Hydraulic pressurizer

A hydraulic pressurizer and hydraulic technology, applied in drilling equipment, wellbore/well components, earthwork drilling and production, etc., can solve problems such as blind operation, large well wall friction, difficulty in guaranteeing drilling pressure, etc., and achieve increased Difficulty of operation, avoiding blind operation, and reducing the effect of circulating pump pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

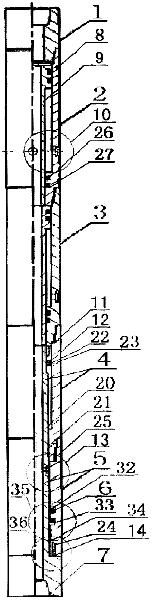

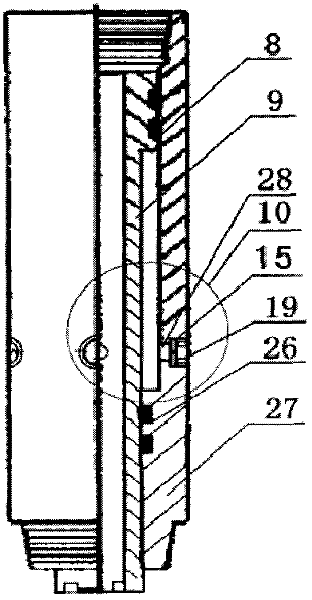

[0029] refer to figure 1 Shown, further illustrate the structure of the present invention. The present invention is composed of an upper joint 1 that can be connected with a drilling tool, two groups of hydraulic pressurization devices 2 and 3, a torque transmission device 4 and a weight-on-bit tracking warning device 5 . The upper end of the hydraulic pressure device 2 is connected to the upper joint 1 through a drill pipe thread, and the lower end is connected to the upper end of the hydraulic pressure device 3 through a drill pipe thread, forming a series connection of two hydraulic pressure devices 2 and 3; The lower end of the hydraulic pressure device 3 is connected with the upper end of the inner square sleeve 21 of the torque transmission device 4 through a drill pipe thread. Torque transmission device 4 is made up of collar 59, retaining ring 11, pressure balance mechanism 12, outer square shaft 20, inner square sleeve 21, sealing ring 22 and 23; The buckle is conne...

Embodiment 2

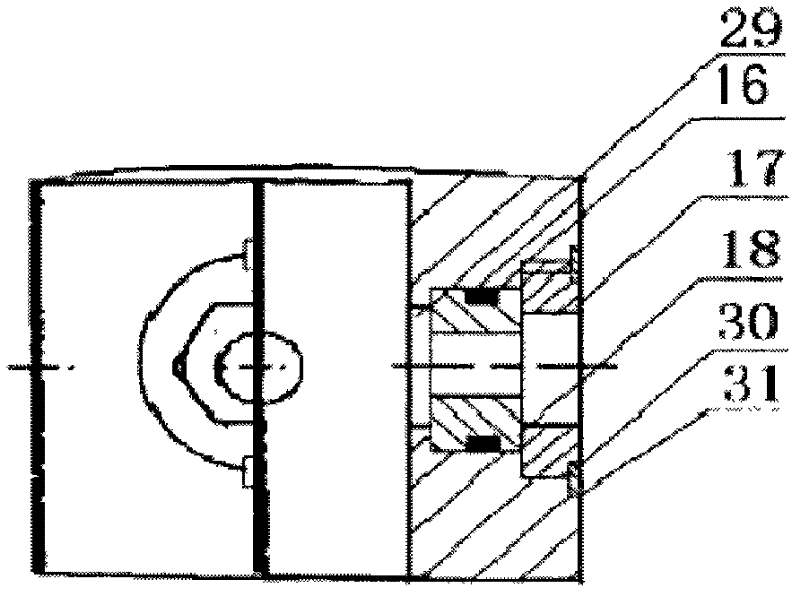

[0033] Embodiment 2 is based on Embodiment 1, further illustrating the structures of the torque transmission device 4 and the weight-on-bit tracker 5 of the present invention. see Figure 4 to Figure 11 As shown, the outer shaft 20 and the central shaft 7 of the torque transmission device 4 and the weight-on-bit tracker 5 in this example are integrated. The inner square sleeve 21 is connected with the sealing cylinder 25 through a drill pipe thread. The outer shaft 20 and the central shaft 7 are installed in the inner square sleeve 21 and the sealing cylinder 25 respectively, and the outer face 41 of the outer square shaft 20 forms a clearance fit with the inner face 46 of the inner square sleeve 21 . The balance mechanism 12 is installed in the annular space formed by the cylindrical surface 40 of the outer square shaft 20 and the inner hole surface 45 of the inner square sleeve 21. The sealing rings 22 and 23 are respectively installed in the sealing rings 56 and 57 of the ...

Embodiment 3

[0035] refer to Figure 1 to Figure 11 As shown, further illustrate the implementation steps of a hydraulic pressurizer:

[0036] In step 101, a hydraulic pressurizer is connected between the drill bit and the drill collar, or between two drill collars, and lowered into the well. At this time, a hydraulic pressurizer is in a stretched state, that is, the lower end surface 62 of the balance mechanism 12 is seated on the inner step 65 of the inner square sleeve 21, and the lower end surface 64 of the retaining ring 11 is seated on the upper end surface 63 of the balance mechanism 12 At the same time, the cemented carbide nozzle 18 of the signal device 13 is facing the steel-bonded alloy ring 24 of the 36 of the liquid discharge mechanism.

[0037] Step 102 When the mud is circulated, the piston 9 is pushed down to the starting point by the mud pressure, that is, close to the respirator 10 . Part of the mud flows out through the drill bit nozzle, and another part of the mud pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com