Patents

Literature

33results about How to "Guaranteed boost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

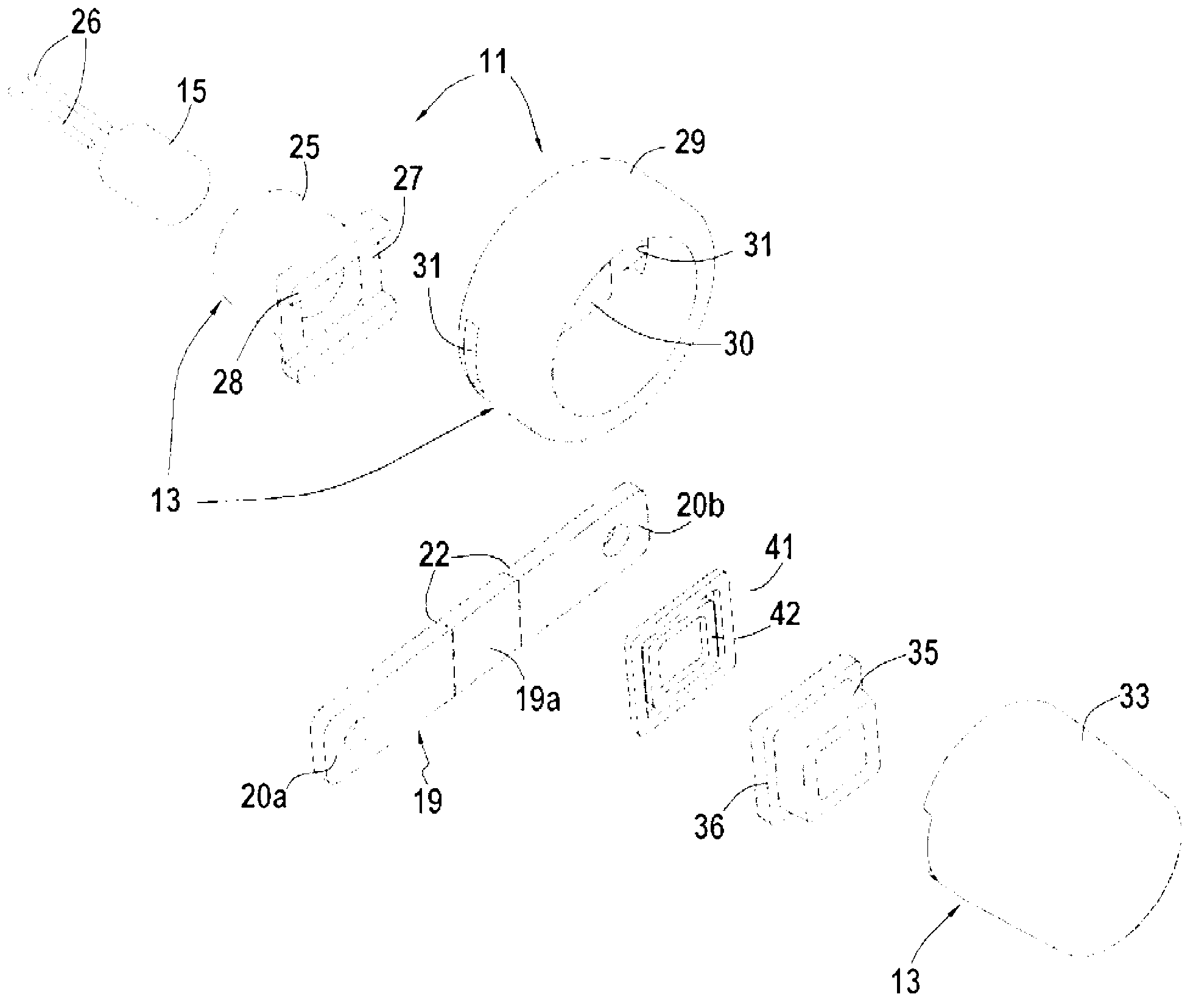

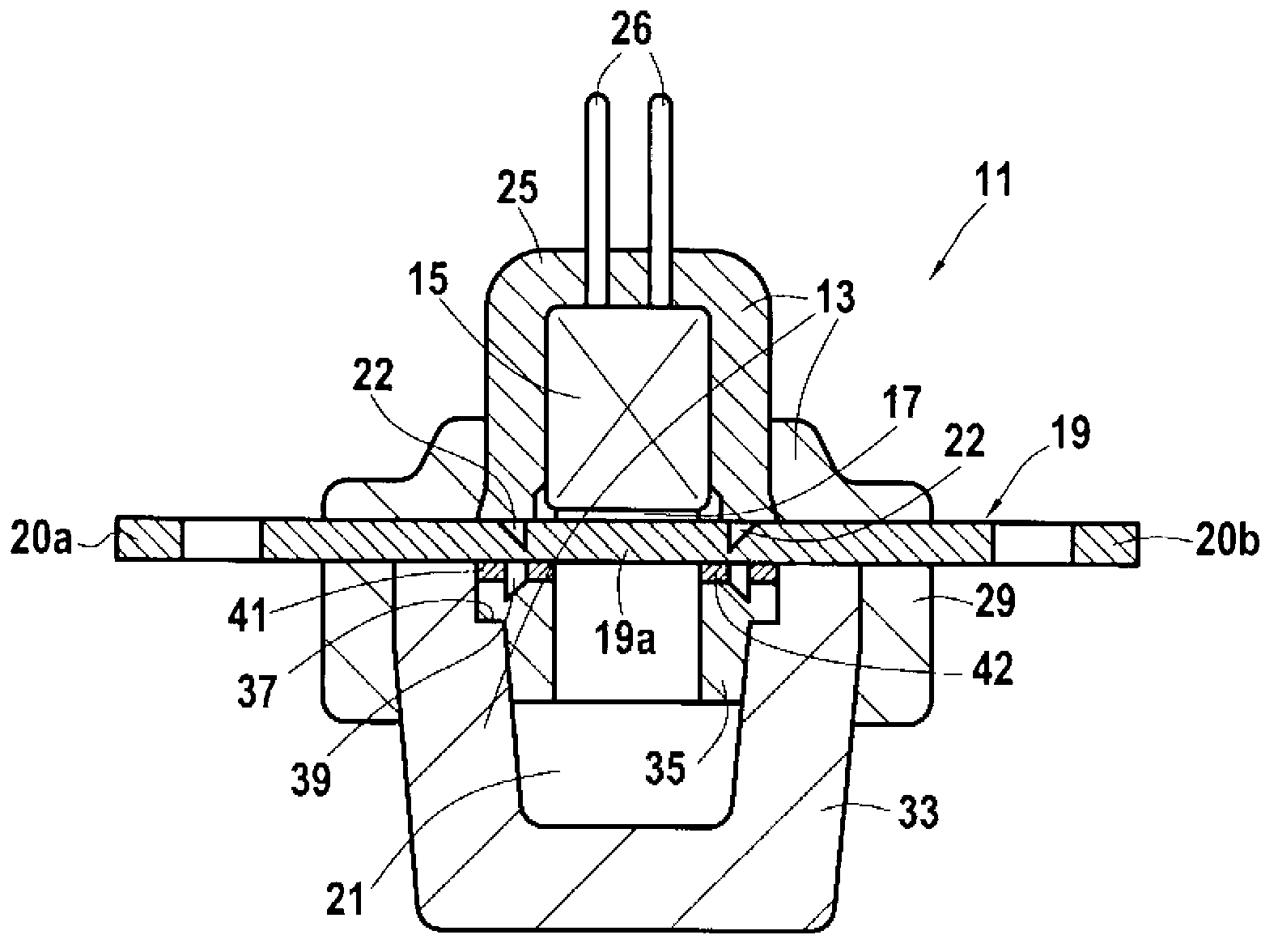

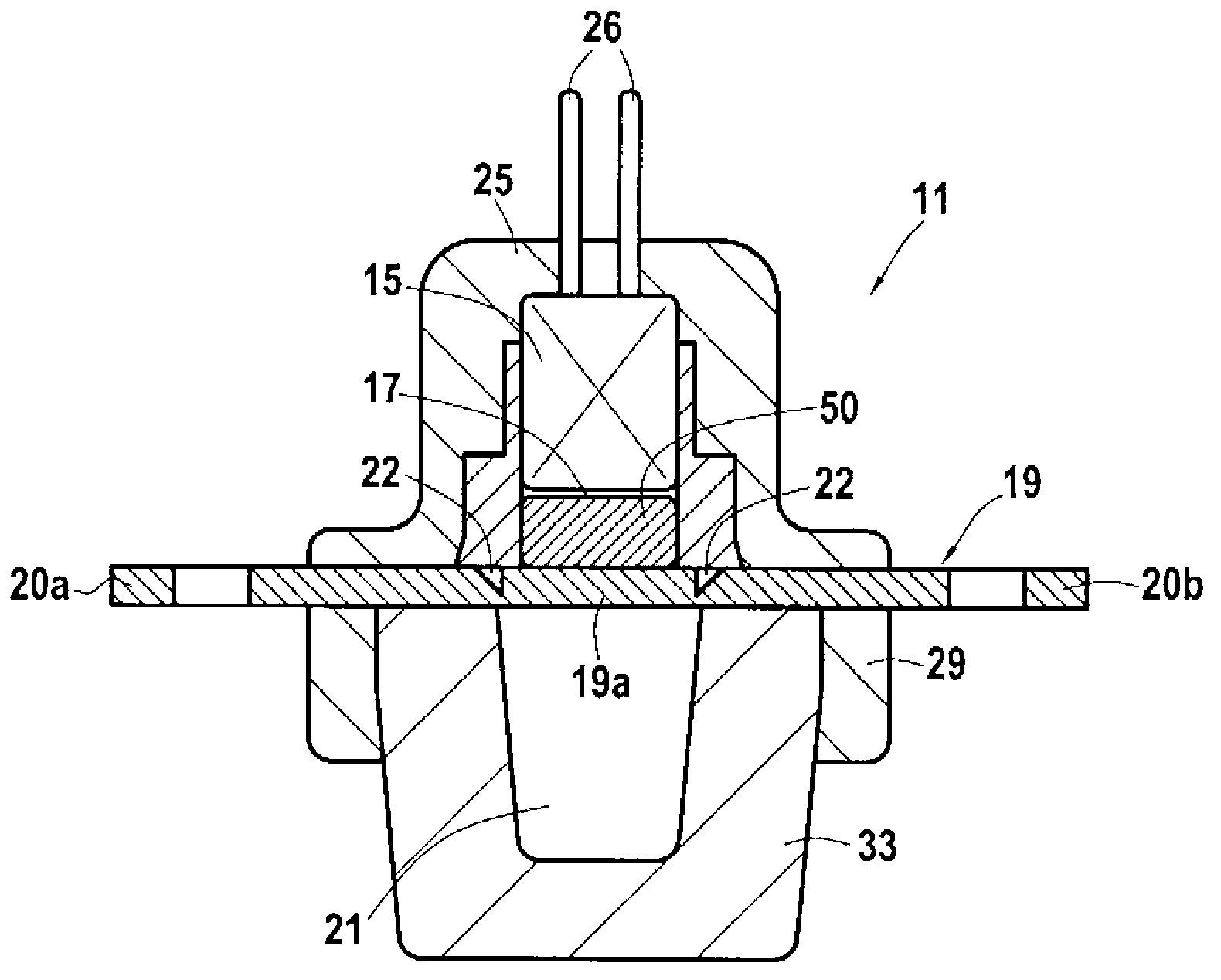

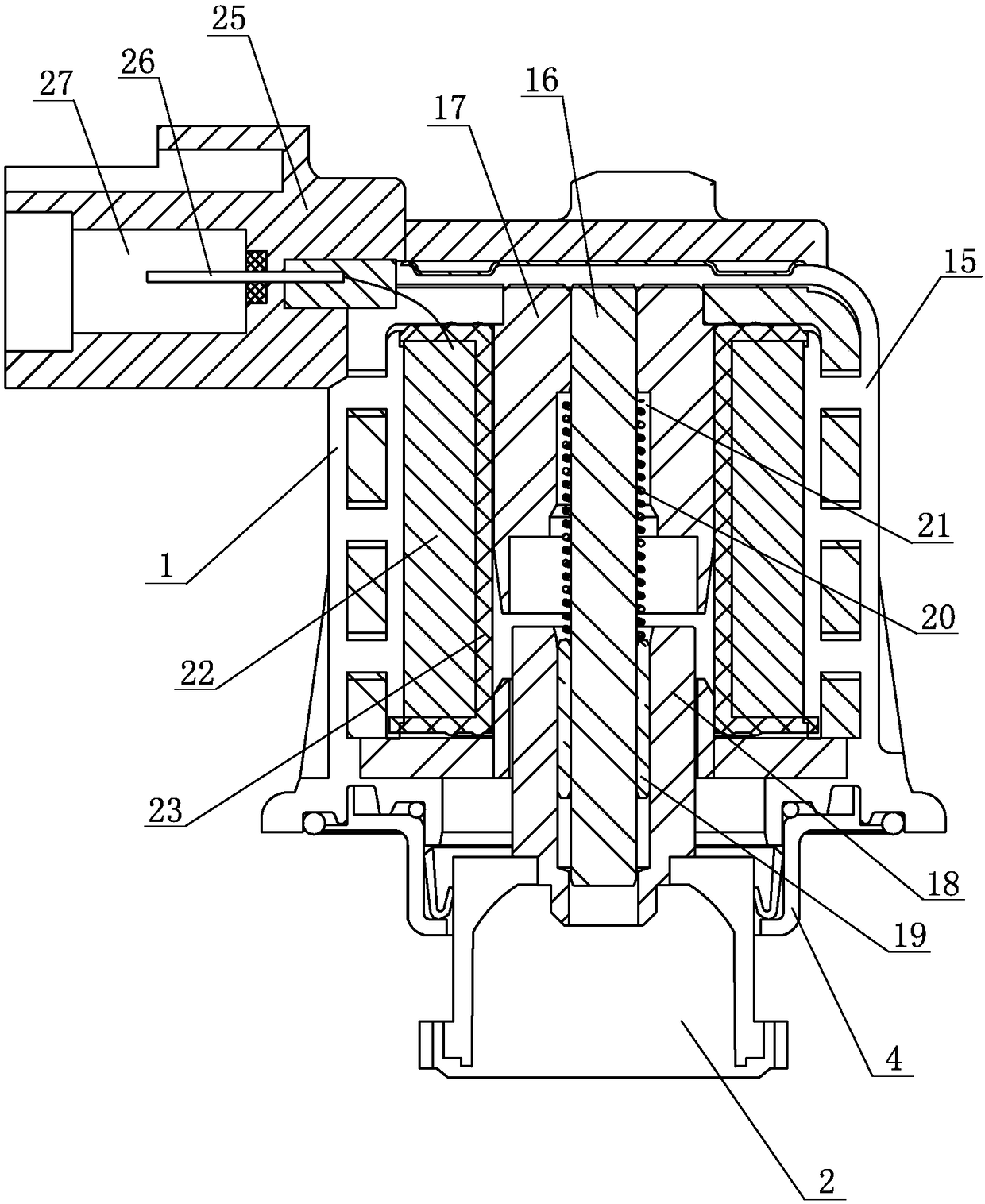

Electric circuit breaker with pyrotechnic actuation

InactiveCN103003907AGuaranteed boostGuaranteed air tightnessBattery cutoff switchesEmergency protective devicesCombustionEngineering

Electric circuit breaker forming a breaker switch in particular, in which a conducting blade is broken by the tripping of a pyrotechnic activation gas generator. According to the invention, a gas generator (15) with pyrotechnic actuation is designed so as to emit gases resulting from the combustion of a charge, and the generator is associated with a variable-configuration chamber (17) and a breakable conducting blade (19) constitutes a back wall of this chamber, the breaking of the blade under the actuation of the gases causing the interruption of the electric circuit of which the blade forms part.

Owner:海瑞克里兹

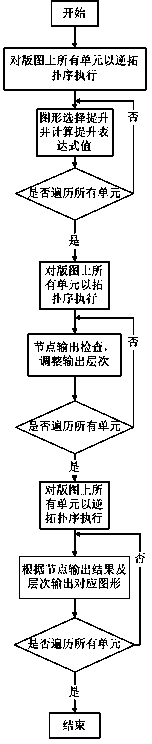

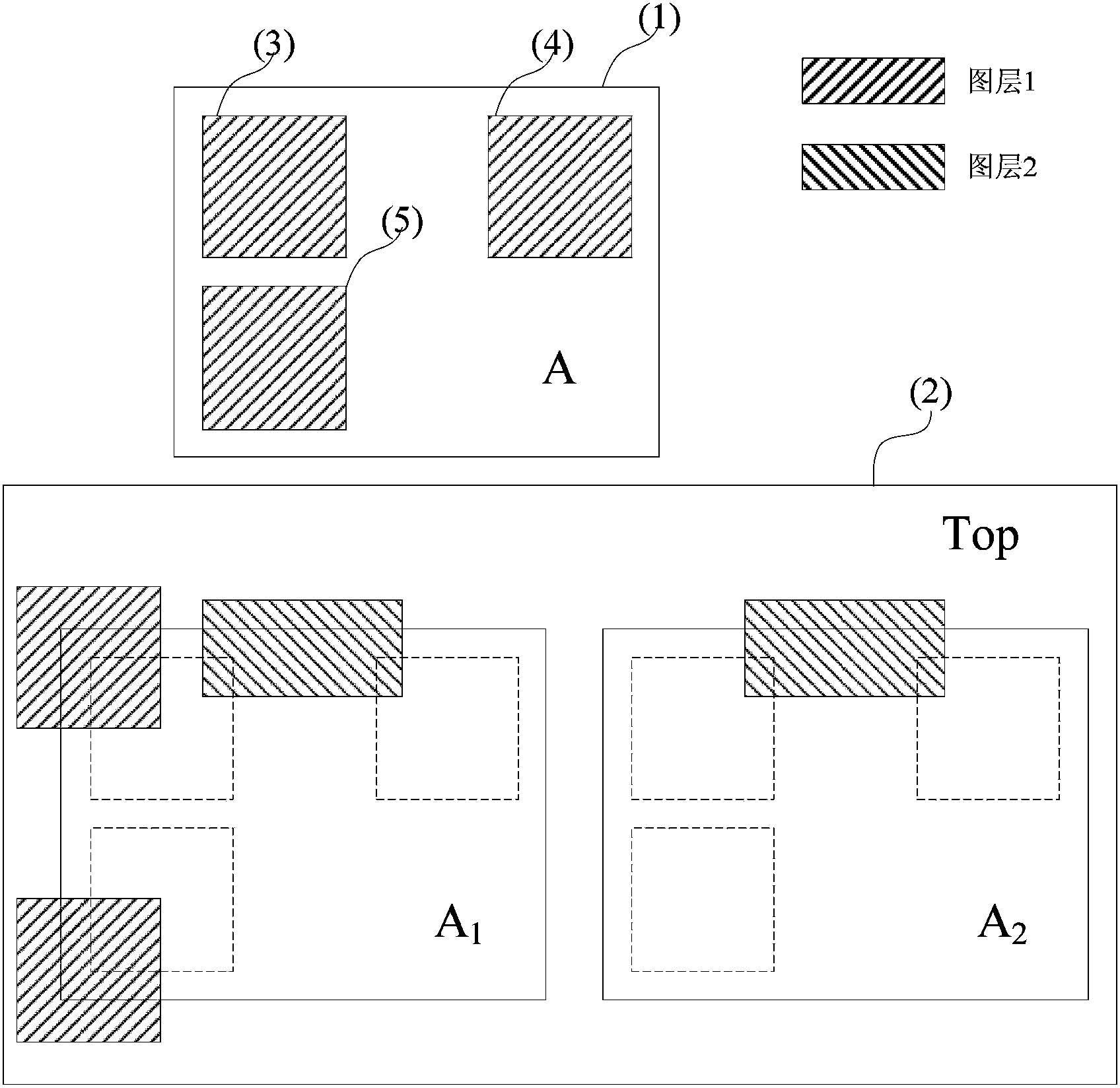

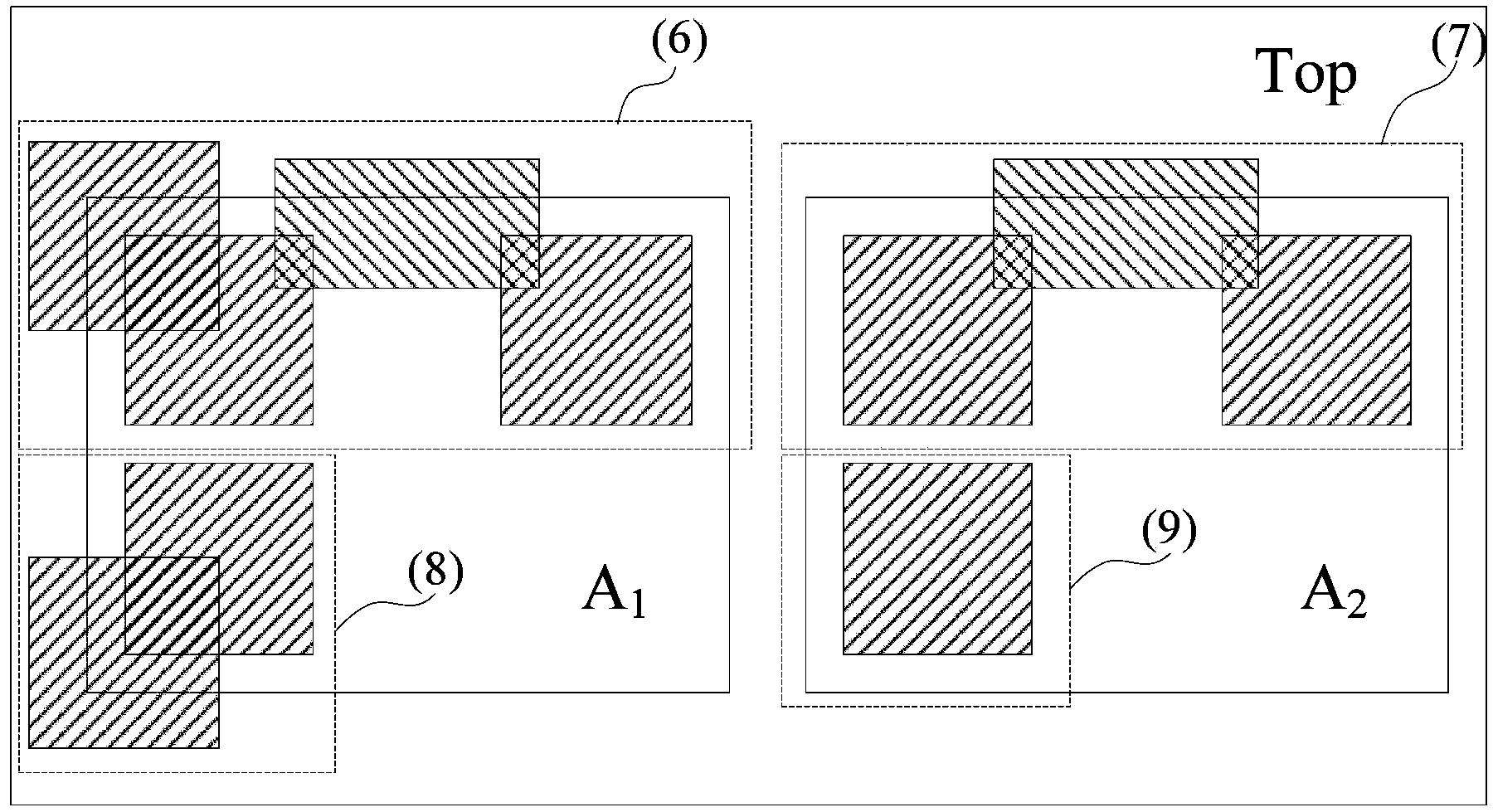

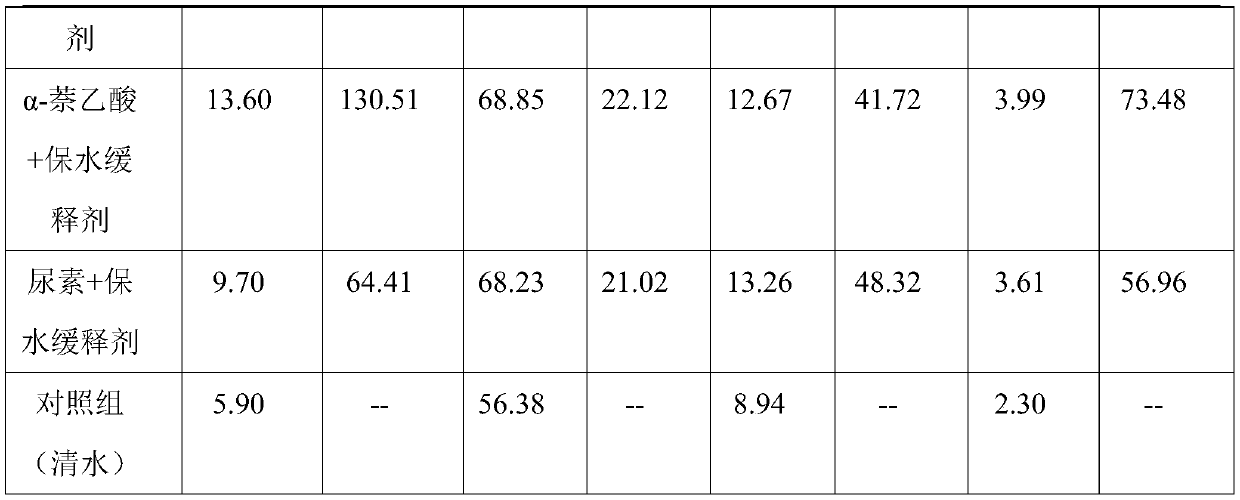

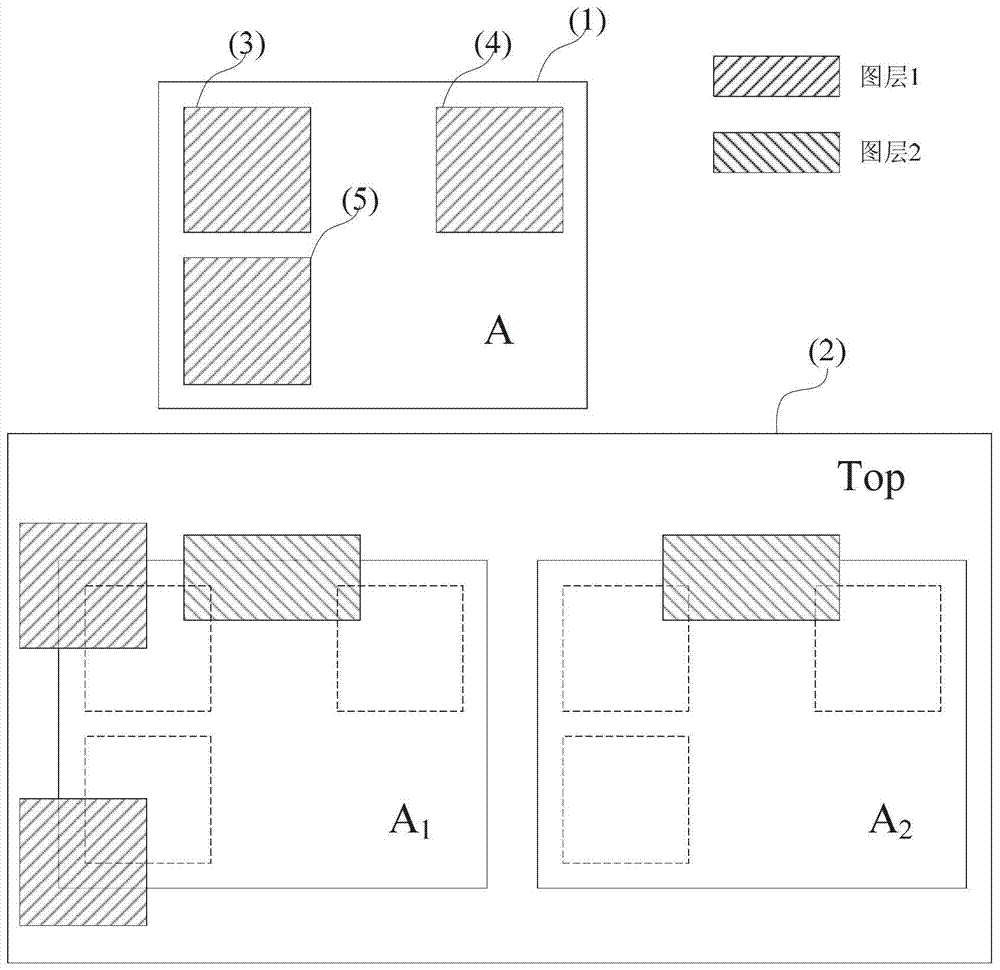

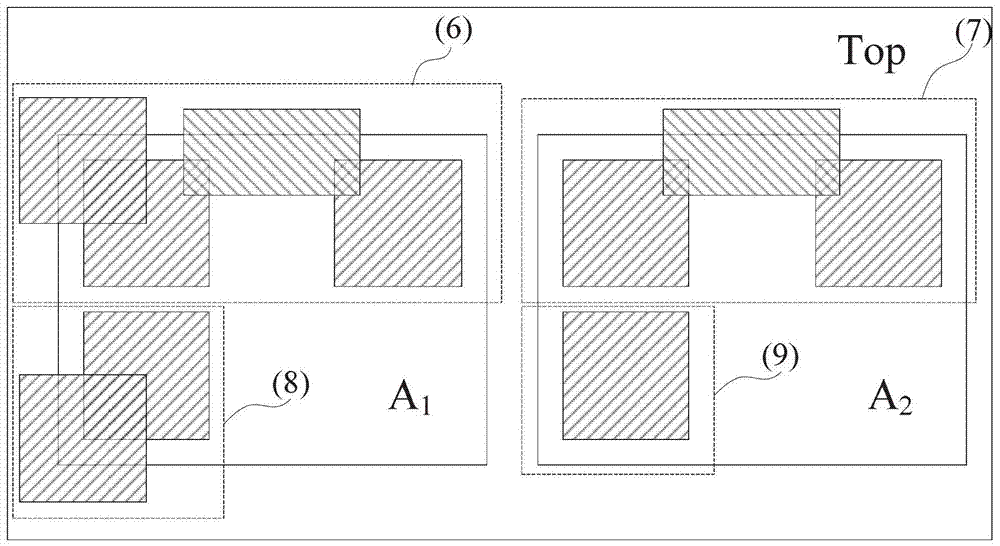

Layered antenna checking method of integrated circuit layout graph verification

ActiveCN103838897AGuaranteed boostBoost ensures noSpecial data processing applicationsGraphicsAlgorithm

The invention discloses a layered antenna checking method of integrated circuit layout graph verification, belongs to the auxiliary design field of integrated circuit computers, and particularly relates to the field of DRC and integrated circular layout graph NE of an integrated circuit layout graph. The method comprises the basic steps that firstly, a graphic selection ascending and expression value calculation ascending method is adopted, and all layers of units are sequentially processed through an inverse topological sequence to obtain a node output conclusion; secondly, a layer result adjusting method is adopted to process all the layers of units through a topological sequence, and output nodes which are judged out are layered and optimized; finally, all the layers of units are processed through the inverse topological sequence, and a result and a layered output graph of the result are output according to existing nodes. The layered antenna checking method is utilized in the integrated circuit layout graph verification, a node expression value with the layered relation is calculated rapidly and conveniently, and the checking efficiency of an antenna is improved.

