Patents

Literature

39results about How to "Guarantee the stability of transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

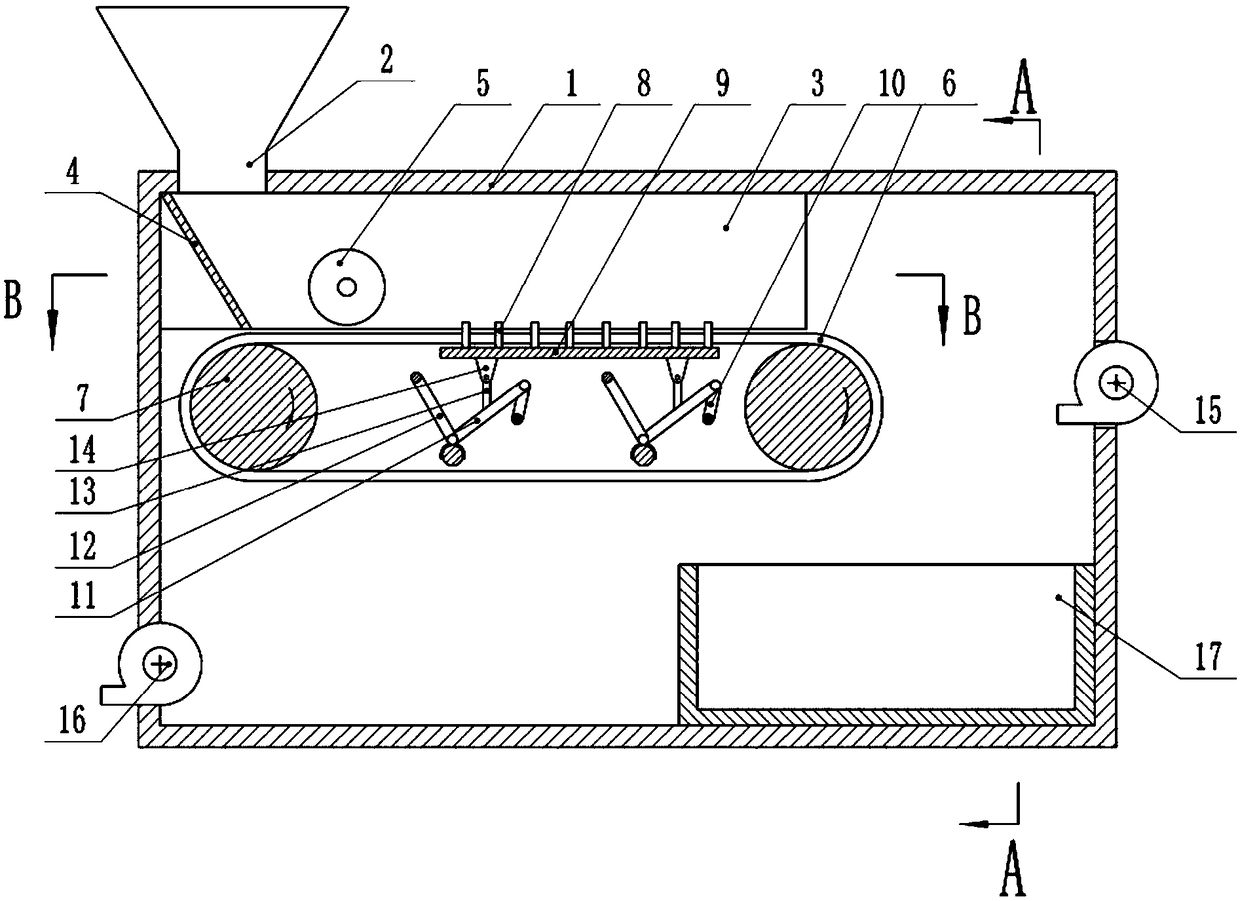

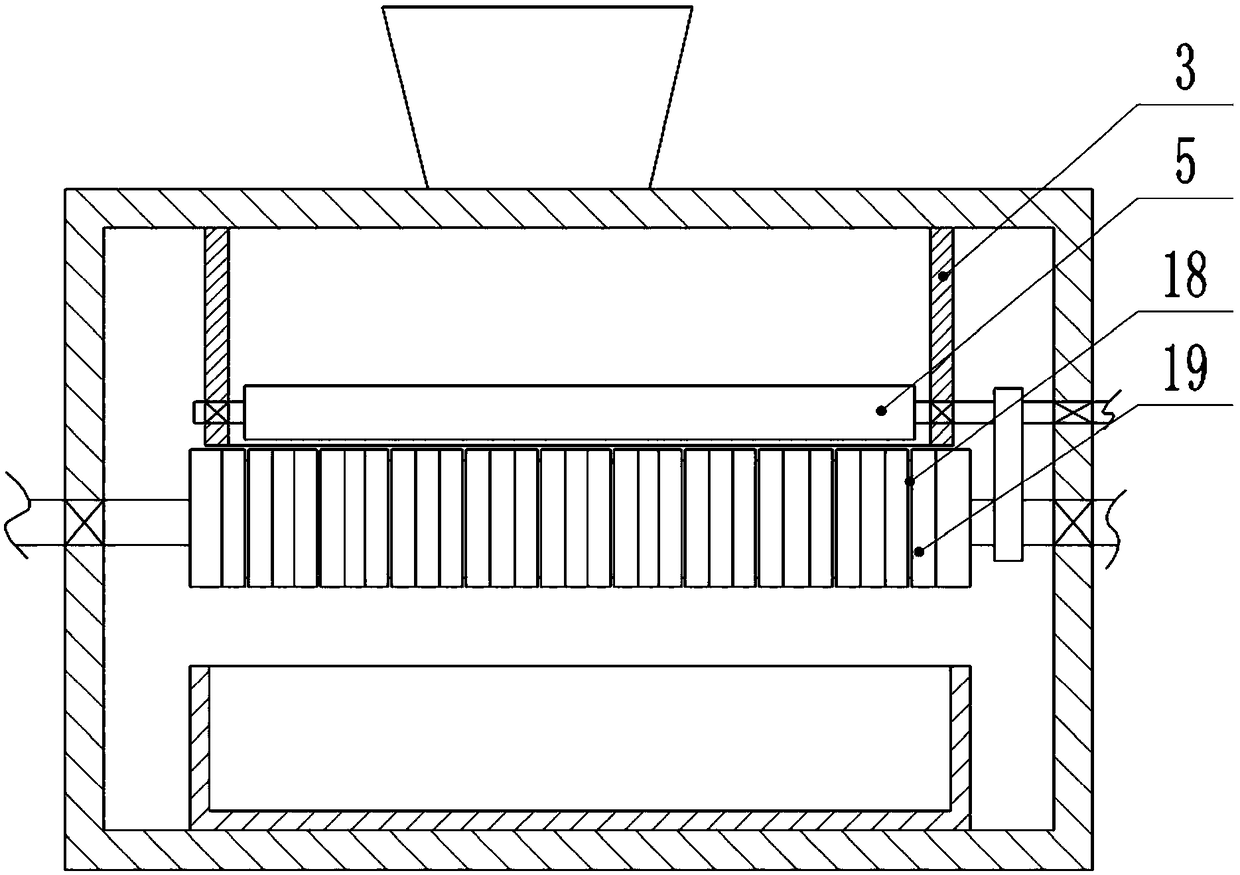

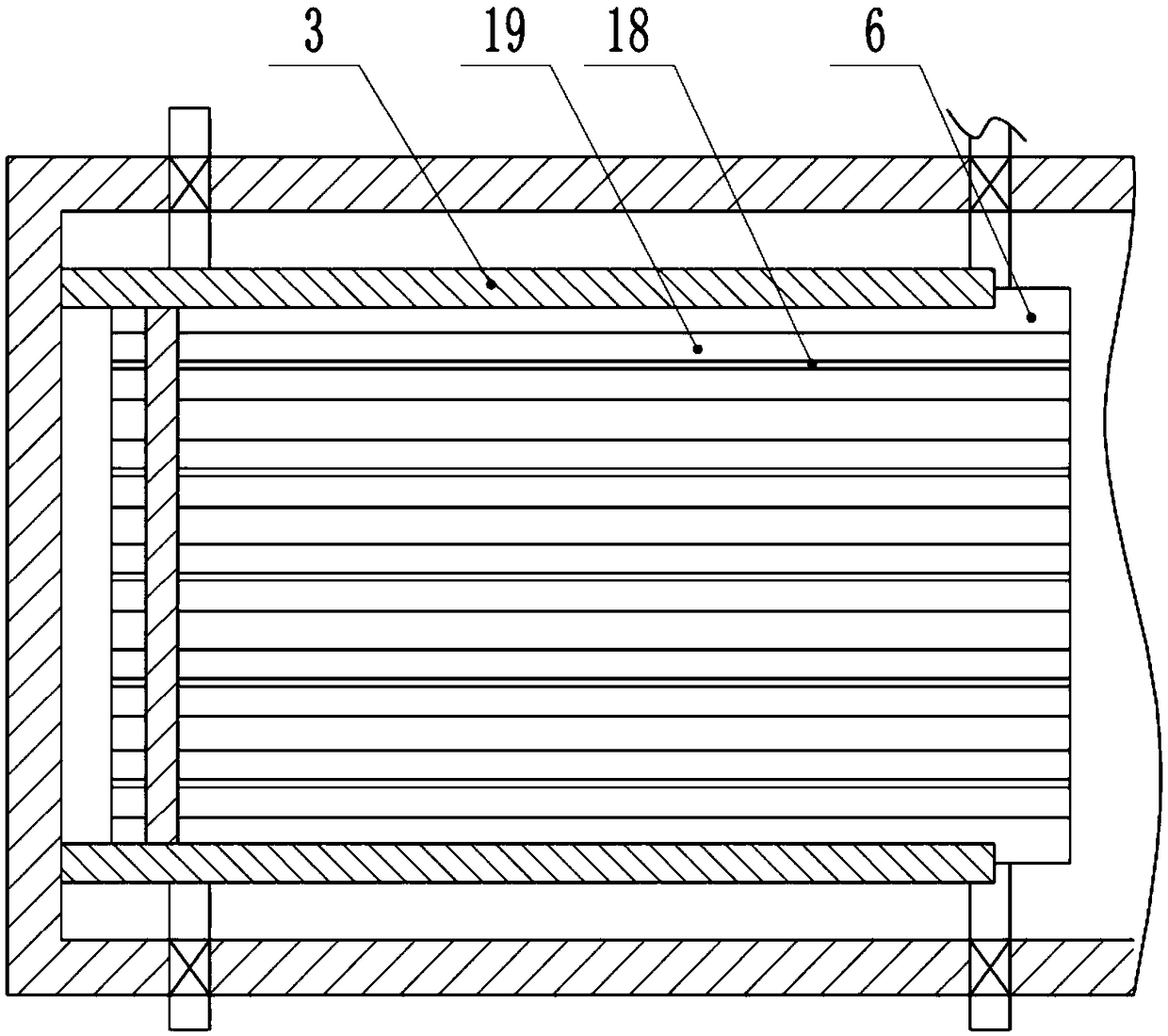

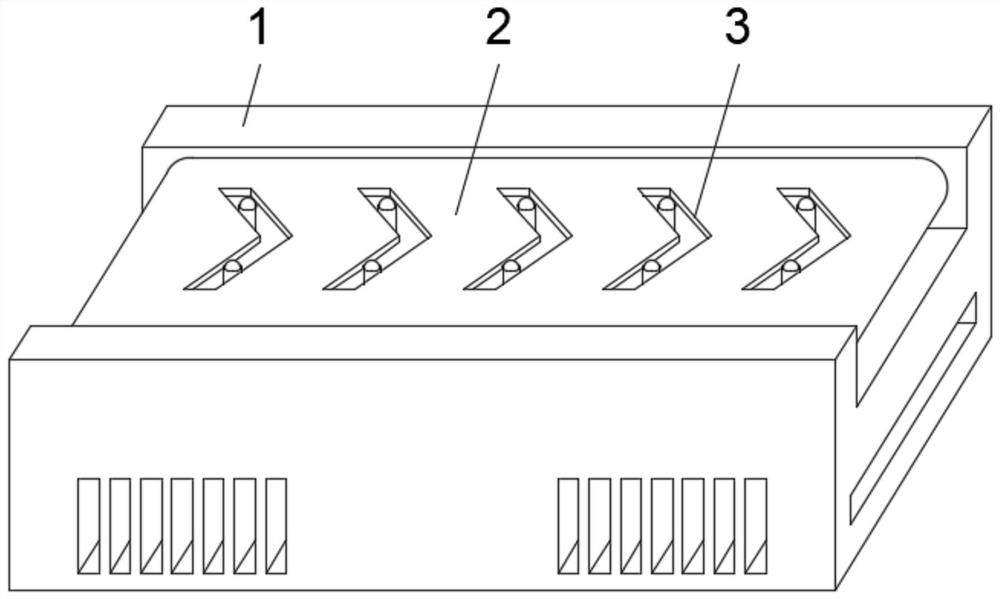

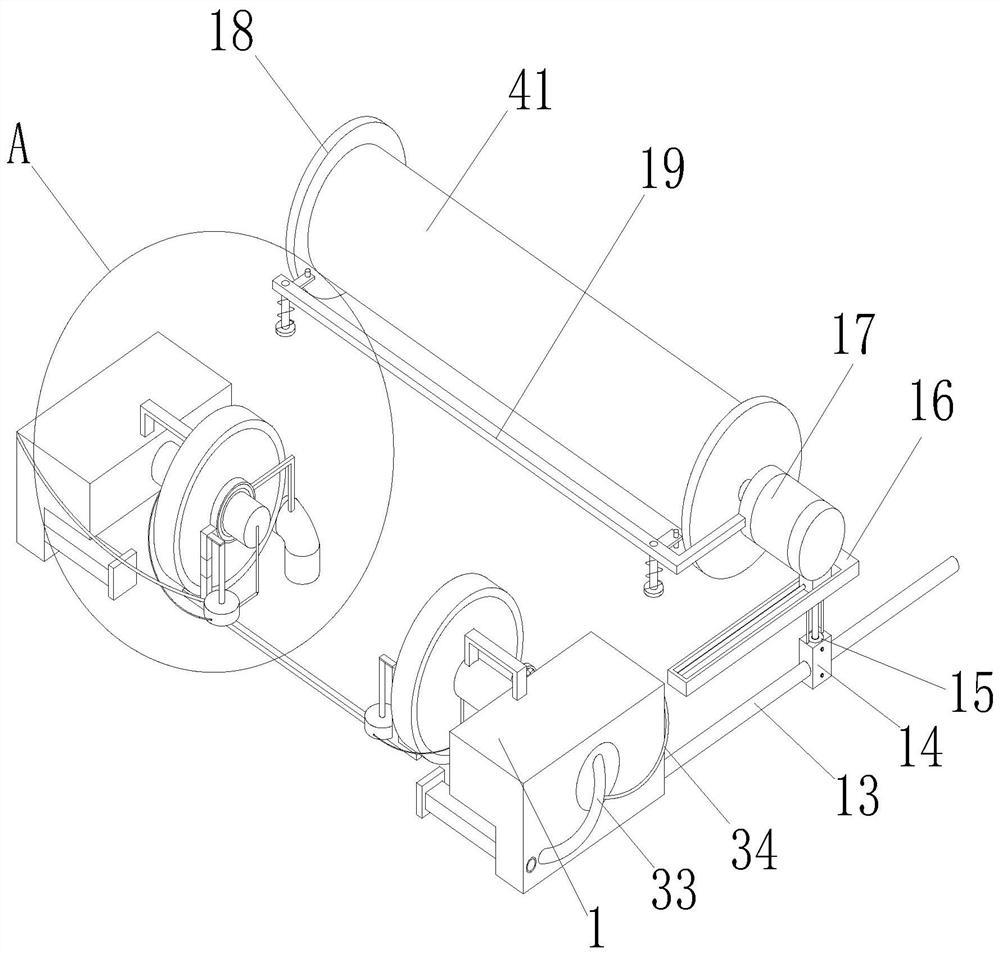

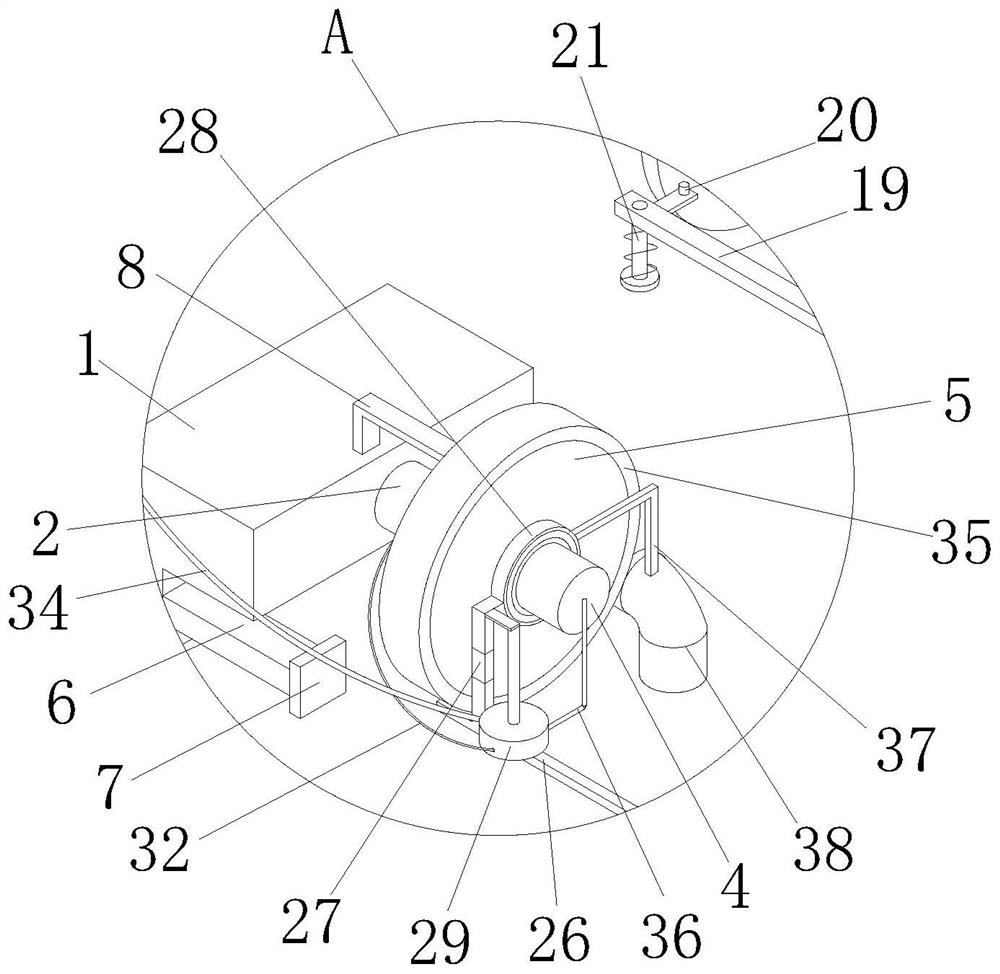

Solid chemical fertilizer drying device

ActiveCN108775772AAvoid cloggingAvoid scatterDrying gas arrangementsPreliminary solid treatment for dryingEngineeringMechanical engineering

The invention belongs to the technical field of chemical fertilizer preparing, and particularly discloses a solid chemical fertilizer drying device. The solid chemical fertilizer drying device comprises a drying box internally provided with a hot air structure and a conveying mechanism. The conveying mechanism comprises two conveying rollers and a power source, and a conveying belt is connected between the two conveying rollers and provided with a plurality of V-shaped grooves. The sides, close to the conveying rollers, of the V-shaped grooves are provided with openings. An overturning mechanism is arranged between the two conveying rollers and comprises two rotation shafts. Bent axles are arranged at the middle portions of the rotation shafts, connecting rods are hinged to the bent axles,oscillating bars are hinged to the inner wall of the drying box, the ends, away from the bent axles, of the connecting rods are hinged to the lower ends of the oscillating bars, and support rods arefixedly connected to the middle portions of the connecting rods. Supports are hinged to the upper ends of the support rods. A horizontal movable plate is fixed between the upper ends of the two supports and provided with a plurality of rows of overturning rods. The overturning rods are located under the openings. The lower ends of the oscillating bars are rotationally connected with vibration rollers. A material collecting box is arranged in the drying box. According to the scheme, chemical fertilizer overturning is achieved in the chemical fertilizer conveying process, and the drying effect is good.

