside the gas generator is reduced, so that the material cost of the gas generator and the quality of the generator can be reduced. The pressing shaping process is used; the perforated gas producing agent is prepared in a pressing forming way, so that the preparation process is simple and efficient; the operation and the control are easy.

Owner:HUBEI HANGPENG CHEM POWER TECH

Low-energy-consumption device and method capable of producing oxygen-enriched gas and high-purity nitrogen simultaneously

PendingCN106989567AReduce output pressureMeet heat transfer requirementsSolidificationLiquefactionAir compressionMolecular sieve

The invention provides a device capable of producing oxygen-enriched gas and high-purity nitrogen simultaneously. The device comprises an air compression system, an air precooling system, a molecular sieve purification system, a booster expansion turbine, a main heat exchanger, a rectifying column and a supercooler. All the devices communicate with one another through corresponding pipelines. The invention further provides a method capable of producing the oxygen-enriched gas and the high-purity nitrogen simultaneously. In specific, air in the atmosphere is divided into two paths after being filtered, compressed and purified; one path of the air enters the booster expansion turbine and then enters an upper column body for rectification separation after passing through the main heat exchanger; and the other path of the air directly enters the main heat exchanger to be cooled and then enters a lower-layer main condensing evaporator and a lower column body in sequence, primary rectification separation is carried out in the lower column body, and then the air enters the upper column body to conduct final rectification separation. By the adoption of the device and method, the oxygen-enriched gas of different purities can be produced while the high-purity nitrogen is produced, the oxygen-enriched gas can be directly used by follow-on production, repeated construction and investment of equipment are reduced, and the production cost is also reduced.

Owner:HENAN KAIYUAN AIR SEPARATION GRP CO LTD

Drilling fluid conveying device provided with self-oscillation superchargers

InactiveCN101629479AIncrease pressureIncrease drilling speedFlushingVibration drillingWell drillingSelf-oscillation

The invention discloses a drilling fluid conveying device provided with self-oscillation superchargers, and belongs to the technical field of drilling fluid conveying devices. The technical problem to be solved is to provide a drilling fluid conveying device which uses a low-power drilling fluid pump and is provided with self-oscillation superchargers. To solve the technical problem, the invention adopts the technical scheme that the drilling fluid conveying device comprises a drilling fluid pump, a drill rod, a drill rod joint, a drill bit and the self-oscillation superchargers; the drill rod joint of the first section is connected between the upper end of the drill rod of the first section and a fluid outlet of the drilling fluid pump; one self-oscillation supercharger is arranged in an inner hole of the drill rod joint of the first section, and the other self-oscillation supercharger is arranged between the lower end of the drill rod of the last section and the upper end of the drill bit; the self-oscillation supercharger comprises a shell, a water inlet hole, a throttling supercharging hole, a diffusion hole, a columnar inner cavity and a water outlet hole; the surface of the water inlet hole is provided with a longitudinal guide groove; and the surface of the columnar inner cavity is provided with a spiral guide groove. The drilling fluid conveying device is applied to conveying drilling fluid. The drilling fluid conveying device has the advantages that the device can remarkably increase the output pressure of the drilling fluid, uses the low-power drilling fluid pump to achieve the pressure output by a high-power drilling fluid pump, reduces the consumption of fuels, and improves the drilling speed.

Owner:宋家雄 +1

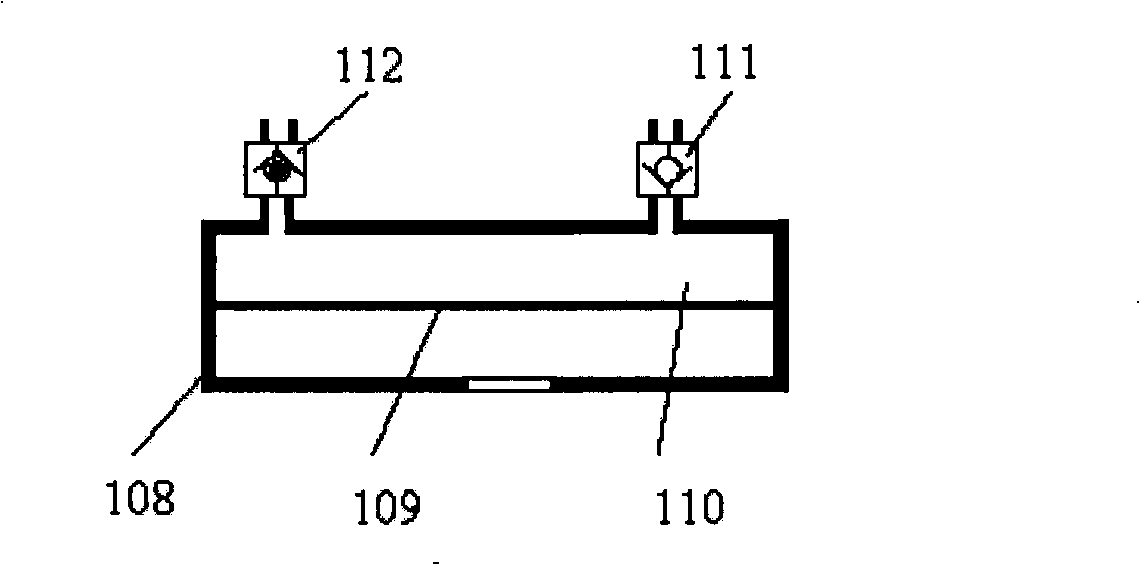

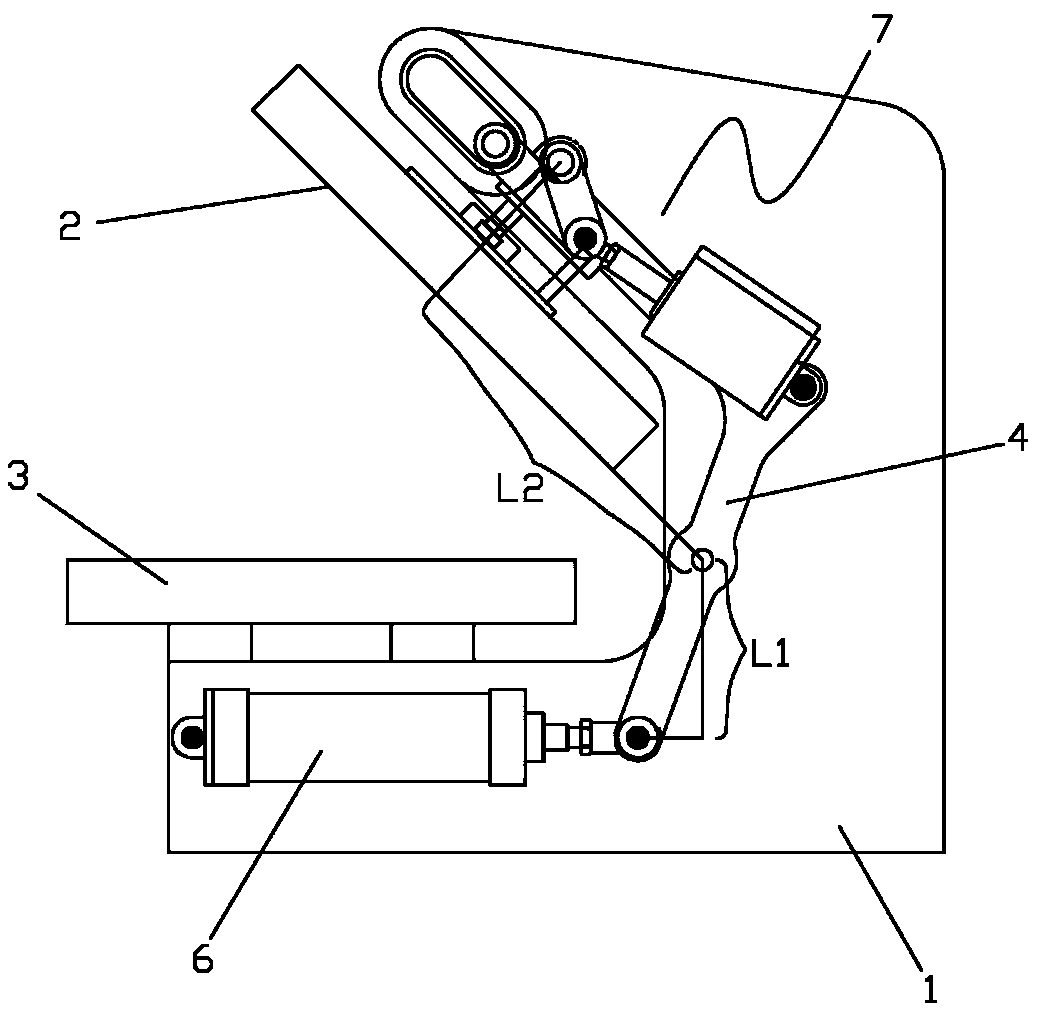

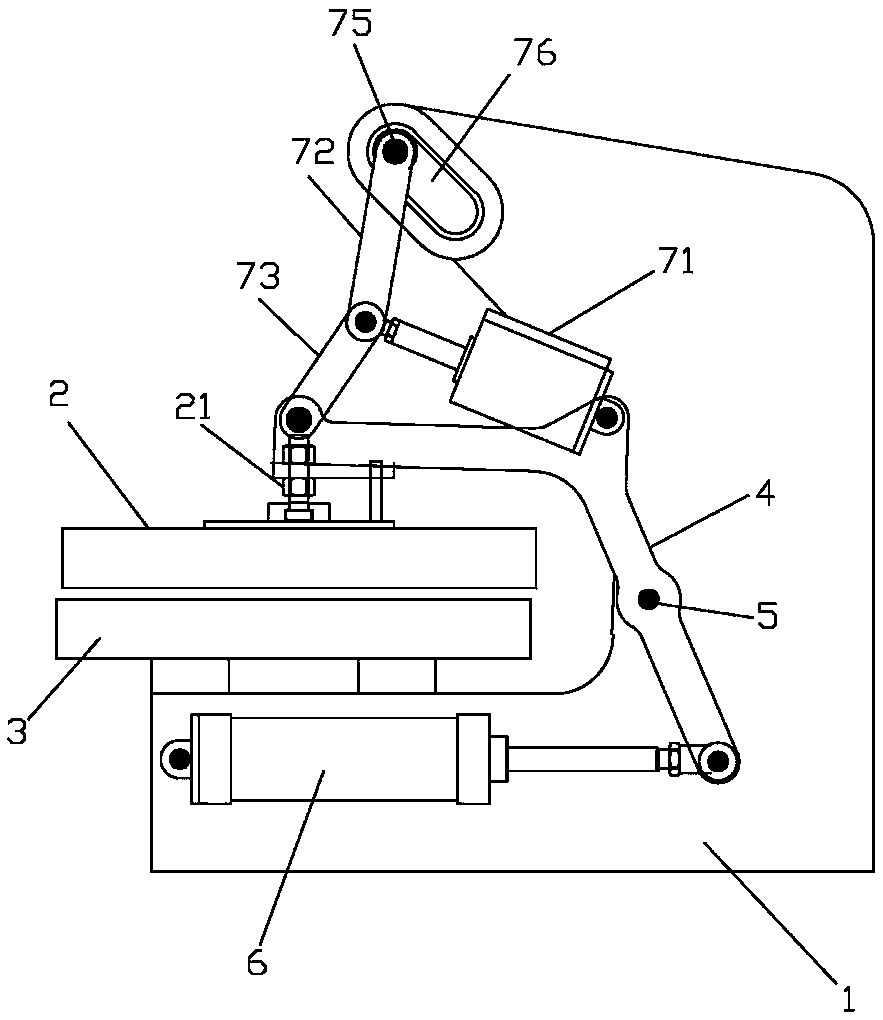

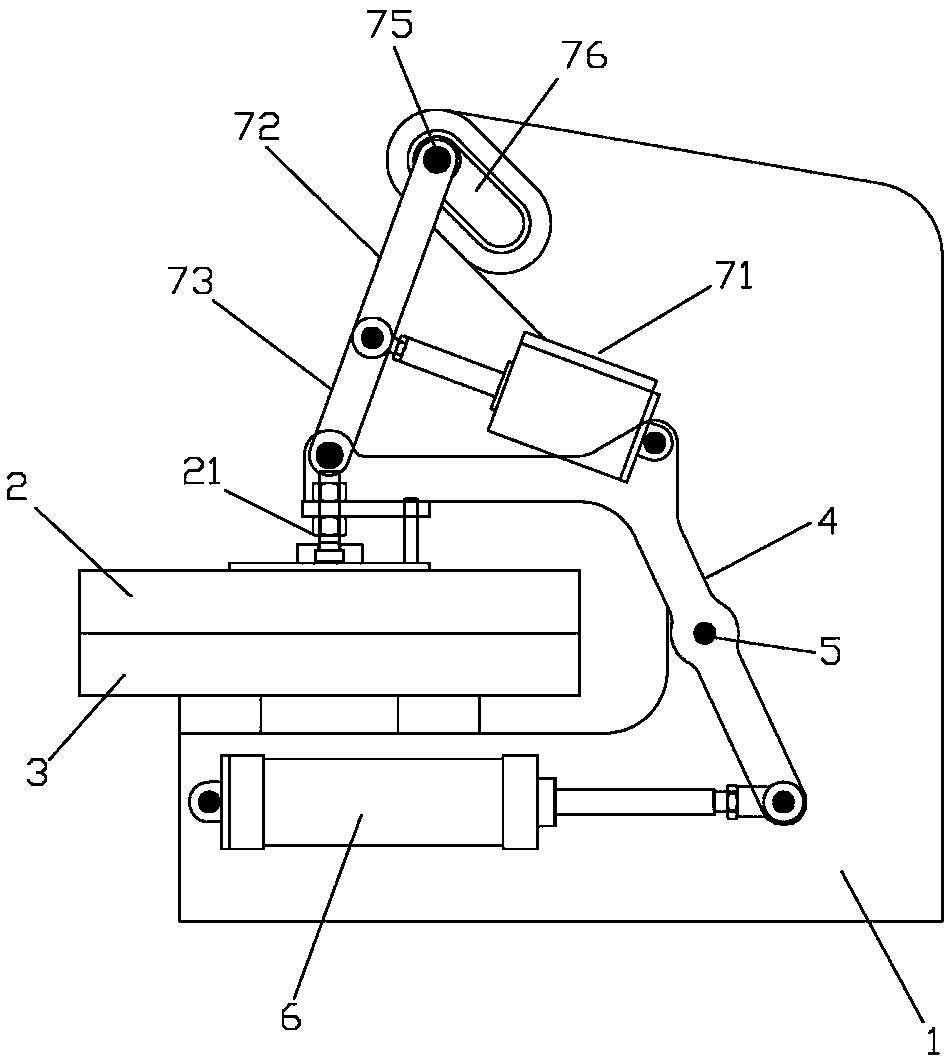

a pressing machine

ActiveCN106515204BLow gas consumptionReduce output pressureTransfer printingEngineeringMechanical engineering

The invention relates to a hot press machine. The two-stage cylinder driving design is adopted. One stage of cylinder is mainly used for driving an upper hot press plate for the idling stroke, and the stroke of the cylinder is increased through a lever; and the stroke of the other stage of cylinder is increased for increasing the output pressure. Compared with an existing cylinder direct-drive structure, the sizes and gas consumption of the two cylinders are greatly reduced, so that the hot press machine is extremely compact in structure, the gas consumption is greatly reduced, and the energy efficiency and economic efficiency are improved.