Owner:北京华大九天科技股份有限公司

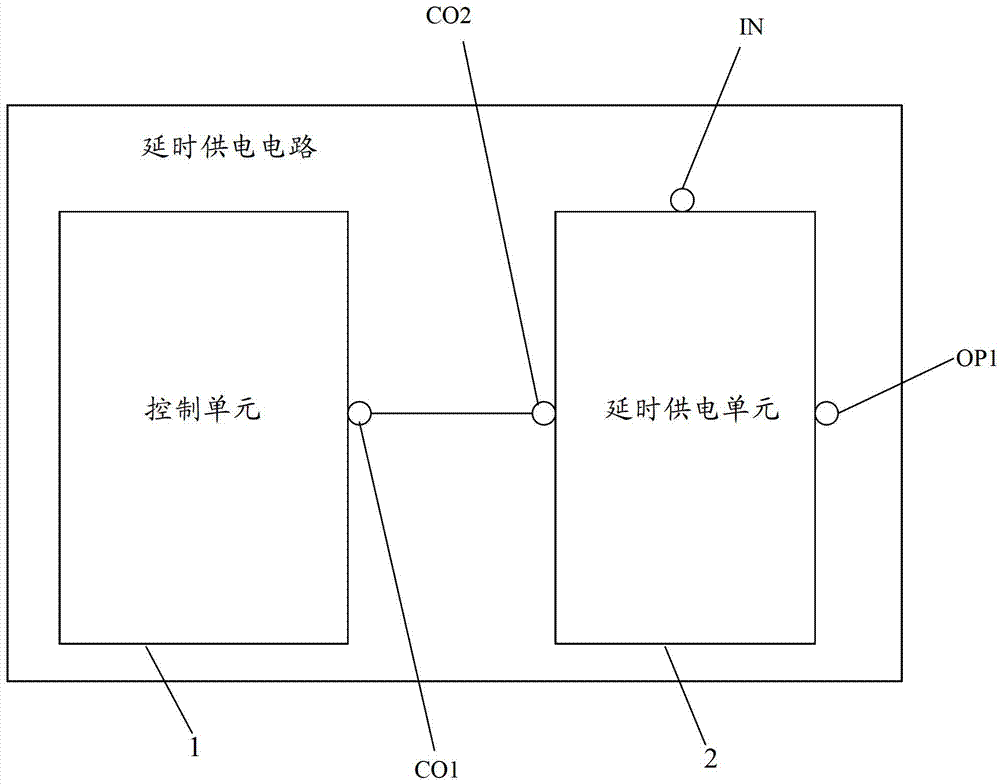

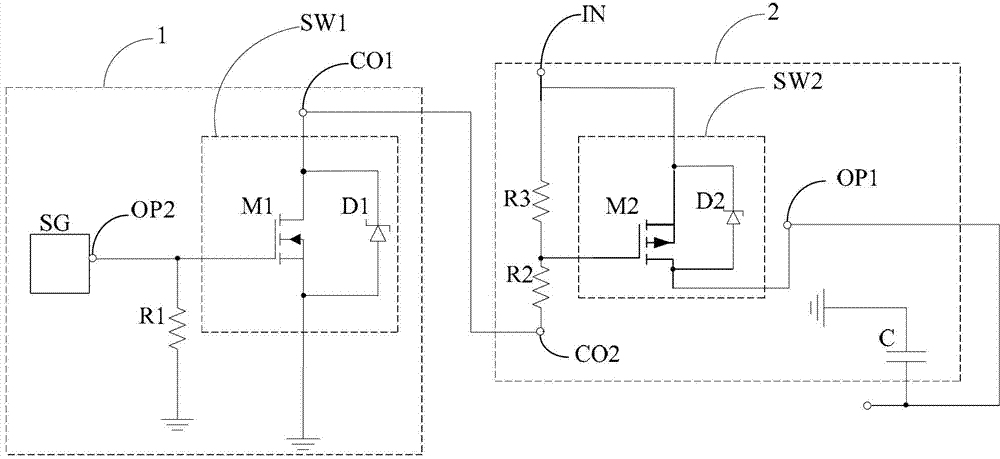

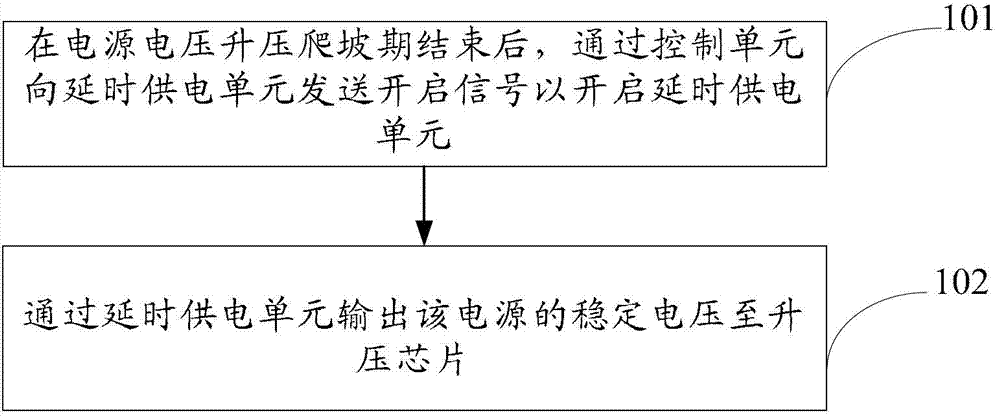

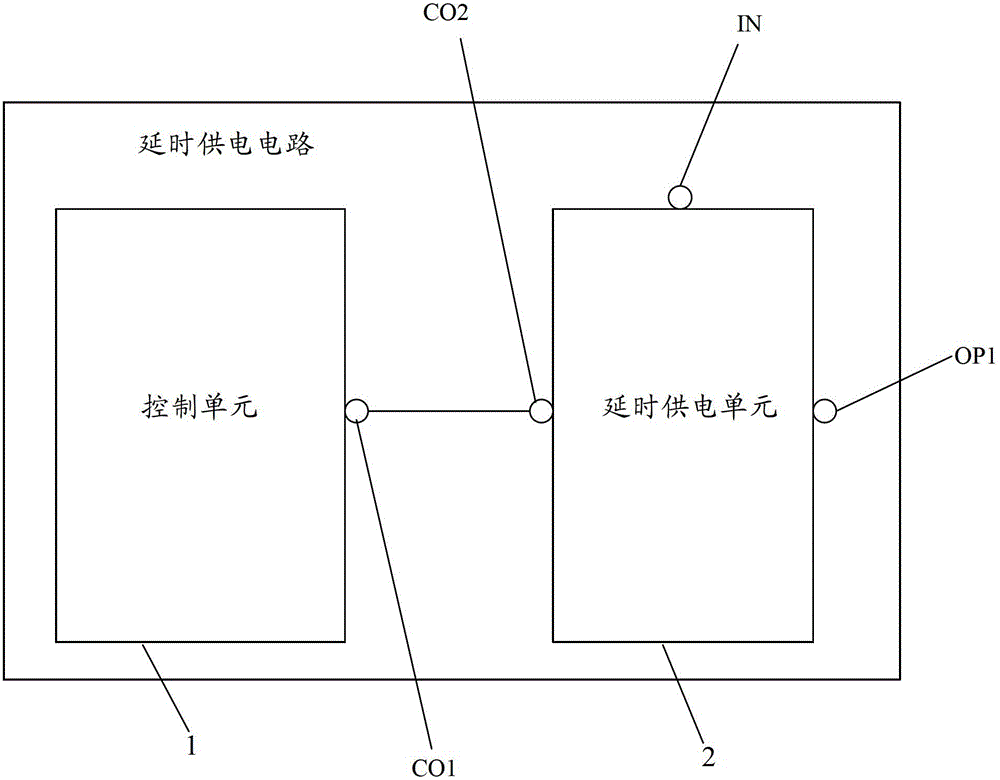

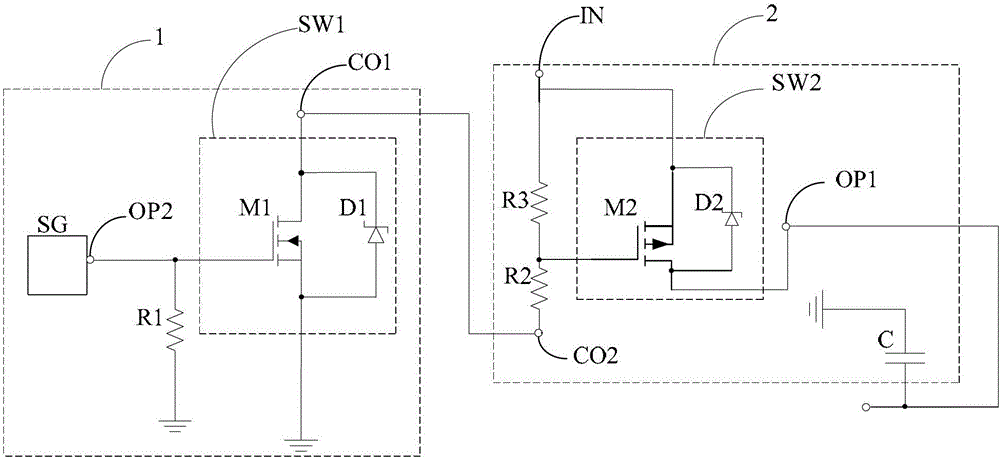

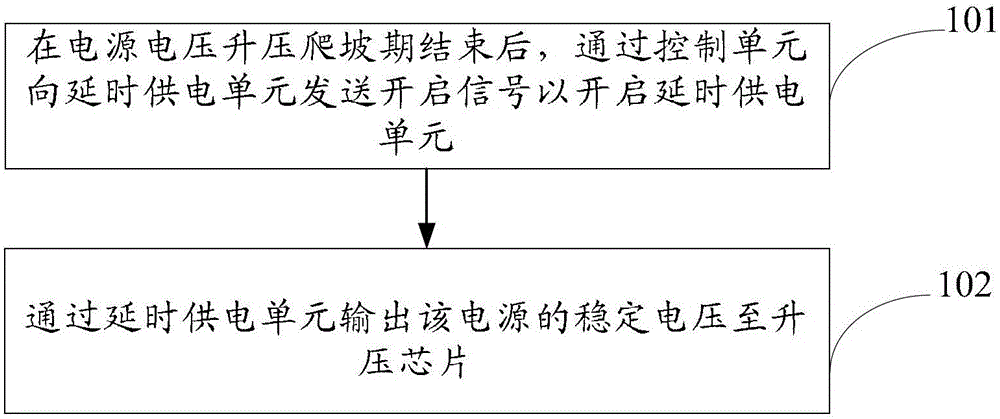

Time-delay power supply circuit, power supply time delay method and boost system

The embodiment of the invention provides a time-delay power supply circuit, a power supply time delay method and a boost system and relates to the field of electronics. By the embodiment of the invention, a boost chip without an enabling pin can be in a working state after a boost period of input power voltage is finished, and a boost effect of the boost chip is ensured. The time-delay power supply circuit comprises a control unit and a time-delay power supply unit, wherein the control unit comprises a first control port, and is connected with the time-delay power supply unit through the first control port and used for controlling the switch-on and switch-off of the time-delay power supply unit; the time-delay power supply unit comprises a second control port, an output port and a power input port; the second control port is connected with the first control port; the power input port is connected with a power supply; and the output port is connected with the input end of the boost chip and used for outputting the stabilized voltage of the power supply to the boost chip after the boost period of the power voltage is finished and a switch-on signal of the control unit is received. The embodiment of the invention is applicable to power supply of the boost chip.

Owner:BOE TECH GRP CO LTD +1

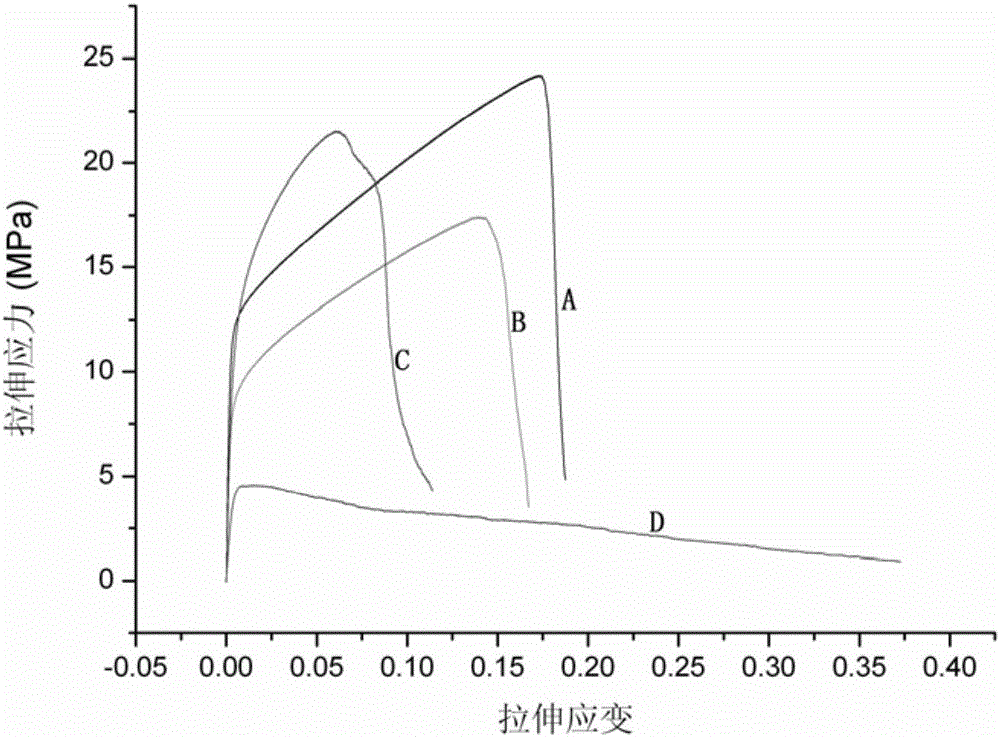

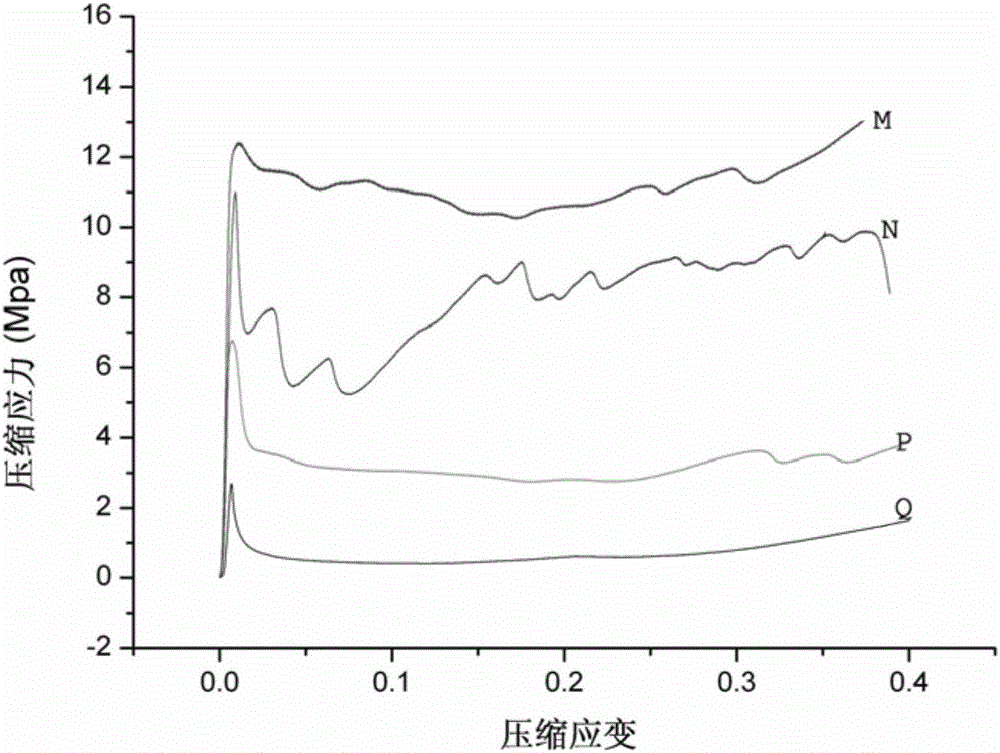

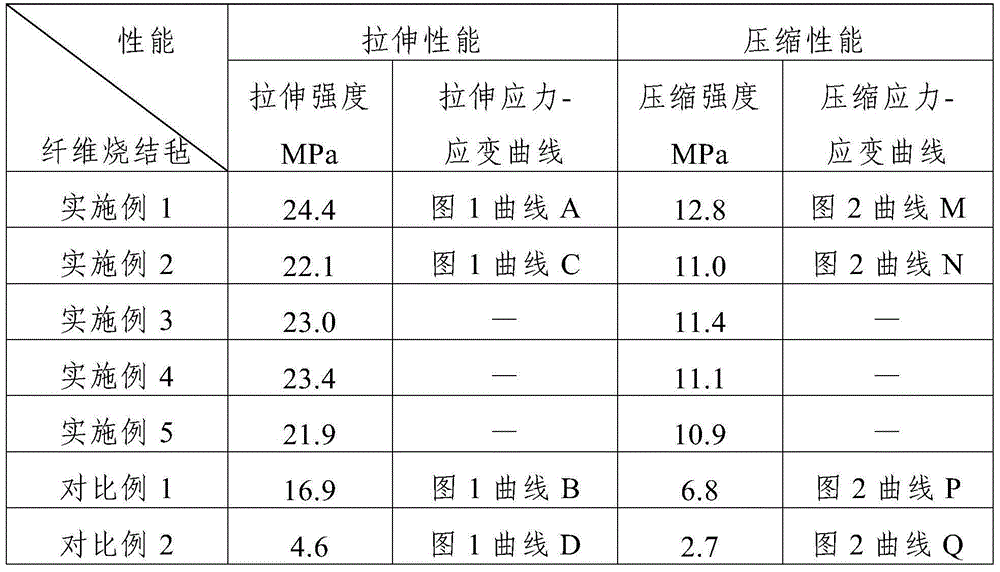

Preparation method for stainless steel fiber sintered felt

The invention provides a preparation method for stainless steel fiber sintered felt. The preparation method comprises the following steps that firstly, stainless steel fiber felt is put in a vacuum sintering furnace, the stainless steel fiber felt is heated up to 300 DEG C-600 DEG C under vacuum conditions, and then the temperature is kept for 30 min-120 min, low temperature sintering treatment is conducted, low temperature sintered felt is obtained after natural cooling; and secondly, the low temperature sintered felt is compressed to be 60%-95% in porosity by adopting a hydraulic press, then the compressed low temperature sintered felt is put in the vacuum sintering furnace, the compressed low temperature sintered felt is heated up to 900 DEG C-1000 DEG C under vacuum conditions, then the temperature is kept for 1 min-30 min, high temperature sintering treatment is conducted, and the stainless steel fiber sintered felt is obtained after natural cooling. According to the preparation method for the stainless steel fiber sintered felt, not only is firm metallurgical bonding among fibers achieved, but also coarsening of crystal grains inside the fibers is avoided, so that the mechanical property of the stainless steel fiber sintered felt is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

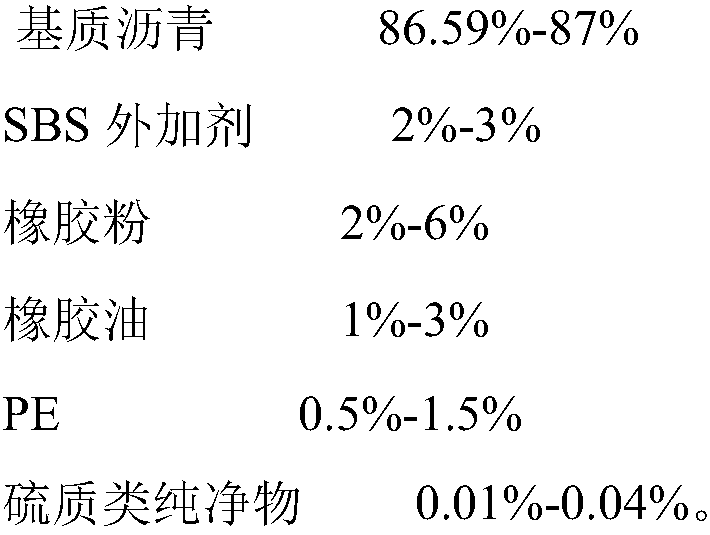

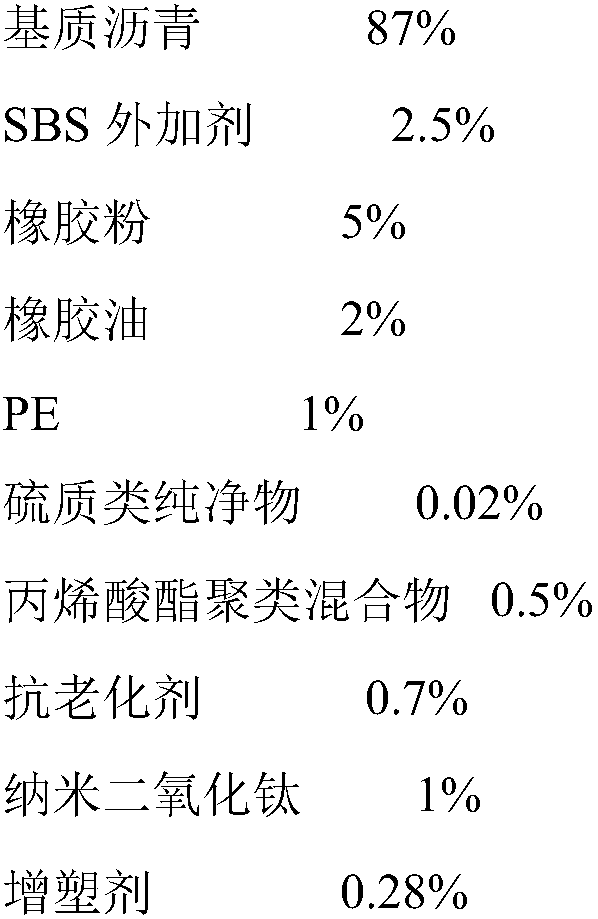

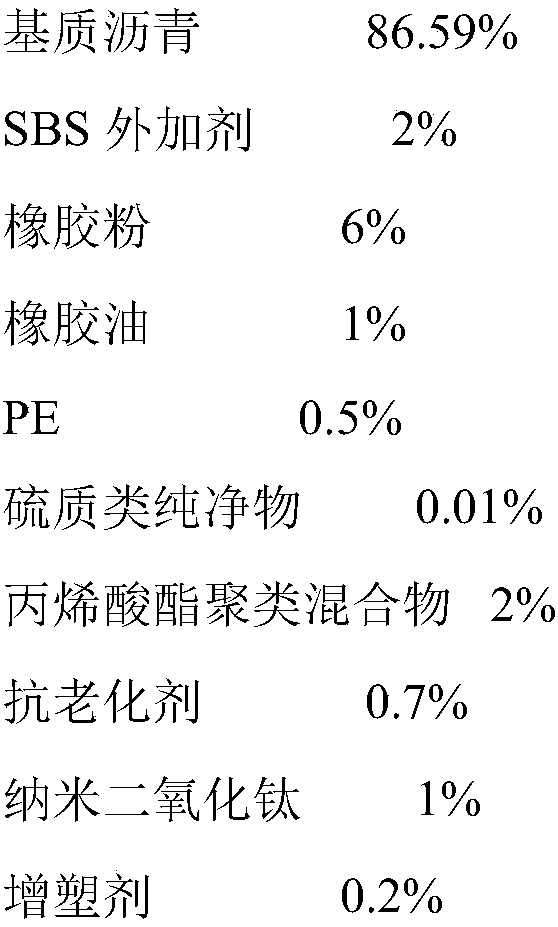

Anti-aging SBS modified asphalt

The invention discloses anti-aging SBS modified asphalt, which is prepared from the following ingredients in percentage by weight: 86.59 to 87 percent of substrate asphalt, 2 to 3 percent of SBS additives, 2 to 6 percent of rubber powder, 1 to 3 percent of rubber oil, 0.5 to 1.5 percent of PE and 0.01 to 0.04 percent of sulfur type pure materials. The anti-aging SBS modified asphalt disclosed by the invention has the advantages that the anti-aging point is high; relatively good ductility and viscosity are realized; the quantity of the mixed SBS additives is low; the production cost is reduced.