Owner:遵义大兴复肥有限责任公司

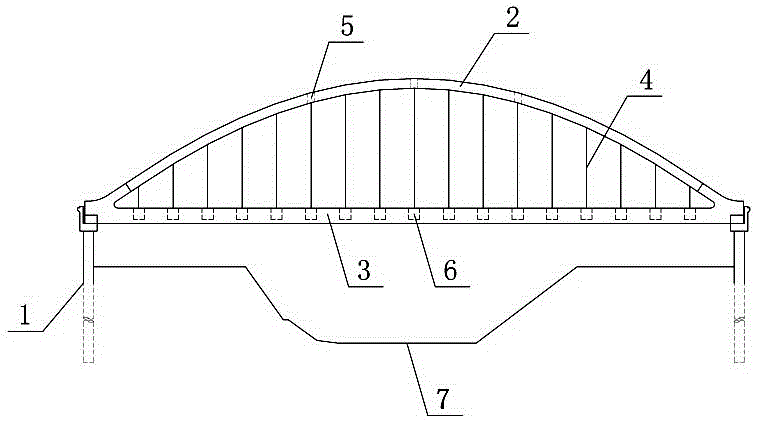

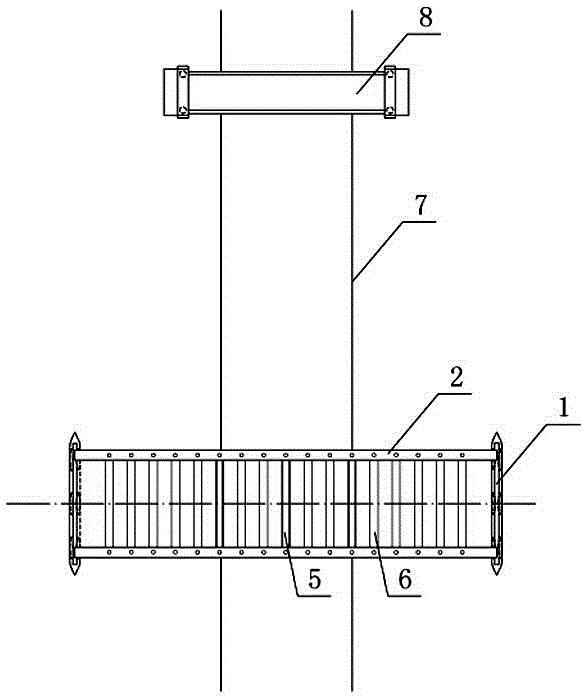

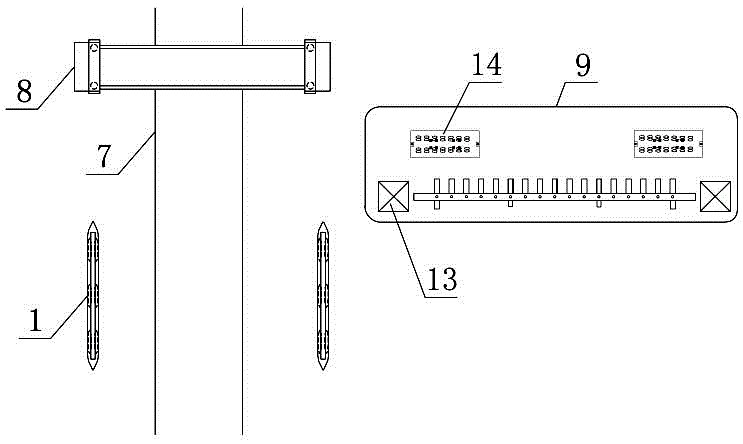

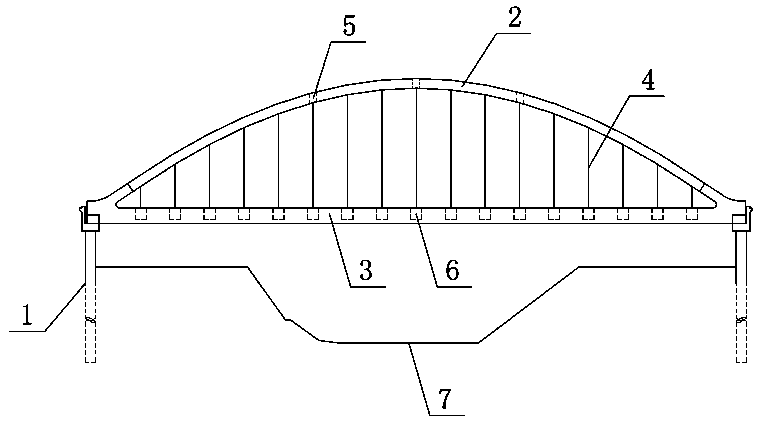

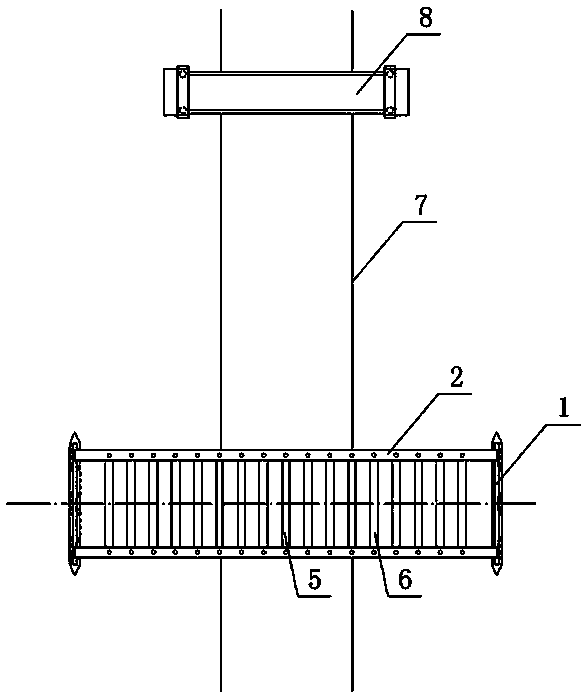

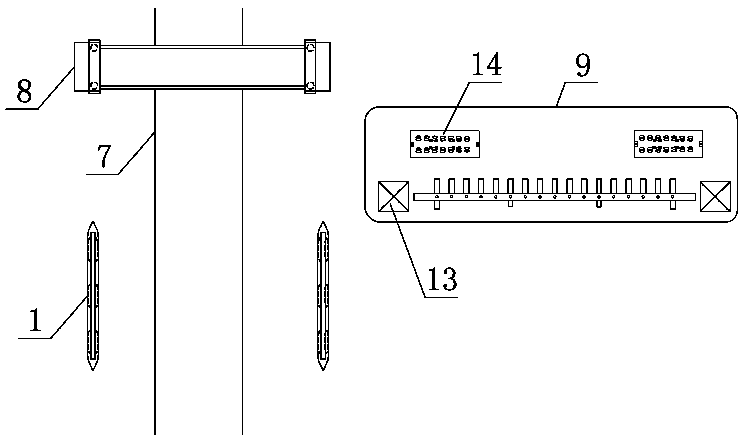

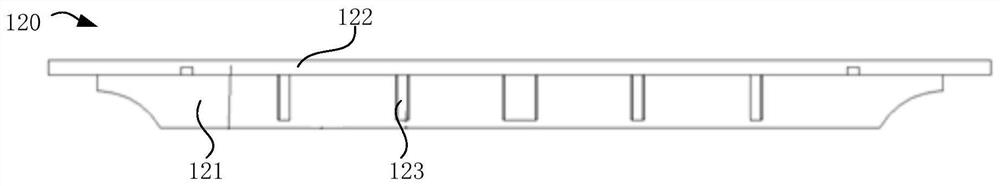

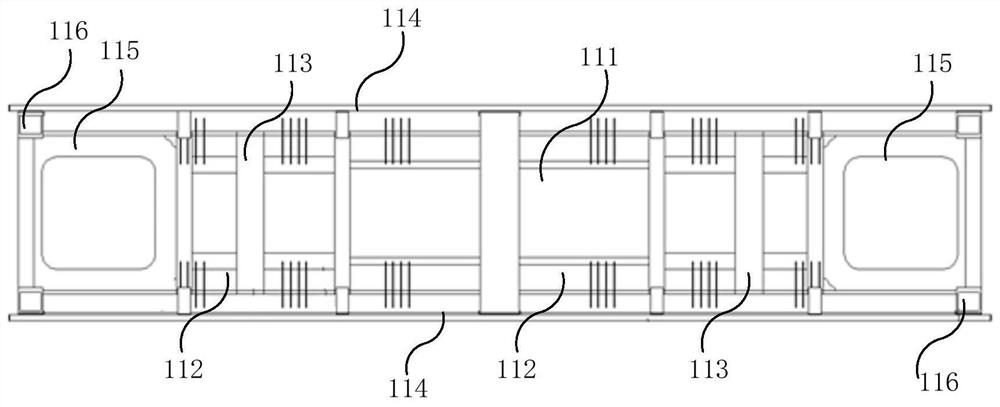

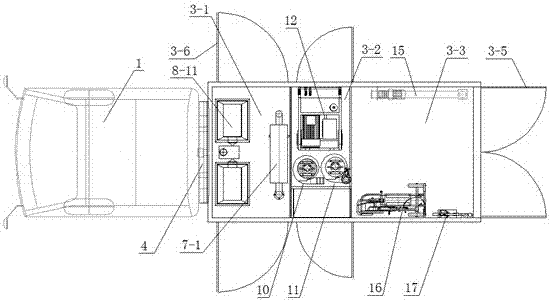

Through tied arch bridge and construction method thereof

ActiveCN106592406AReduce investmentAvoid high-altitude constructionBridge erection/assemblyArch-type bridgeBridge deckEngineering

The invention discloses a through tied arch bridge and a construction method thereof. The through tied arch bridge is composed of two single-piece arch rib units. Each single-piece arch rib unit comprises an arch rib and a tie beam, wherein a hanger rod is arranged between the arch rib and the tie beam. The two arch ribs are connected as a whole through transverse supports. The two tie beams are connected as a whole through transverse beams. A bridge deck slab is erected on the transverse beams. Each arch rib is formed by connecting arch rib sections, each tie beam is formed by connecting tie beam sections, and the arch-shaped arch rib sections and the tie beam sections are arranged correspondingly. Each transverse support is formed by connecting two transverse support sections, wherein the two transverse support sections are fixedly connected on the arch ribs of the two single-piece arch rib units correspondingly. Each transverse beam is formed by connecting two transverse beam sections, wherein the two transverse beam sections are fixedly connected on the tie beams of the two single-piece arch rib units correspondingly. By connecting each group of transverse beam sections and each group of transverse support sections on bridge location construction site, the erection work of a bridge main body can be completed, so that the construction period is shortened effectively, capital investment is reduced, and the construction method is especially suitable for bridge construction of crossing important riverways or important lines.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +1