Owner:台州新同创科技有限公司

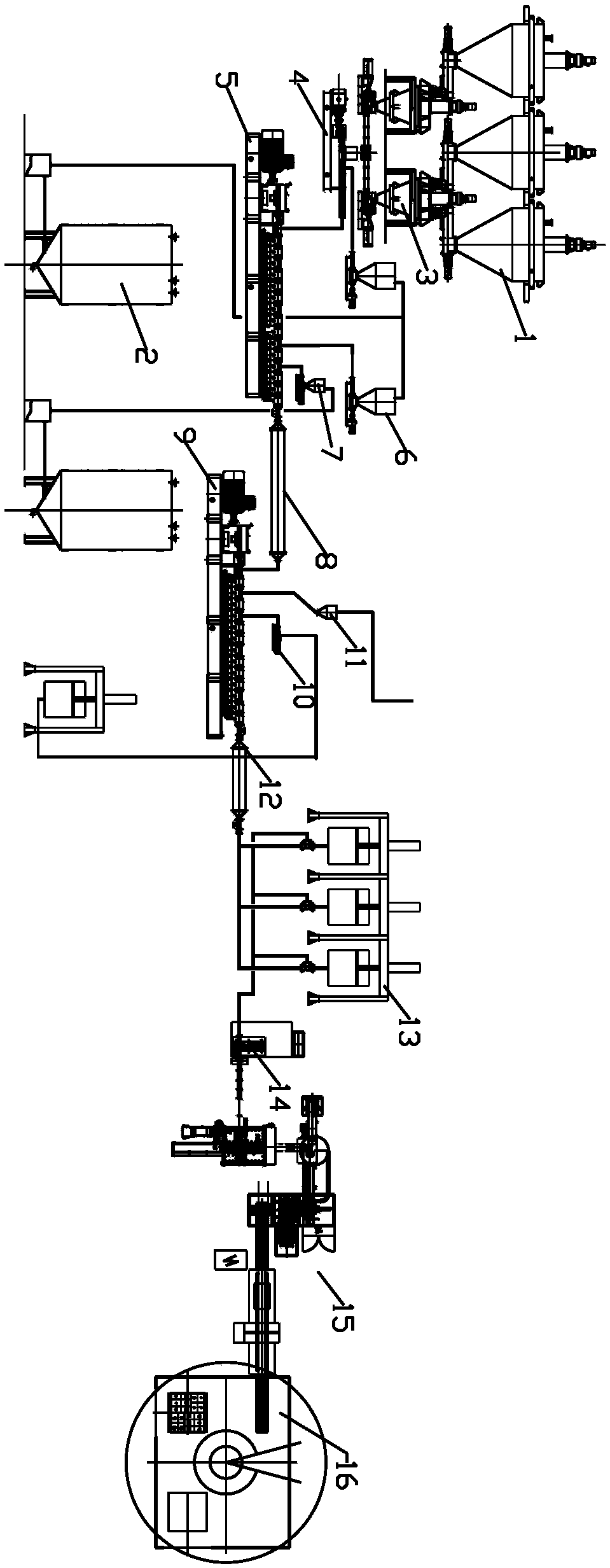

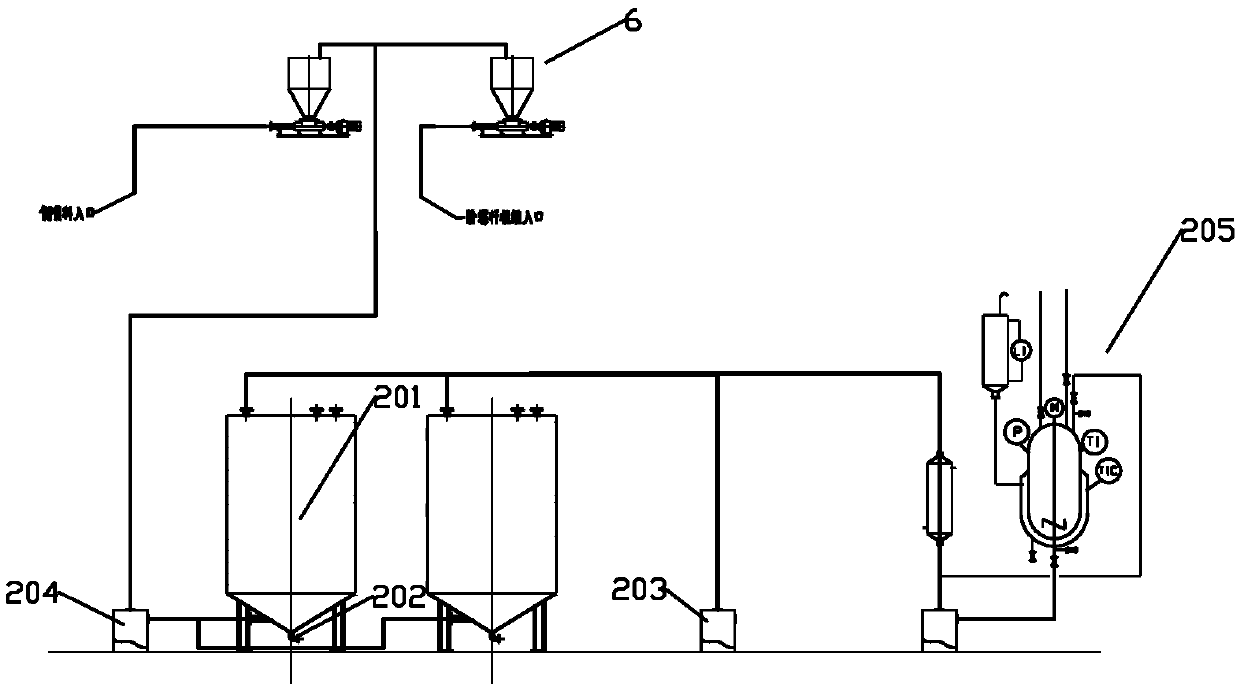

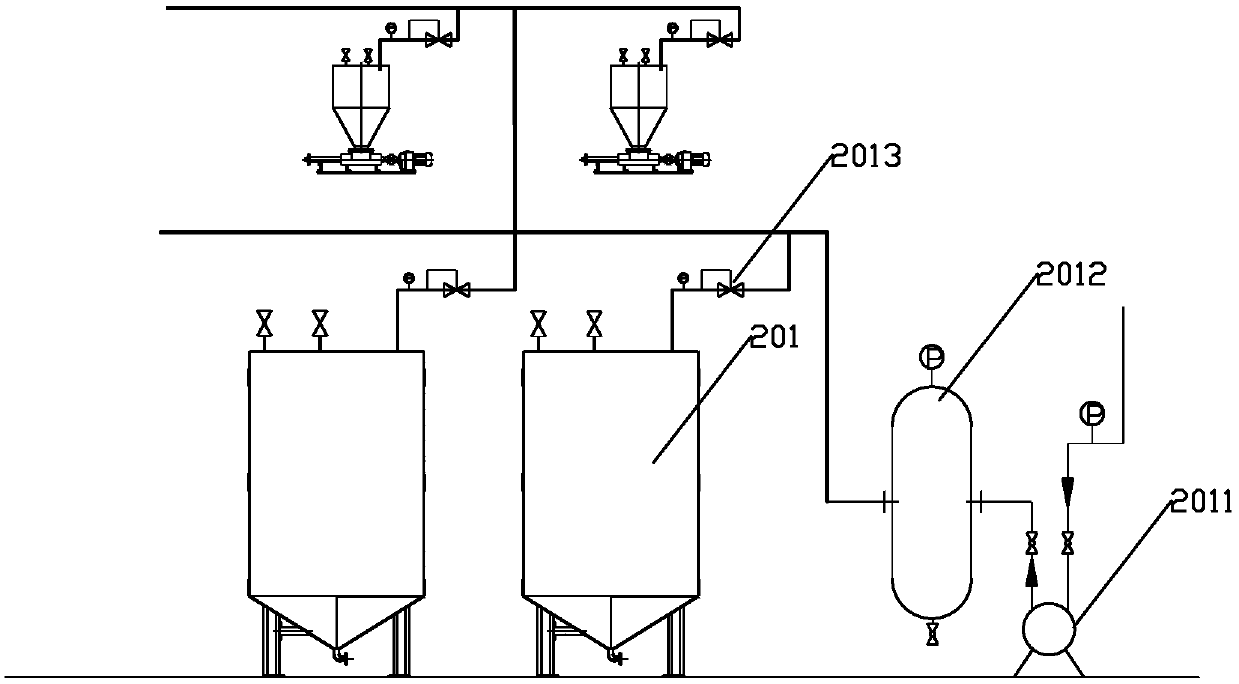

Automatic production line of sealant

ActiveCN109689192AReduce output pressureImprove cooling effectMixer accessoriesSolid materialProduction lineBuffer tank

The invention discloses an automatic production line of sealant, comprising a sealant making device and a packaging device. The sealant making device comprises a material storage device, a liquid storage device, a material feeding device, a side feeding device, a first-order screw unit, a liquid feeding device, a cold-heat exchanger, a second-stage screw unit, a color material feeding device, a cooler and a buffer tank device. The packaging device includes a filling device and a packaging apparatus. The automatic production line of sealant of the invention can achieve fully automatic continuous production of the sealant from the raw material to the finished product, and saves the energy.

Owner:GUANGZHOU BAIYUN CHEM IND

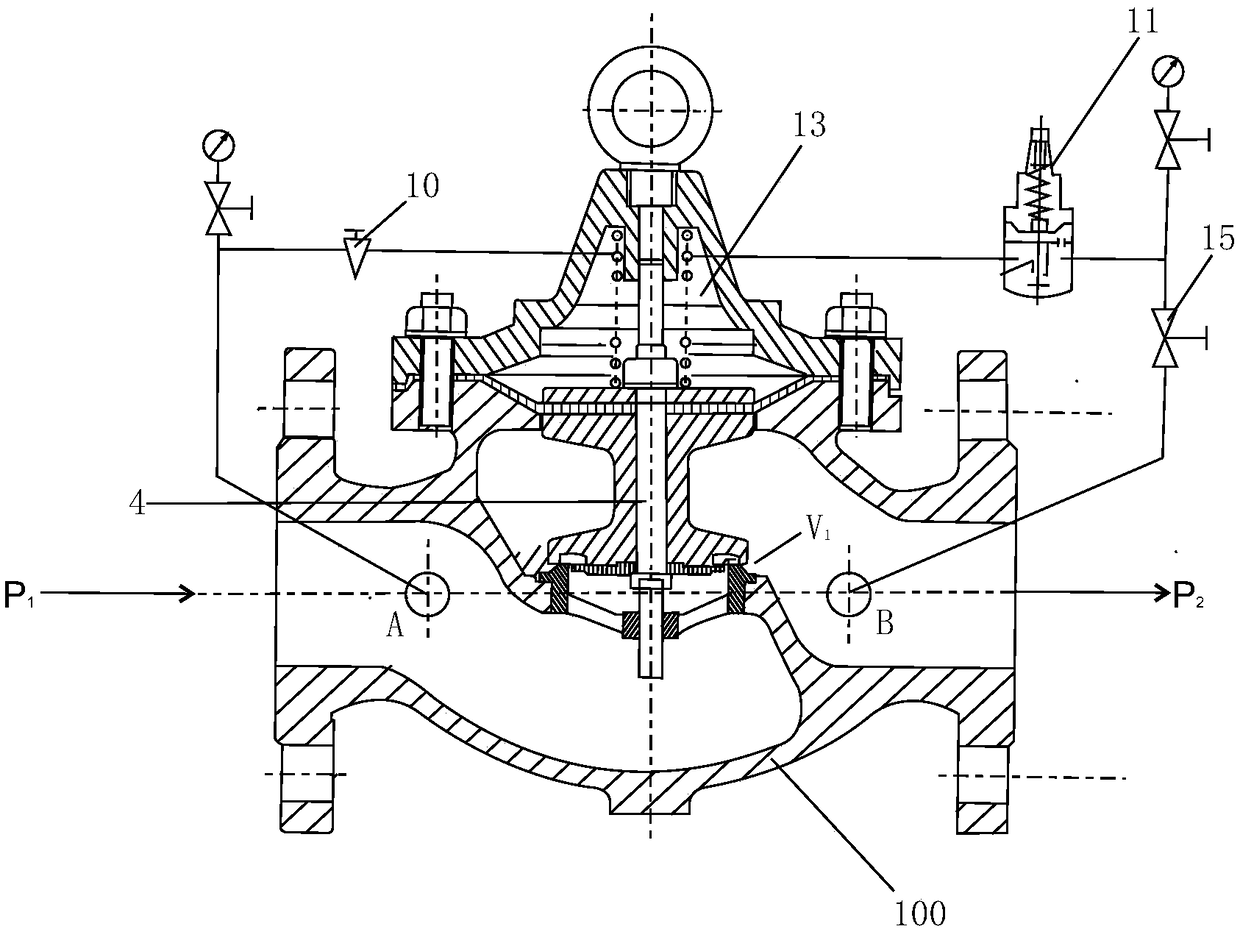

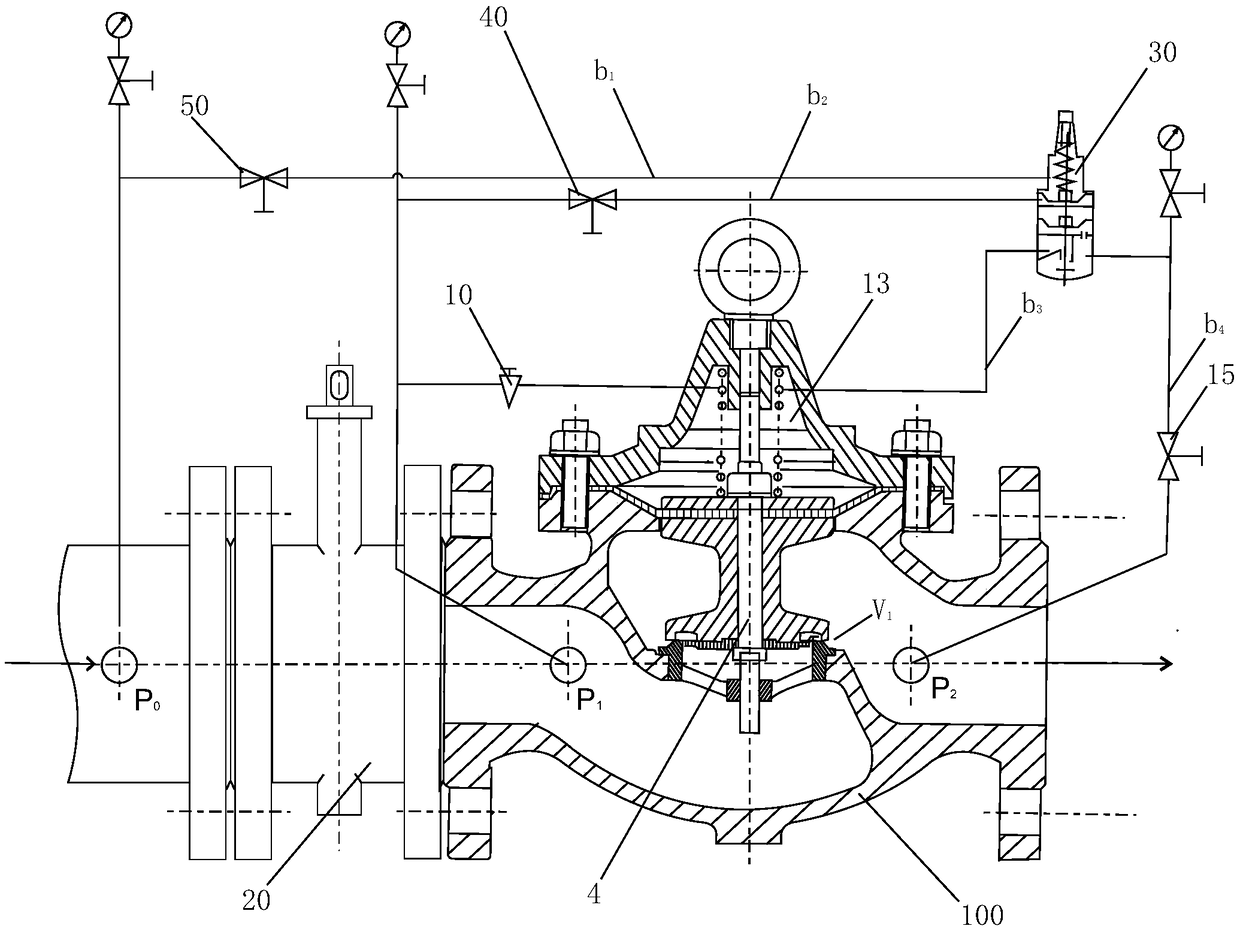

Novel reducing valve with output pressure responding to flow changes

PendingCN108087611AReduce output pressureReduces the chance of water leaks and pipe burstsOperating means/releasing devices for valvesFluid pressure control without auxillary powerPipingTraffic volume