Owner:江苏中新苏通市政工程有限公司

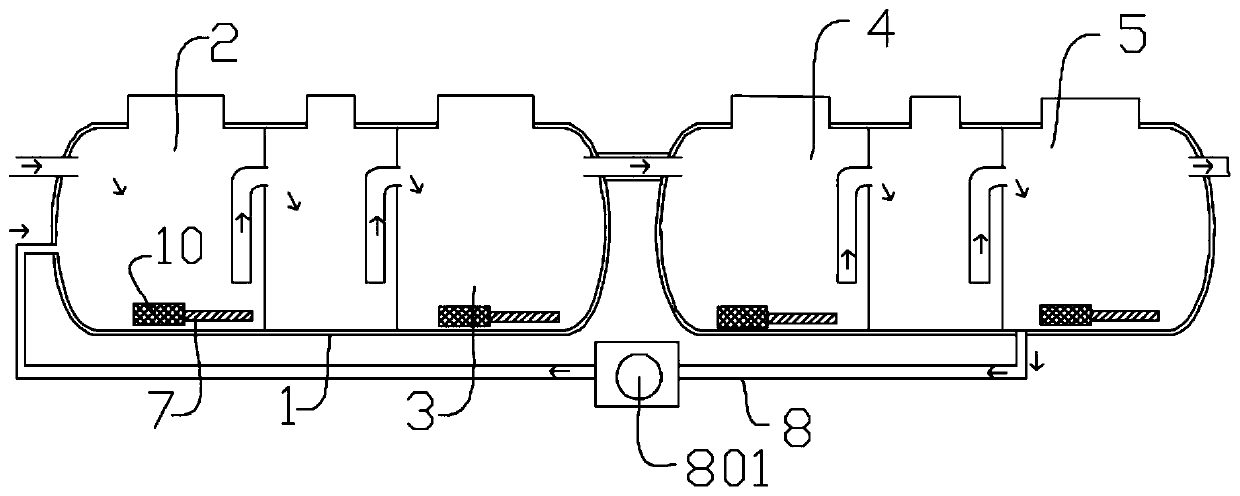

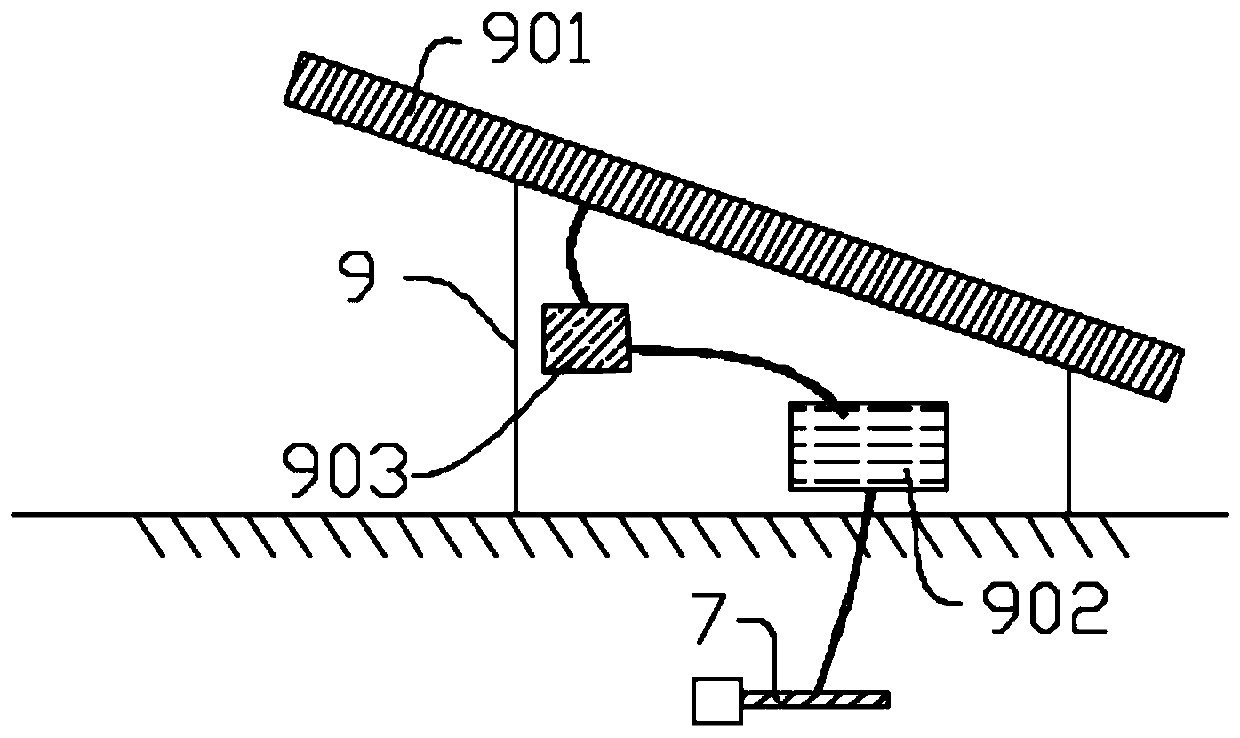

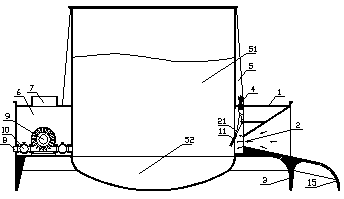

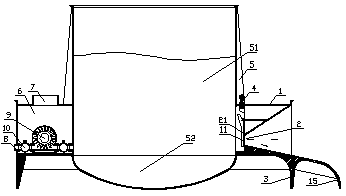

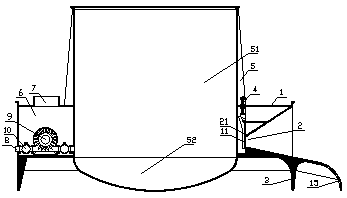

System and process for micro-power sewage treatment in plateau environment

PendingCN110498557AAvoid enteringImprove the living environmentBatteries circuit arrangementsTreatment using aerobic processesHigh energyNitrifying bacteria

The invention discloses a system and process for micro-power sewage treatment in a plateau environment. The system includes a tank body, wherein the tank body is arranged on a low-temperature antifreeze layer on surface of the plateau, the tank body is provided with a functional pool, and the functional pool includes an anaerobic pool, an anoxic pool, an aerobic pool, a sedimentation pool and a purification tank. The process comprises the steps: selecting a lighting environment, adopting a good lighting zone in the plateau environment as the selected zone, performing digging so as to form an installation pit under the surface of the selected plateau zone, installing a solar power supply device on the ground surface, introducing sewage from the anaerobic pool, adding matched composite nitrifying bacteria according to the characteristics of the sewage, guiding the sewage to flow through the entire system, finally discharging the sewage from the purification pool, and heating the sewage inside the tank body through a heating element so as to maintain the temperature at 15-25 DEG C. The invention aims to solve the problems of inconvenient sewage treatment, high cost, high energy consumption and no suitability for wide and sparsely-populated areas in the plateau environment are solved.

Owner:四川天府泓源环保科技有限公司

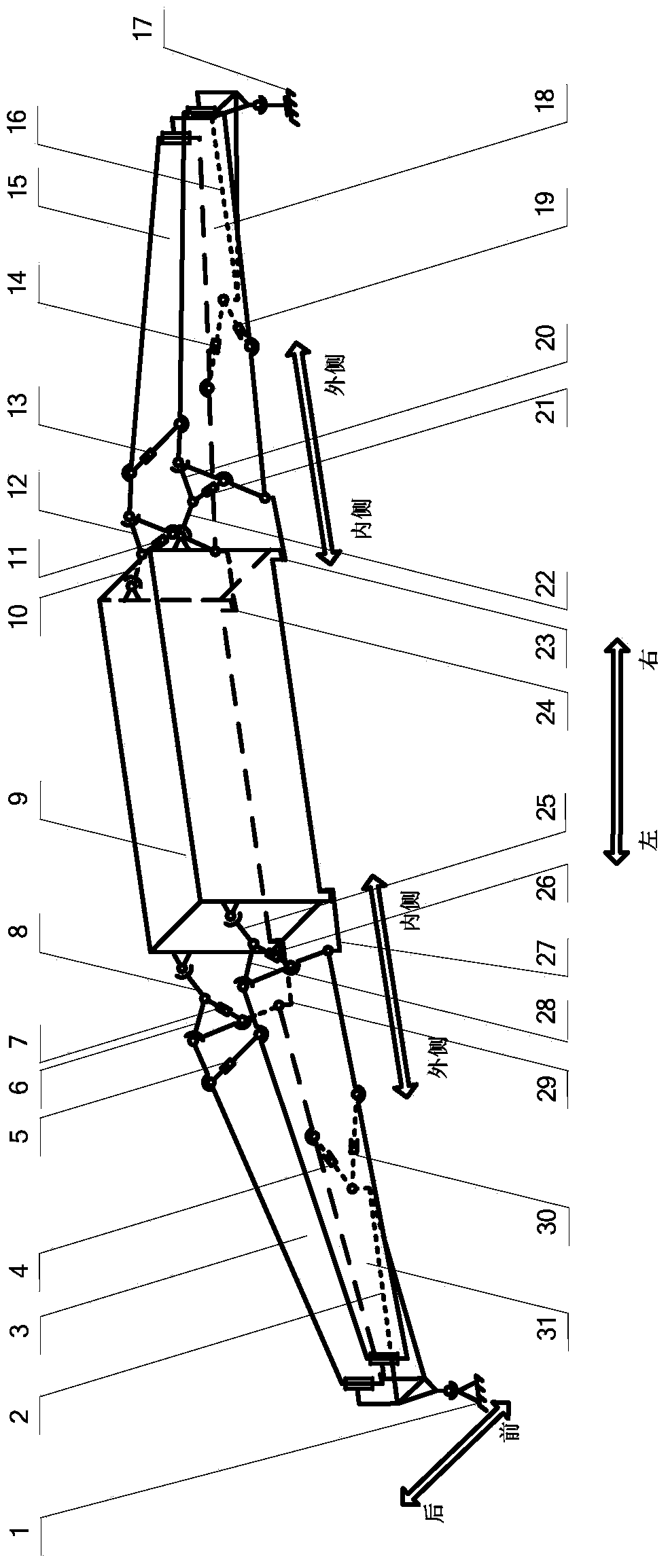

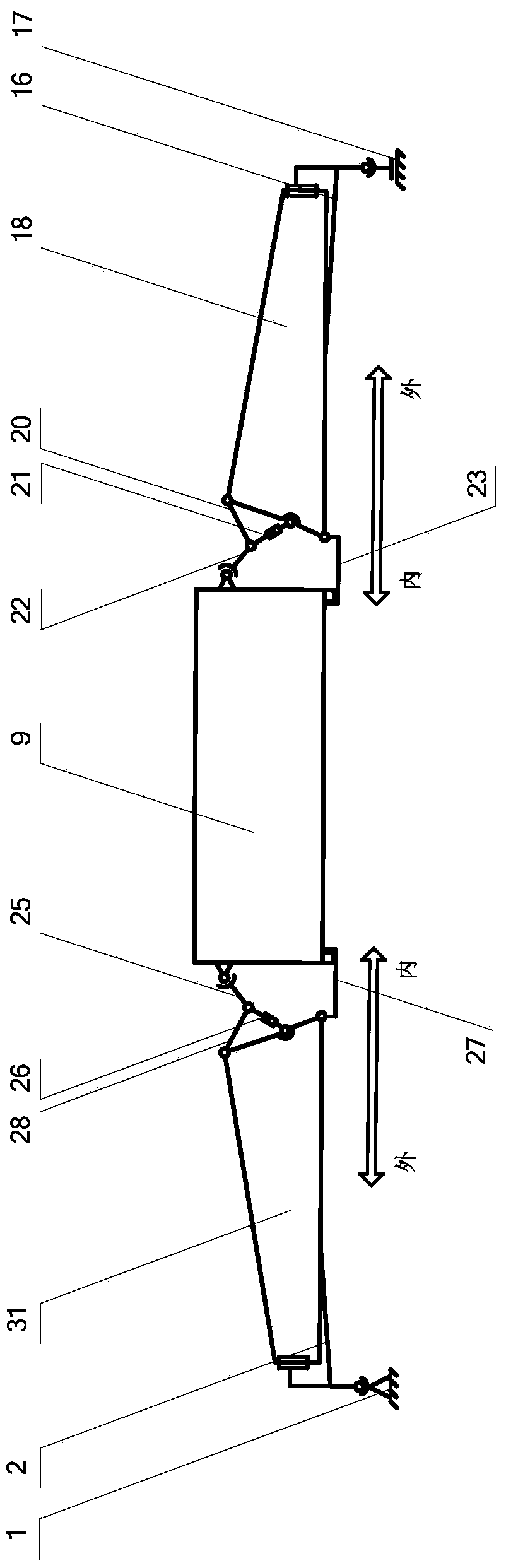

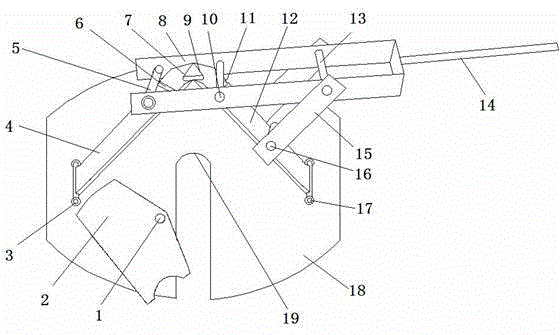

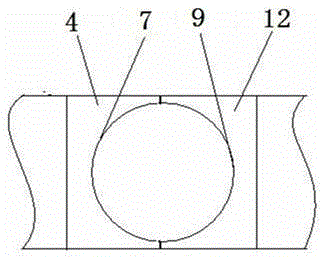

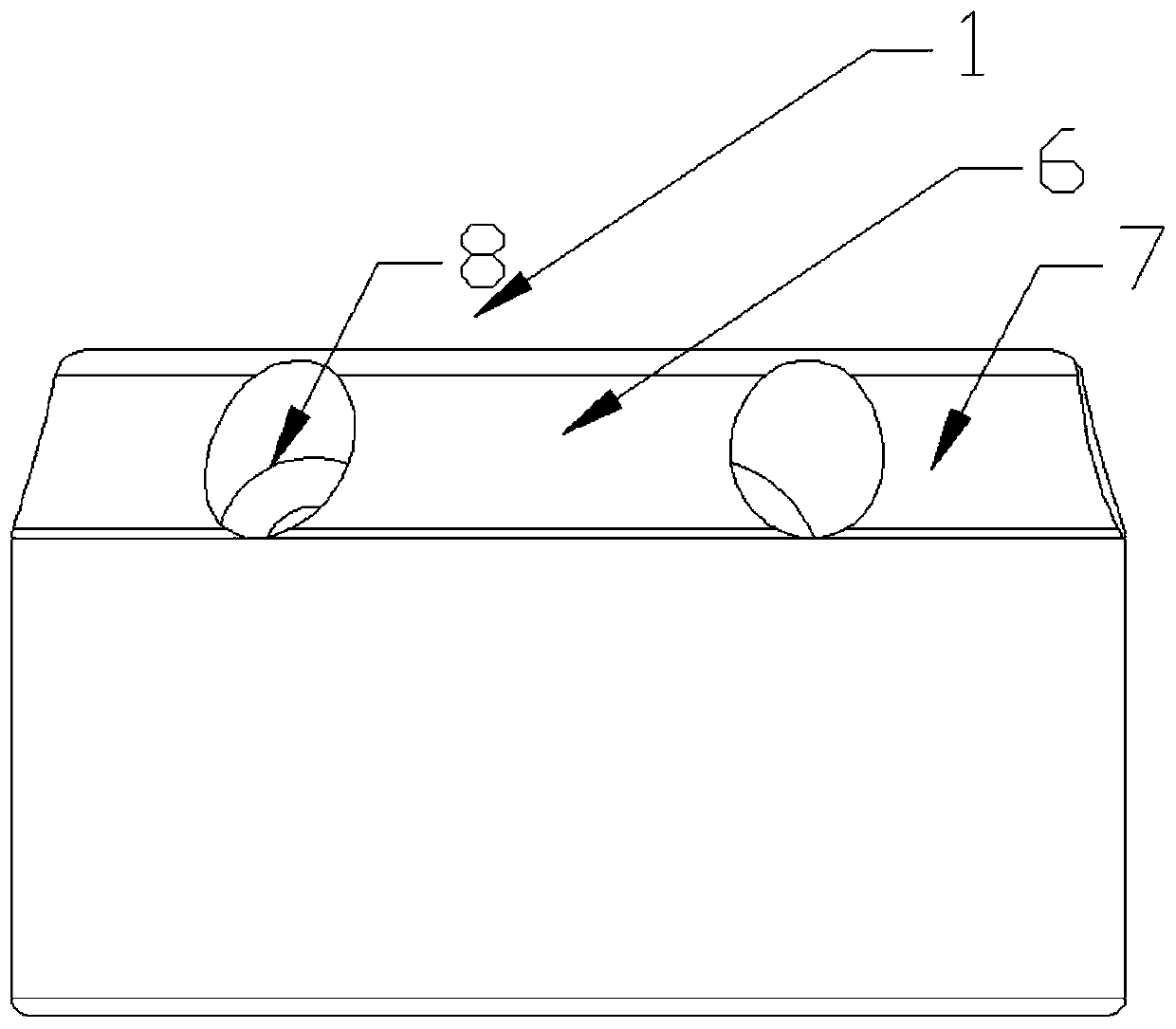

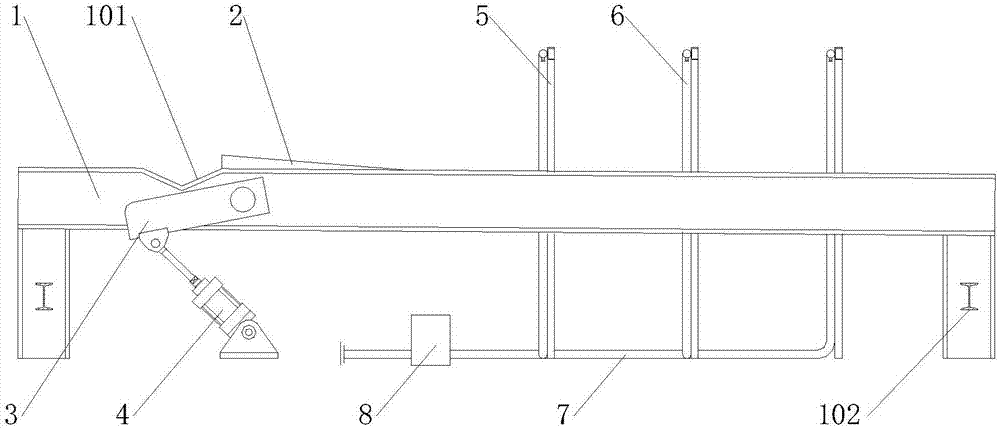

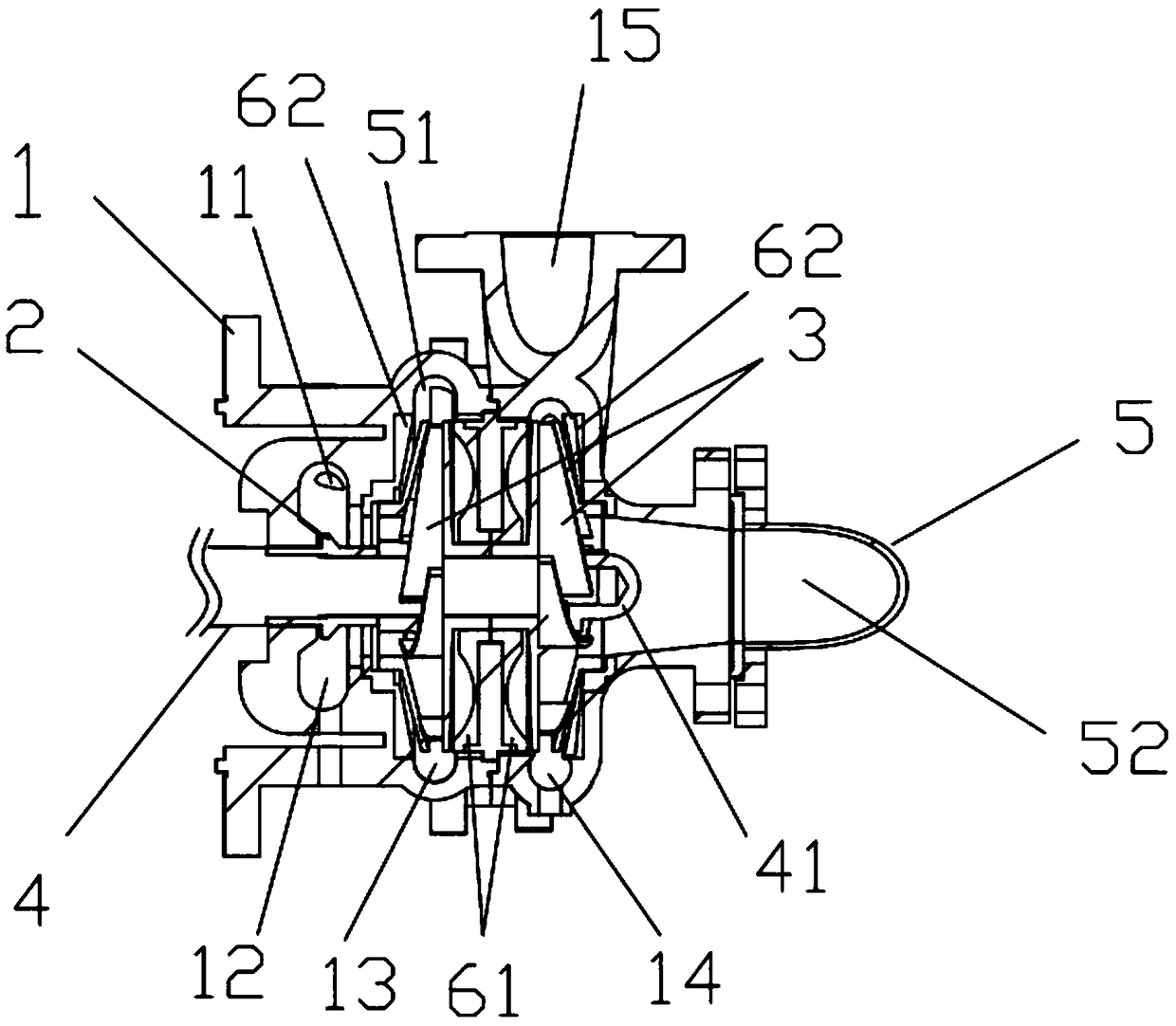

Lifting mechanism of schnabel car

InactiveCN104192155AGuaranteed boostGuarantee the stability of transportationWagons/vansCargo supporting/securing componentsEngineeringPiston rod

A lifting mechanism of a schnabel car is mainly characterized in that central disks of the outer ends of two half schnabel car lifting mechanisms are connected with the outer ends of guide beams through ball pairs, the outer end of each guide beam is hinged to the outer end of a front schnabel beam and the outer end of a rear schnabel beam, the upper portions of the inner ends of each front schnabel beam and the corresponding rear schnabel beam which are identical and connected in parallel are hinged to one end of a front outer connecting rod and one end of a rear outer connecting rod, the other end of the front outer connecting rod and the other end of the rear outer connecting rod are hinged to one end of a front inner connecting rod and one end of a rear inner connecting rod, the other end of the front inner connecting rod and the other end of the rear inner connecting rod are connected with the upper portions of goods, and a rotating pair of the front inner connecting rod, a rotating pair of the rear inner connecting rod, a rotating pair of the front outer connecting rod and a rotating pair of the rear outer connecting rod are respectively connected with a piston rod of a lifting oil cylinder, a cylinder body of each lifting oil cylinder is connected with the middle of the inner end of the corresponding schnabel beam, the lower portions of the inner ends of the two corresponding schnabel beams are hinged to one end of a front car lug and one end of a rear car lug, the other end of each front car lug and the other end of the corresponding rear car lug are connected with the lower ends of the goods, and a width regulating mechanism is installed between each front schnabel beam and the corresponding rear schnabel beam. According to the lifting mechanism of the schnabel car, small lifting force is exerted by the lifting oil cylinders so that the goods with the same weight can be lifted, and the lifting mechanism of the schnabel car has the advantage of saving labor.