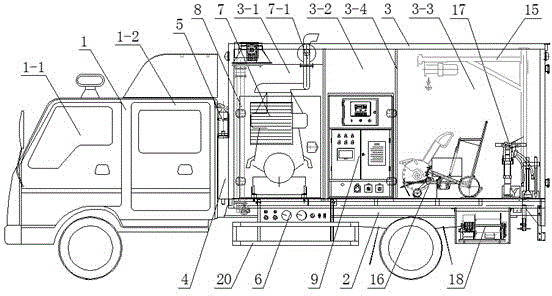

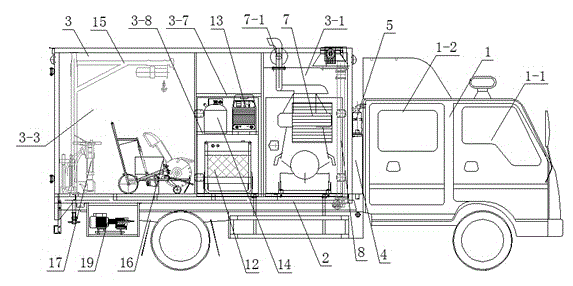

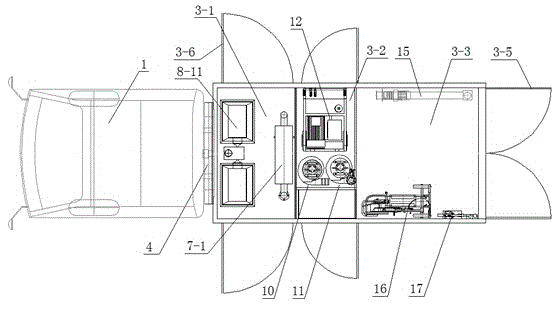

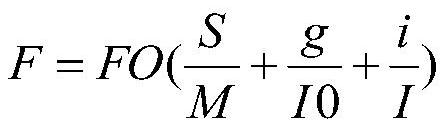

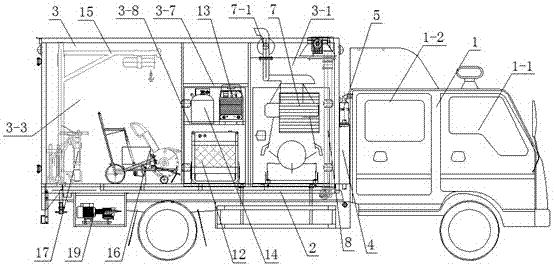

Multifunctional vehicle for emergency disaster relief and drainage of stagnant water

ActiveCN104943599AAvoid inconvenienceSave spaceSearchlight transportationItem transportation vehiclesPower stationFuel tank

The invention discloses a multifunctional vehicle for emergency disaster relief and drainage of stagnant water. The multifunctional vehicle comprises a carrier loader chassis as well as a driving cab and a carriage which are arranged on the chassis, wherein a backpack type hydraulic oil tank and a fire extinguisher are arranged in a gap between the driving cab and the carriage, and a chassis power take-off hydraulic power station connected with the hydraulic oil tank is arranged on the chassis; a power generation bin, an equipment bin and a tool bin are arranged in the carriage, a vehicle-mounted power generation unit and a hidden type vehicle-mounted lifting rotary illumination device are arranged in the power generation bin, a vehicle-mounted cantilever crane is arranged on one side of the tool bin, a hydraulic saw and a hydraulic pickaxe are arranged on the other side of the tool bin through a support, and a cable hoist, an integrated type vehicle-mounted cleaning machine and an extension ladder are hoisted at the bottom of the carriage. The multifunctional vehicle for emergency disaster relief and drainage of stagnant water integrates multiple functions through reasonable and compact layout design within a limited space range, the power generation unit is arranged at the front part of the carriage and in the position where the gravity center of the load of the whole vehicle is located, so that the transportation stability of the vehicle is effectively guaranteed, and the vehicle traveling safety is effectively guaranteed.