The invention discloses a novel reducing valve with output pressure responding to flow changes. The novel reducing valve comprises a reducing valve main valve, a throttle valve, and a double-acting pilot valve; the reducing valve main valve is provided with a control cavity; the double-acting pilot valve is provided with a throttle valve differential pressure input part; and the high-pressure endand the low-pressure end of the throttle valve are connected with the throttle valve differential pressure input part on the double-acting pilot valve through pipelines. According to the novel reducing valve with the output pressure responding to the flow changes, self-regulation of the output pressure can be achieved according to the flow of the pipelines, the average output pressure is greatly reduced, the pipelines and the valve are prevented from always being under high pressure whether in water-using peak or trough times, the probability of leakage and pipe burst of a piping system is reduced, energy and resources are saved, and the maintenance charge is reduced.

Owner:HANGZHOU CHUNJIANG VALVE

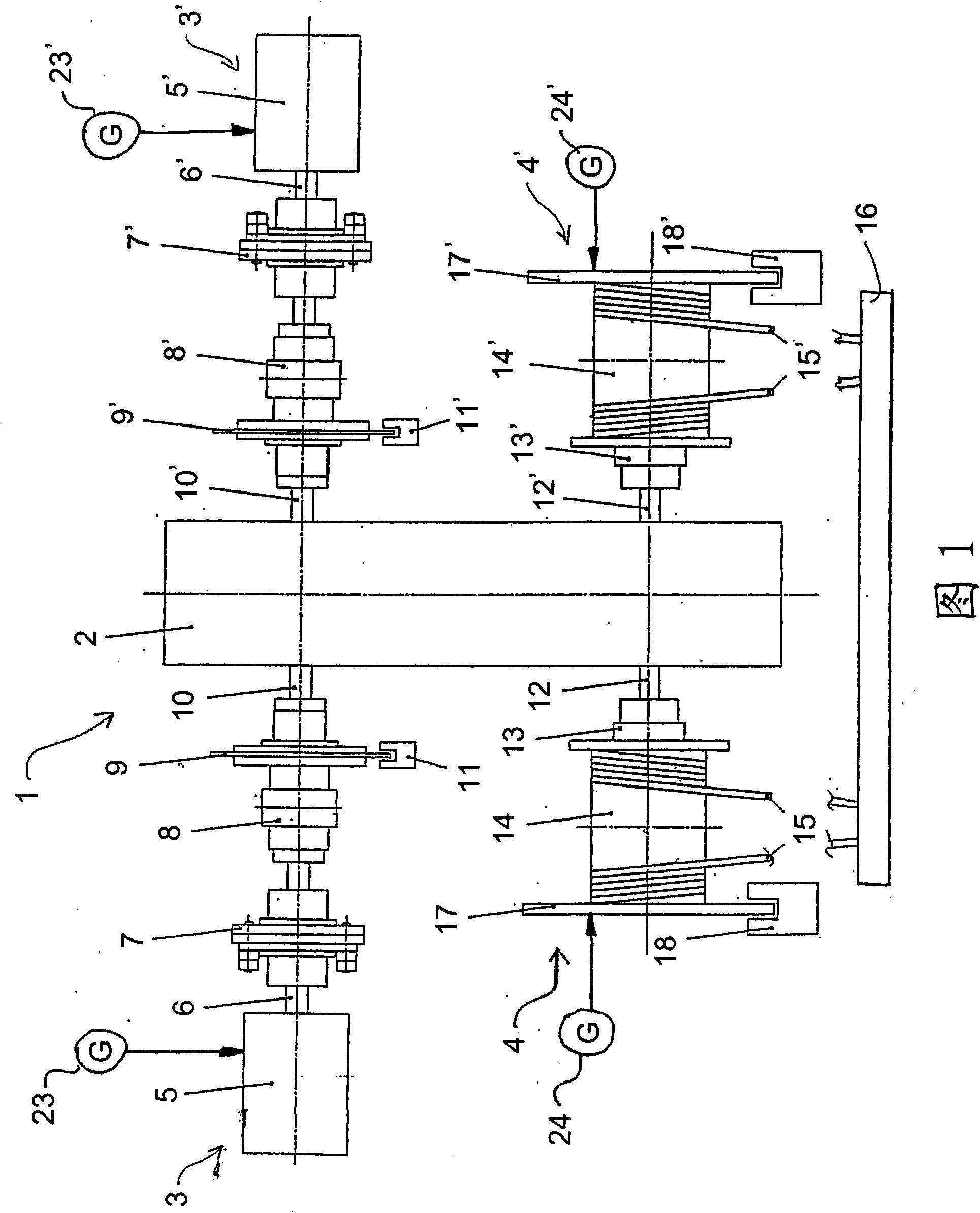

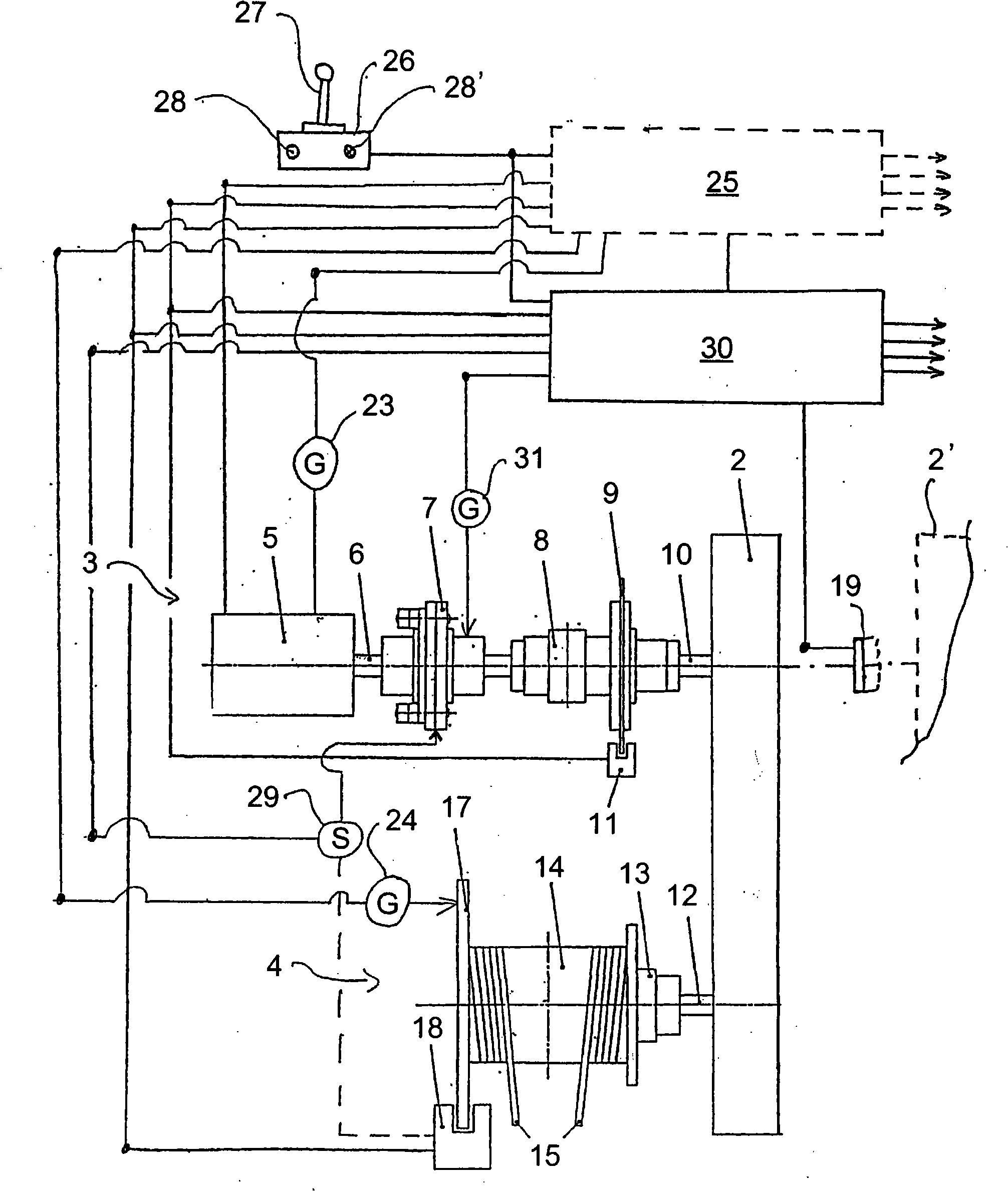

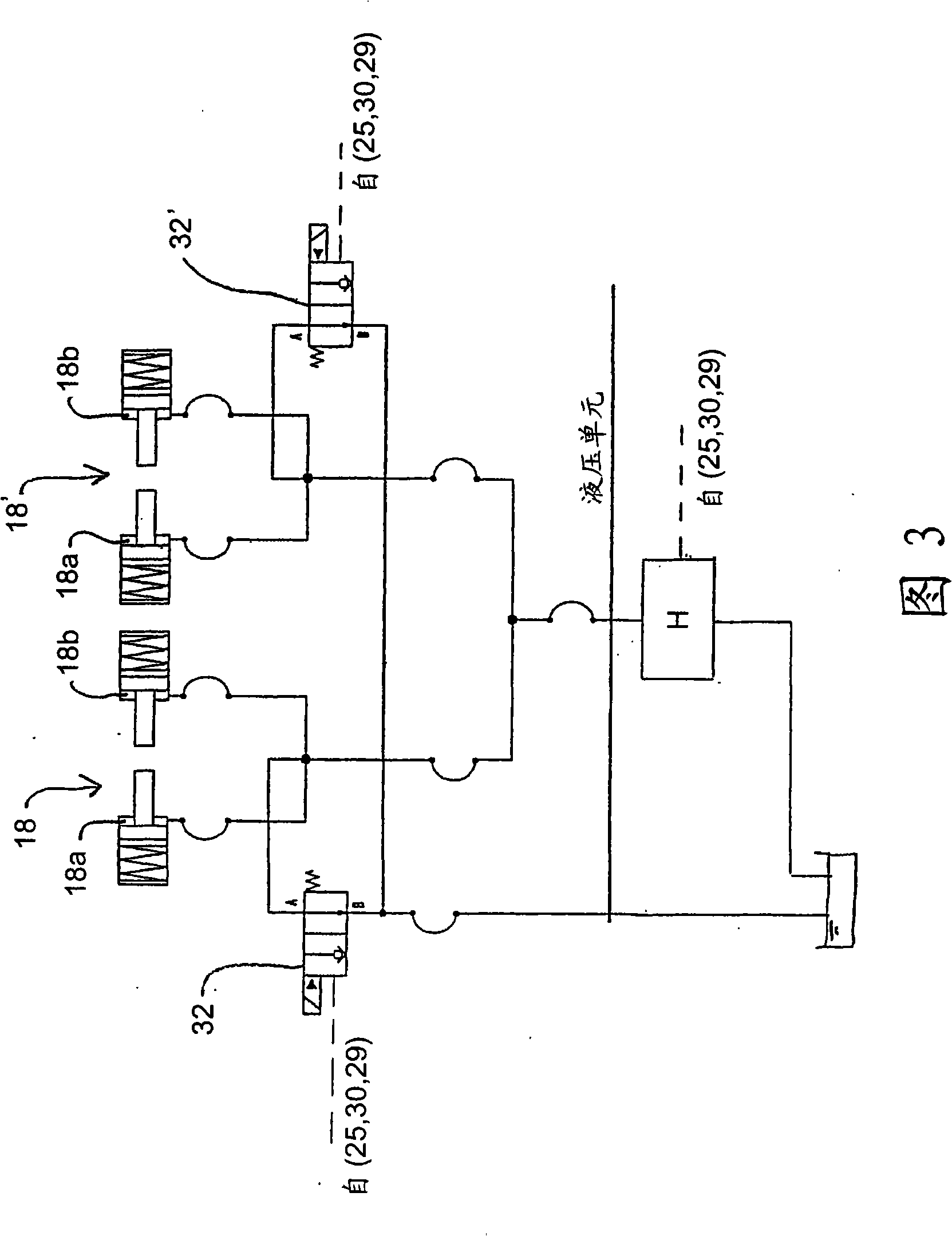

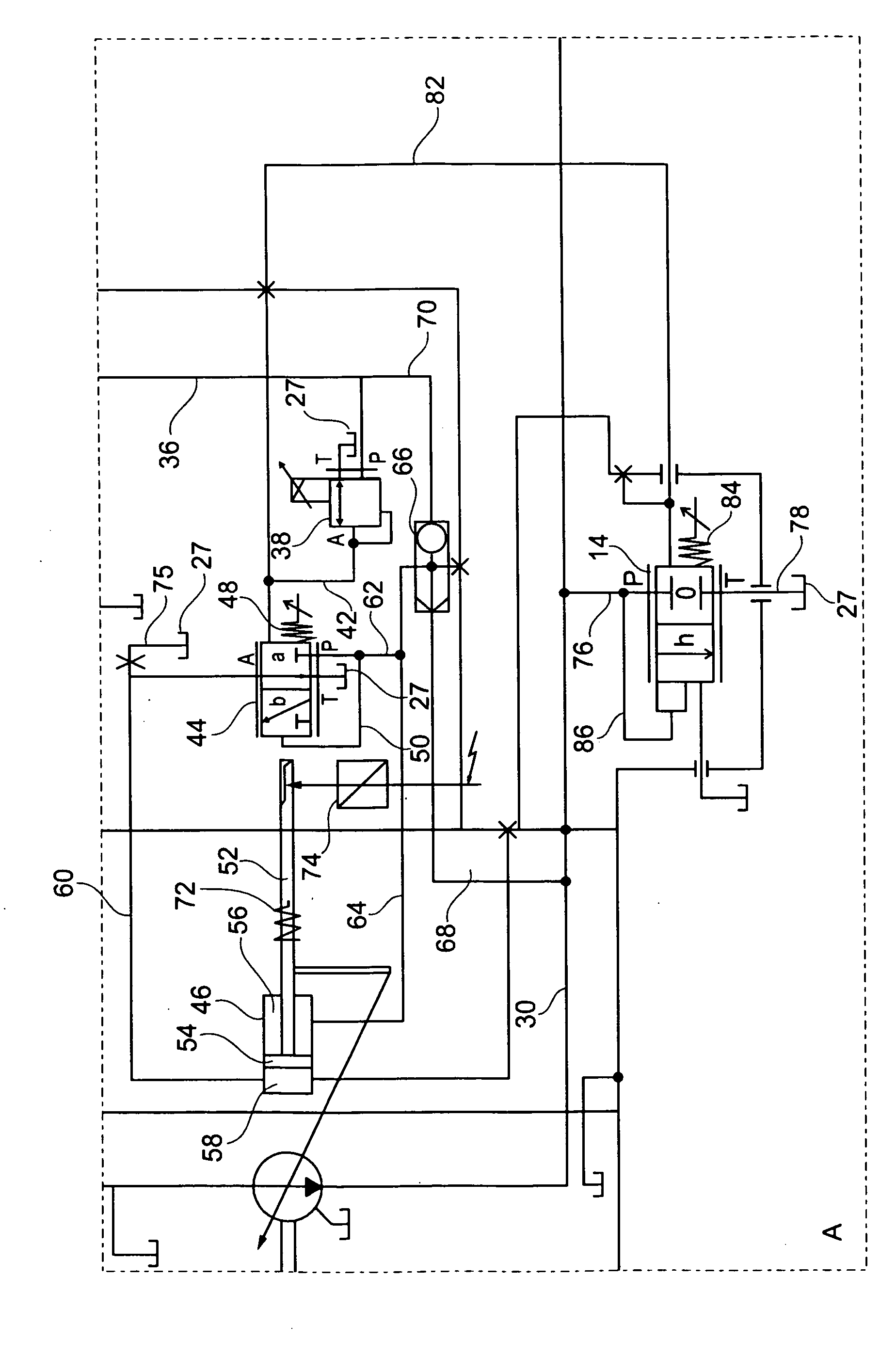

Control and regulation device for safeguarding a conveyor device, conveyor device and crane unit

ActiveCN101336205AAccurate and reliable detectionEasy to adjustWinding mechanismsCranesSignal onContainer crane

The invention relates to a control and regulation device for safeguarding a conveyor device (1), in particular, a crane unit in the case of overload. A brake device (11, 18) acting on the conveyor device (1) is provided, along with a controller (30) for the brake device (11, 18), an overload sensor (29), recording the overload and emitting an overload signal and a speed sensor (31, 24), recording a cA process for the production of iohexol comprises alkylating 5-Acetamido-N,N'-bis(2,3-dihydroxypropyl)-2,4,6- triiodoisophthalamide using 2(2-methoxy-ethoxy)-ethanol as solvent in the presence of a base, and optionally isolating crude iohexol from the reaction mixture. Preferably, the alkylating agent is 1-chloro-2,3 propanediol and the base is an alkali metal hydroxide such as sodium hydroxide or potassium hydroxide.onveyed item speed and emitting a speed signal. The controller (30) reacts to the overload signal on the braking device (11, 18), such that this device stops the conveyor device and thus safeguards a conveyed item (16).; On a subsequent unload signal the controller (30) releases the conveyor device (1) such that the conveyor device (1) is moved into an unload position by the effect of the load of the conveyed item (16) and the effect of the braking device (11, 18) on the conveyor device (1) is regulated according to the speed signal from the speed sensor (24, 31) such that the conveyed item (16) is moved into the unload state at an essentially constant conveyor speed. The invention further relates to a conveyor device with such a control and regulation arrangement and a container crane unit with two conveyor devices provided with such a control and regulation device.

Owner:PINTSCH BUBENZER

Gas shield welding contact tube

PendingCN108436237ASolve the lack of wear resistanceIncrease delivery speedElectrode accessoriesGas cylinderShielding gas