Owner:YANSHAN UNIV

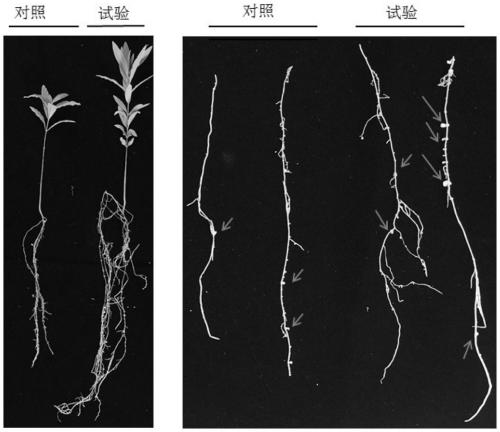

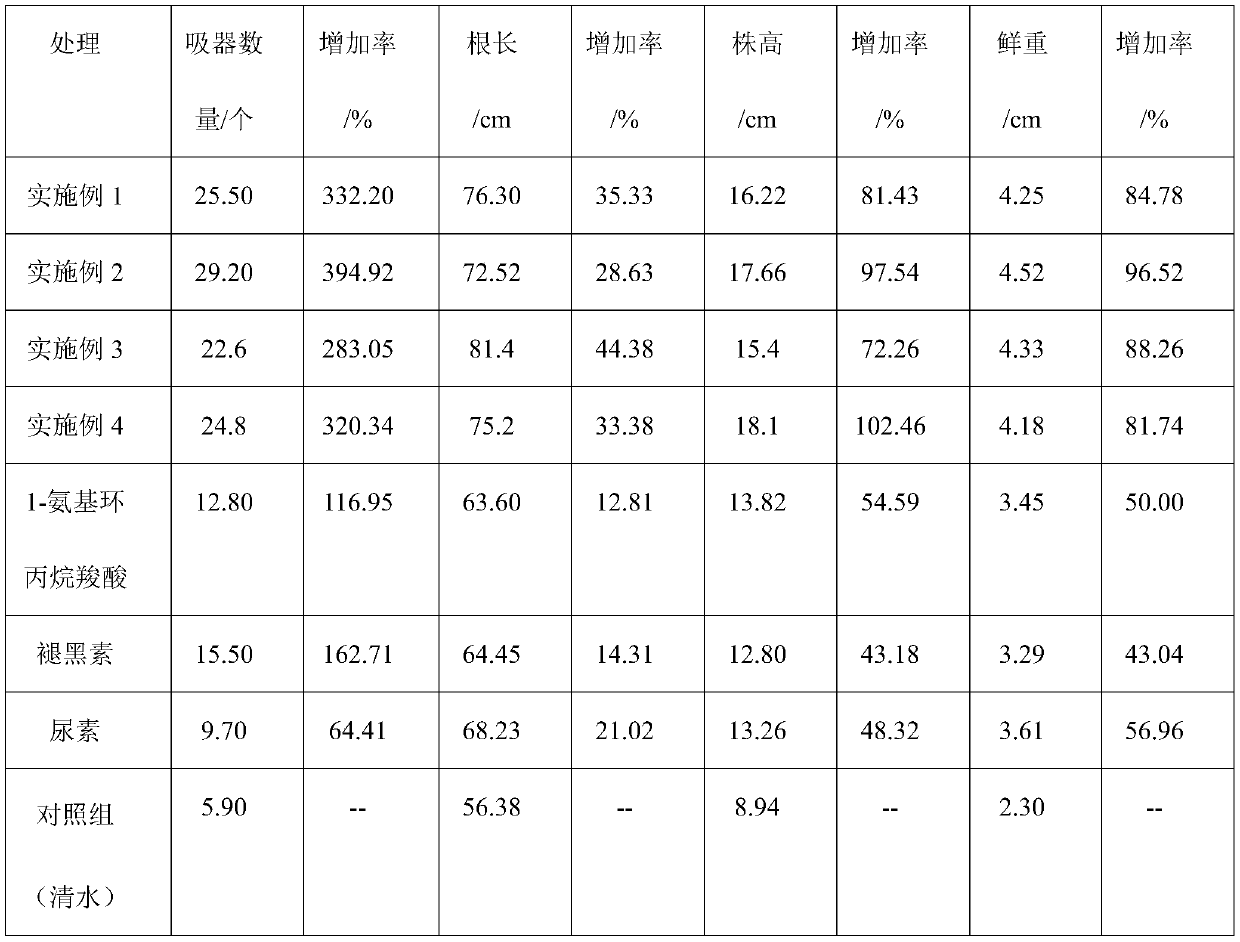

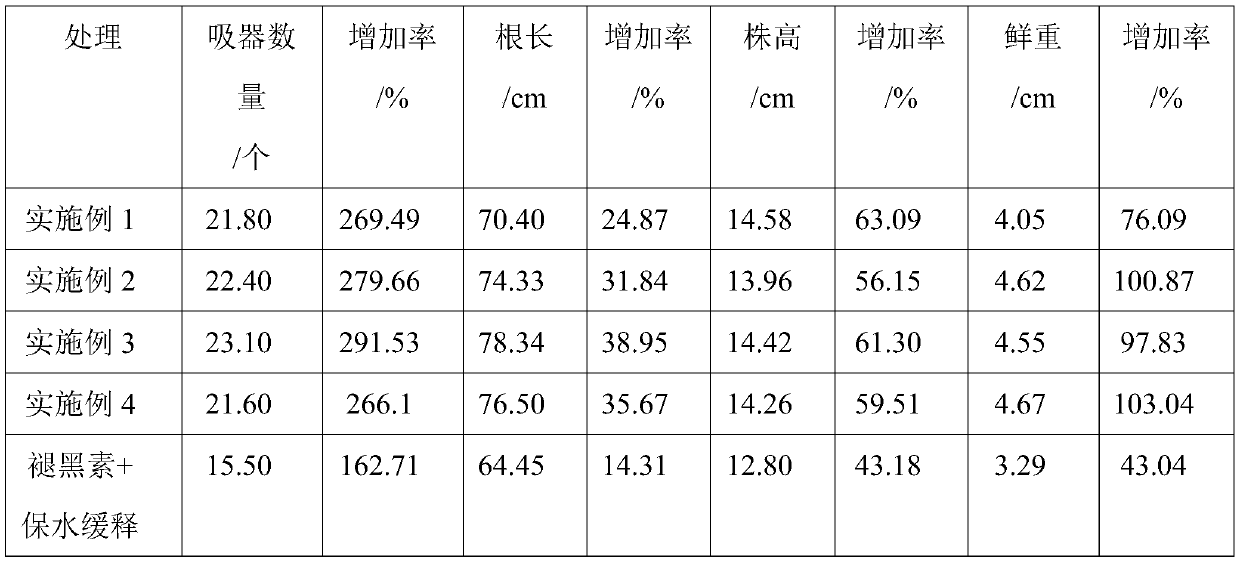

Compound plant growth promoter and application thereof in promoting sandalwood growth and parasitic haustorium development

InactiveCN109924206APromote rootingImprove developmentBiocidePlant growth regulators1-aminocyclopropanecarboxylic acidCarboxylic acid

The invention discloses a compound plant growth promoter and application thereof in promoting sandalwood growth and parasitic haustorium development. Each 100 parts of the compound plant growth promoter comprises the following components in parts by weight: 1-3 parts of 1-aminocyclopropanecarboxylic acid, 1-3 parts of melatonin, 10-15 parts of urea and the balance of a milk powder carrier. The milk powder carrier comprises the following components in parts by weight: 2-3 parts of white carbon black, 5-7 parts of a diffusion agent, 1-2 parts of an emulsifier and 7-10 parts of beta-cyclodextrin.The compound plant growth promoter can obviously promote the rooting, haustorium development and growth of sandalwood, improves photosynthesis and improves afforestation quality of sandalwood artificial forests. At the same time, the compound plant growth promoter can also significantly promote the growth of other precious tree species such as Dalbergia odorifera and teak, and has a wide application range.

Owner:RES INST OF TROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Steel wire rope greasy filth cleaning device

The invention provides a steel wire rope greasy filth cleaning device, which comprises a greasy filth collecting bottom plate and is characterized in that a notch allowing a steel wire rope to pass is formed in the greasy filth collecting bottom plate, a left scraper and a right scraper which are opposite and are connected through a hinging shaft are respectively arranged at the two sides of the greasy filth collecting bottom plate, the upper ends of the left scraper and the right scraper are respectively provided with circular arc-shaped concave cutter openings, the two circular arc-shaped concave cutting edges are in butt joint for forming a greasy filth scraping circular cutter opening, a connecting plate is fixedly connected on the right scraper, the outer end of the connecting plate is connected with the right end of a clamping frame through a hinging shaft, one end of the clamping frame is connected with a handle, the clamping frame is in a fork shape, the middle part of the clamping frame is fixedly connected with a right clamping rod, and the left end of the clamping frame is assembled with a left clamping screw rod. The steel wire rope greasy filth cleaning device has the advantages that the cleaning is convenient and fast, the cleaning effect is good, and the work intensity is reduced.

Owner:铁法煤业(集团)有限责任公司晓南矿

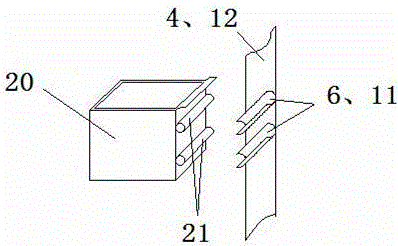

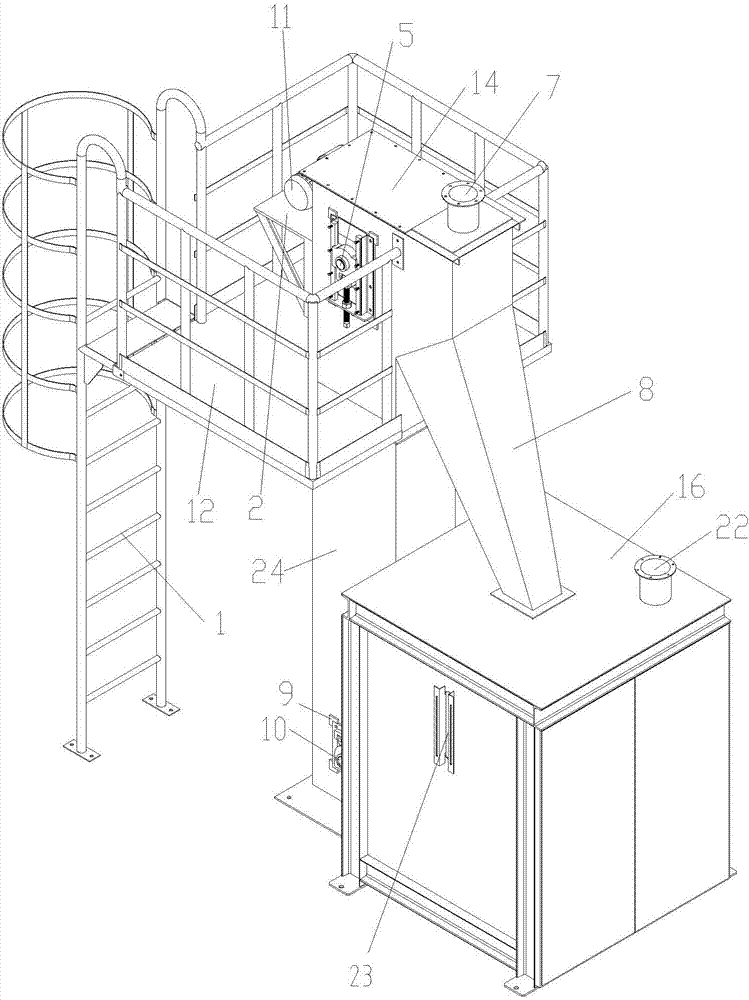

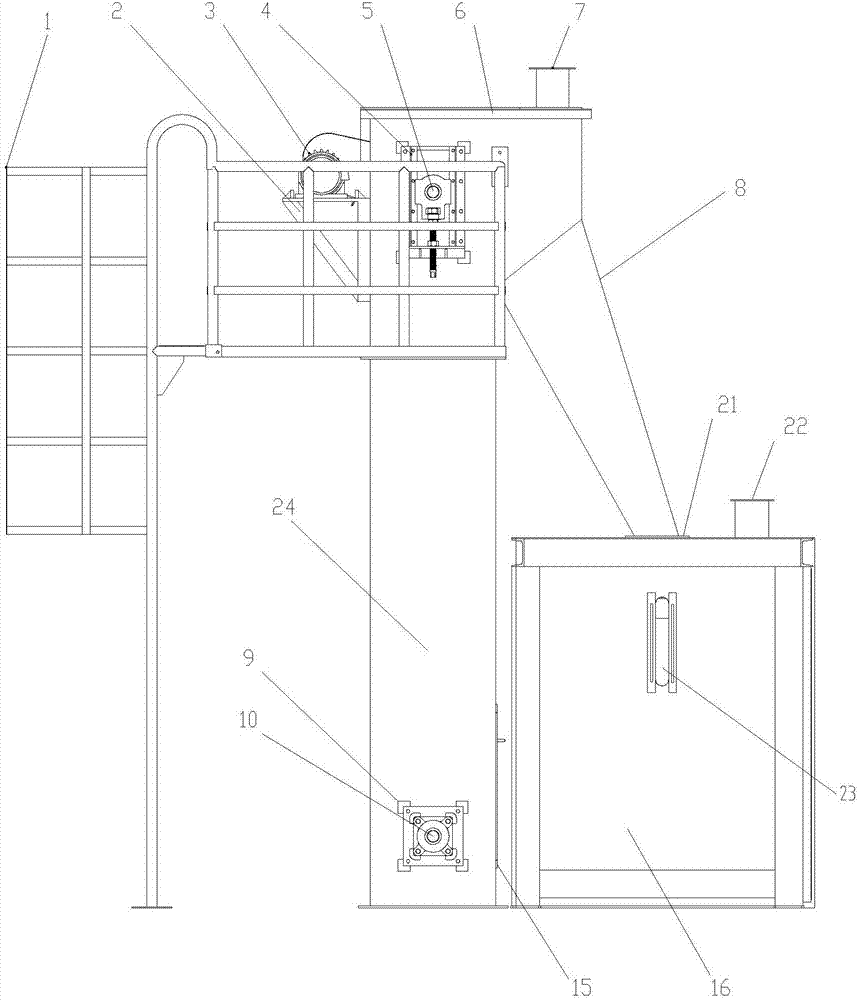

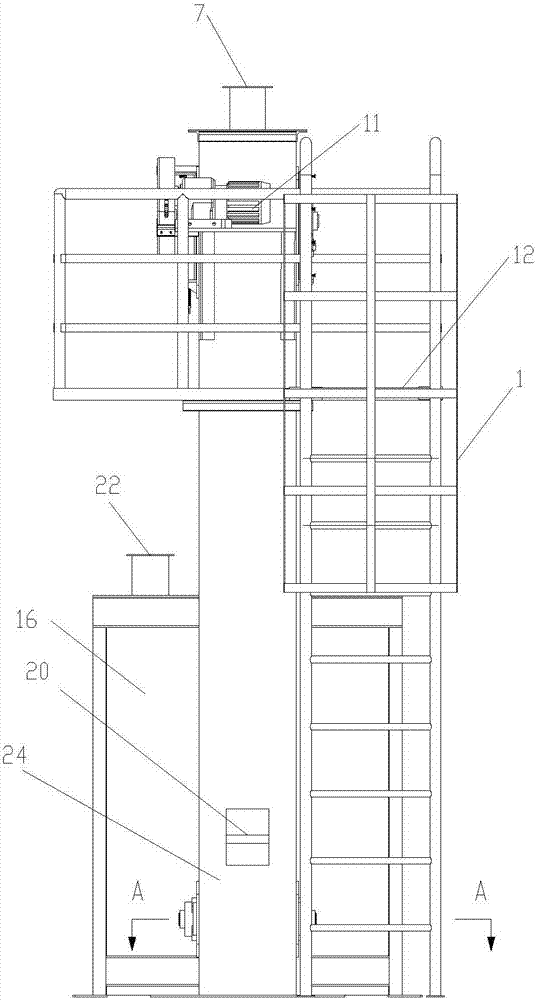

Automatic transferring and bagging system for metal slag

InactiveCN107265049AEasy to transportEasy to recycleConveyorsControl devices for conveyorsSlagFlange

The invention provides an automatic transferring and bagging system for metal slag. The automatic transferring and bagging system comprises a transporting device and a bagging device; the transporting device comprises a transporting channel, a driving rotating mechanism is arranged on the top of the transporting channel, a driven rotating mechanism is arranged at the bottom of the transporting channel, the driving rotating mechanism and the driven rotating mechanism achieve linkage through an annular chain, a plurality of hoppers are arranged on the chain, a first feeding inlet is formed in one side of the bottom of the transporting channel, and a discharging outlet is formed in the other side of the top of the transporting channel; the bagging device comprises a fine ash bin arranged on one side of the transporting channel, a second feeding inlet is formed in the top of the fine ash bin and connected with the discharging outlet of the transporting channel through a hollow material guiding pipeline, and a ton bag is hung in the fine ash bin; the transporting channel and / or the top of the fine ash bin is provided with a dust collection flange port, and the dust collection flange port is connected with an external dust collection device through a pipeline. According to the automatic transferring and bagging system for the metal slag, the tedious transporting and recycling procedures of normal-temperature metal slag are reduced, the operation time is shortened, and automation is achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

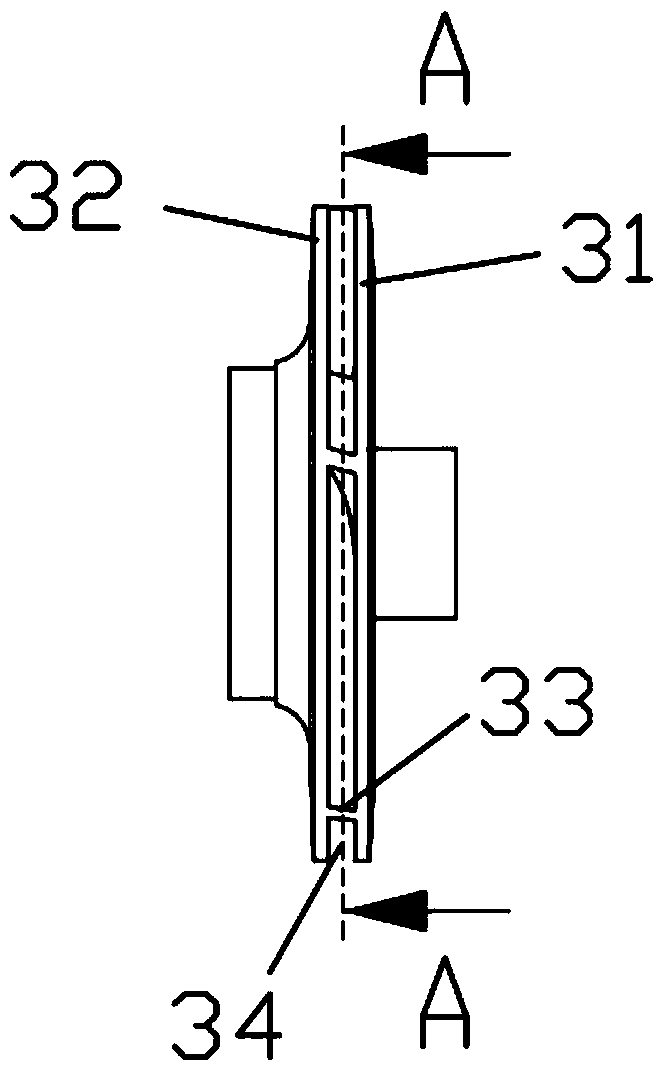

Valve seat and high-pressure inclined inlet nozzle

PendingCN110000016AReduce cloggingAffect the atomization effectValve arrangementsSpray nozzlesCycloneSpray nozzle

The invention discloses a valve seat. The valve seat is characterized in that a vacuum groove is formed in the cavity wall, close to a nozzle hole, of a first sealing cavity, through the arrangement of the vacuum groove, when a high-speed fluid medium rotates along the cavity wall of the first sealing cavity to flow towards the nozzle hole, the high-speed fluid medium drives air in the vacuum groove to form a cyclone so as to form a negative pressure state, and in the process of forming the cyclone, the air enters the nozzle hole along with the fluid medium and is finally converted into mist and ejected. In the process, a cyclone turbulence flow of air in the vacuum groove can take away the residual part of the fluid medium on a partial inverted conical surface or partial spherical cambered surface structure below a sphere after the sphere makes contact with the inverted conical surface or spherical cambered surface structure in a sealing mode, so that fluid medium residues are avoided, and the situation that the nozzle hole is blocked after impurities are hardened and dried, and the atomization effect is influenced is avoided.

Owner:JIANGSU BATON TECH CO LTD

Harmless treatment method for moso bamboo wet carbonization wastewater, crop growth regulator and use method of crop growth regulator

InactiveCN111675362AAchieve reuseThe harmless treatment method is simpleBiocidePlant growth regulatorsNutritionCarbonization

The invention provides a harmless treatment method for wastewater generated in wet carbonization of moso bamboos, a crop growth regulator and a use method of the crop growth regulator. The invention belongs to the technical field of waste recycling; the harmless treatment method provided by the invention can remove tar and other impurities in wastewater, a middle-layer liquid phase obtained through standing can be used for preparing the crop growth regulator, and recycling of moso bamboo carbonization wastewater is achieved. Meanwhile, the harmless treatment method provided by the invention issimple and easy to operate. The invention also provides the crop growth regulator which takes the middle-layer liquid phase obtained by harmless treatment of the moso bamboo carbonization wastewateras a main component, and the liquid phase contains organic acid compounds, polyphenol compounds and mineral elements (such as calcium, iron and the like), so that a certain nutrition source can be provided for plant growth, and the growth of crops can be promoted.

Owner:安徽真之木新材料科技有限公司

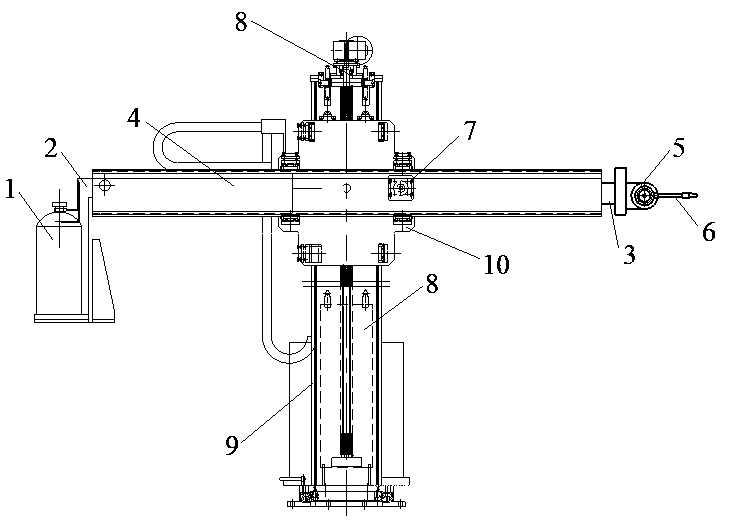

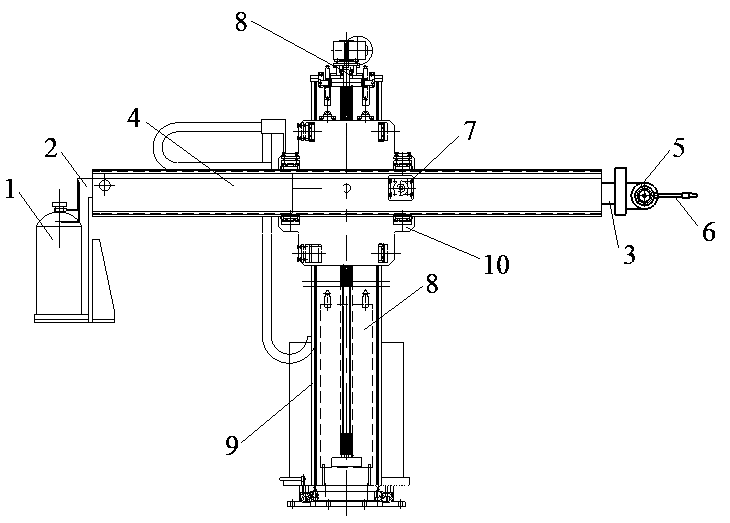

Spraying device for cast iron tube

InactiveCN107354283APlay a limiting rolePlay a role in boostingFurnace typesHeat treatment furnacesVertical tubeSpray nozzle

The invention discloses a cast iron pipe spraying device, comprising a conveying track, one end of the conveying track is provided with a group of symmetrically arranged V-shaped grooves, one end of the V-shaped groove is provided with a diagonal brace, the lower end of the V-shaped groove is provided with a push plate, and one end of the push plate is Connected with a jacking cylinder; the outside of the conveying track is provided with a plurality of side-by-side mounting frames, and each mounting frame is equipped with an L-shaped spray pipe, and the spray pipe includes interconnected horizontal pipes and vertical pipes , the bottom of the horizontal tube is evenly distributed with a number of nozzles, one end of the horizontal tube is provided with a sealing plate, the lower end of the vertical tube is connected to the water inlet through the delivery pipe, and the delivery pipe is provided with a booster pump. In the invention, through the structural cooperation of the spray pipe and the conveying track, the cast iron pipe can be rapidly cooled during the conveying process, and the automation degree is high and the cooling effect is good.

Owner:湖州市下昂多联铸造有限公司

Automatic enamel spraying machine

InactiveCN109967276ASpray evenlyAdjustable parametersMovable spraying apparatusEngineeringControl theory

Disclosed is an automatic enamel spraying machine. A material barrel communicates with a spraying head through a material pipe, the material pipe is arranged in a telescopic arm in an axial penetrating mode, a gear arranged on the outer wall of the spraying head is connected with a gear in the telescopic arm through a toothed bar, and the end, arranged outside the telescopic arm, of the spraying head is connected with a nozzle through a servo rotating spraying head. The gear in the telescopic arm is in transmission connection with a continuously variable servo motor arranged on the telescopicarm, and the servo motor is electrically connected with a PLC. A machine head is composed of a precision reducer, the servo motor, a paint spraying clamping adjusting mechanism and the like. Through arotating mechanism, the spraying head can be rotated at any angle. By the adoption of driving with the precision reducer and the servo motor, precision is high. An encoder is adopted so that precisesetting can be conducted. The machine head is provided with a clamping block and a fixing mechanism which are installed with a spraying system, so that paint spraying adjustment and fine adjustment are facilitated.

Owner:沈阳华维激光设备制造有限公司

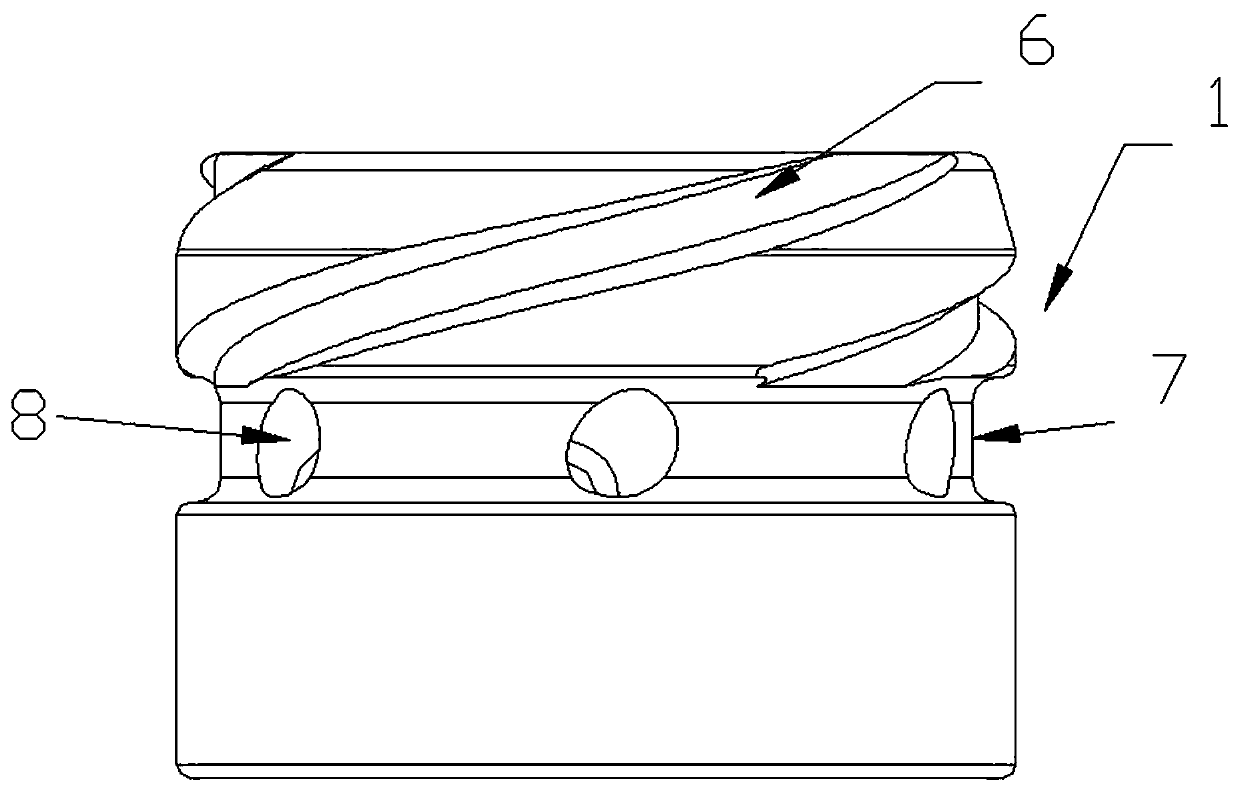

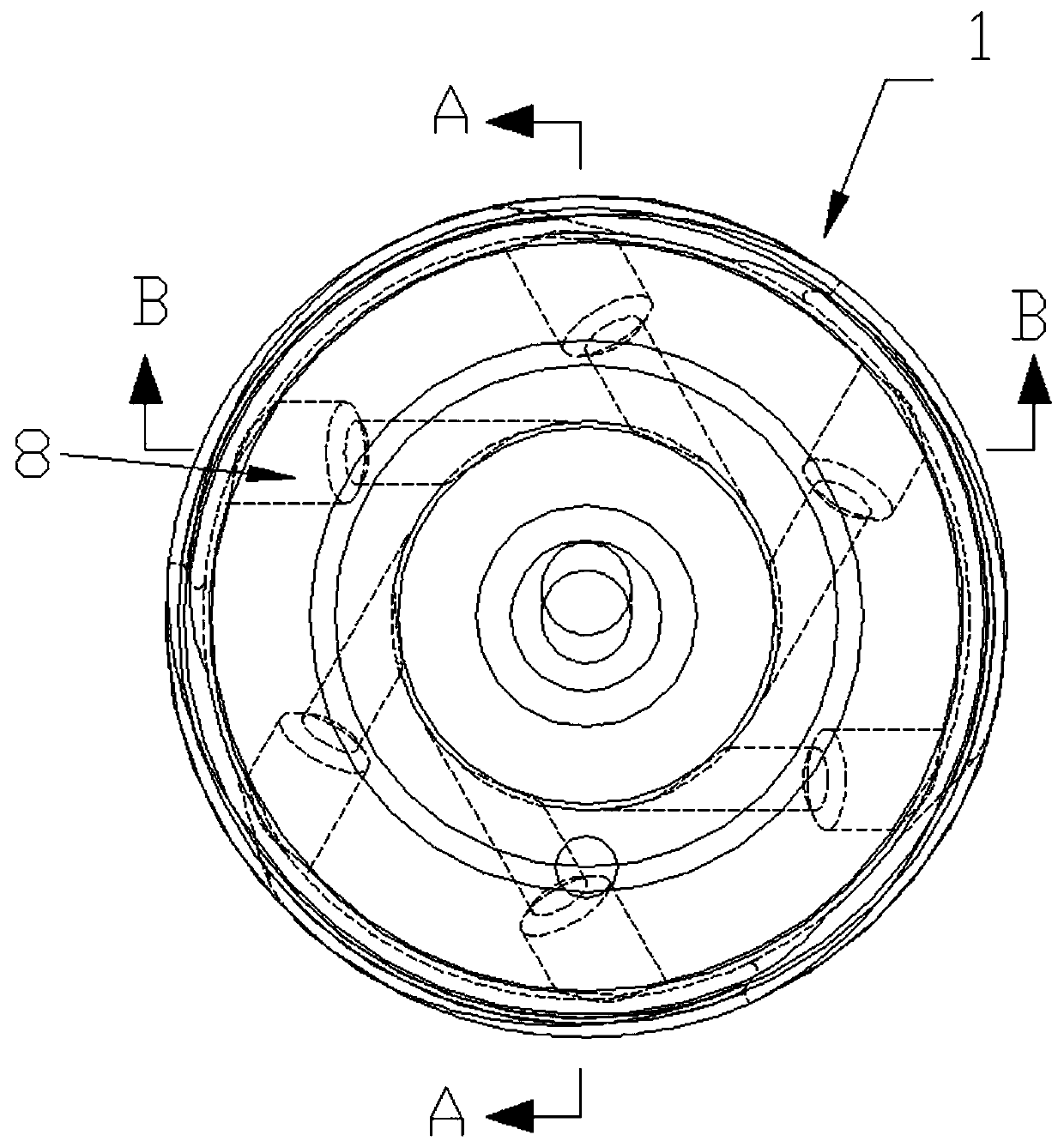

High-pressure pump for ceramic production

PendingCN109340122ANo pulse phenomenonIncrease boost effectSpecific fluid pumpsPump componentsImpellerEngineering

The invention discloses a high-pressure pump for ceramic production. The high-pressure pump includes a pump body, the pump body comprises a first feed port, a first cavity communicating with the firstfeed port, a second cavity communicating with the first cavity, a third cavity, a first discharge hole communicating with the third cavity, a crushing wheel arranged in the first cavity, impellers arranged in the second cavity and the third cavity correspondingly, a rotating shaft driving the crushing wheel and the impellers to rotate, and a feeding pipe communicating with the second cavity and the third cavity, and slurry enters from the first feed port, passes through the first cavity, the second cavity, the feeding pipe and the third cavity successively, and finally the slurry is discharged from the first discharge hole. According to the high-pressure pump for ceramic production, the pressurization effect of the high pressure-pump on the slurry and the transportation efficiency of theslurry are improved.