Owner:河南宜和城保装备科技实业有限公司

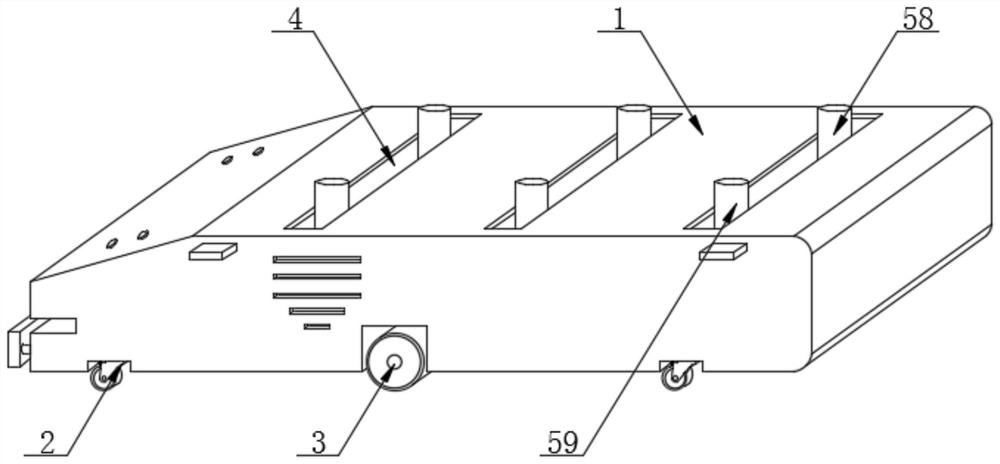

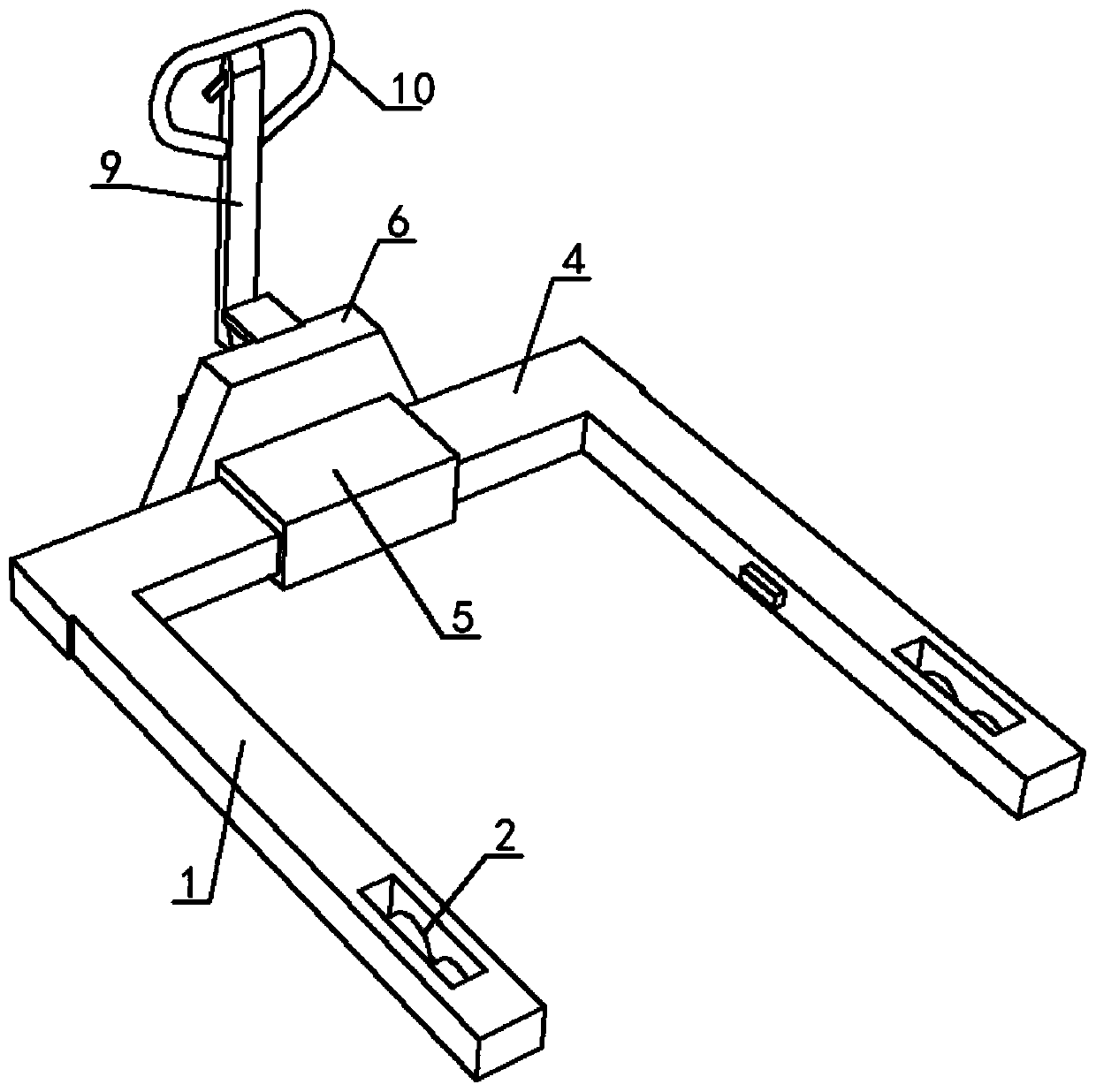

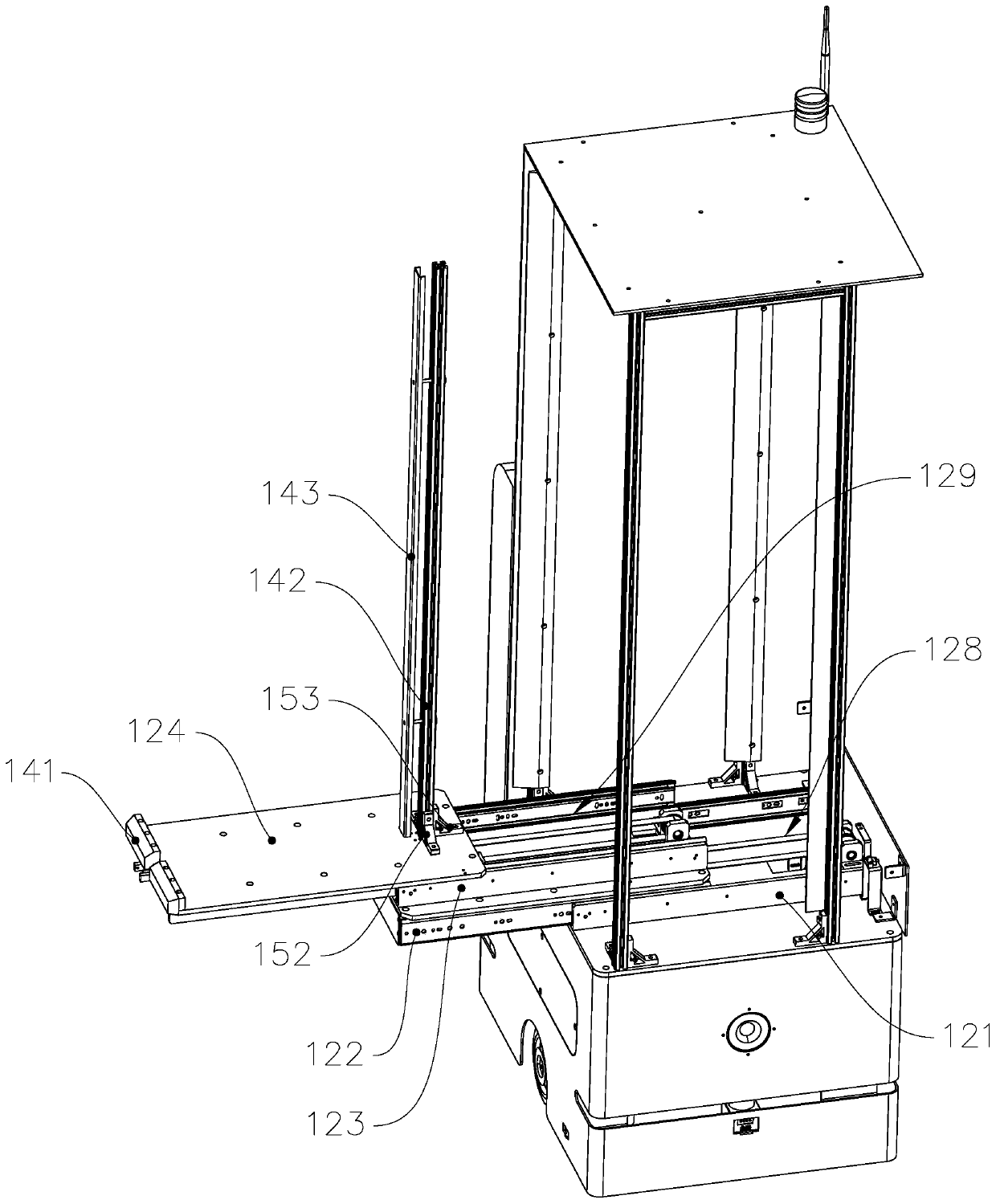

Latent traction type AGV forklift stable in transportation

InactiveCN112678478ATransport stableEasy to holdSupporting framesMechanical conveyorsTransit systemTransportation technology