The invention discloses a gas shield welding contact tube which comprises a contact tube body, a gas diffuser arranged at the front end of the contact tube body, and a guide nozzle arranged at the front end of the gas diffuser. Ceramic protectors are arranged in the contact tube body and the gas diffuser. Core holes for allowing welding wires to pass are formed in the ceramic protectors. The welding wires pass through the ceramic protectors via the core holes and are guided out from the guide nozzle. Air holes for allowing protecting gases to pass are formed in the gas diffuser. After passingthrough the air holes, the protecting gases are linear and no interference airflow exists among the protecting gases. The airflow surrounds a soldering point of the guide nozzle to form protective atmosphere. The welding wires are automatically centered by the ceramic protectors, so that abrasion is reduced, heat conduction is isolated, and continuous welding at high temperature is realized. The gas transmission speed is increased and the output pressure of a gas cylinder is reduced by the gas diffuser, so that the utilization rate of carbon dioxide is effectively increased, the discharge is reduced, and the welding quality is improved. The contact tube adopts a split structure, and parts can be replaced as required, so that the using and maintaining costs are reduced.

Owner:青岛光峰自动化科技有限公司

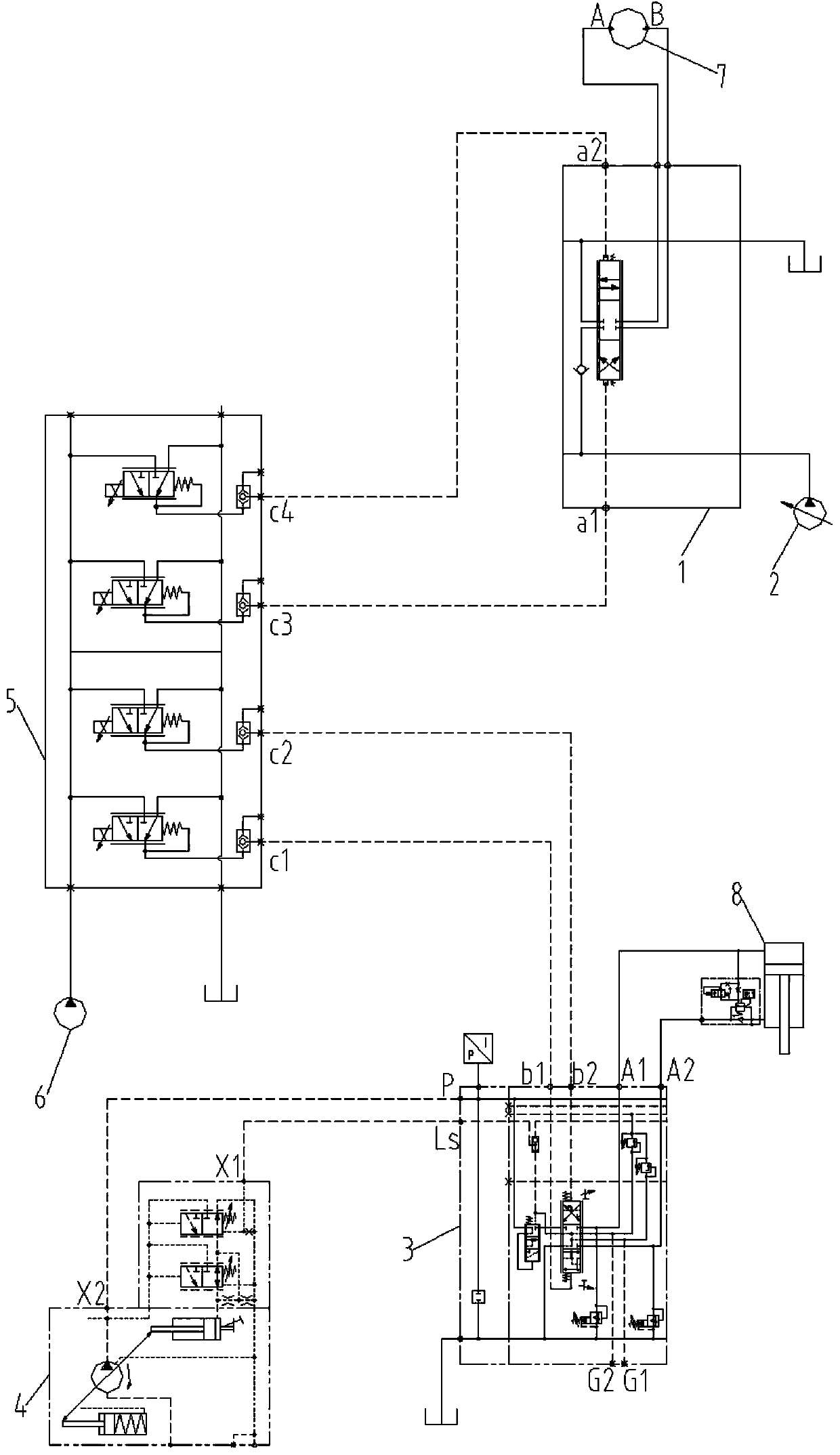

Drill-holding-prevention electric control system for power head and control method thereof and rotary drilling rig

ActiveCN110984956APrevent drilling phenomenonReduce output pressureConstructionsRotary drillingElectric controlControl valves

The invention discloses a drill-holding-prevention electric control system for a power head. The system comprises a main valve, a main pump, an auxiliary valve, an auxiliary pump and a pilot valve connected with a pilot pump, wherein the main pump is connected with a power head motor through the main valve; the auxiliary pump is connected with a pressurizing oil cylinder through the auxiliary valve; and the main valve and the auxiliary valve are further connected with the pilot valve so that reversing of the main valve and the auxiliary valve can be controlled through the pilot valve. The system further comprises a controller and a flow control valve electrically connected with the controller; the power head motor is provided with a rotating speed detection device which is electrically connected with the controller and used for detecting the rotating speed of a power head; one end of the flow control valve is connected with an auxiliary valve feedback oil port through a reversing valvein the auxiliary valve, and the other end of the flow control valve is connected with an oil tank; and the controller can control the opening degree of a valve port of the flow control valve according to feedback information of the rotating speed detection device so that the pressurizing force of the pressurizing oil cylinder can be reduced. The invention further discloses a control method of thedrill-holding-prevention electric control system and a rotary drilling rig. With the adoption of the method, drill holding can be prevented.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO

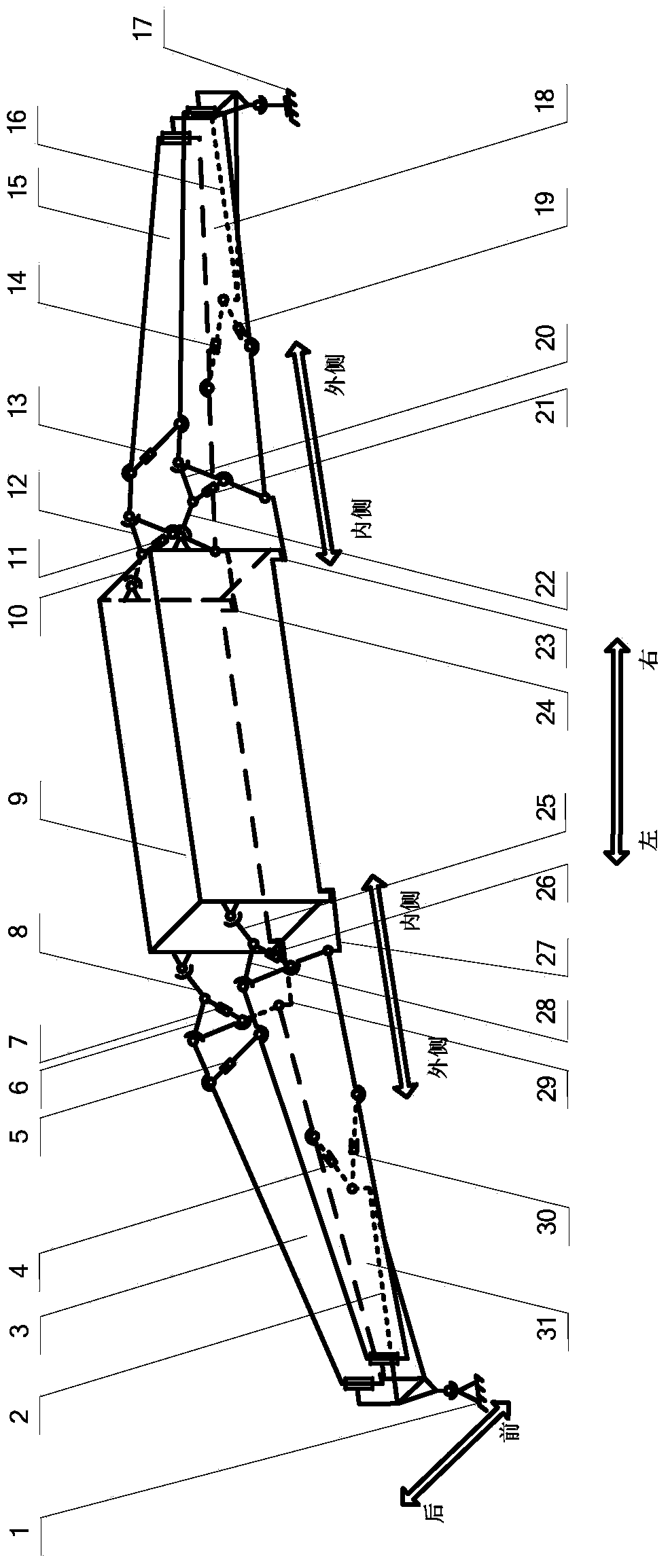

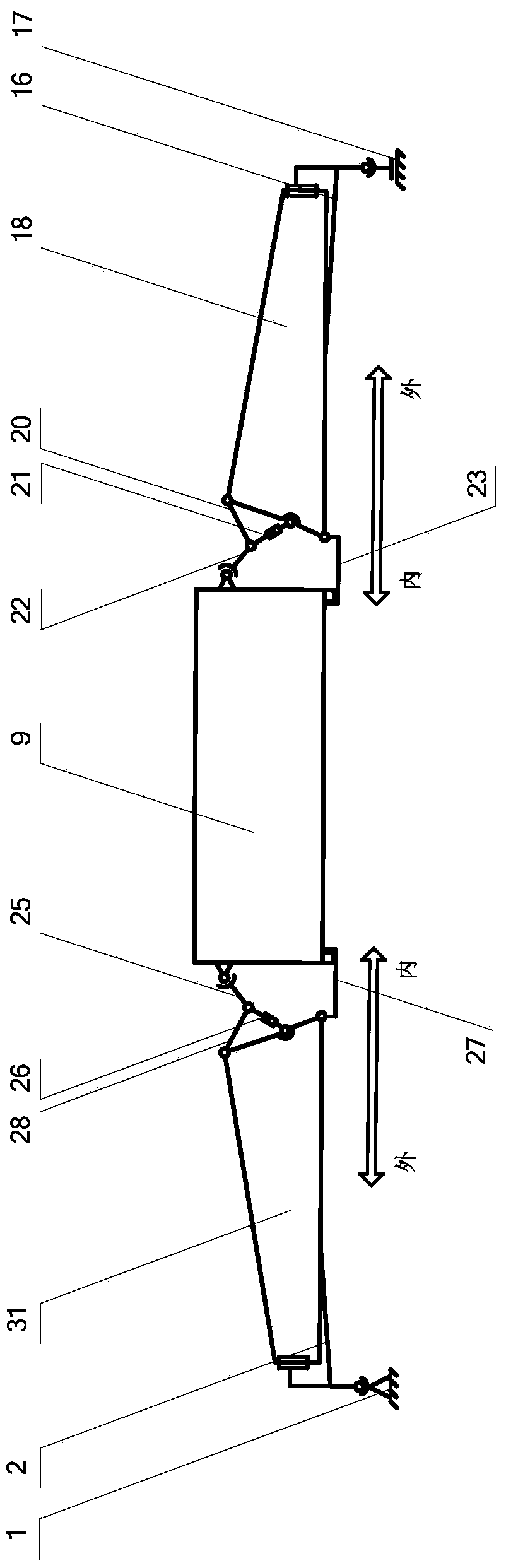

Lifting mechanism of schnabel car

InactiveCN104192155AGuaranteed boostGuarantee the stability of transportationWagons/vansCargo supporting/securing componentsEngineeringPiston rod