Owner:佛山市欣科科技有限公司

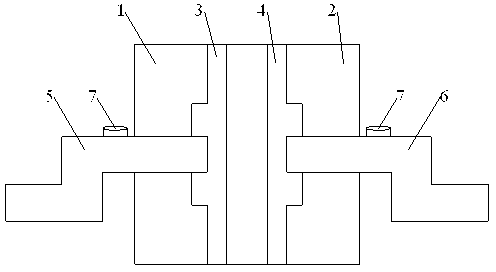

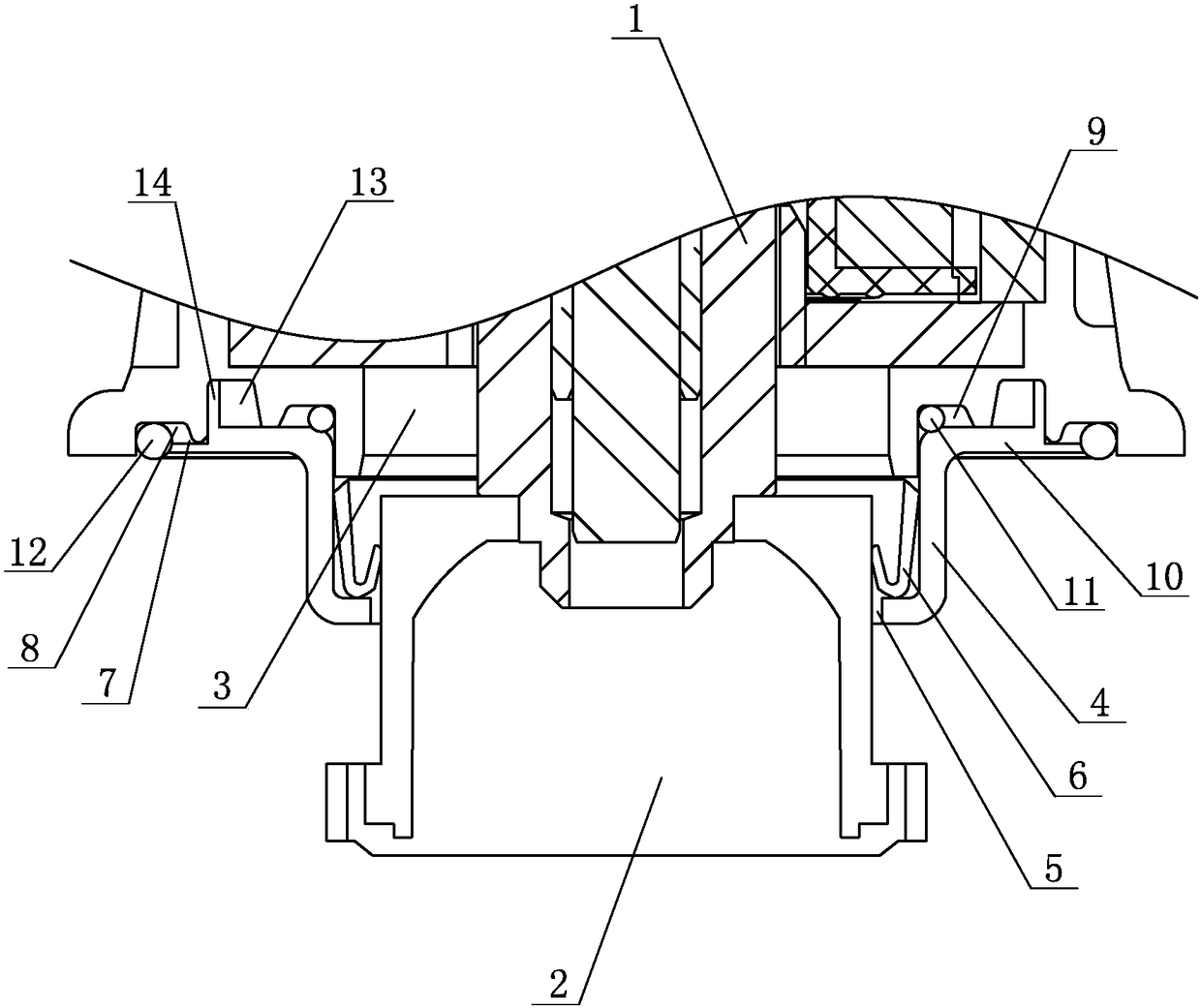

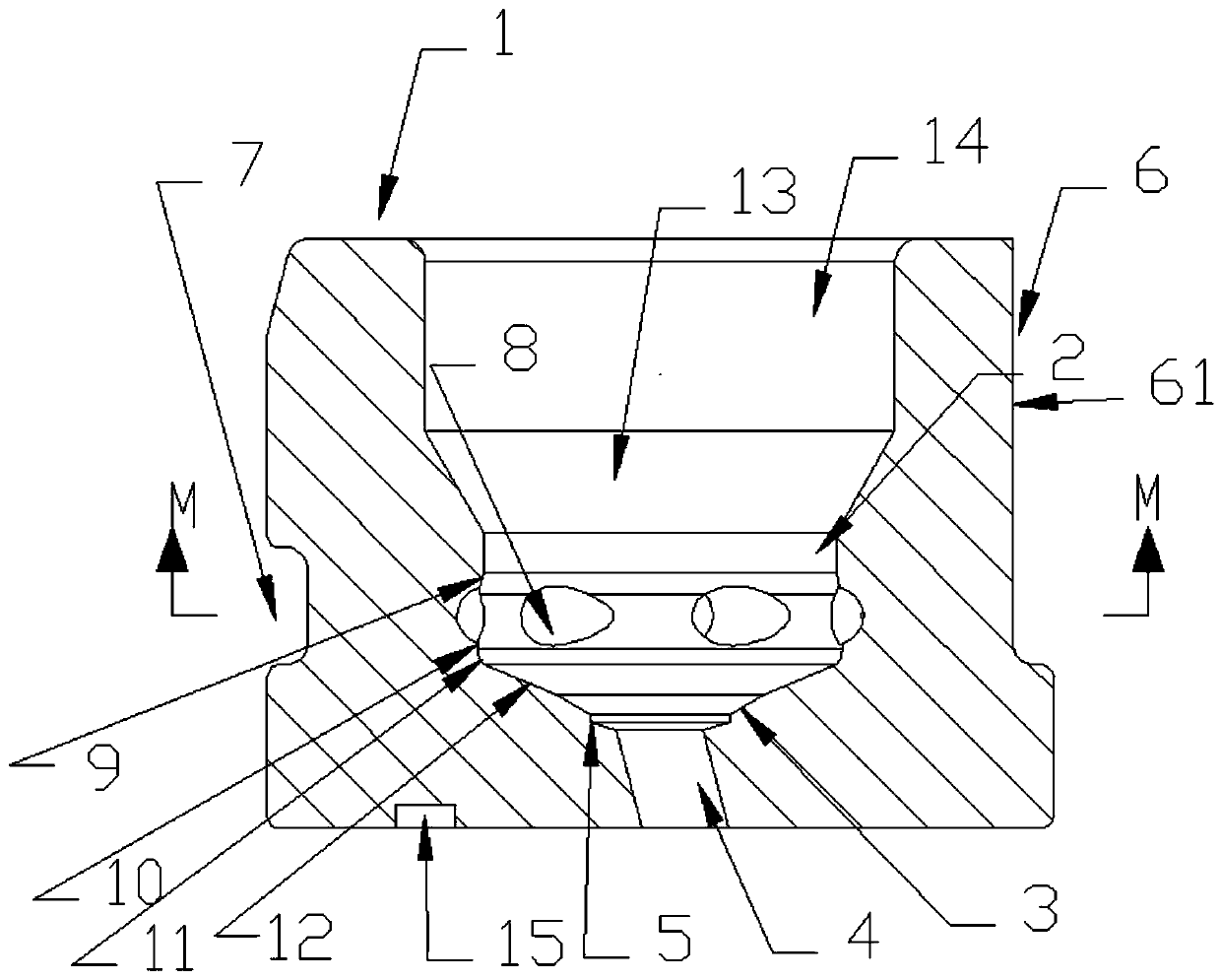

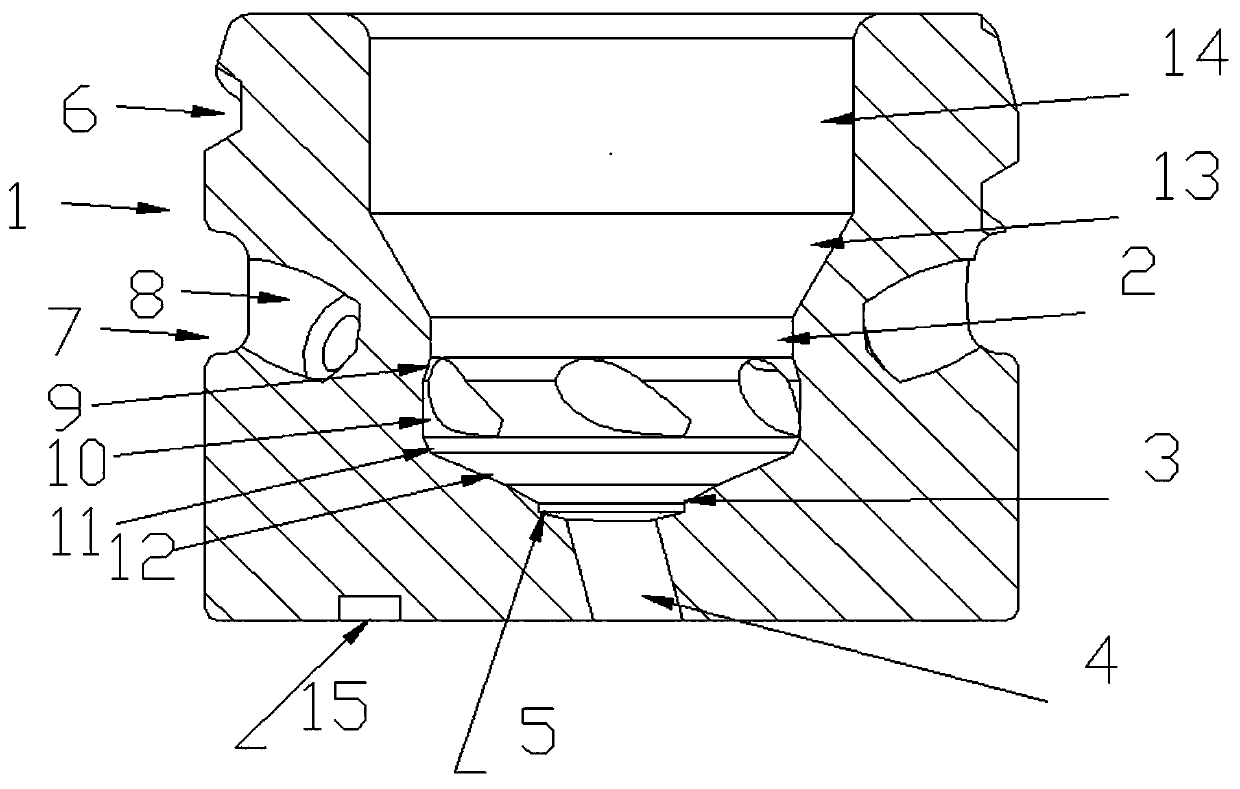

Rocking handle device of drawer-type frame body for breaker

InactiveCN103247484AGuaranteed boostGuaranteed cutProtective switch detailsEngineeringCircuit breaker

The invention discloses a rocking handle device of a drawer-type frame body for a breaker. The rocking handle device comprises a first framework and a second framework which are detachably connected, wherein a first baffle connected with the breaker is arranged in the first framework, a second baffle connected with the breaker is arranged in the second framework, a first rocking handle is connected to the first framework, a second rocking handle is connected to the second framework, the first rocking handle is movably connected with the first baffle, and the second rocking handle is movably connected with the second baffle. Through the above mode, the lifting and the lowering of the breaker can be ensured, so that the breaker is prevented from being damaged, and further a good protection effect can be realized on the breaker.