The invention discloses a latent traction type AGV forklift stable in transportation. A stabilizing mechanism comprises a servo motor, a first fixing plate and a second fixing plate, the output end of the servo motor is fixedly connected with a driving bevel gear, and a two-way lead screw is in threaded connection between the interior of the first fixing plate and the interior of the second fixing plate. The invention relates to the technical field of cargo transportation. According to the latent traction type AGV forklift stable in transportation, when goods are transported, the distance between the first fixing plate and the second fixing plate is adjusted through rotation of the two-way lead screw, and then the position between a first protrusion and a second protrusion is adjusted, so that the goods are clamped conveniently, it is guaranteed that the goods are prevented from falling off during goods transportation, then the transportation stability of an AGV body is guaranteed, and the problems that when an emergency occurs in the transportation process of an existing latent traction type AGV, goods are prone to falling off, a whole transportation system is affected, and the transportation efficiency is greatly reduced are solved.

Owner:安徽宇锋智慧物联科技有限公司

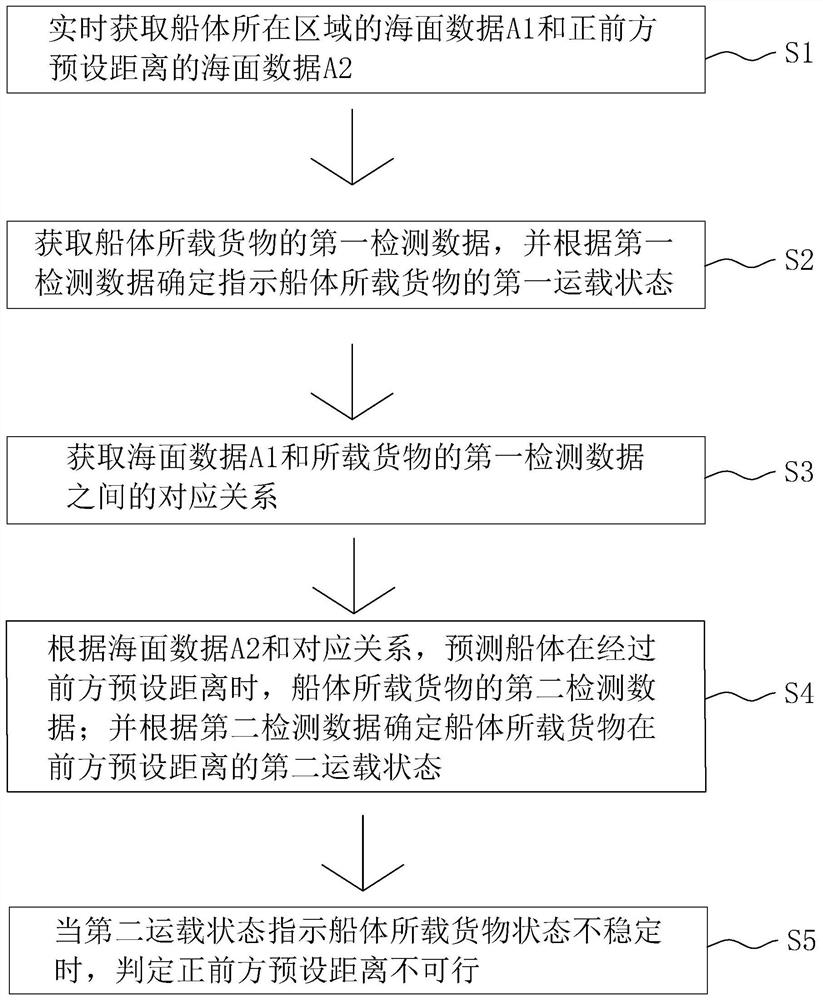

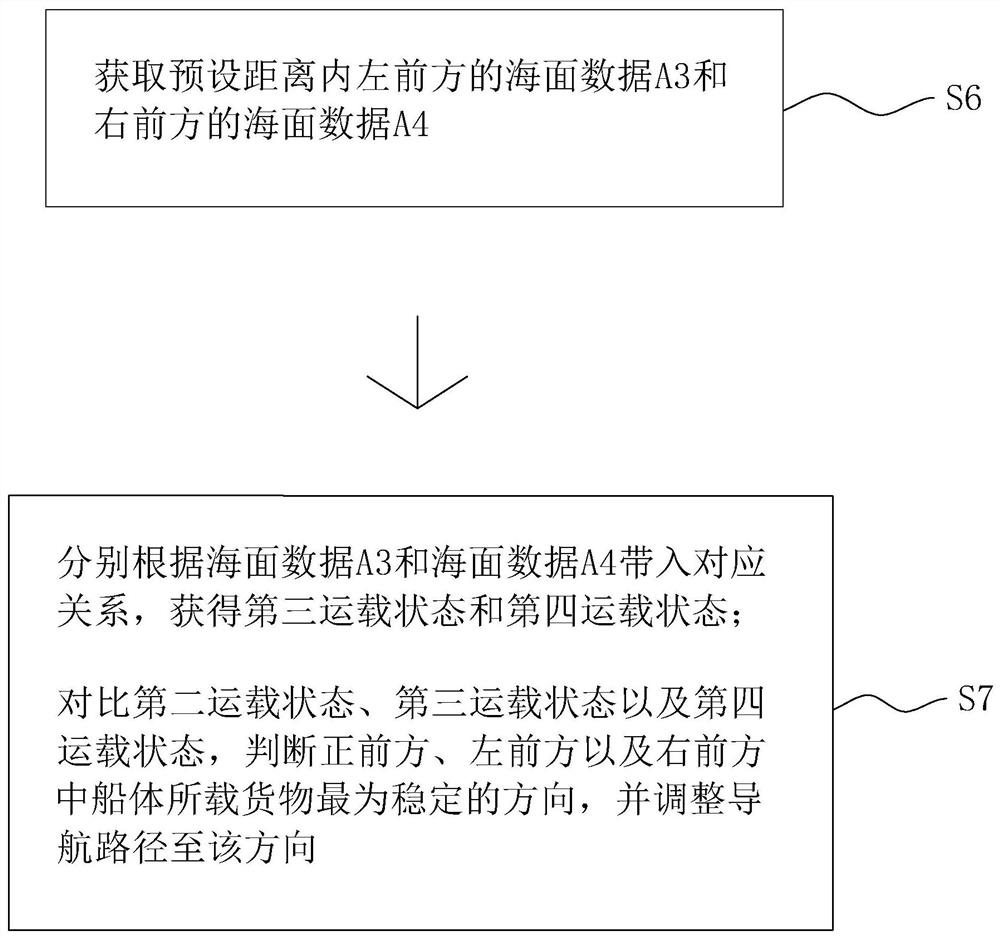

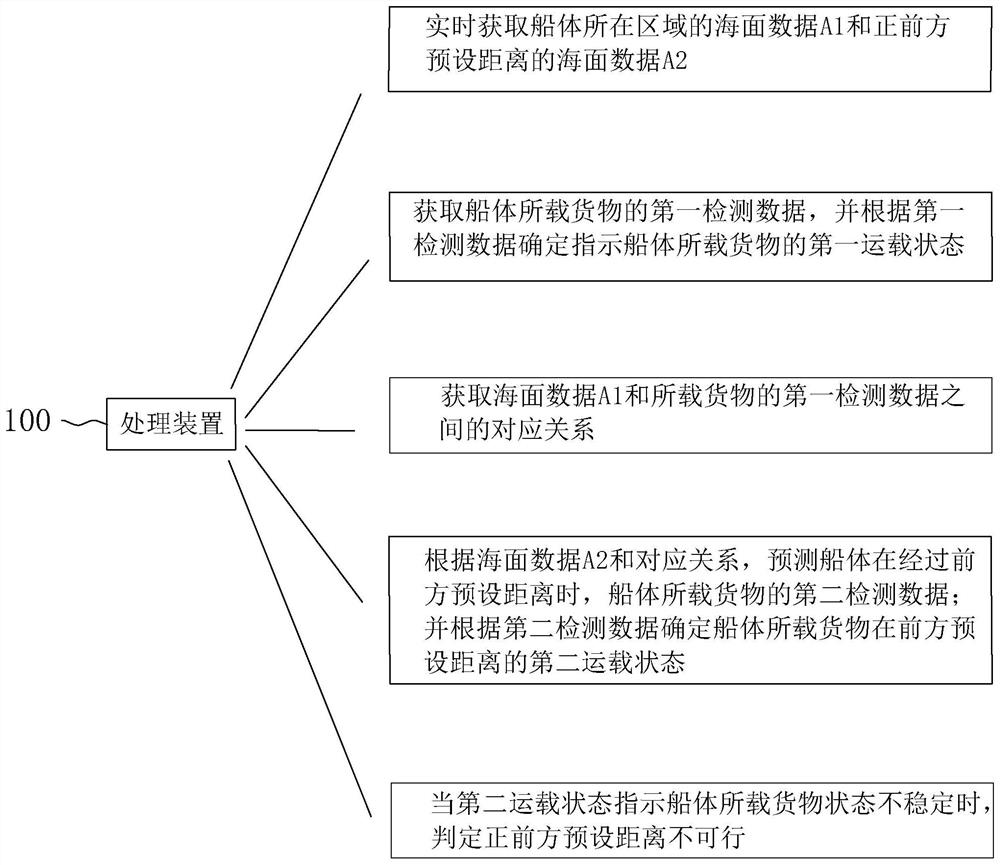

Route planning method, device and system based on dangerous goods transportation

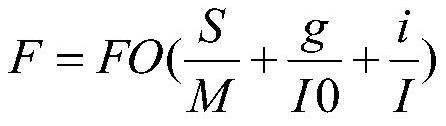