A lifting mechanism of a schnabel car is mainly characterized in that central disks of the outer ends of two half schnabel car lifting mechanisms are connected with the outer ends of guide beams through ball pairs, the outer end of each guide beam is hinged to the outer end of a front schnabel beam and the outer end of a rear schnabel beam, the upper portions of the inner ends of each front schnabel beam and the corresponding rear schnabel beam which are identical and connected in parallel are hinged to one end of a front outer connecting rod and one end of a rear outer connecting rod, the other end of the front outer connecting rod and the other end of the rear outer connecting rod are hinged to one end of a front inner connecting rod and one end of a rear inner connecting rod, the other end of the front inner connecting rod and the other end of the rear inner connecting rod are connected with the upper portions of goods, and a rotating pair of the front inner connecting rod, a rotating pair of the rear inner connecting rod, a rotating pair of the front outer connecting rod and a rotating pair of the rear outer connecting rod are respectively connected with a piston rod of a lifting oil cylinder, a cylinder body of each lifting oil cylinder is connected with the middle of the inner end of the corresponding schnabel beam, the lower portions of the inner ends of the two corresponding schnabel beams are hinged to one end of a front car lug and one end of a rear car lug, the other end of each front car lug and the other end of the corresponding rear car lug are connected with the lower ends of the goods, and a width regulating mechanism is installed between each front schnabel beam and the corresponding rear schnabel beam. According to the lifting mechanism of the schnabel car, small lifting force is exerted by the lifting oil cylinders so that the goods with the same weight can be lifted, and the lifting mechanism of the schnabel car has the advantage of saving labor.

Owner:YANSHAN UNIV

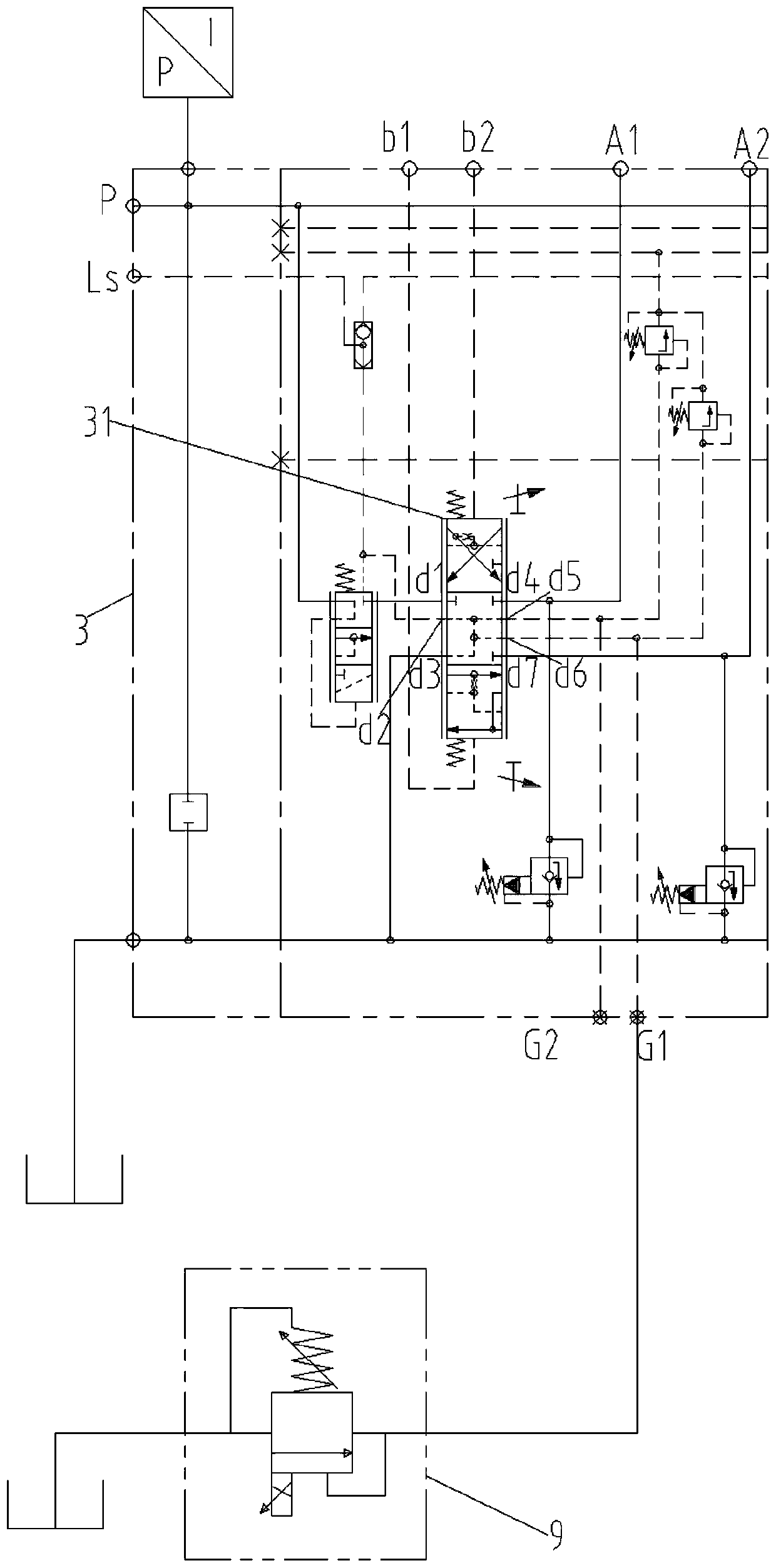

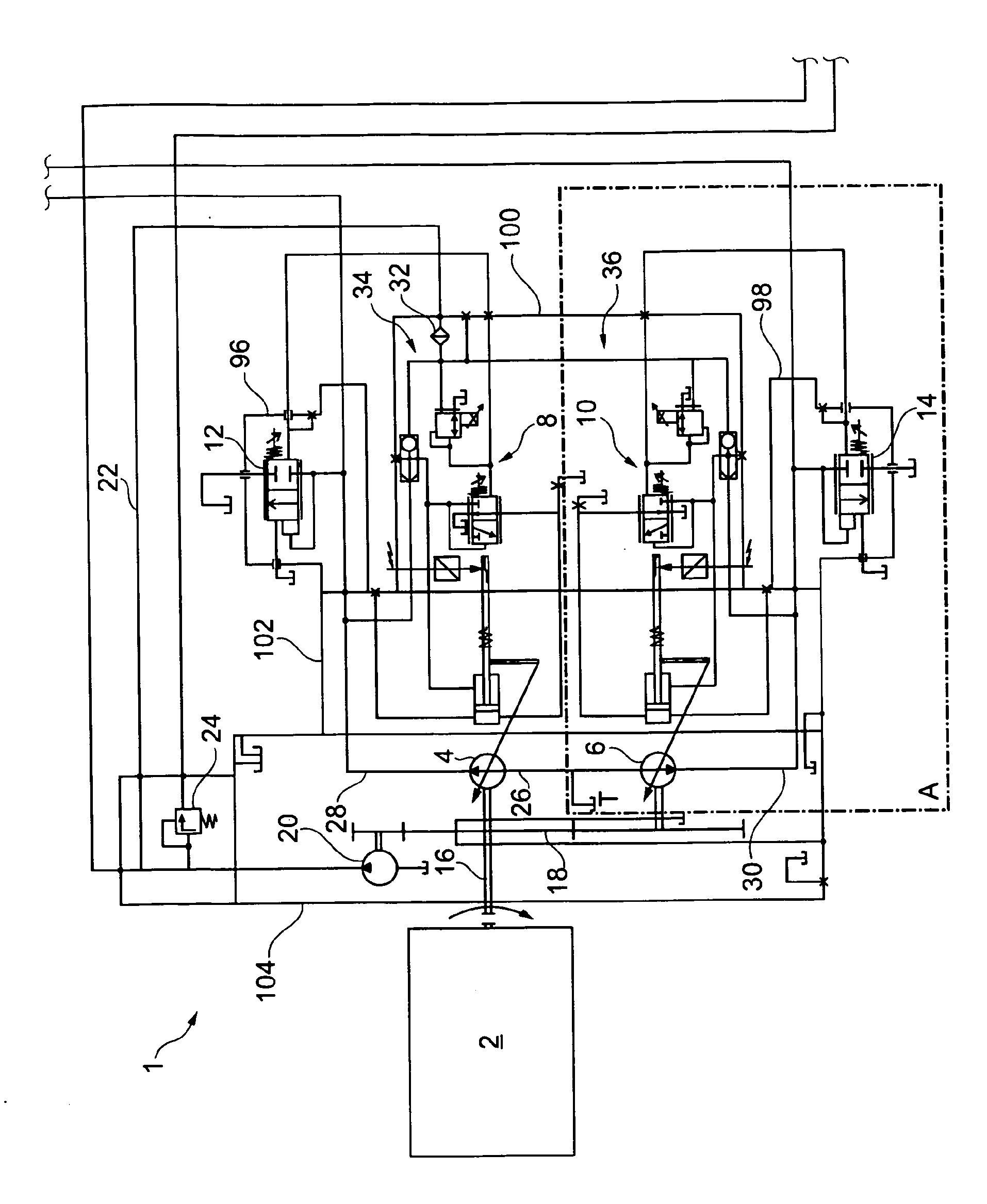

Hydraulic assembly comprising a variable displacement pump and a relief valve

InactiveCN102713313AReduce output pressureAvoid pressure spikesServomotorsServometer circuitsEngineeringPressure difference

The invention relates to a hydraulic assembly comprising at least one variable displacement pump (4, 6), which is set by a pump controller (8, 10) depending on a target pressure. The at least one variable displacement pump is used to supply at least one load with a pressure medium quantity. Furthermore, a comparison valve (12, 14) is provided, by means of which the outlet pressure is reduced to the target pressure starting at a certain pressure difference, which is to say, when the outlet pressure exceeds the target pressure by a predetermined value, the outlet pressure is lowered directly or indirectly by means of the comparison valve.

