Coal mine main shaft prevent heavy bucket lowering protection device

A protection device and the technology of the main shaft, which is applied to the lifting equipment, transportation and packaging, elevators, etc. in the mine, can solve the problems of accidents when the heavy bucket is lowered, and the failure to prevent the lowering of the heavy bucket, so as to prevent the lowering of the heavy bucket and ensure Safety improvement, accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

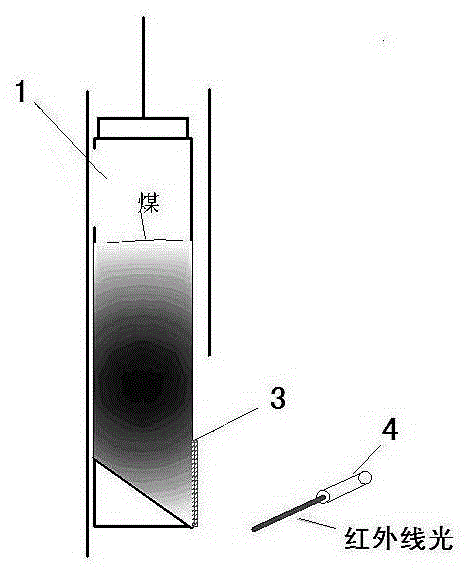

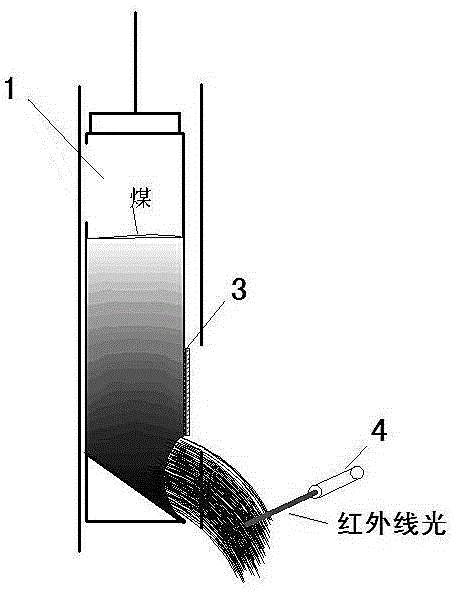

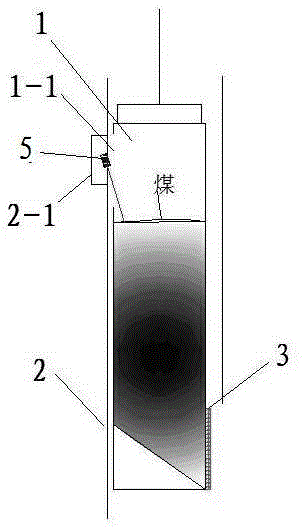

[0017] See Figure 4-8 , the specific structure is as follows: the skip 1 with the coal loading port 1-1 and the unloading door 3 runs in the shaft 2 of the main shaft. Box 2-1, a fixed frame 9, a laser sensor 5 and a control circuit board are arranged in the protective box 2-1; a 120mm square laser perforation is set on the wellbore wall, and the transmitting and receiving probe of the laser sensor 5 is located at the laser perforation. It is used for monitoring the coal level in the skip by the sensor laser beam. The upper end of the fixed frame 9 is connected to the horizontal adjustment seat 8 through a rotating shaft, and the vertical angle adjustment seat 6 is connected to the vertical angle adjustment seat 8 by the adjustment bolt 7 on the horizontal adjustment seat 8, and the laser sensor 5 is fixedly connected to the vertical angle adjustment seat 6; the left and right rotation angle is 180 degrees, Adjust the angle 90 degrees up and down. Able to meet the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com