Owner:谈行

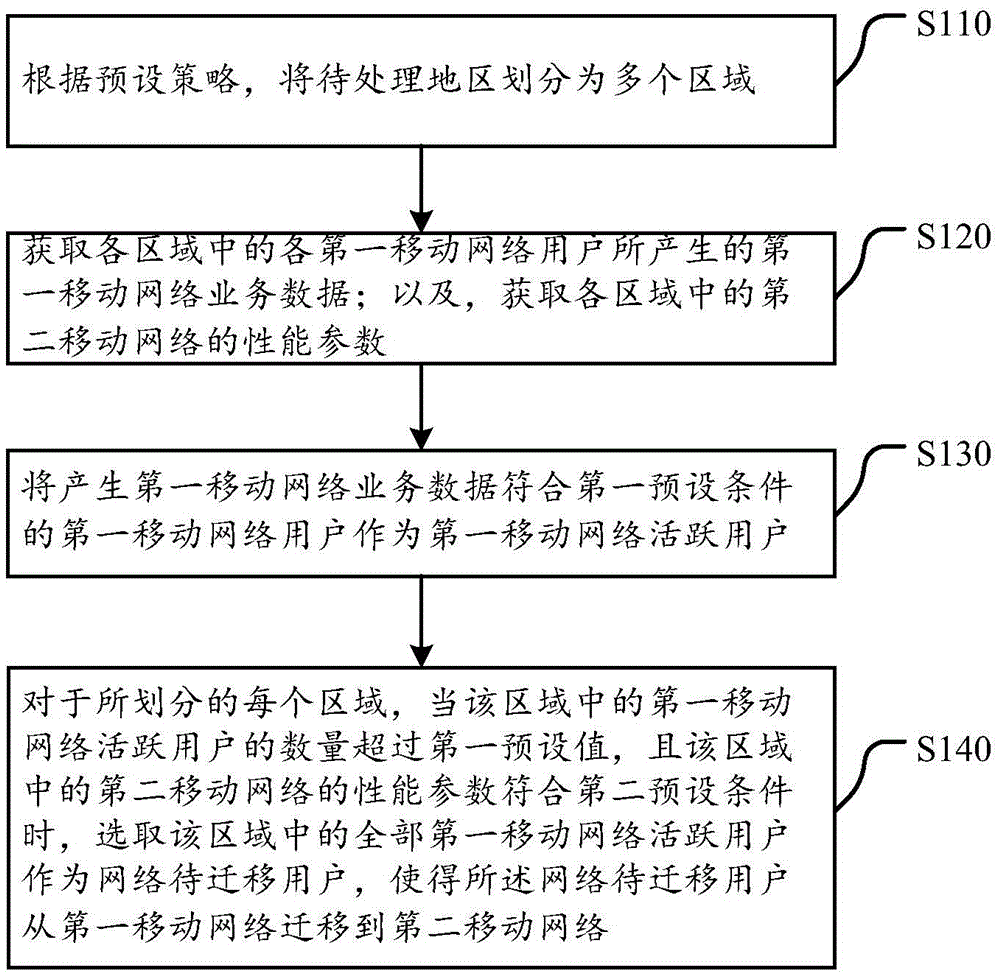

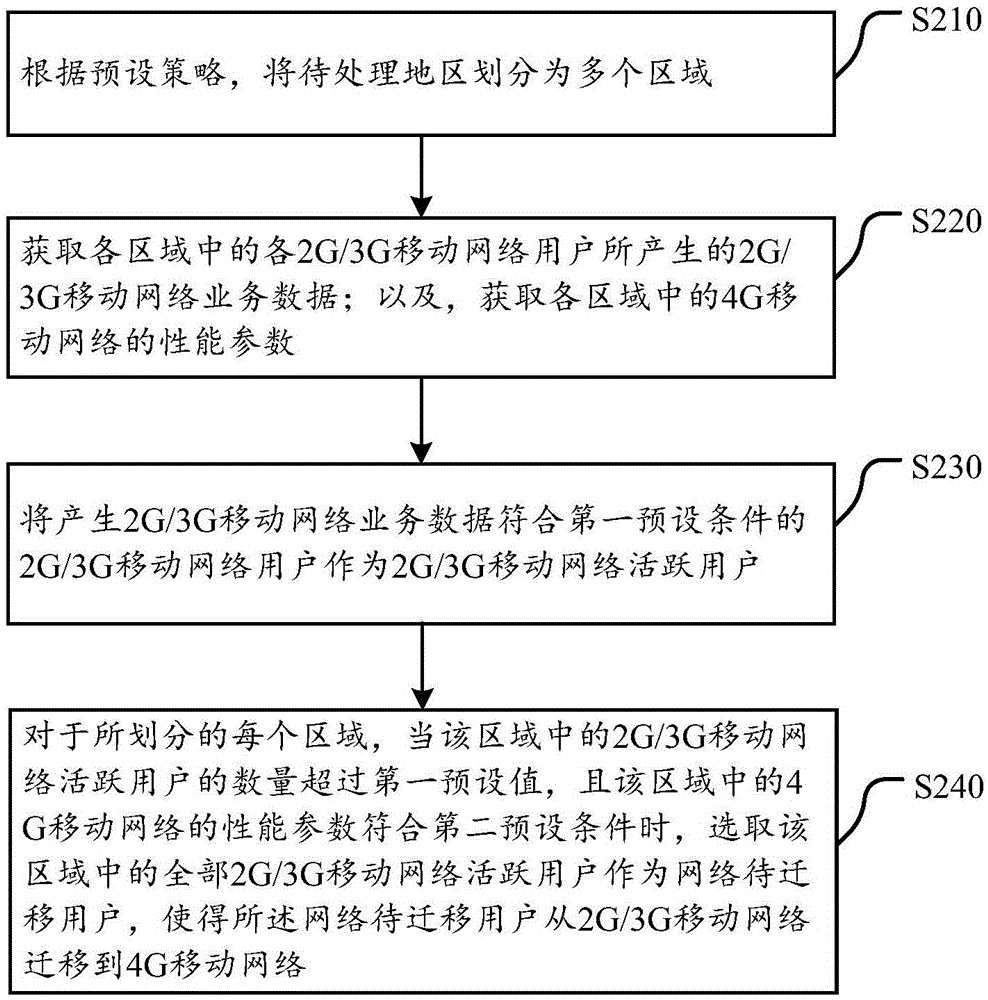

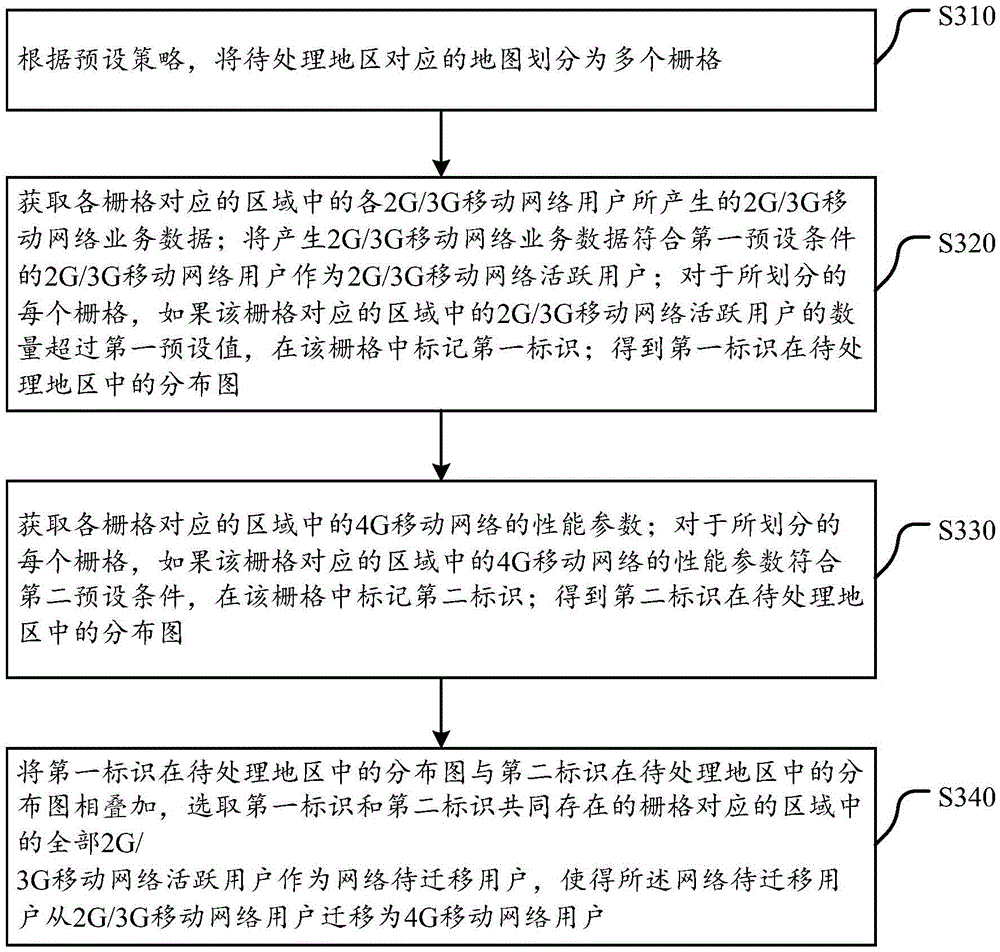

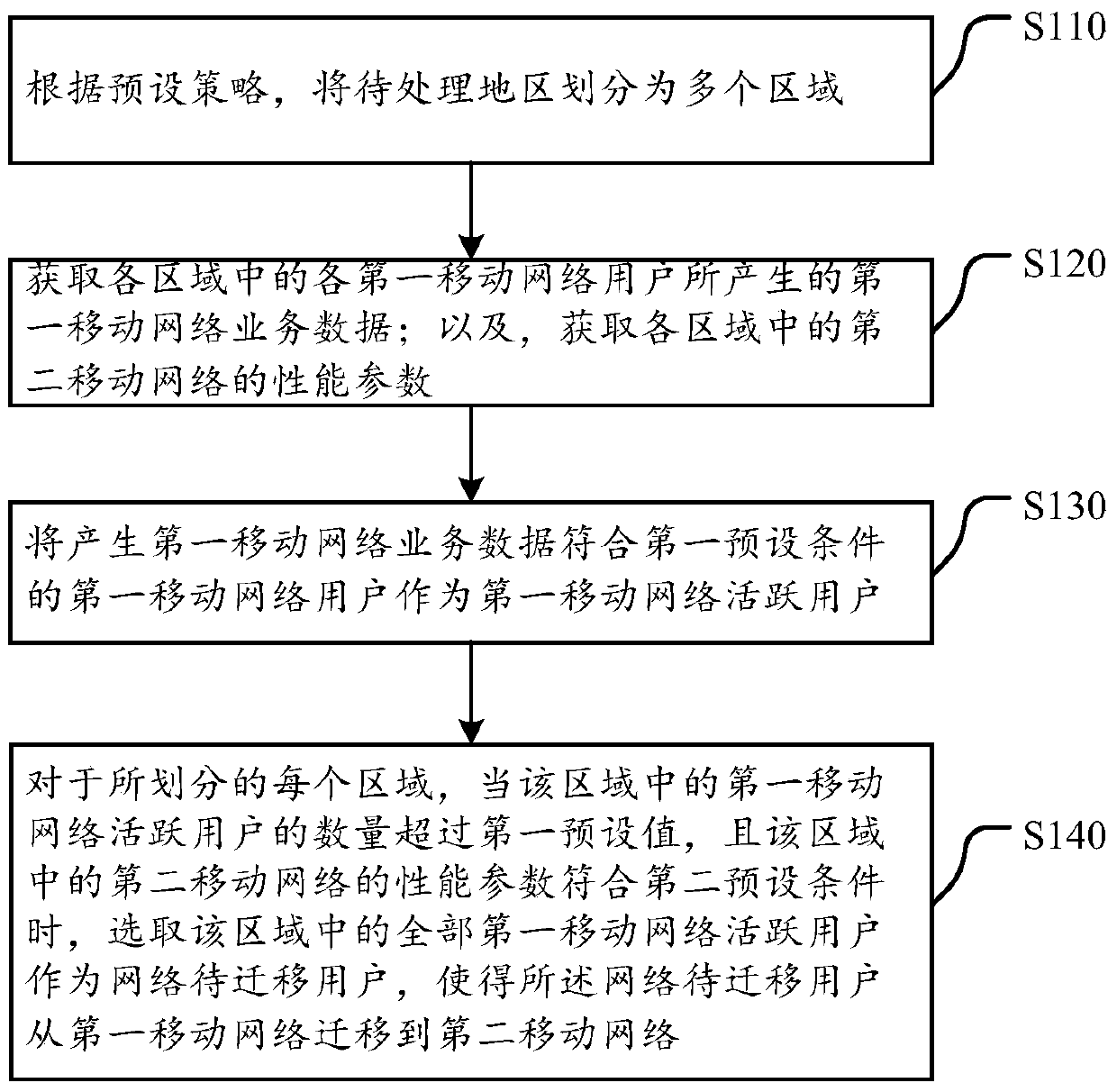

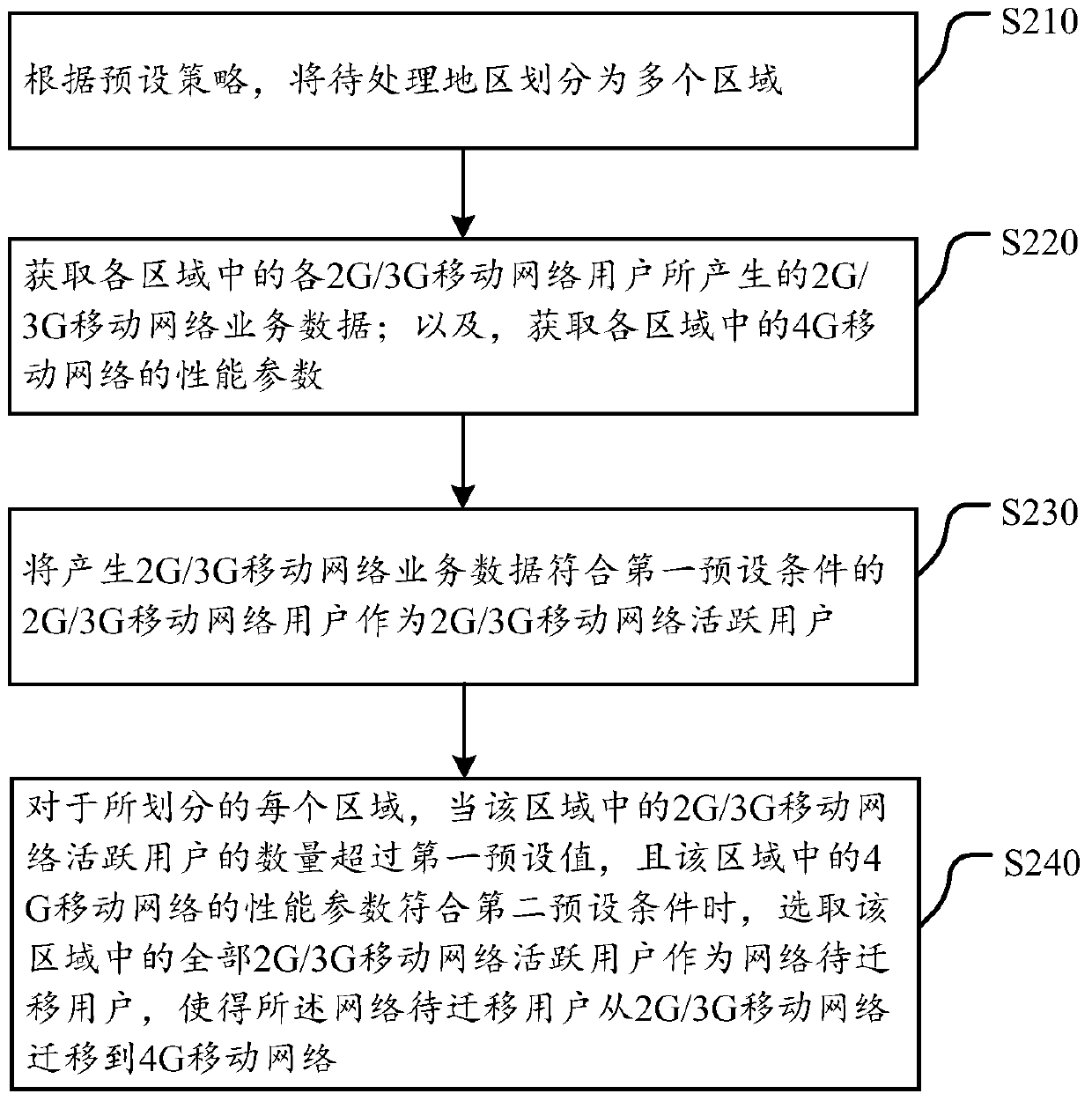

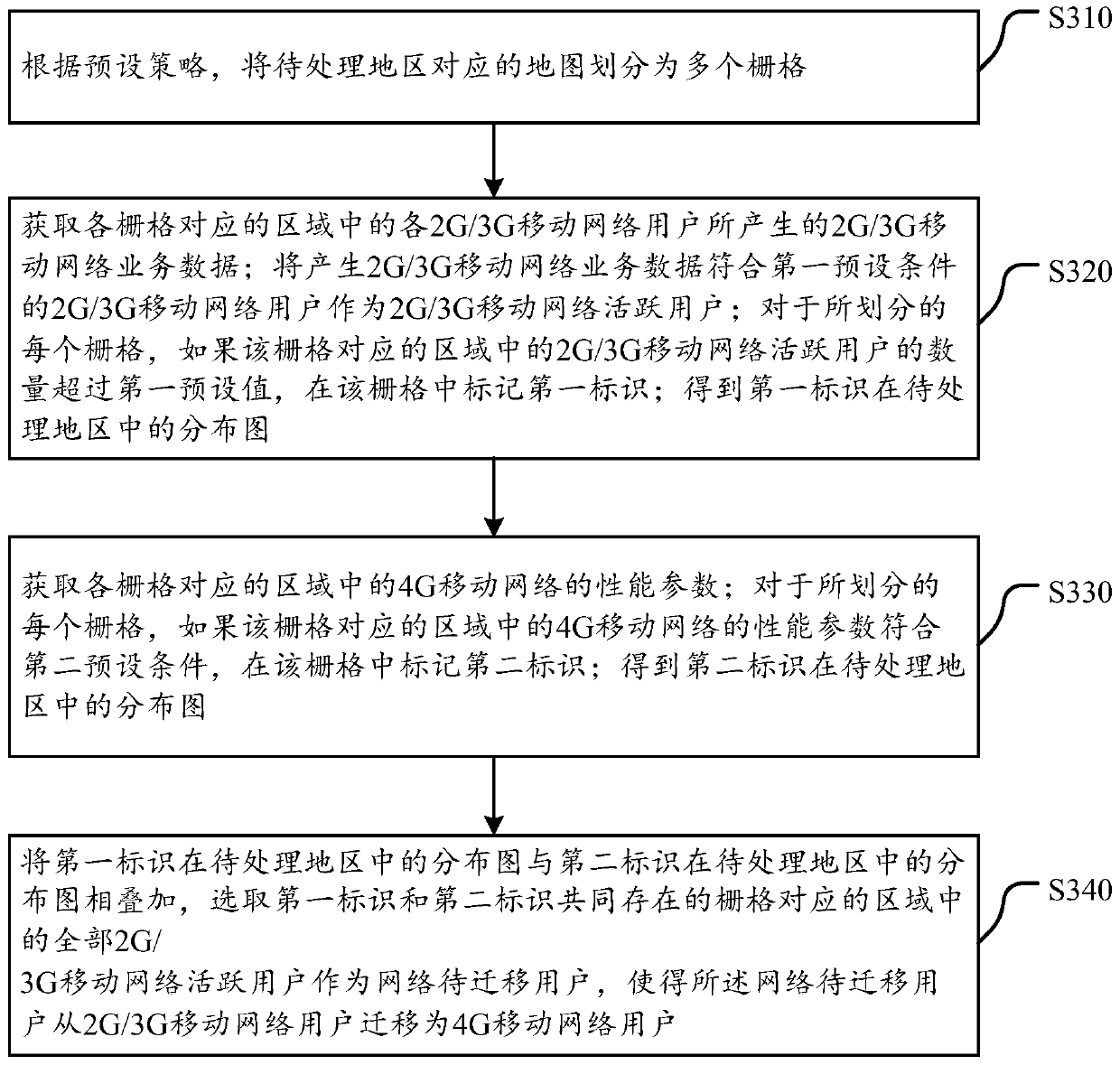

Method and device for selecting to-be-migrated network users

ActiveCN106686677AMeet the needs of useRefine selection granularityAssess restrictionGranularityProcess region

The invention discloses a method and device for selecting to-be-migrated network users. The method includes the steps that a to-be-processed region is divided into multiple areas according to a preset strategy; first mobile network service data generated by first mobile network users in each area is acquired; performance parameters of a second mobile network in each area are acquired; the first mobile network users with the generated first mobile network service data meeting a first preset condition are taken as first mobile network active users; for each area obtained after division, when the number of the first mobile network active users in the area exceeds a first preset value and the performance parameters of the second mobile network in the area meet a second preset condition, the first mobile network active users in the area are selected as to-be-migrated network users. According to the scheme, the selection granularity of network migration objects is greatly refined; all the migrated users can experience the advantages of the second mobile networks, and positive migration result feedback is formed.

Owner:北京神州泰岳智能数据技术有限公司

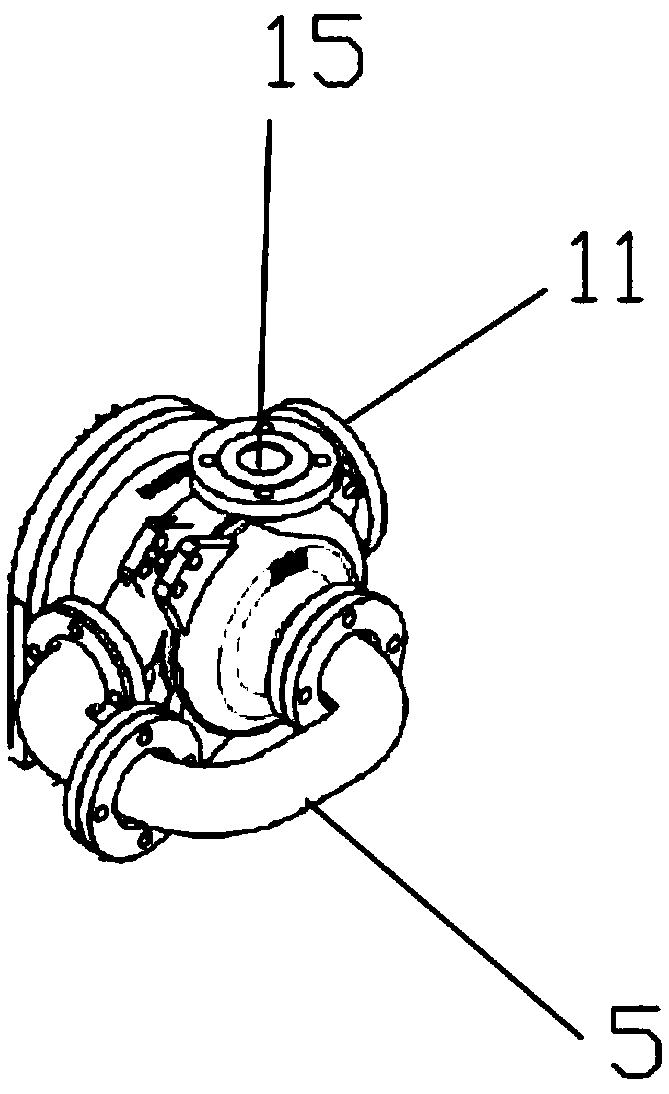

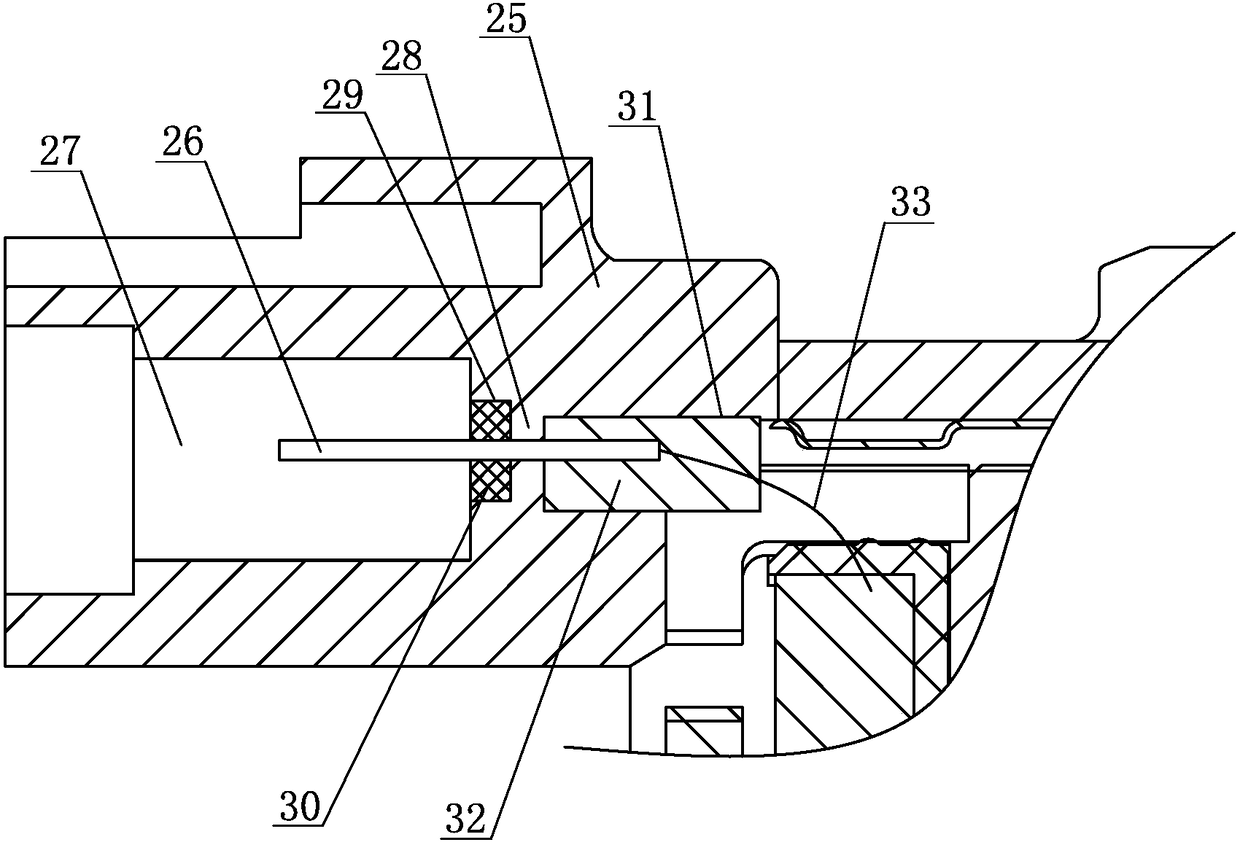

High-performance electric-control bypass valve for turbocharger

PendingCN108087109AEasy to installImprove sealingInternal combustion piston enginesEngine componentsTurbochargerEngineering

The invention discloses a high-performance electric-control bypass valve for a turbocharger. The high-performance electric-control bypass valve comprises a valve body and a valve body sealing member arranged at the bottom of the valve body. The bypass valve is characterized in that an outlet is arranged at the bottom of the valve body, the valve body sealing member is movably arranged in the outlet, a columnar cover plate is arranged on the outlet, multiple sealing rings are arranged at a joint of the columnar cover plate and the valve body for sealing, and a stainless steel guide column integrally formed with the valve body is arranged in the valve body. Sealing effect of the valve body is improved, service life of the valve body is prolonged, response time of the valve body is increased,turbocharging quality is ensured, and performance and power of an engine are guaranteed.

Owner:YK IND CO LTD

Power generation device for increasing water level through sea waves and method for generating power through device

InactiveCN110966133AAccelerate sinkingGood energy gathering effectWater-power plantsMachines/enginesSea wavesEnvironmental engineering

The invention discloses a power generation device for increasing a water level by using sea waves. A reservoir is included. The device is characterized in that a sea wave energy gathering device is arranged on at least one side of the reservoir; at least one water-turbine generator set installation cabin is arranged on the other side of the reservoir; a water inlet is arranged in a connection portion of the reservoir and the sea wave energy gathering device; and the water inlet is provided with a one-way valve, and the one-way valve is locked or opened through a locking device. Sinking or floating of the power generation device capable of increasing the water level through the sea waves can be achieved, and technical problems of construction, transportation and installation of the whole power generation device capable of increasing the water level through the sea waves are solved.

Owner:NINGBO ZHENHAI JIEDENG APPL TECH INST

Valve seat and transverse cut-in type nozzle

PendingCN110005831AGood effectReduce cloggingLiquid spraying apparatusLift valveSpray nozzleCavity wall

The invention discloses a valve seat. A vacuum groove is formed in the portion, close to a nozzle hole, of the cavity wall of a first sealing cavity. By forming the vacuum groove, when a high-speed fluid medium flows to the nozzle hole in a rotating manner along the cavity wall of the first sealing cavity, the high-speed fluid medium drives air in the vacuum groove to form a cyclone, and thereforethe negative pressure state is formed; and in the cyclone forming process, the air and the fluid medium enter the nozzle hole together and are finally sprayed out in the manner of mist. In the process, part of the fluid medium can be left on part of a reverse conical surface or a spherical cambered surface structure below a sphere after the sphere and the reverse conical surface or the sphericalcambered surface make contact and are sealed, and can be taken away by means of cyclone turbulence of the air in the vacuum groove, and therefore no fluid medium is left, and the situation that because the nozzle hole is blocked after impurities are hardened and dried, the atomization effect is influenced is then reduced.

Owner:JIANGSU BATON TECH CO LTD

Delayed power supply circuit, power supply delay method and boosting system

The embodiment of the invention provides a time-delay power supply circuit, a power supply time delay method and a boost system and relates to the field of electronics. By the embodiment of the invention, a boost chip without an enabling pin can be in a working state after a boost period of input power voltage is finished, and a boost effect of the boost chip is ensured. The time-delay power supply circuit comprises a control unit and a time-delay power supply unit, wherein the control unit comprises a first control port, and is connected with the time-delay power supply unit through the first control port and used for controlling the switch-on and switch-off of the time-delay power supply unit; the time-delay power supply unit comprises a second control port, an output port and a power input port; the second control port is connected with the first control port; the power input port is connected with a power supply; and the output port is connected with the input end of the boost chip and used for outputting the stabilized voltage of the power supply to the boost chip after the boost period of the power voltage is finished and a switch-on signal of the control unit is received. The embodiment of the invention is applicable to power supply of the boost chip.

Owner:BOE TECH GRP CO LTD +1

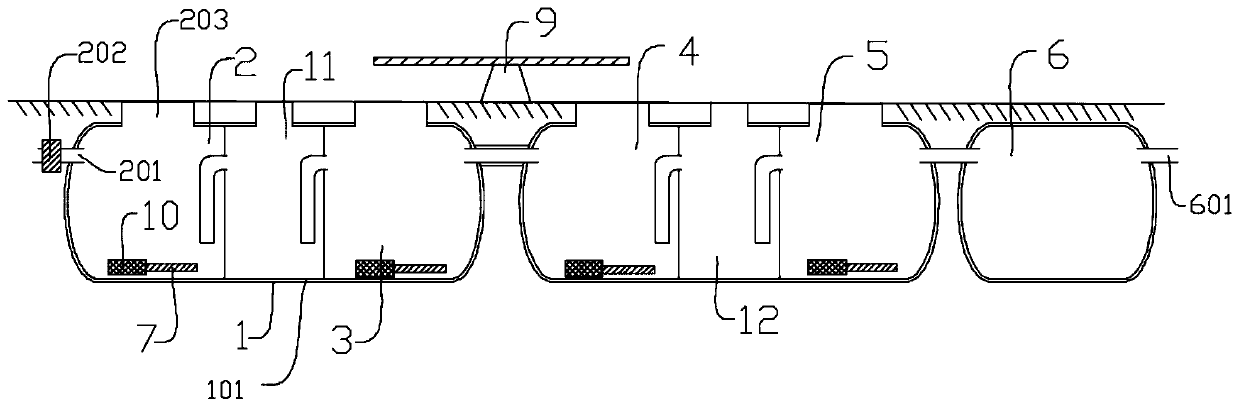

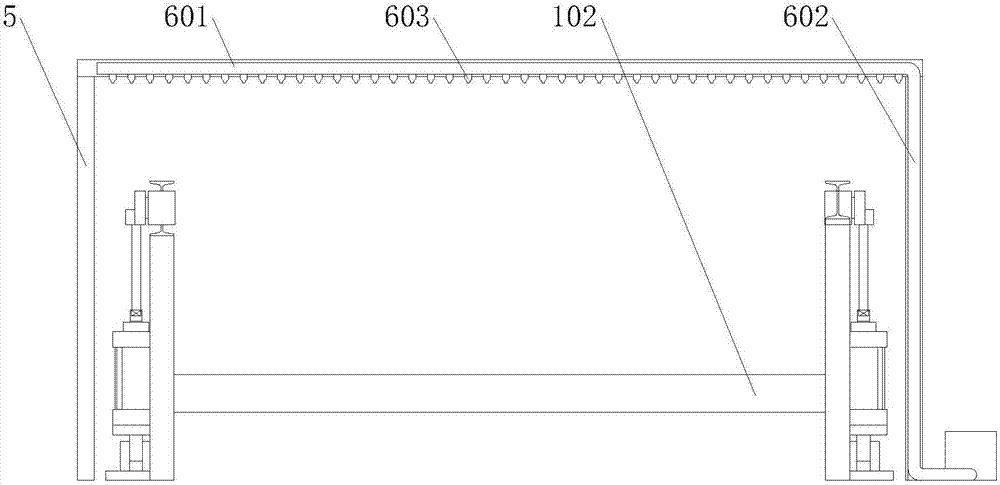

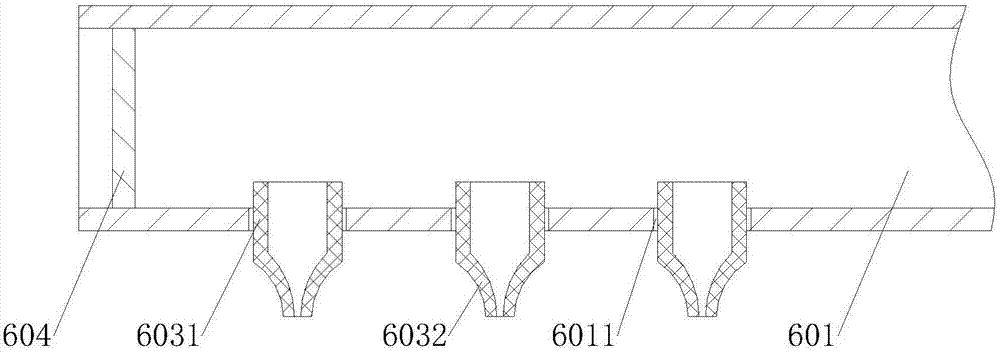

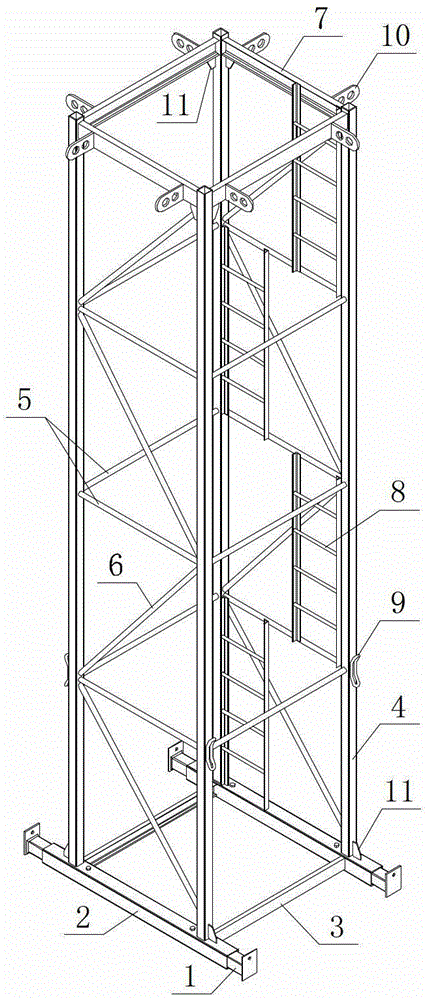

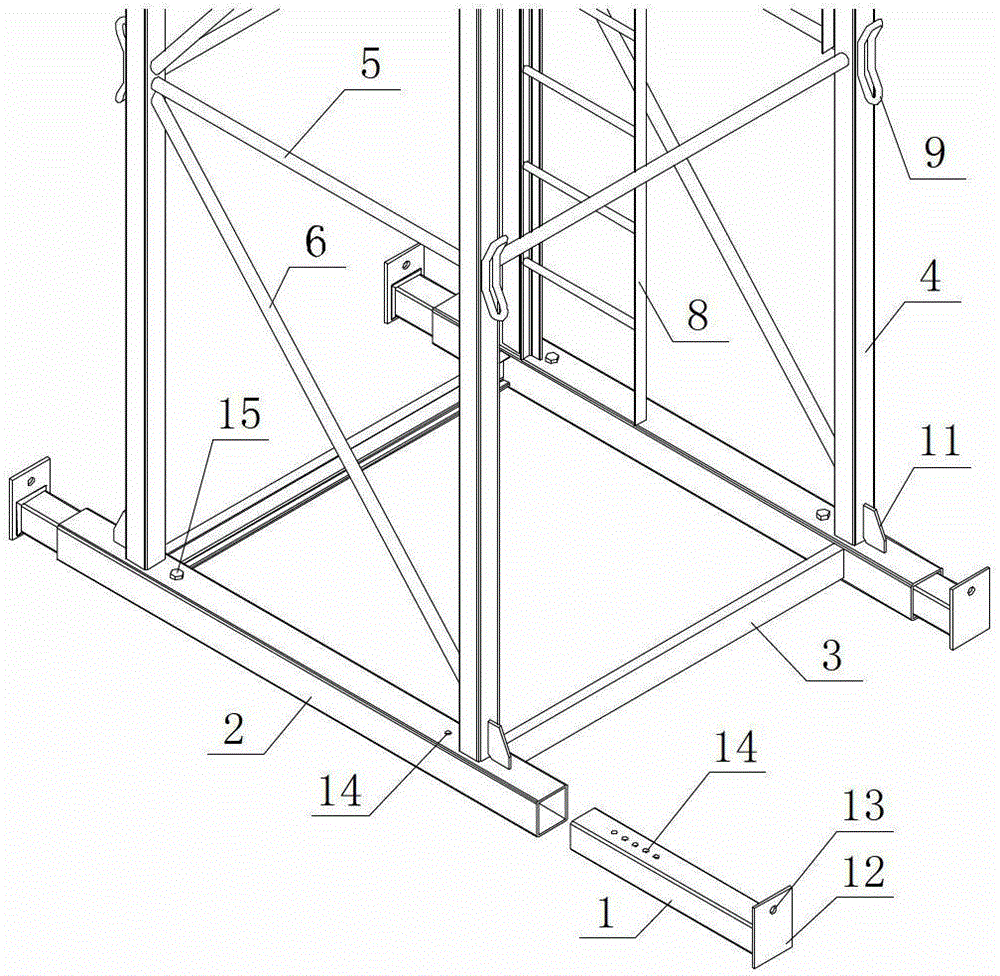

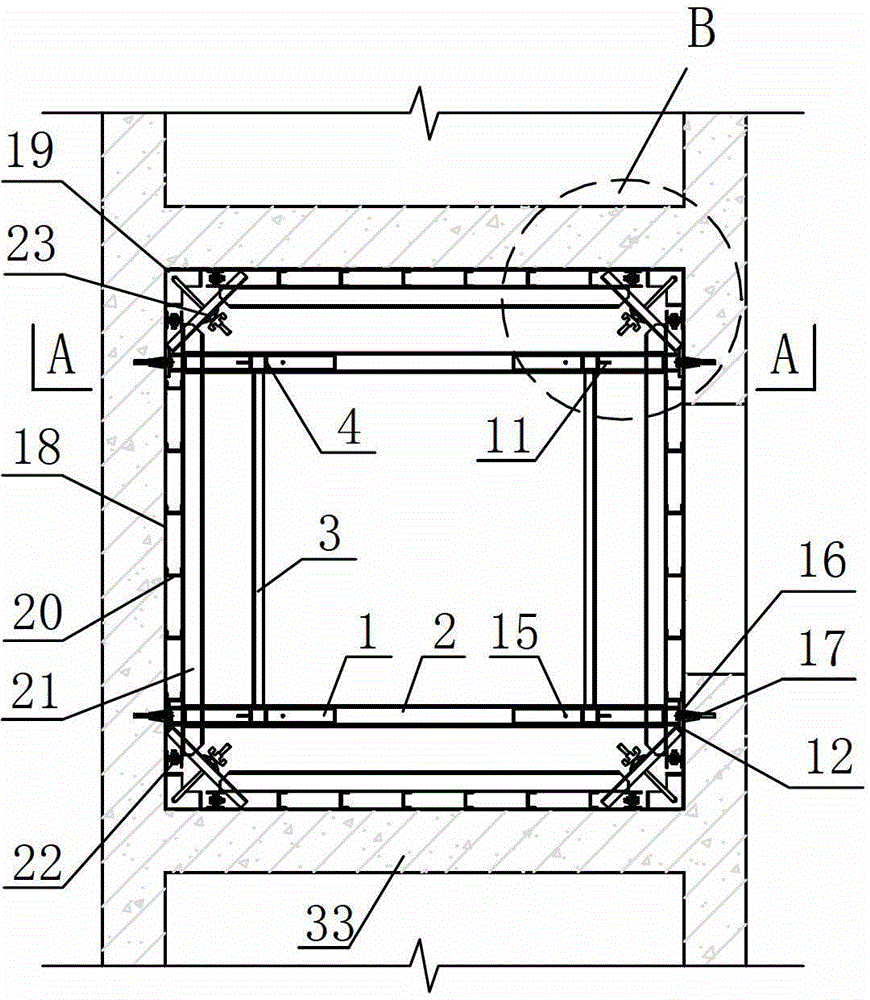

System for lifting elevator shaft mold and construction method for cast-in-place wall of elevator shaft

InactiveCN103015706BSimple structureChange sizeForms/shuttering/falseworksBuilding material handlingVertical edgeEngineering

A system for lifting an elevator shaft mold comprises a lifting frame, a combined shaft mold and a lifting device, wherein the lifting frame is a frame type operation platform which is formed by a base bearing beam, a main beam, a sub beam, an upright, a middle layer beam, a diagonal bracing, a top layer beam and a climbing ladder; through a reserved hole in a bearing beam end part connecting plate, the lifting frame is fixedly connected to an elevator shaft wall by using bearing high-strength bolts and embedded high-strength nuts which are formed on the elevator shaft wall; the combined shaft mold comprises a big steel template and an internal corner mold; through a side end vertical edge channel steel, the big steel template and the internal corner mold are fixed by using assembling bolts and reinforced by internal corner mold hook bolts to form an integral combined shaft mold; through a reserved hole in the lower part of the big steel template, the combined shaft mold is fixed on the elevator shaft wall by using a supporting lug bolt and embedded nuts which are formed on the wall; and the lifting device comprises lifting hoists and inverted hooks. During construction, the lifting hoists are mounted with the big steel template and the lifting frame as a supporting point of one another, so as to lift the lifting frame and the big steel template in sequence; and the lifting frame and the big steel template are lifted when every layer is constructed. The system for lifting the elevator shaft mold, provided by the invention, can be integrally assembled and disassembled and is convenient in construction.