Owner:ROBERT BOSCH GMBH

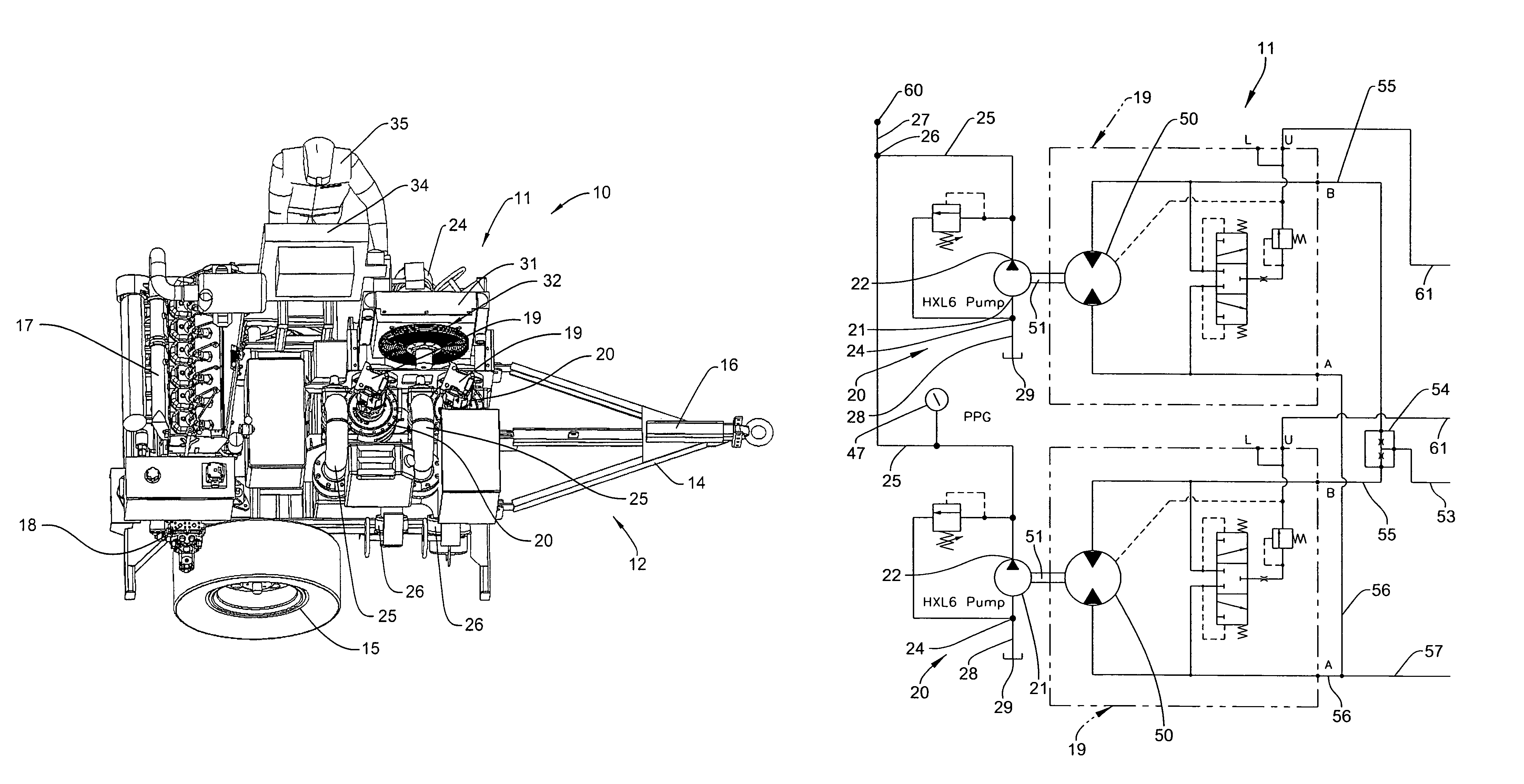

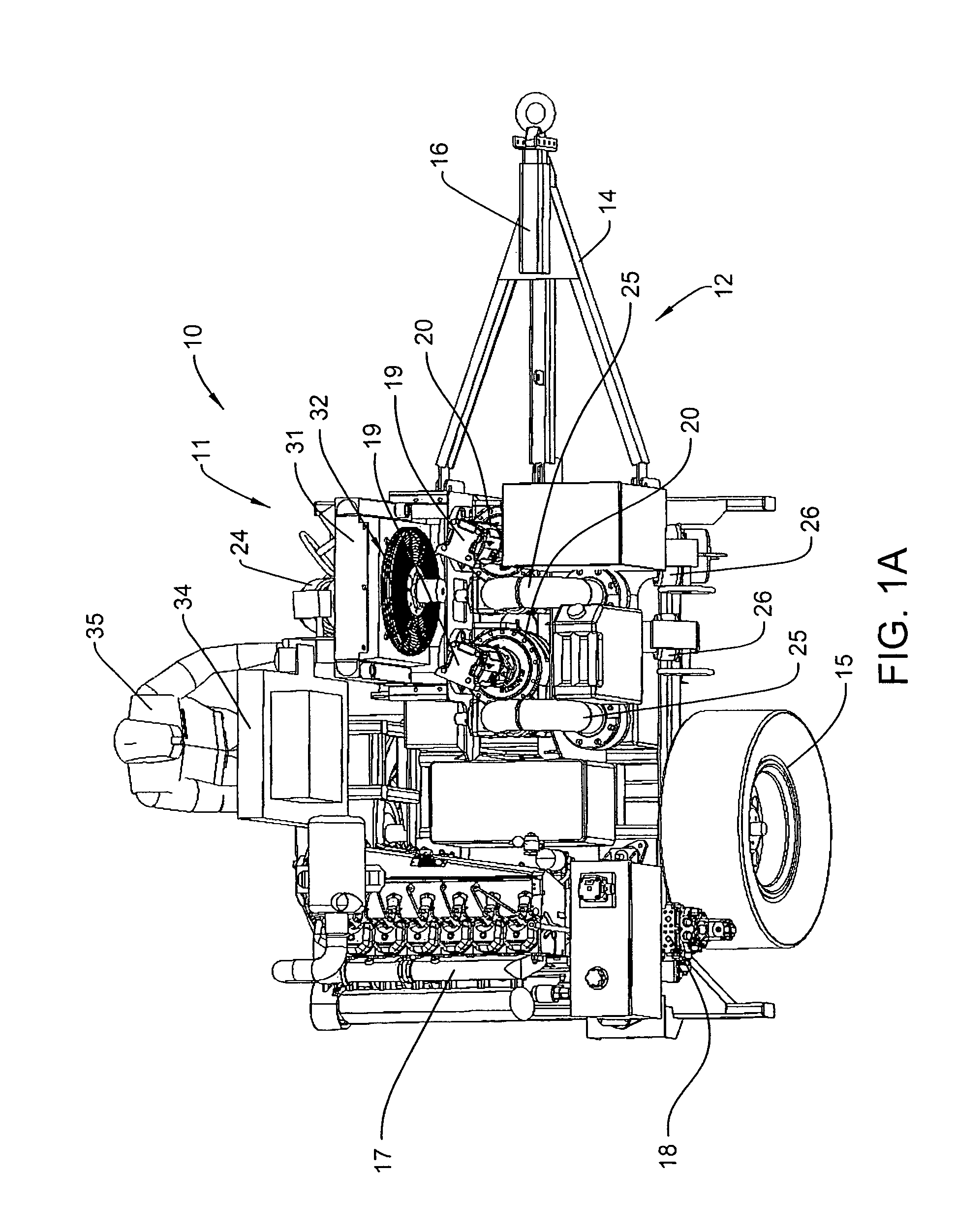

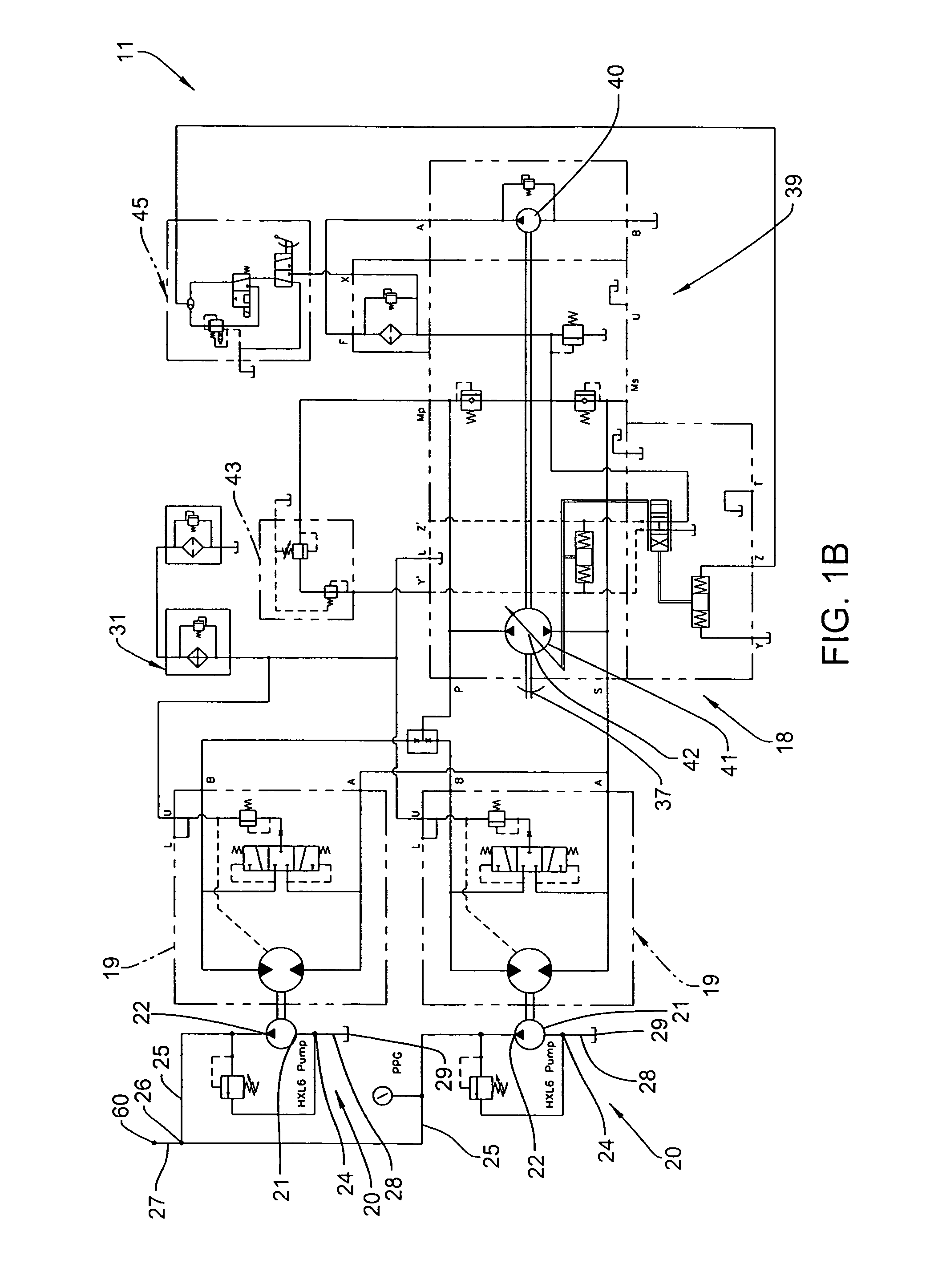

Hydraulic drive and control system for pumps using a charge pump

ActiveUS8341955B2Complex maintenanceQuick changeFluid parameterFluid couplingsControl systemHydraulic fluid

A pumping system is provided which is a mobile, vehicle-mounted pumping system, such as for water or fuels, which mounts on a vehicle and may be used for various applications. The pumping system operates a drive system and control system for liquid pumps almost exclusively by hydraulic fluid pressure.

Owner:BRANTLEY DANIEL R +3

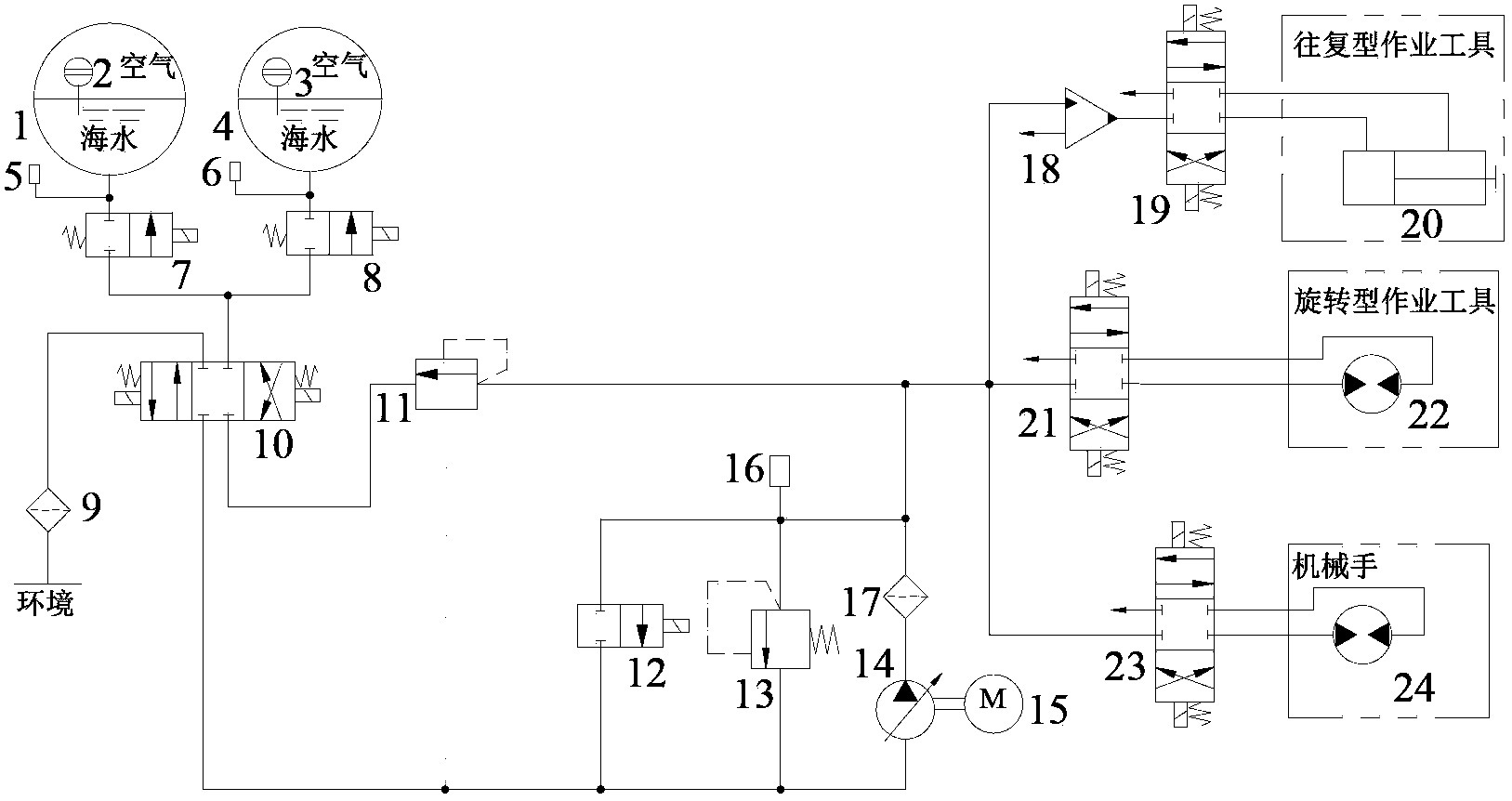

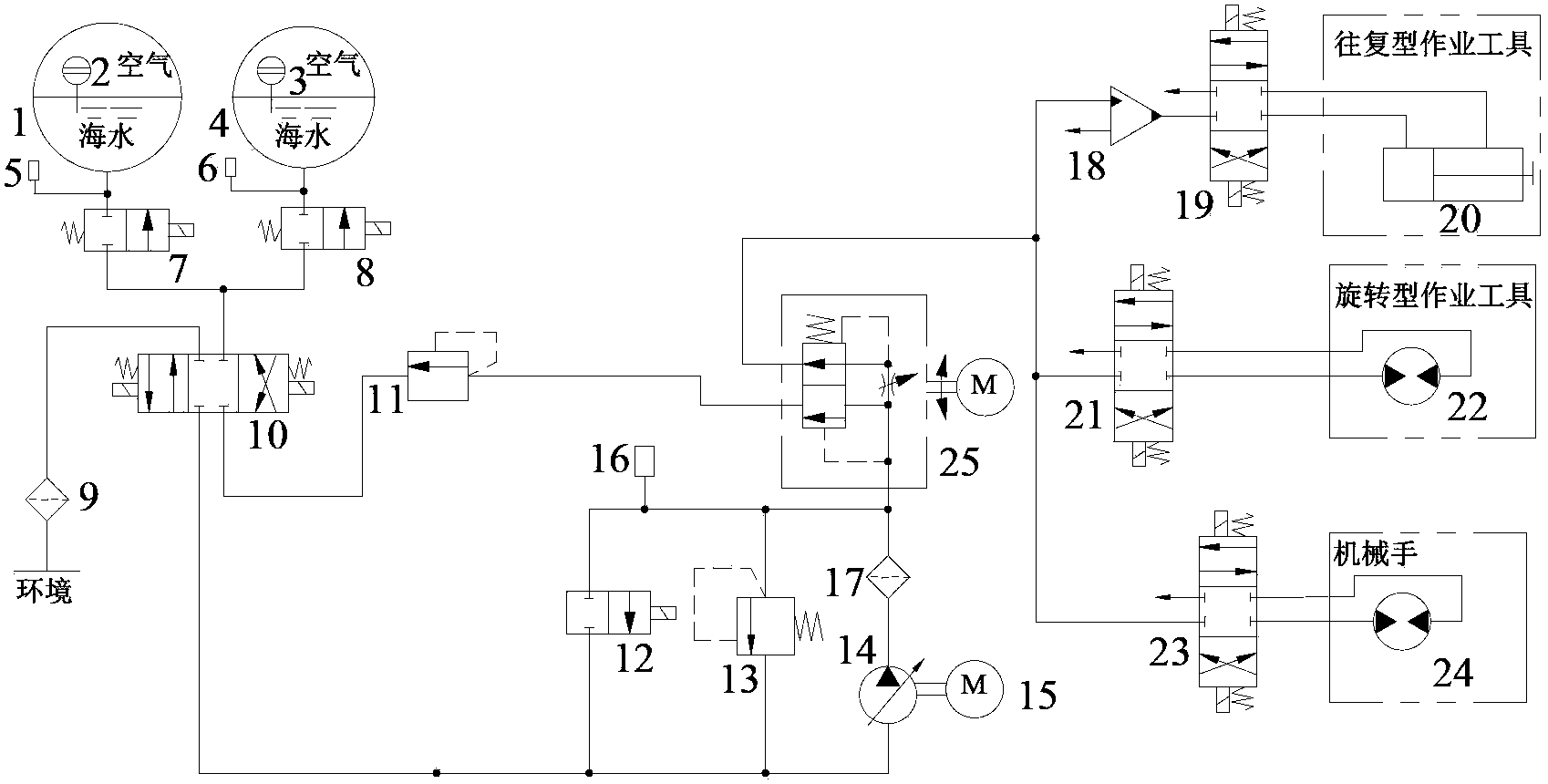

Water hydraulic system of multifunctional submersible

ActiveCN102774483BImprove reliabilityAchieve reductionUnderwater vesselsUnderwater equipmentWater sourceHydraulic pump

The invention provides a water hydraulic system of a multifunctional submersible. The water hydraulic system comprises a power source, a flotage and posture regulating mechanism and an operating mechanism, wherein the power source mainly comprises a motor, a hydraulic pump and a solenoid directional valve; the flotage and posture regulating mechanism mainly comprises a plurality of water ballast tanks and balanced valves; through injecting water into and draining off water from different tanks, not only the flotage regulation on the submersible is realized, but also trim control and heel control are realized, so that the single independent systems for flotage regulation and trim and heel control are integrated into a unified system; and in addition, under the matching of all the valves, the operating mechanism can be driven to finish underwater operation. The water hydraulic system can provide water sources of different flow and pressure so as to meet the requirements of different types of working tools on the power source; and meanwhile, the water hydraulic system enables flotage regulation and trim and heel control to have different performances in different water depths, namely the water hydraulic system can meet deep-depth applicability and shallow-depth fast response.