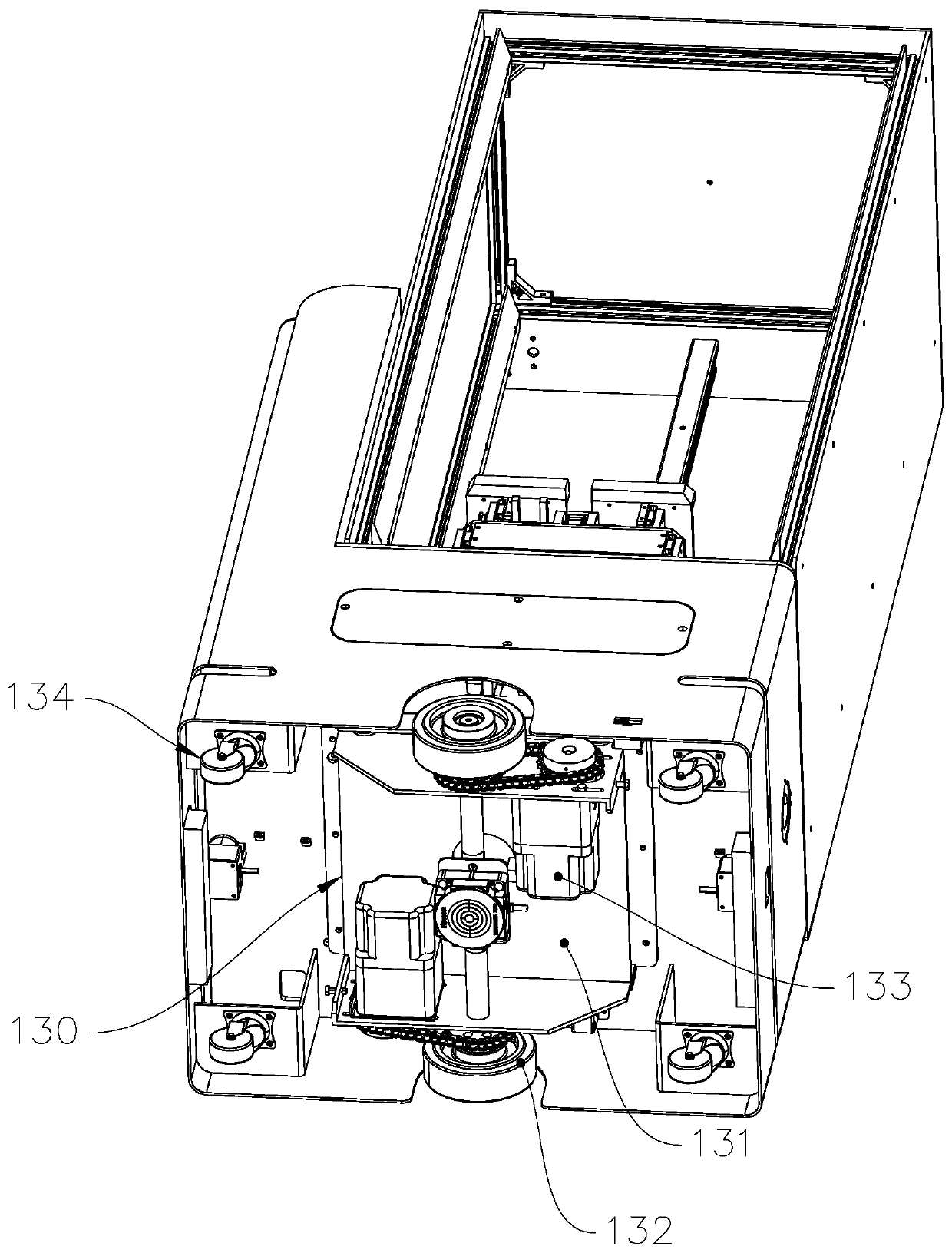

ActiveCN111707271AGuarantee the stability of transportationSecond Carrying Status AccurateNavigational calculation instrumentsRoute planningHull

The invention relates to a route planning method, device and system based on dangerous goods transportation. The method comprises the steps: acquiring the sea surface data A1 of an area where a ship body is located and sea surface data A2 of a preset distance right ahead in real time; acquiring first detection data of goods carried by the ship body, and determining a first carrying state indicating the goods carried by the ship body according to the first detection data; acquiring a corresponding relationship between the sea surface data A1 and the first detection data; according to the sea surface data A2 and the corresponding relationship, predicting second detection data of goods carried by the ship body when the ship body passes through a front preset distance; determining a second carrying state of the cargo carried by the ship body at a preset distance right ahead according to the second detection data; when the second carrying state indicates that the state of the goods carriedby the ship body is unstable, judging that the preset distance right ahead is infeasible. According to the method, the ship body can judge the stability of the carried goods by judging the second carrying state, the advancing route of the ship body is judged, and the stability of the hazardous chemical substance transportation process is guaranteed.