Owner:广西建工第五建筑工程集团有限公司

A valve seat and a spiral oblique entry nozzle

ActiveCN109812364BReduce cloggingAffect the atomization effectFuel injection apparatusMachines/enginesCycloneLiquid medium

The invention discloses a valve seat. A vacuum groove is formed on the wall of the first sealed cavity close to the nozzle hole. By setting the vacuum groove, the high-speed fluid medium rotates along the wall of the first sealed cavity and flows to the When the nozzle hole is described, the high-speed fluid medium drives the air in the vacuum tank to form a cyclone, thereby forming a negative pressure state, and in the process of forming the cyclone, the air enters the nozzle hole together with the fluid medium, and finally forms a mist spray. During this process, the cyclone disturbance of the air in the vacuum tank can take away the remaining part of the fluid medium on the part of the inverted cone surface or the spherical arc surface structure under the sphere after the sphere contacts and seals the inverted cone surface or the spherical arc surface structure, In this way, the residual fluid medium is avoided, and the impurities are hardened and dried to block the nozzle hole and affect the atomization effect.

Owner:常州江苏大学工程技术研究院 +1

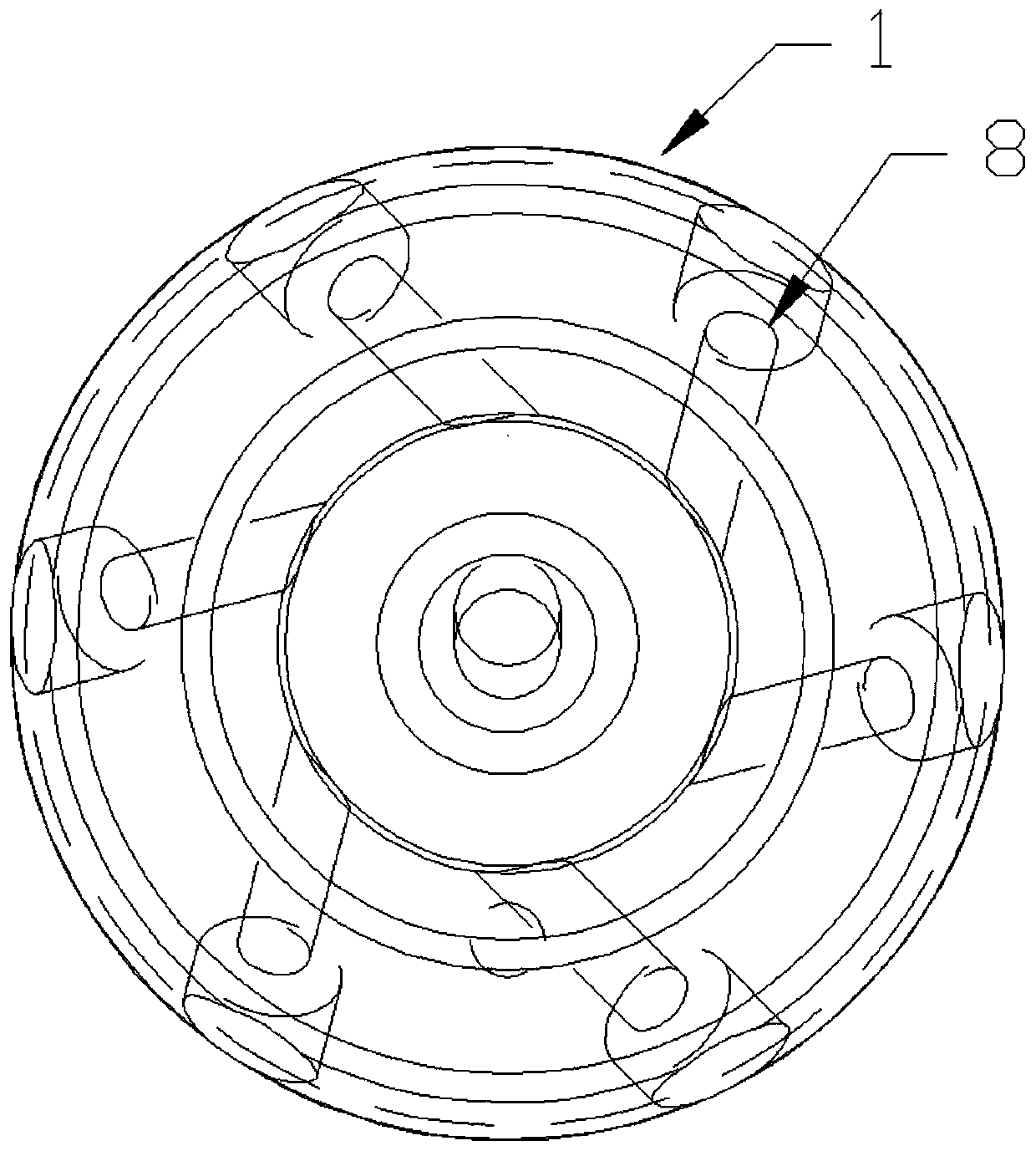

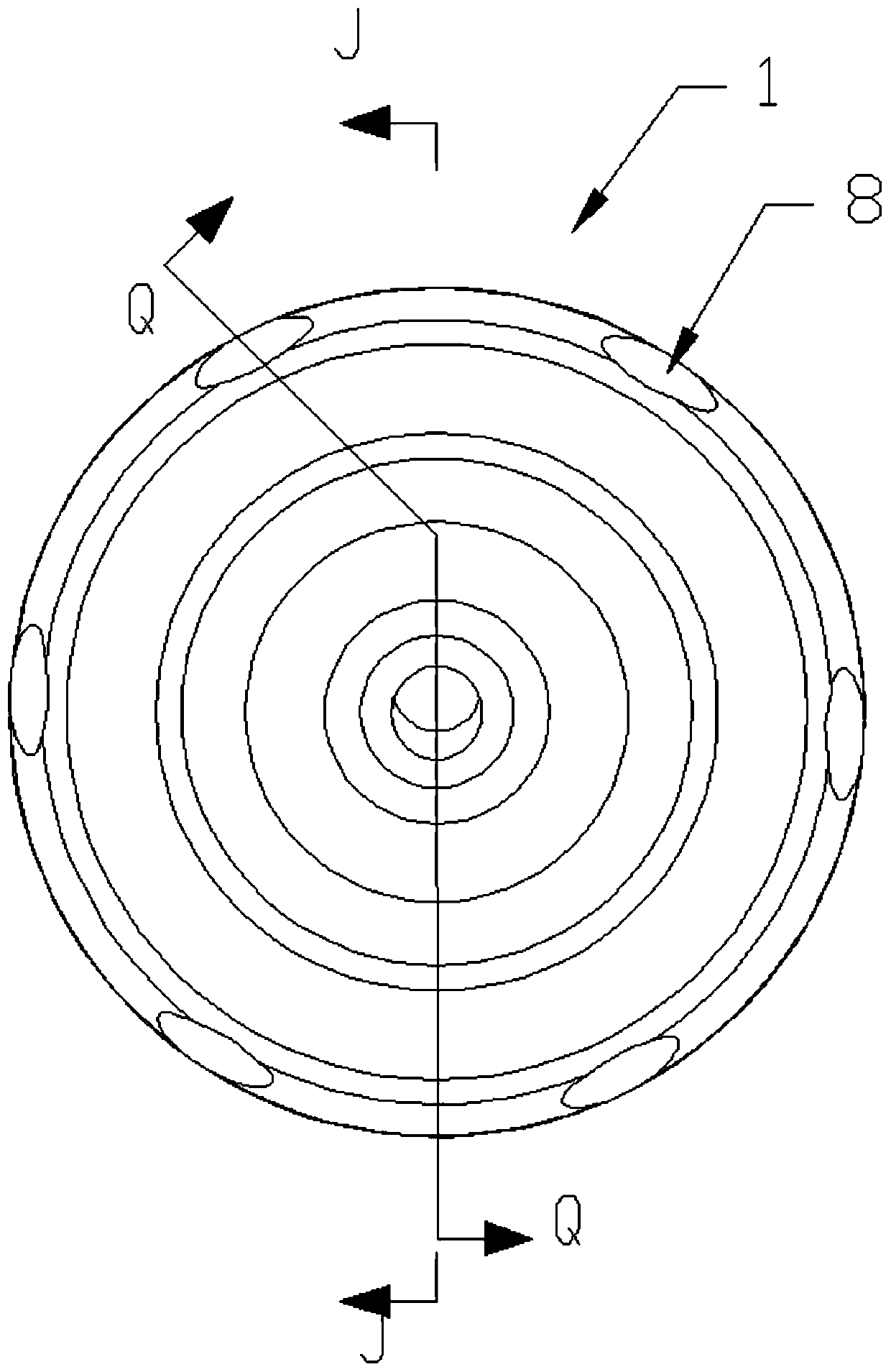

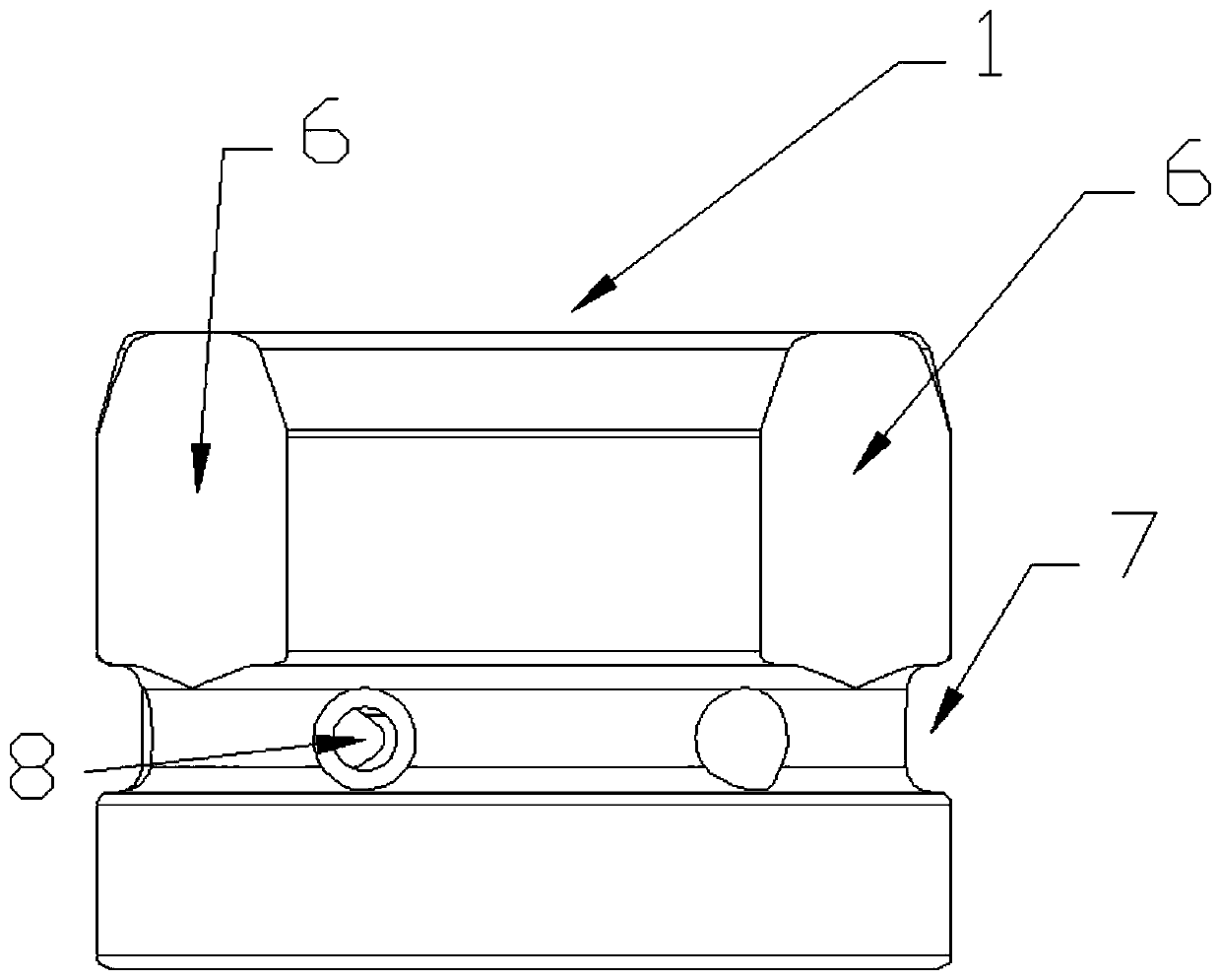

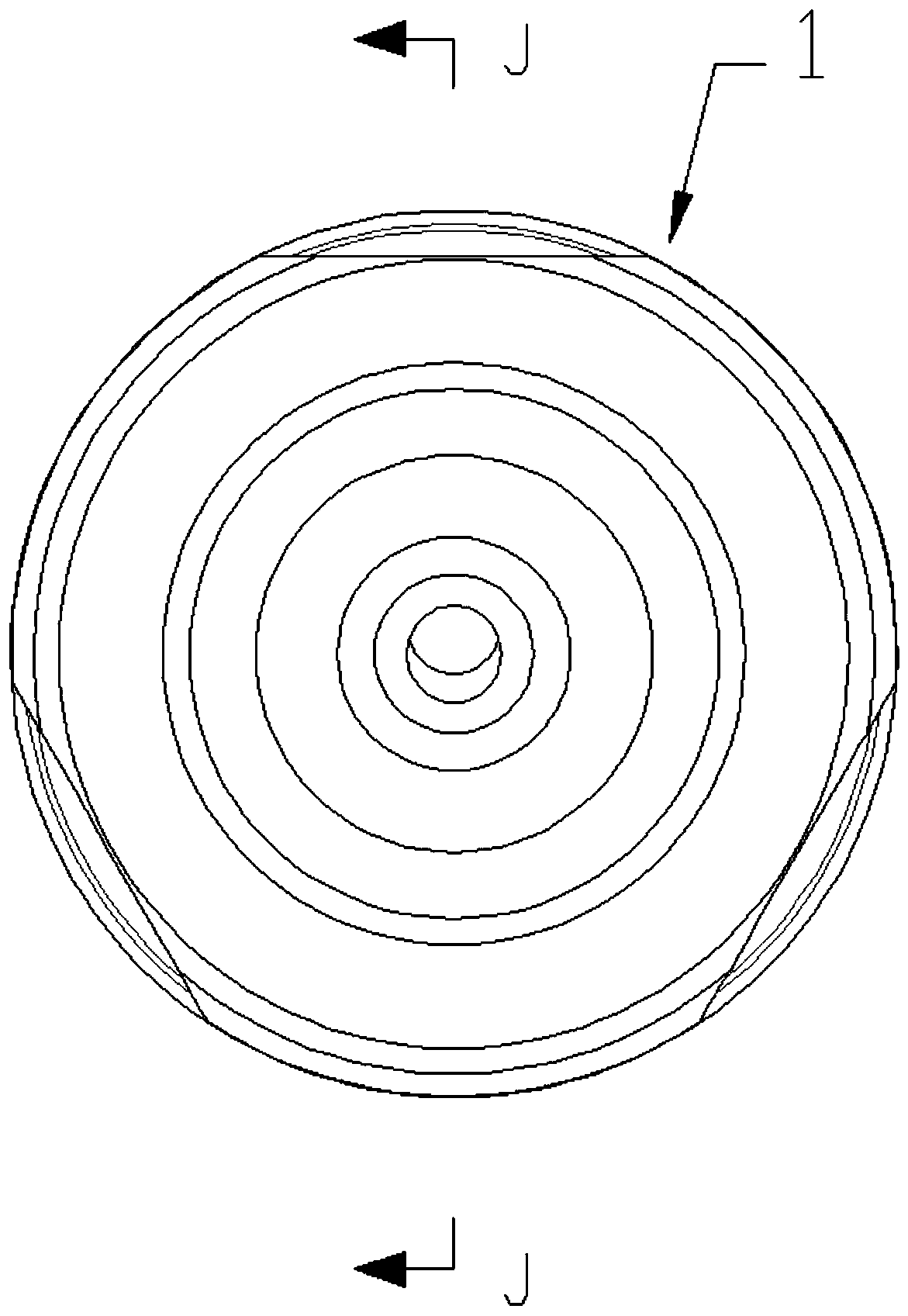

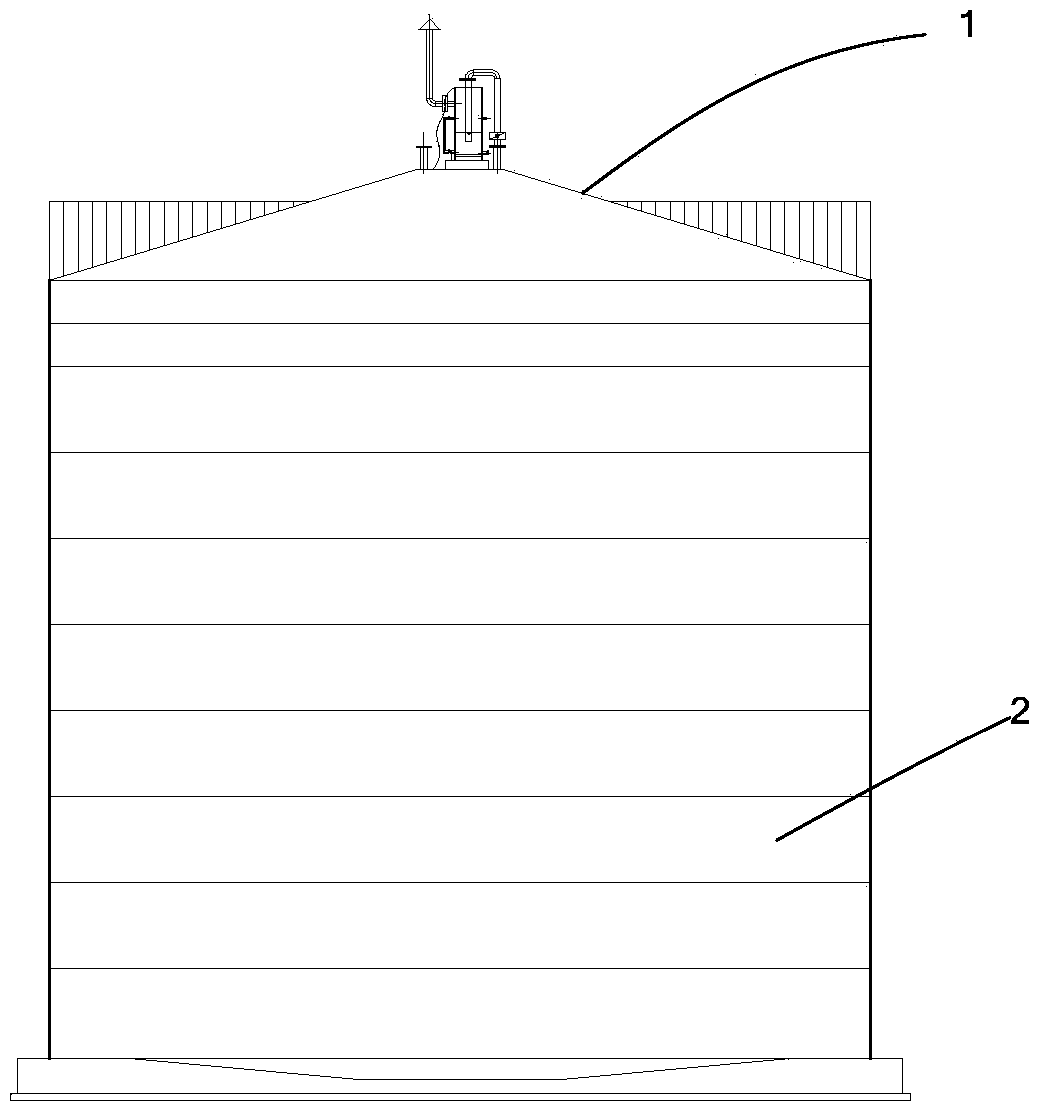

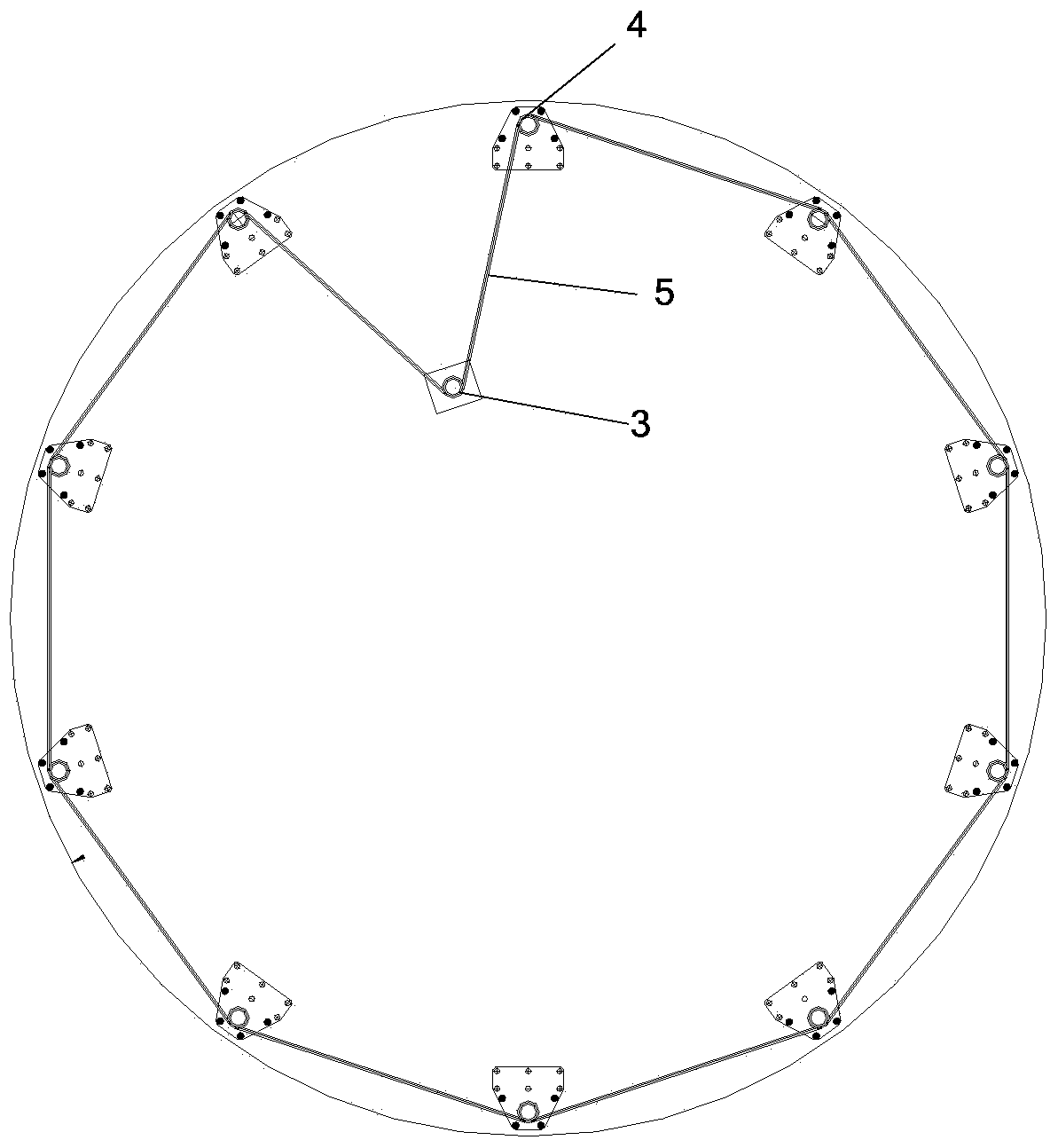

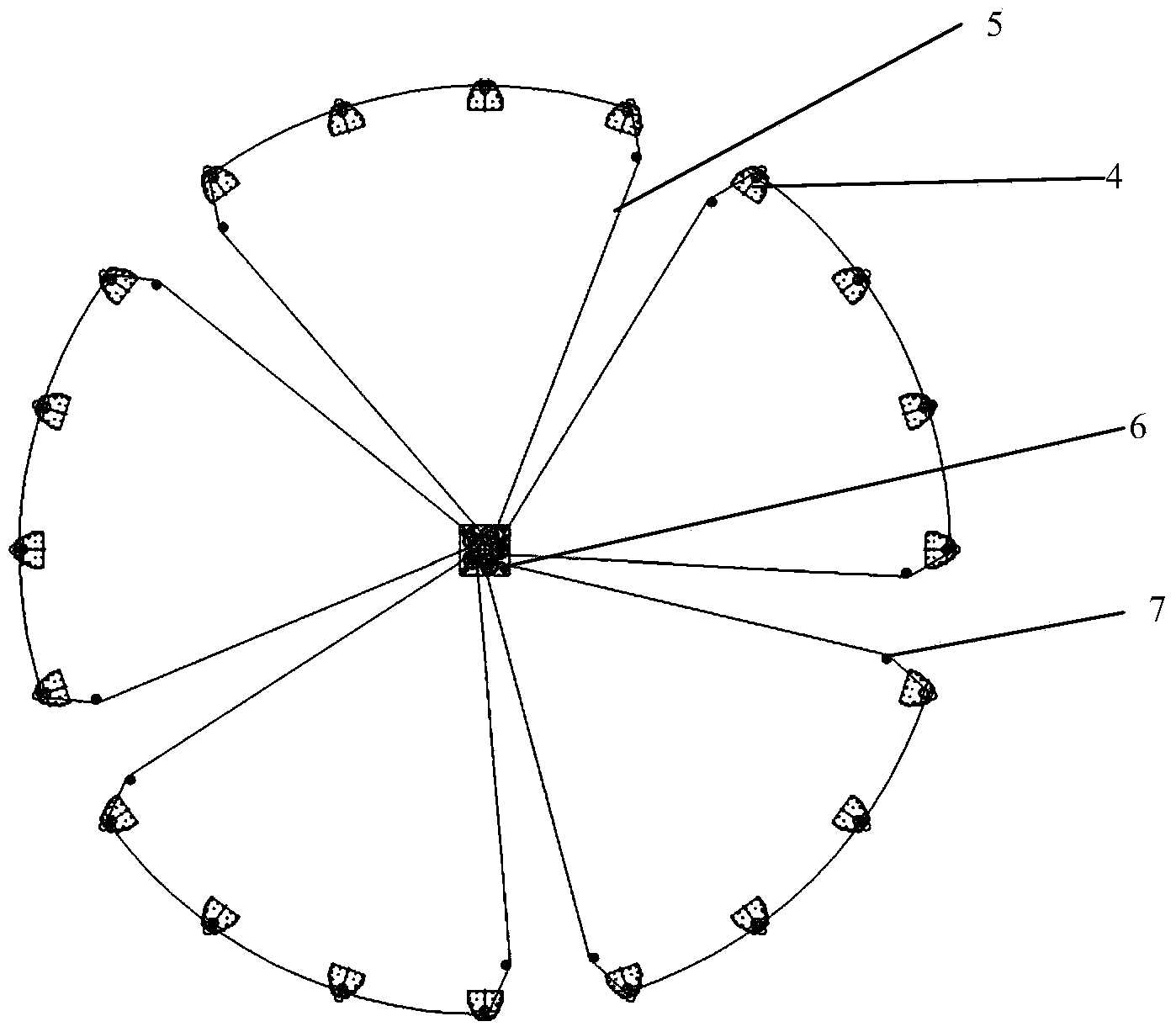

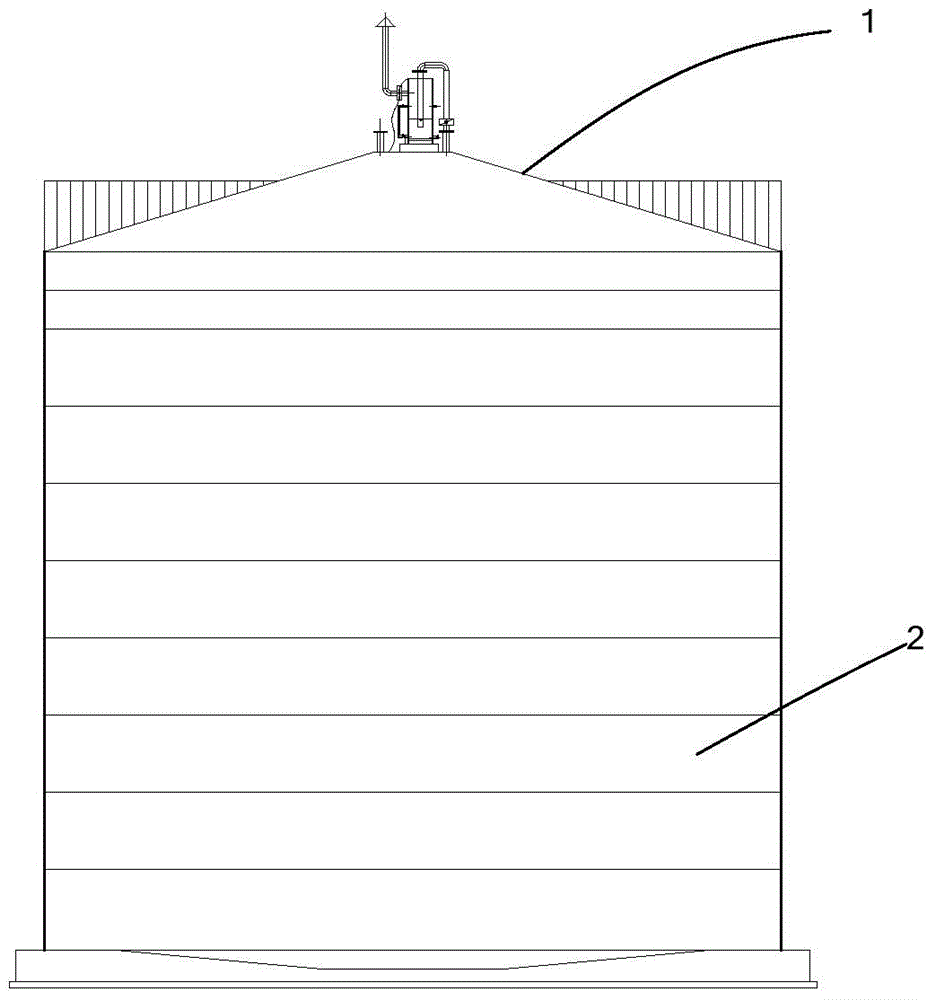

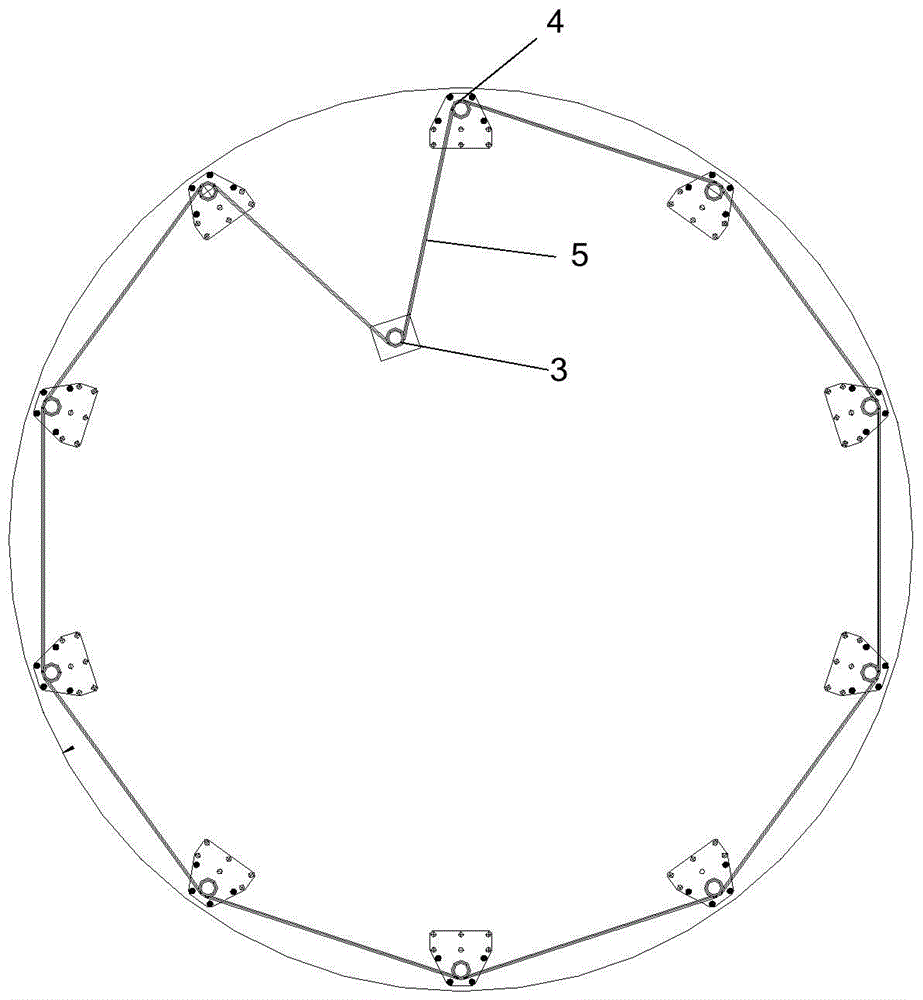

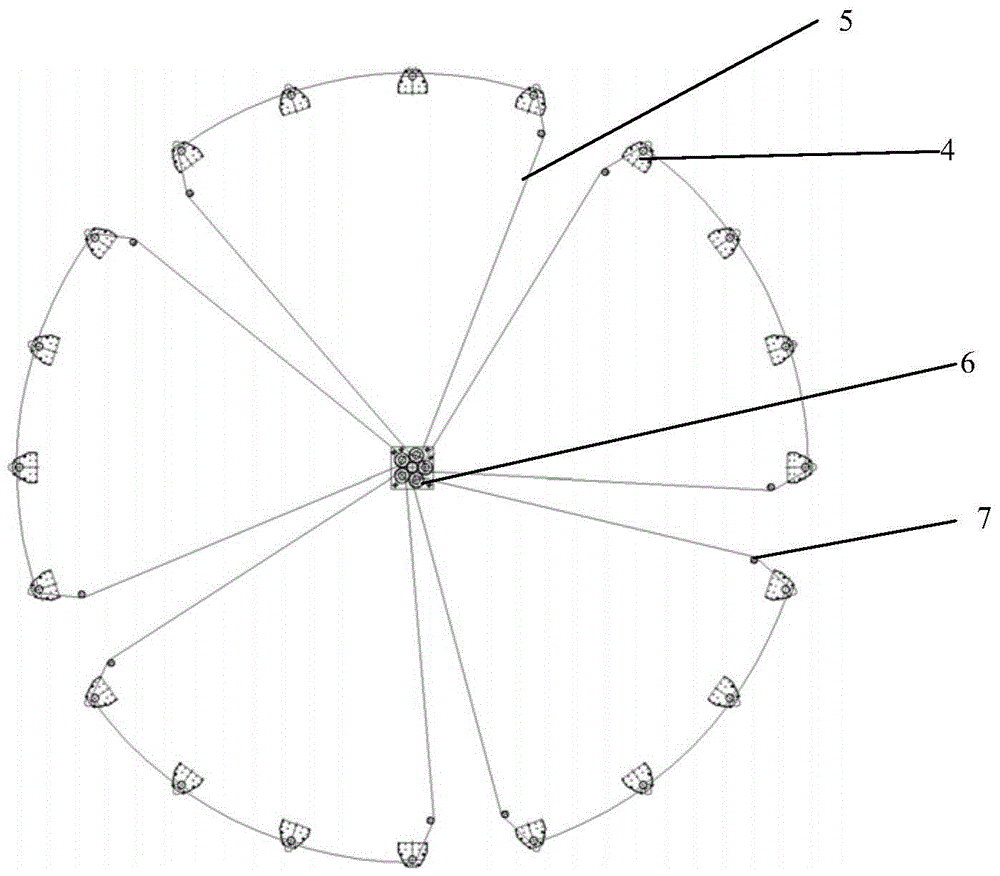

Multiple-gear-train lifting driving system

The invention relates to the field of manufacture of methane tanks, in particular to a multiple-gear-train lifting driving system which comprises a speed reducer, a gear transmission mechanism and a plurality of chain wheels. The speed reducer drives the plurality of chain wheels through the gear transmission mechanism, and each of the chain wheels is connected with one or more lifting mechanisms through a chain correspondingly. According to the multiple-gear-train lifting driving system, the gear transmission mechanism drives a plurality of chains to drive the lifting mechanisms, the plurality of chains are utilized, lengths of the chains are shortened, accumulation errors of the chains are greatly reduced, the errors are controlled within a permissible range, synchronous lifting of assembly plates around large and middle methane tanks is ensured, labor cost is reduced, and production efficiency is ensured.

Owner:北京科创环能装备技术有限公司

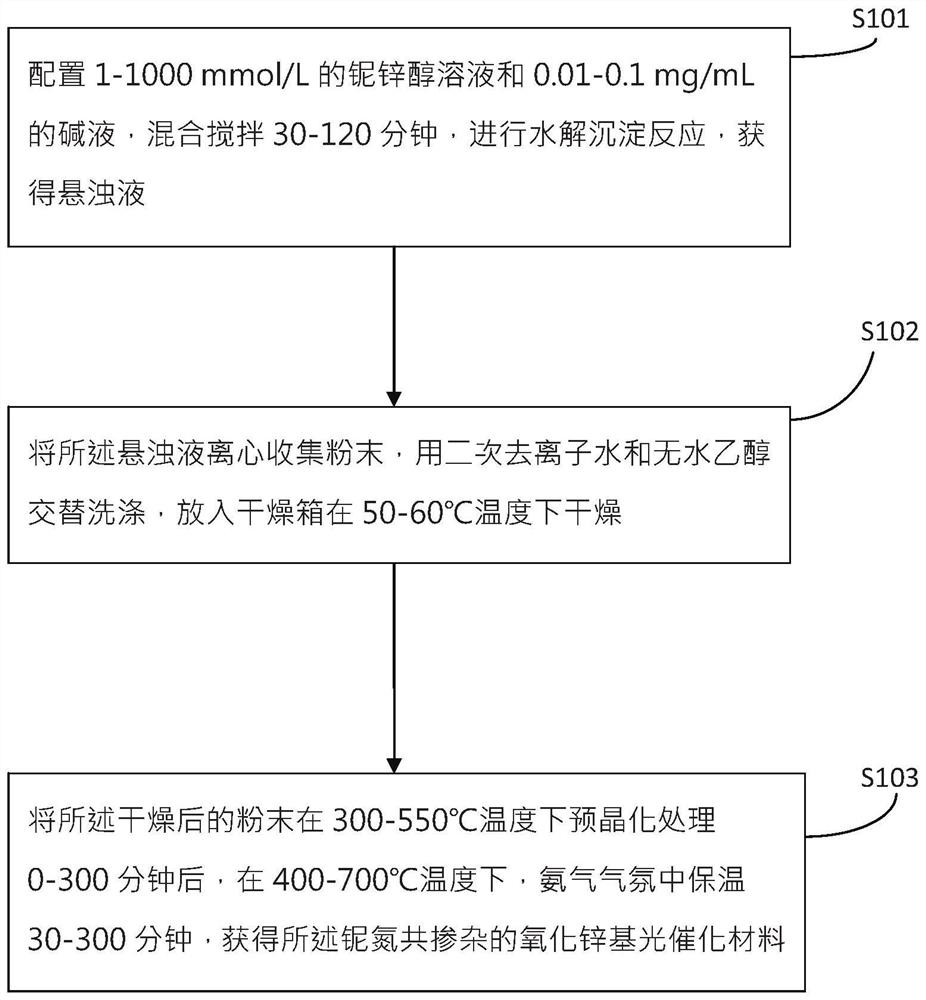

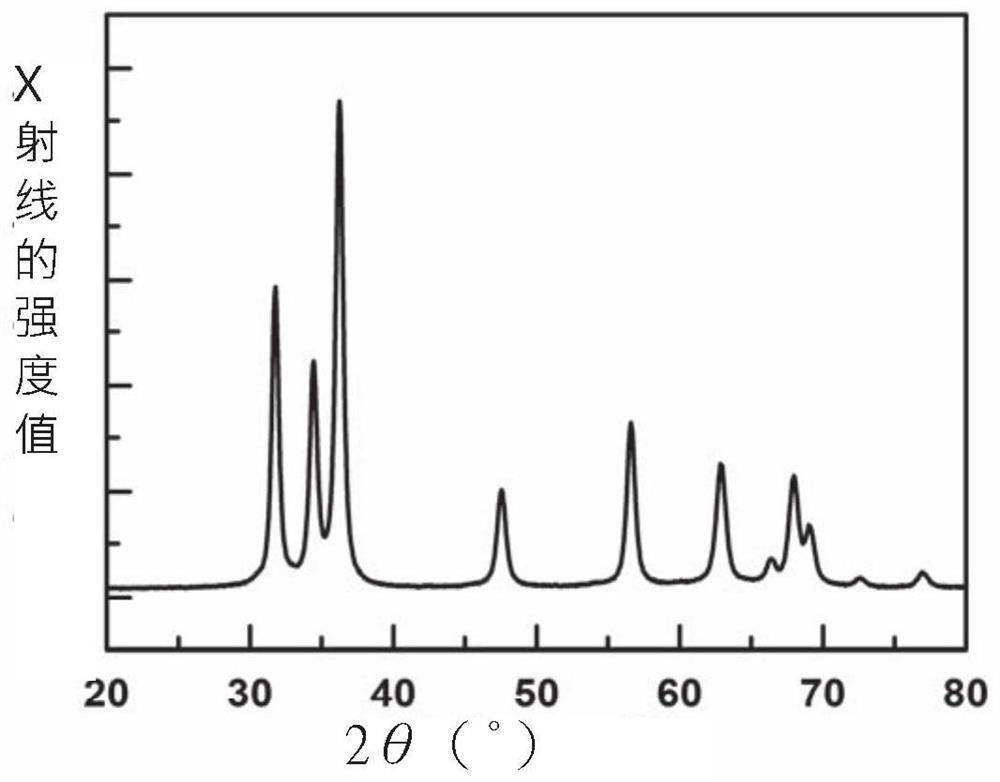

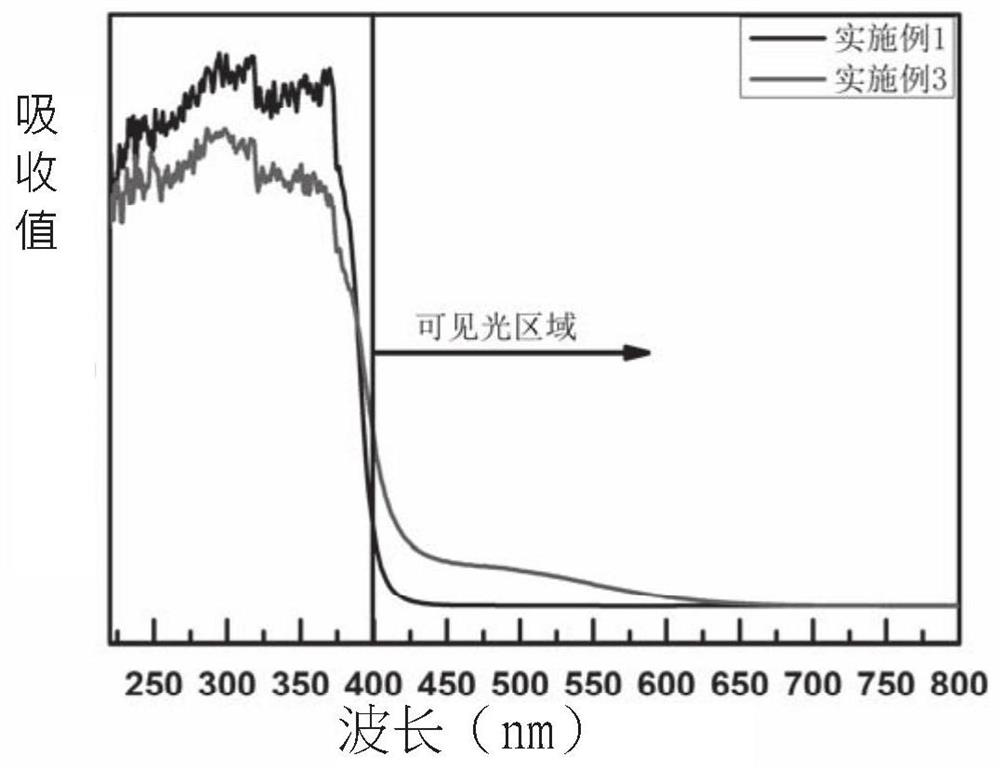

Zinc oxide-based photocatalytic material co-doped with niobium nitrogen and its preparation method and application

ActiveCN108067283BReduced operating requirementsEnsuring the boosting effect of nitrogen dopingWater/sewage treatment by irradiationWater treatment compoundsPhysical chemistryPhoto catalysis

The invention provides a method for preparing a niobium nitrogen co-doped zinc oxide-based photocatalytic material, which includes the following steps: preparing 1-1000mmol / L niobium-zinc alcohol solution and 0.01-0.1mg / mL alkali solution, mixing and stirring 30-120 minutes, carry out a hydrolysis precipitation reaction to obtain a suspension; centrifuge the suspension to collect the powder, wash it alternately with secondary deionized water and absolute ethanol, put it into a drying box and dry it at a temperature of 50-60°C ; Pre-crystallize the dried powder at a temperature of 300-550°C for 0-300 minutes, and then heat it in an ammonia atmosphere at a temperature of 400-700°C for 30-300 minutes to obtain it. The preparation process of the invention is simple, greatly reduces the operating requirements in the material preparation process, and is suitable for industrial promotion. The invention also provides a niobium nitrogen co-doped zinc oxide-based photocatalytic material and its application.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Multi-wheel lift drive system

ActiveCN103542049BShorten the lengthReduce cumulative errorGearingWinding mechanismsReducerGear transmission

The invention relates to the field of manufacture of methane tanks, in particular to a multiple-gear-train lifting driving system which comprises a speed reducer, a gear transmission mechanism and a plurality of chain wheels. The speed reducer drives the plurality of chain wheels through the gear transmission mechanism, and each of the chain wheels is connected with one or more lifting mechanisms through a chain correspondingly. According to the multiple-gear-train lifting driving system, the gear transmission mechanism drives a plurality of chains to drive the lifting mechanisms, the plurality of chains are utilized, lengths of the chains are shortened, accumulation errors of the chains are greatly reduced, the errors are controlled within a permissible range, synchronous lifting of assembly plates around large and middle methane tanks is ensured, labor cost is reduced, and production efficiency is ensured.

Owner:北京科创环能装备技术有限公司

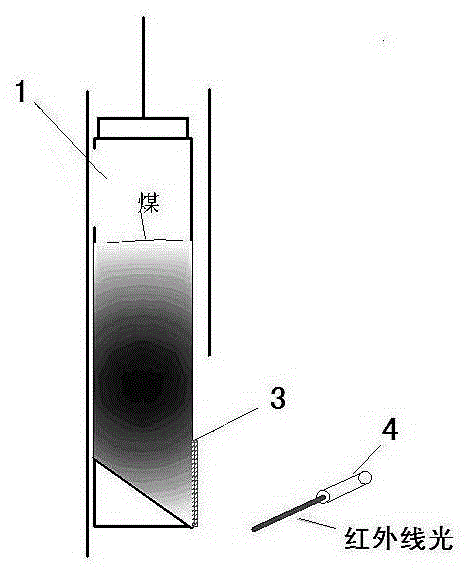

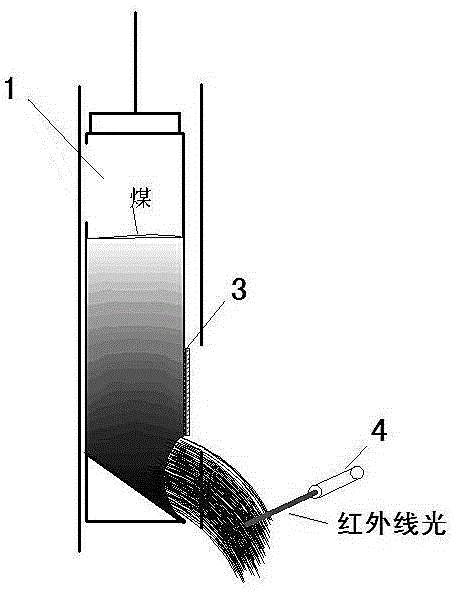

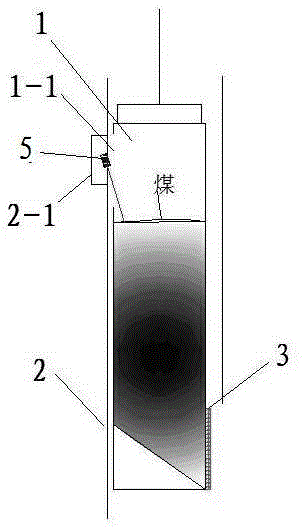

Coal mine main shaft prevent heavy bucket lowering protection device