Owner:HUAZHONG UNIV OF SCI & TECH

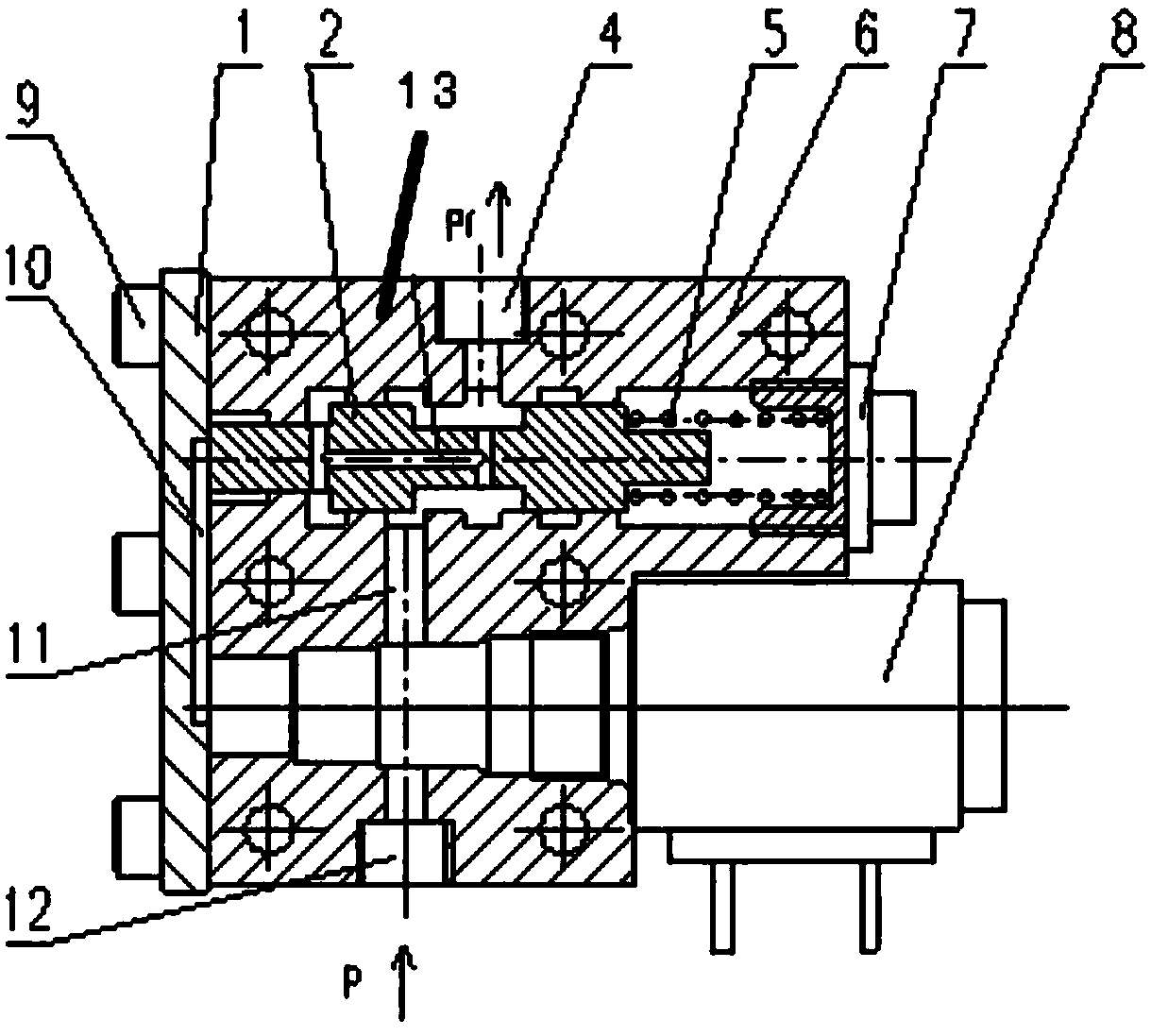

Inversely-proportional pressure relief valve for vehicle integrated transmission box

ActiveCN109488649ARealize functionHigh output pressureOperating means/releasing devices for valvesServomotor componentsElectro hydraulicEngineering

The invention provides an inversely-proportional pressure relief valve for a vehicle integrated transmission box. The inversely-proportional pressure relief valve comprises a valve body, a hydraulic pressure relief valve and an electro-hydraulic proportional pressure relief valve; the hydraulic pressure relief valve is connected with the electro-hydraulic proportional pressure relief valve and arranged in the valve body; the hydraulic pressure relief valve comprises an inversely-proportional valve element and a spring which are connected mutually, the valve body is connected with a fan clutch,the spring is used for enabling the output oil pressure of the hydraulic pressure relief valve and the pilot control oil pressure of the electro-hydraulic proportional pressure relief valve to be ininverse proportion under the effect of the spring. According to the inversely-proportional pressure relief valve, the function of the electro-hydraulic proportional pressure relief valve is achieved,namely, the output pressure and a control current are in inverse proportion, the inversely-proportional pressure relief valve has the characteristic of inverse proportion, the output pressure of the proportional valve is maximum under the deenergized situation, and the output pressure of the proportional valve is minimum when the control current is maximum.

Owner:CHINA NORTH VEHICLE RES INST

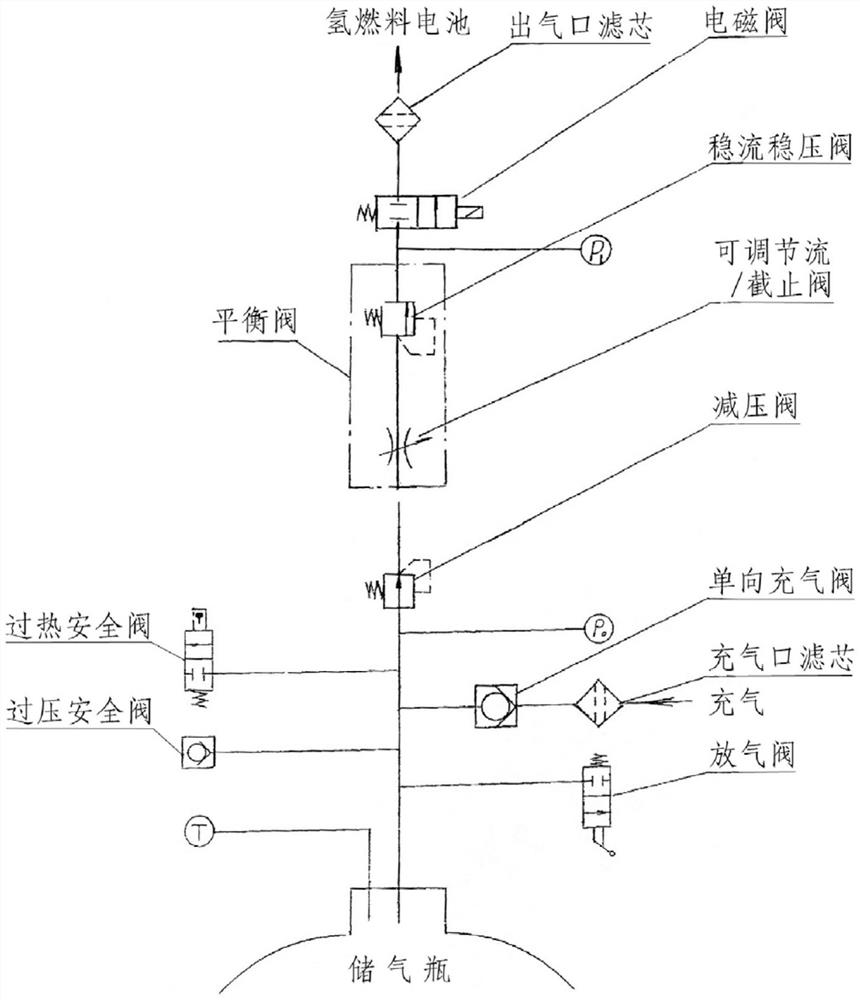

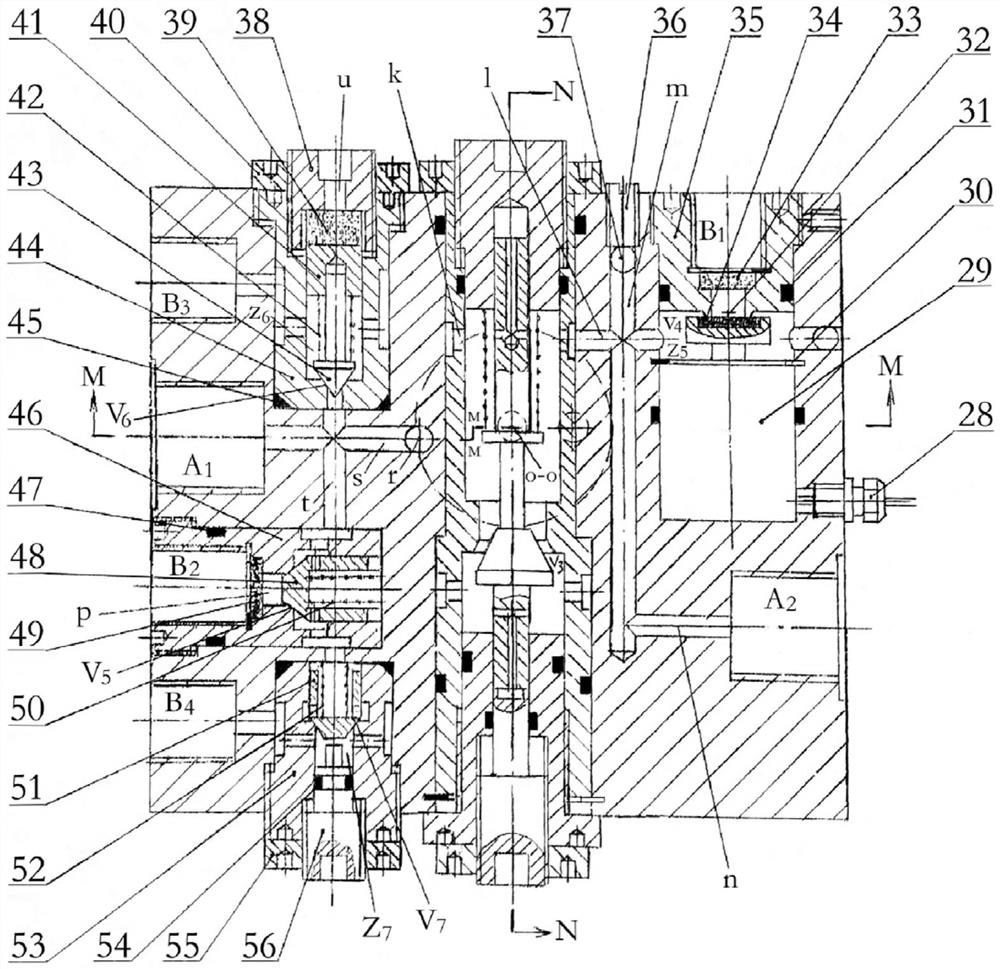

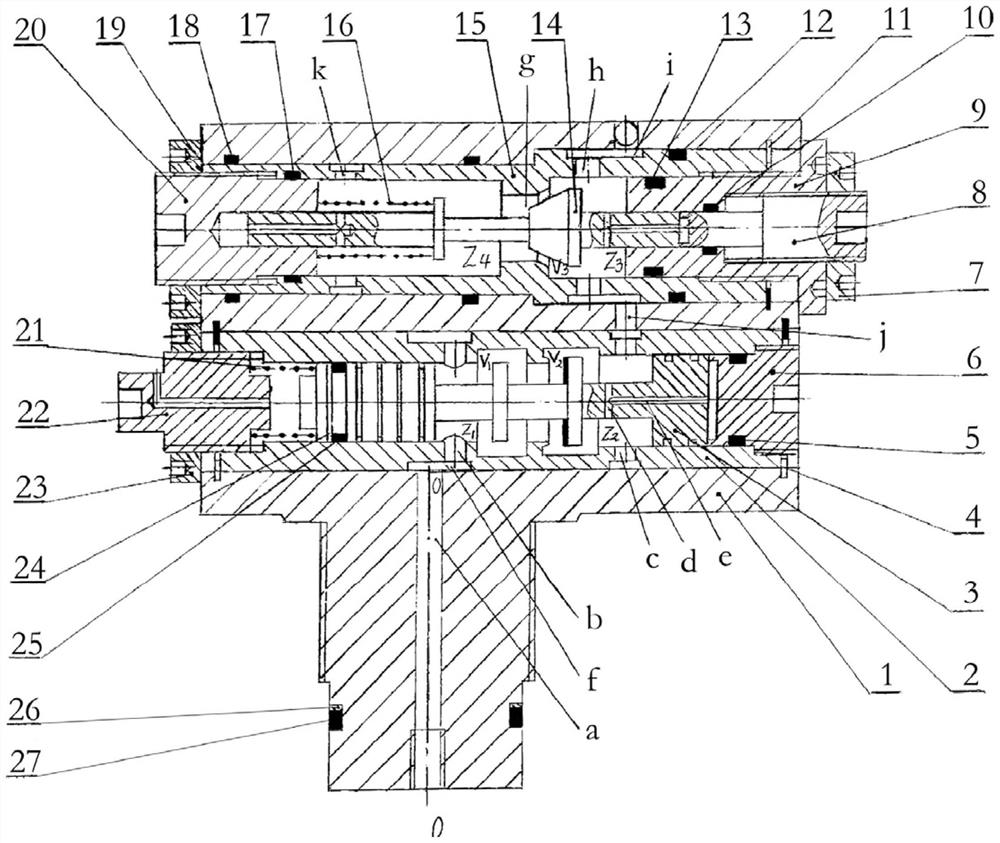

Ultrahigh pressure cylinder valve of hydrogen energy vehicle

PendingCN113108241ASolve the problem of the bottle valveRequirements fitVessel mounting detailsContainer filling methodsUltra high pressureEngineering

The invention discloses an ultrahigh pressure cylinder valve of a hydrogen energy vehicle. The ultrahigh pressure cylinder valve of the hydrogen energy vehicle comprises a valve body, and a double-valve-port pressure reducing valve, a balance valve composed of a throttling valve and a flow and pressure stabilizing valve, an electromagnetic valve, a one-way inflation valve, an overpressure safety valve, an overheat safety valve, a deflation valve, an inflation port filter element, an air outlet filter element, a temperature sensor, an in-cylinder air pressure and output pressure sensor interface and the like are arranged in the valve body. All the parts are arranged in the valve body according to design requirements and communicate through corresponding channels in the valve body, and the characteristics of being high in integration degree, safety and monitoring performance are achieved; the output pressure can be adjusted according to the requirements of a fuel cell, the fluctuation of the output pressure and the flow is greatly reduced, and the requirements of the fuel cell are met; when a hydrogen storage bottle is overpressure and overtemperature, the corresponding safety valve acts to release high-pressure hydrogen in the bottle to relieve pressure, so that overpressure explosion is avoided; and the air pressure, the air temperature and the output pressure in the bottle can be monitored at any time.

