Solid material and liquid material combined dual-nozzle 3D printer and printing method thereof

A 3D printer and dual-nozzle technology, applied in the field of 3D printing, can solve the problems of scratching the model, affecting the printing quality, and scratching the printing model by the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

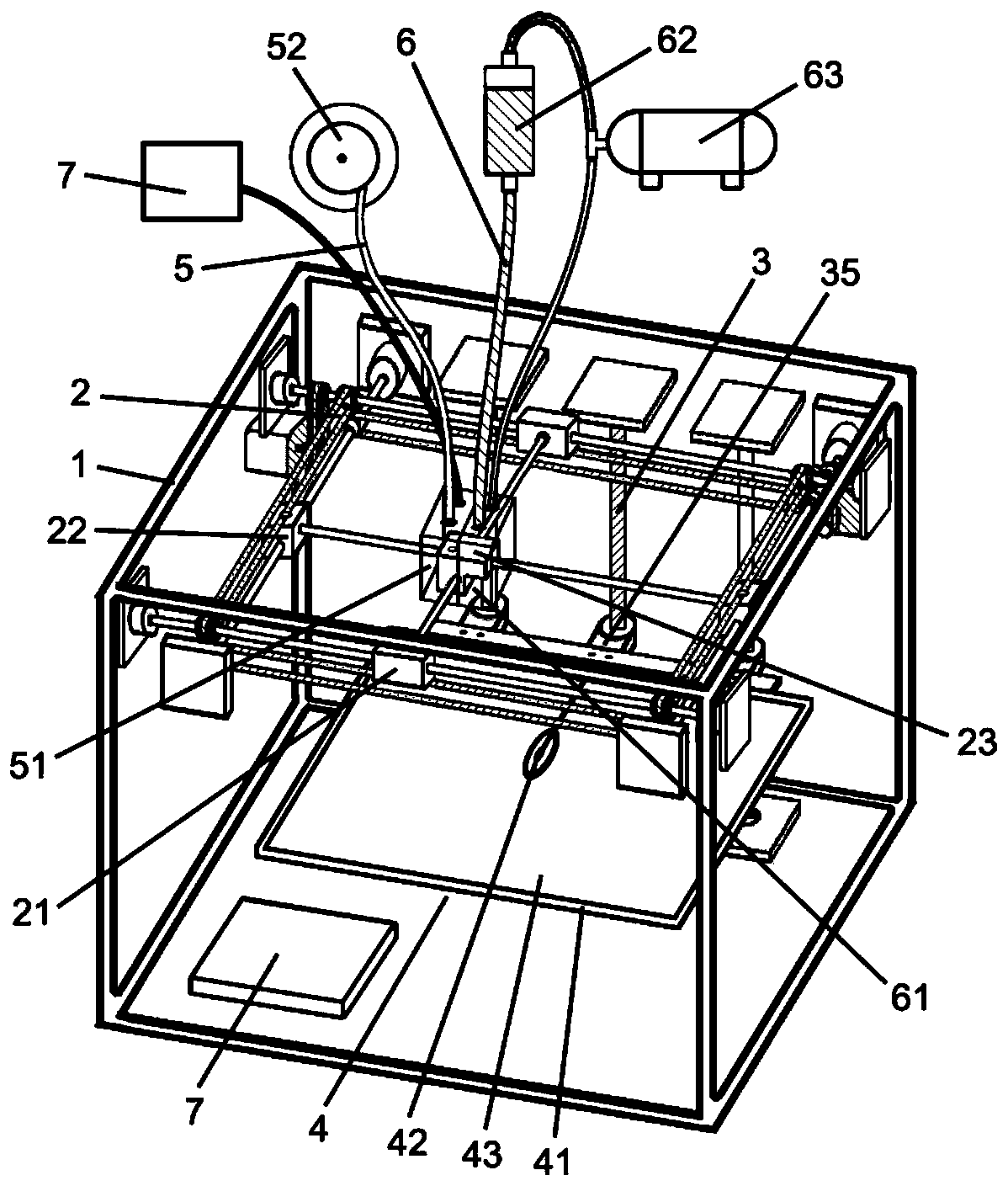

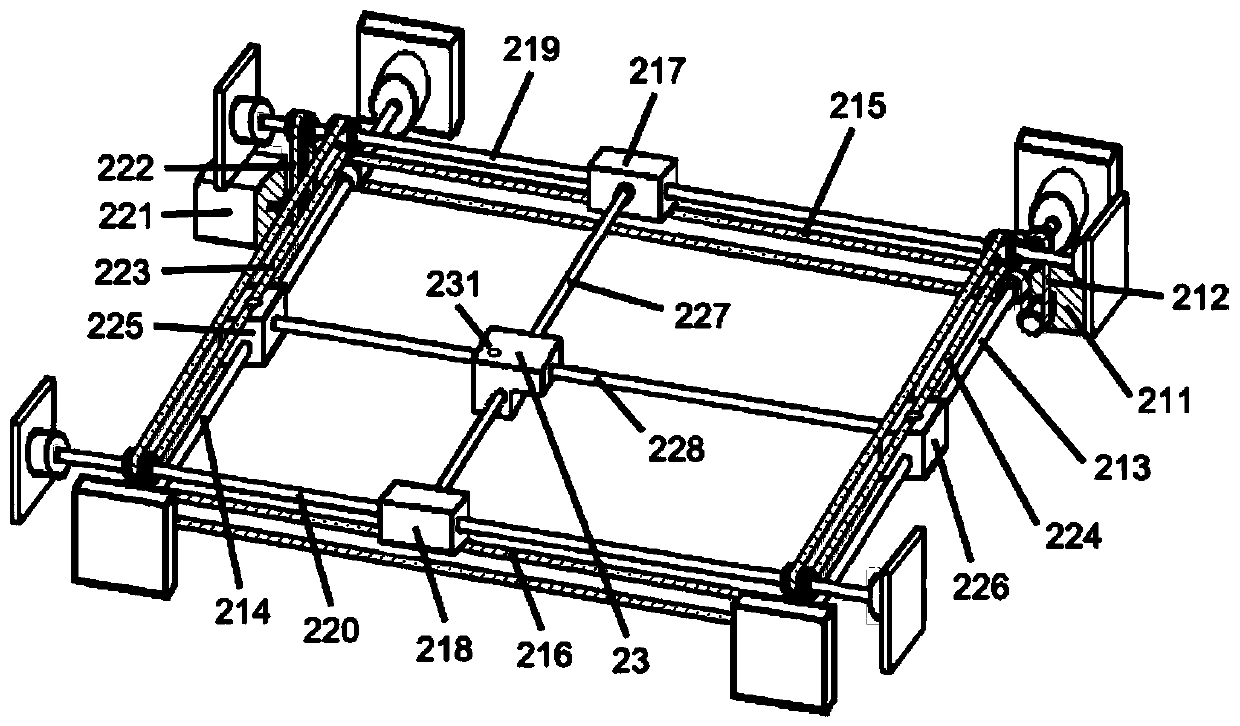

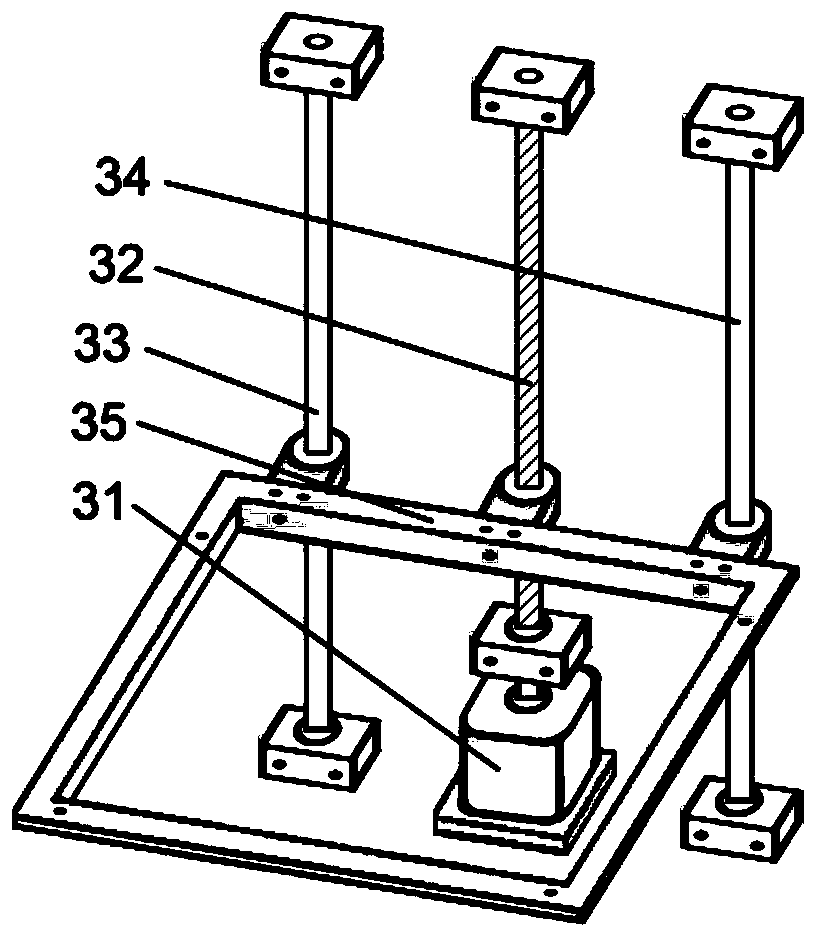

[0068] Such as Figure 1-4 As shown, a solid-liquid material combined dual-nozzle 3D printer includes a frame 1, an XY plane movement module 2, a Z-axis movement module 3, a loading plate 4, a solid material printing unit 5, a liquid material printing unit 6 and an overall The control module 7; the frame 1 is a square frame structure; the XY surface motion module 2 is installed horizontally on the upper part of the frame 1; the Z-axis motion module 3 is installed on the rear of the frame 1, and the loading plate 4 is installed on the Z-axis motion module 3 On the Z-axis lifting frame 35; the solid material printing unit 5 includes a solid printing head module 51, a wire feeding module 53 and a wire reel 52 equipped with solid wire, and the wire reel 52 is connected with the solid printing head module 51 through the wire feeding module 53; The liquid material printing unit 6 comprises a liquid print head module 61, a pressure cylinder 62 and an air source 63 filled with liquid ...

Embodiment 2

[0106] Different from Example 1, this example uses a thermosetting two-component epoxy resin (DEP) as a liquid material instead of a solid material. Therefore, on the basis of Embodiment 1, this embodiment makes the following changes:

[0107] Such as Figure 8B As shown, a solid-liquid material combined dual-nozzle 3D printer has two pressure cylinders 62, two peristaltic hoses 650, two three-way valve sets 646, and a mixing tube assembly 661 is added to the feeding module 66, Others are identical with embodiment 1;

[0108] Two components A and B of DEP are respectively installed in the pressure cylinder 62A and the pressure cylinder 62B, and communicate with the feed ports 659 of the two three-way valve sets; , and communicate with two three-way valve sets 646 respectively; the two peristaltic hoses 650 are made of the same material, have the same wall thickness, and have the same inner diameter or be adjusted accordingly according to the mixing ratio of the two component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com