Automatic enamel spraying machine

A spraying machine and enamel technology, applied in the field of spraying, can solve the problems of being unable to meet the needs of large-scale industrialization, affecting the health of workers, and low efficiency of manual spraying, etc., and achieve the effect of compact structure, high mechanical strength, and adjustable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

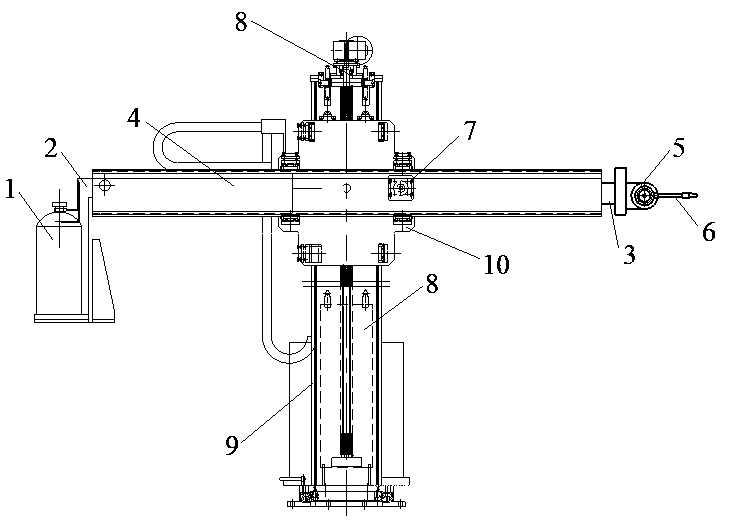

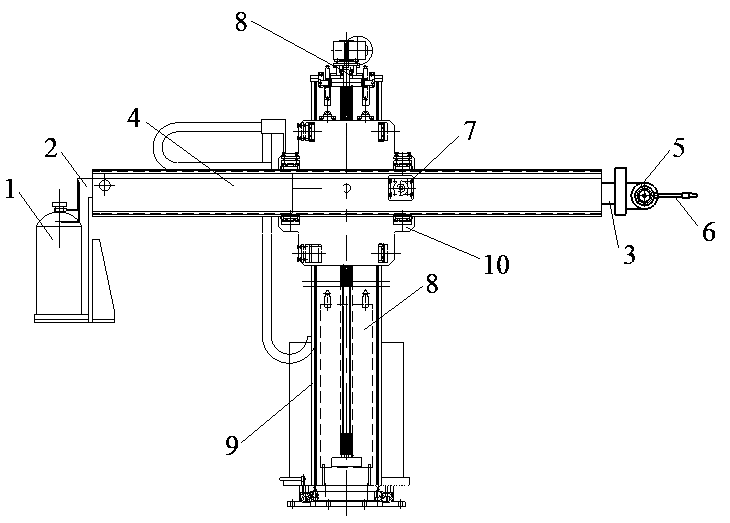

[0025] The purpose of this embodiment is to provide an automatic enamel spraying machine for spraying enamel.

[0026] This embodiment specifically provides an automatic enamel spraying machine. The barrel 1 is connected to the nozzle 3 through the material tube 2. The material tube 2 is axially arranged inside the telescopic arm 4. The gear arranged on the outer wall of the nozzle 3 is connected to the telescopic On the gear inside the arm 4, the nozzle 6 is connected to the nozzle 6 through the servo rotating nozzle 5 at the end of the nozzle 3 arranged outside the telescopic arm 4; 7. Electrically connect to PLC.

[0027] The machine head is composed of a precision reducer, a servo motor, and a paint-spraying clamping adjustment mechanism. Through the rotating mechanism, the nozzle can be rotated at any angle. Driven by a precision reducer and a servo motor, the precision is high, and an encoder can be used for precise setting. The clamping block and fixing mechanism ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com