Owner:HANGZHOU CHUNJIANG VALVE

Lubrication system and method configured for supplying pressurized oil to an engine

ActiveUS20120042846A1Increase volumeMaximize displacementLubrication of auxillariesLubricant conduit arrangementsRotary pumpSolenoid valve

A lubrication system includes a rotary pump, an eductor, and a solenoid valve and is configured to provide pressurized oil to an engine. The rotary pump is configured to generate oil flow. A supplemental supply line selectively provides pressurized oil into the eductor. The solenoid valve is movable between a first position and a second position. The solenoid valve supplies a fluid signal that allows pressurized oil to flow from the supplemental supply line and into the eductor when the solenoid valve is in the first position to increase the volume of oil flowing from a sump of the engine into the rotary pump. When the solenoid valve does not supply a fluid signal, pressurized oil is prevented from entering the eductor and the volume of oil flowing from the sump and through the eductor to the rotary pump is not increased.

Owner:GM GLOBAL TECH OPERATIONS LLC

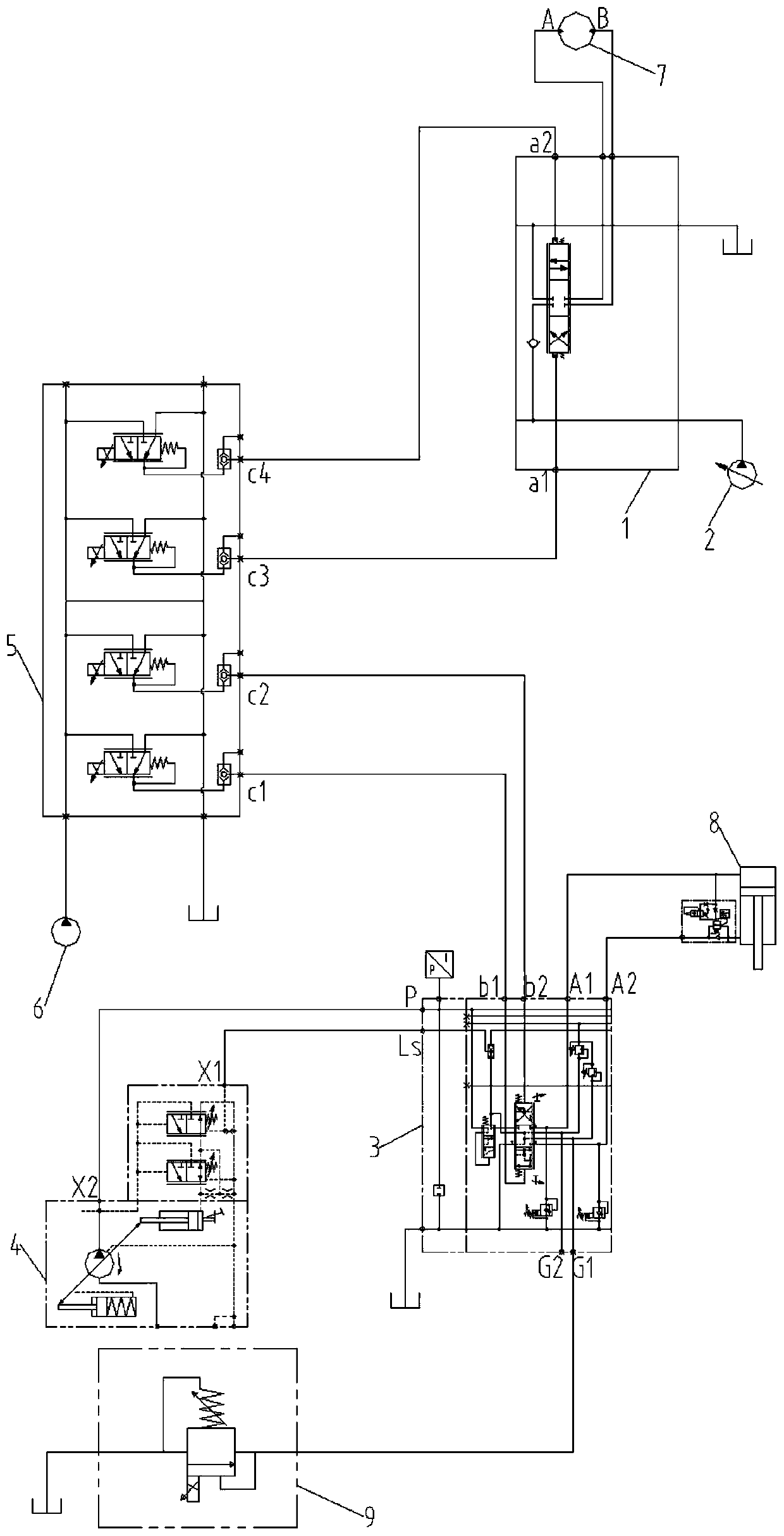

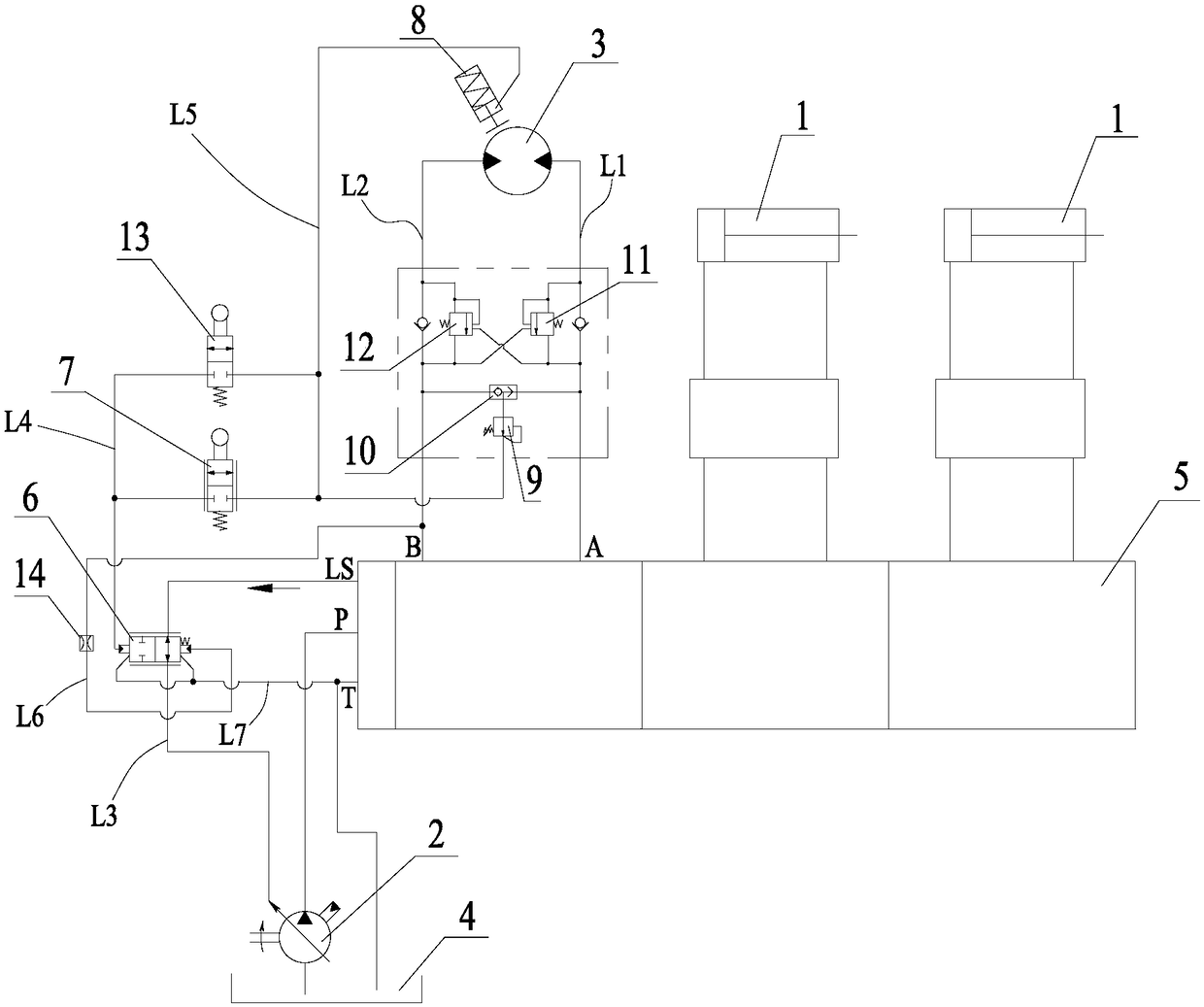

Winch telescopic hydraulic control system and engineering machinery

ActiveCN109132891AReduce extension speedReduce output pressureServomotorsLoad-engaging elementsHydraulic controlControl system

The invention relates to the field of boom extension and retraction control systems and discloses a winch telescopic hydraulic control system and engineering machinery. A main oil pump (2) of the winch telescopic hydraulic control system can be controlled to selectively pump pressure oil to a motor (3) through a first working oil circuit (L1) or a second working oil circuit (L2) to drive a boom toextend or retract; a feedback control oil circuit (L3) is connected with the main oil pump; a proportional on-off valve (6) provided with a first liquid control chamber is arranged on the feedback control oil circuit (L3); a stroke control oil circuit (L4) is connected with the first liquid control chamber; a proportional stroke valve (7) is arranged on the stroke control oil circuit (L4); when the boom extends to a predetermined extension position, the opening of an oil opening of the proportional stroke valve (7) is increased along with the increase in the extension length of the boom, andthe first liquid control chamber is communicated with the first working oil circuit (L1) to control the gradual change of the proportional on-off valve (6) from an on state to an off state. Therefore,the safety during the boom extension is improved.

Owner:CHANGSHA ZOOMLION FIRE FIGHTING VEHICLE

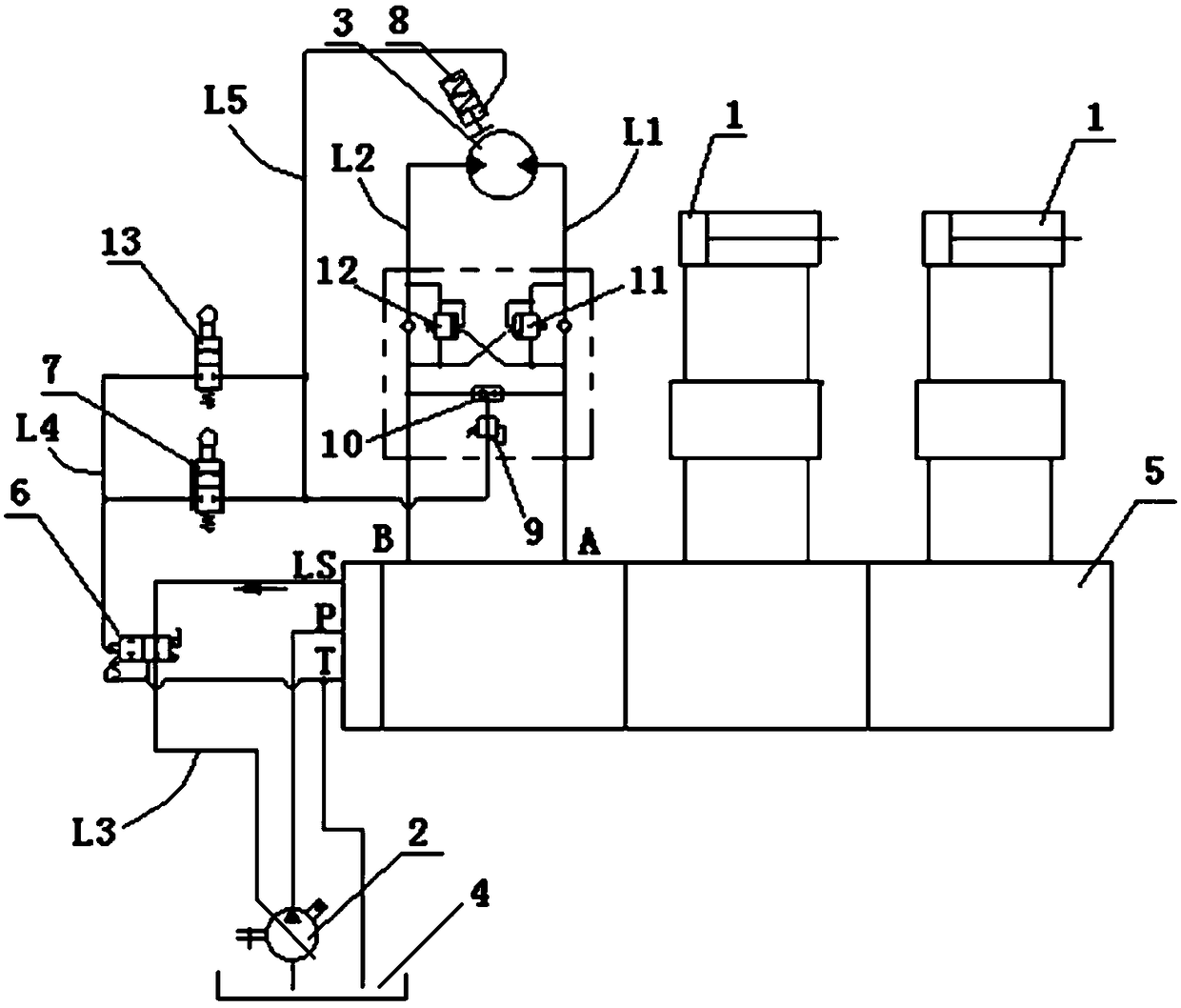

Winch telescopic hydraulic control system and engineering machinery

ActiveCN109160427AReduce extension speedReduce output pressureServomotor componentsServomotorsControl systemControl valves

The invention relates to the field of cantilever crane telescopic control systems, and discloses a winch telescopic hydraulic control system and engineering machinery. A main oil pump (2) of the winchtelescopic hydraulic control system is selectively communicated with a first working oil path (L1) or a second working oil path (L2) through an operating valve (5) to control a cantilever crane to stretch or retract, the main oil pump (2) is connected to a feedback control oil path (L3), an on-off control valve (6) linked to the retracting operation of the operating valve in a communicating stateis arranged on the feedback control oil path, the on-off control valve has a hydraulically controlled cavity, the hydraulically controlled cavity is connected to a stroke control oil path (L4), a stroke valve is arranged on the stroke control oil path, and the stroke valve can be triggered by the cantilever crane to connect the stroke control oil path (L4) when the cantilever crane stretches outto a preset stretching position in the stretching process of the cantilever crane and the hydraulically controlled cavity communicates to the first working oil path (L1), so that the on-off control valve (6) is switched to a cut-off state, and therefore, the safety of the cantilever crane stretching out is improved.

Owner:CHANGSHA ZOOMLION FIRE FIGHTING VEHICLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com