InactiveCN103395678BPrevent devolutionMonitor real changesElevatorsMine liftsMining engineeringStructural engineering

A mine main shaft protection device capable of preventing a heavy skip from downward falling comprises a shaft and the skip provided with a coaling opening and a unloading door and is characterized in that a protective box is fixed to the outer wall of the shaft, a fixed frame, a laser sensor and a control circuit board are arranged in the protective box, the laser sensor is arranged on the fixed frame, a laser transmission hole is formed in the wall of the shaft, a transmitting and receiving probe of the laser sensor is arranged in the laser transmission hole, and the coaling opening formed in the wall of the skip is used as the transmission route of a laser bundle. The mine main shaft protection device has the advantages of being suitable for any coal mine elevating electric control system which utilizes the skip, capable of accurately monitoring the true changing condition of the coal level in the skip, accurate in detection, high in safety and reliability, capable of normally working in places where much dust is produced when main shaft skip unloading is conducted, suitable for the complex electromagnetic environment on a coal mine spot, stable in motion, easy to inhaul and maintain, and capable of effectively preventing the heavy skip from downward falling, eradicating occurrence of heavy skip downward-falling accidents and guaranteeing safe elevating of a main shaft.

Owner:铁法煤业(集团)有限责任公司晓南矿

Compound slow-release type plant growth accelerant and application thereof to promotion of santalum album parasitic haustorium development

InactiveCN109907049APromote growthImprove developmentPlant growth regulatorsBiocideTectonaAccelerant

The invention discloses a compound slow-release type plant growth accelerant and an application thereof to promotion of santalum album parasitic haustorium development. Every 100 parts of the compoundslow-release type plant growth accelerant comprises components in parts by weight as follows: 1-3 parts of melatonin, 1-3 parts of alpha-naphthylacetic acid, 10-15 parts of urea and the balance of awater-retention slow-release agent. The compound slow-release type plant growth accelerant can remarkably promote rooting and haustorium development and growth of santalum album, improve photosynthesis and improve afforestation quality of artificial santalum album forest. Meanwhile, the compound slow-release type plant growth accelerant further has a remarkable function of promoting growth of other rare trees such as dalbergia odorifera, tectona grandis and the like, and has a wider applicable range.

Owner:RES INST OF TROPICAL FORESTRY CHINESE ACAD OF FORESTRY

A Hierarchical Antenna Inspection Method for Integrated Circuit Layout Verification

ActiveCN103838897BGuaranteed boostBoost ensures noSpecial data processing applicationsGraphicsComputer architecture

The invention discloses a layered antenna checking method of integrated circuit layout graph verification, belongs to the auxiliary design field of integrated circuit computers, and particularly relates to the field of DRC and integrated circular layout graph NE of an integrated circuit layout graph. The method comprises the basic steps that firstly, a graphic selection ascending and expression value calculation ascending method is adopted, and all layers of units are sequentially processed through an inverse topological sequence to obtain a node output conclusion; secondly, a layer result adjusting method is adopted to process all the layers of units through a topological sequence, and output nodes which are judged out are layered and optimized; finally, all the layers of units are processed through the inverse topological sequence, and a result and a layered output graph of the result are output according to existing nodes. The layered antenna checking method is utilized in the integrated circuit layout graph verification, a node expression value with the layered relation is calculated rapidly and conveniently, and the checking efficiency of an antenna is improved.

Owner:北京华大九天科技股份有限公司

A method and device for selecting network users to be migrated

ActiveCN106686677BMeet the needs of useRefine selection granularityAssess restrictionEngineeringNetwork service

The invention discloses a method and device for selecting to-be-migrated network users. The method includes the steps that a to-be-processed region is divided into multiple areas according to a preset strategy; first mobile network service data generated by first mobile network users in each area is acquired; performance parameters of a second mobile network in each area are acquired; the first mobile network users with the generated first mobile network service data meeting a first preset condition are taken as first mobile network active users; for each area obtained after division, when the number of the first mobile network active users in the area exceeds a first preset value and the performance parameters of the second mobile network in the area meet a second preset condition, the first mobile network active users in the area are selected as to-be-migrated network users. According to the scheme, the selection granularity of network migration objects is greatly refined; all the migrated users can experience the advantages of the second mobile networks, and positive migration result feedback is formed.

Owner:北京神州泰岳智能数据技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com