Owner:华瑞物流股份有限公司

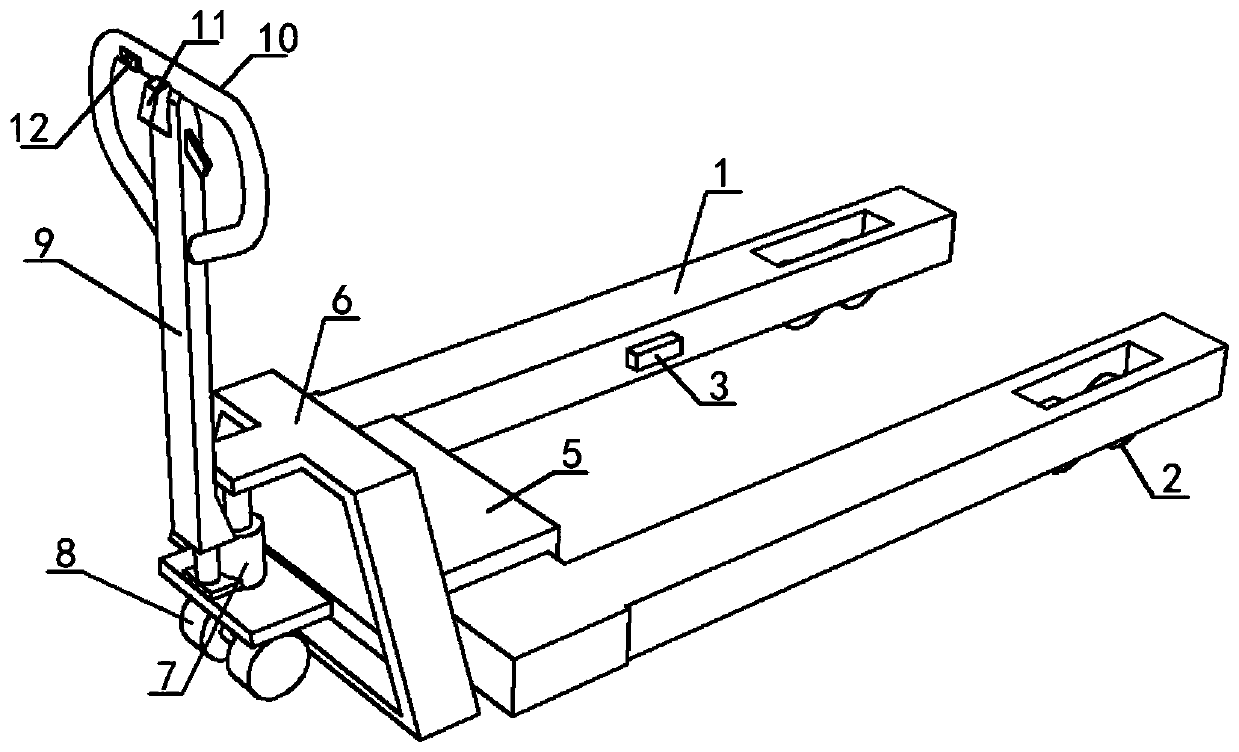

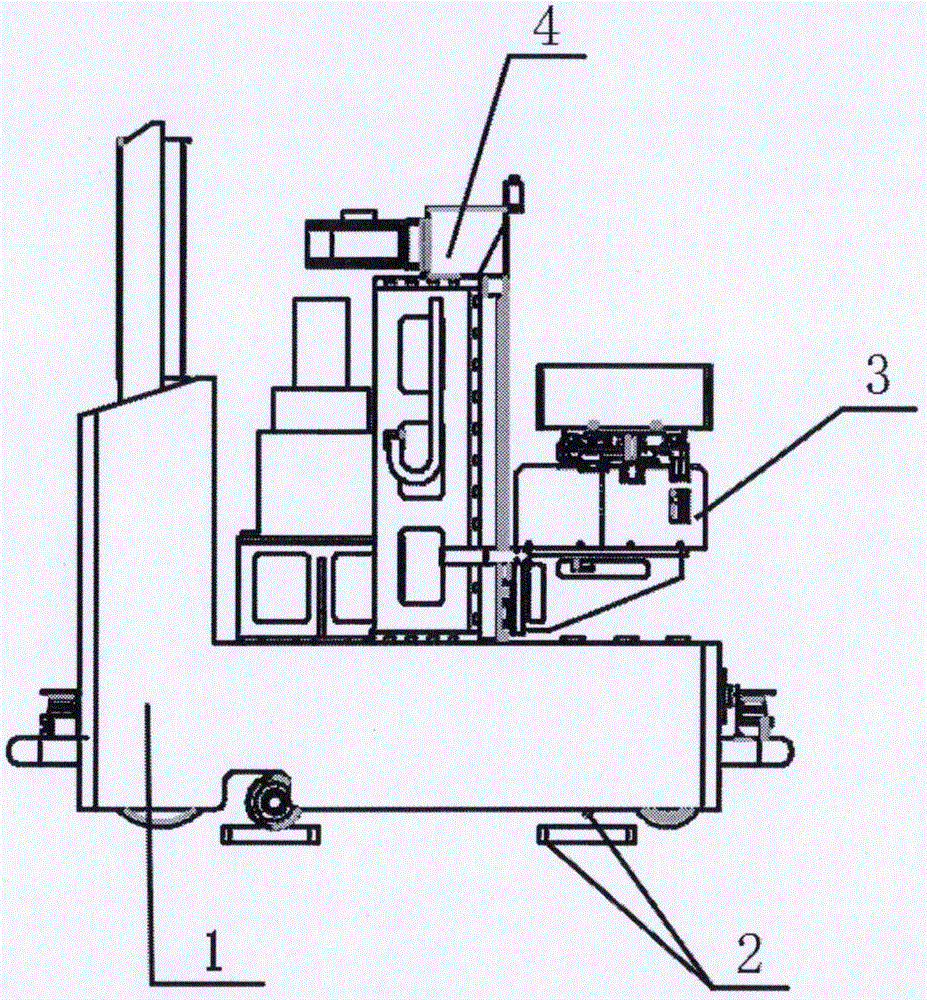

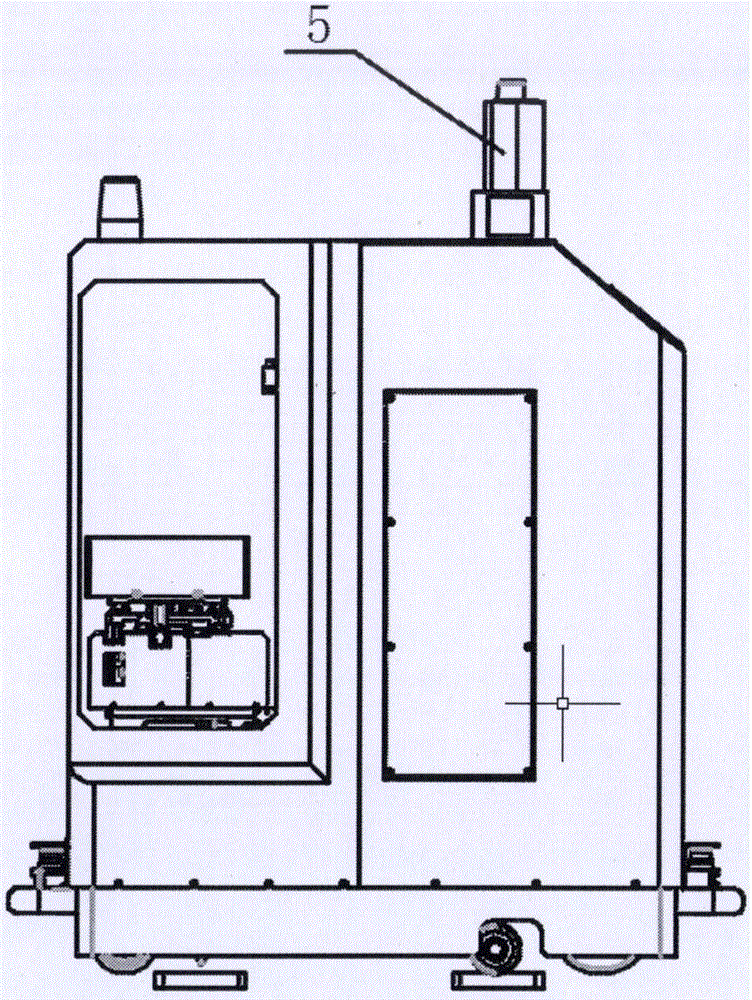

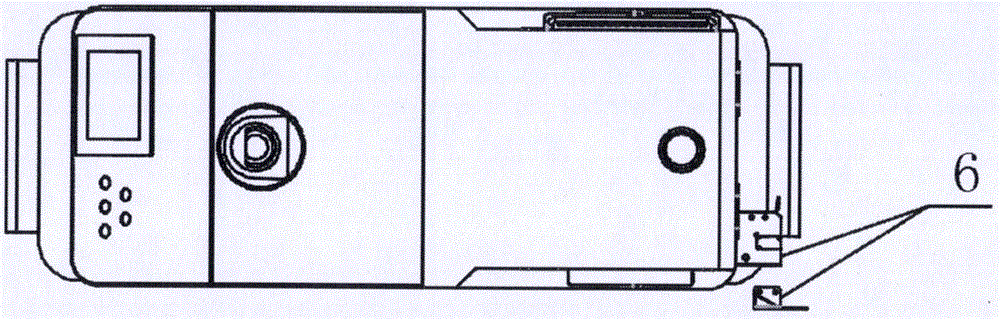

Hydraulic vehicle for construction site

InactiveCN110606114AIncrease widthGuarantee the stability of transportationSpecial purpose weighing apparatusHand carts with multiple axesHydraulic cylinderControl engineering

The invention discloses a hydraulic vehicle for a construction site. The hydraulic vehicle is characterized in that the hydraulic vehicle comprises sliding plates, pressure sensors, a telescopic disc,a universal wheel, a traction rod, a handle, a display screen and a sliding button; rollers are arranged at the lower parts of one ends of the sliding plates; the pressure sensors are arranged on theinner sides of one ends of the sliding plates; a telescopic rod is connected with the front parts of one ends of the sliding plates; the side surface of one end of the telescopic rod is embedded intothe telescopic disc; a front end is connected with the front side of one end of the telescopic disc; a hydraulic cylinder pressure rod is arranged on the inner side of one end of the front end; the lower side of one end of the hydraulic cylinder pressure rod is connected with the universal wheel; the traction rod is arranged on the upper side of one end of the front end; the handle is arranged onthe upper side of one end of the traction rod; the display screen is arranged at the front part of one end of the handle; and the sliding button is arranged at the front part of one end of the handle. The hydraulic vehicle for the construction site has characteristics of automatic adjustment and visualization of the cargo weight. The hydraulic vehicle achieves the effects of being appliable to the transportation of cargoes with different widths by the controllable setting of the spacing between the sliding plates.

Owner:徐州宏嵩机电设备有限公司

Fork plate type carrier

PendingCN106082016AImproved parking accuracy and work efficiencyReduce re-back into placeLifting devicesPosition errorLaser ranging

The invention discloses a fork plate type carrier which comprises a self-walking carrier body, a guide device, a laser ranging device, precision locating devices, a pallet fork device and a perpendicular lifting mechanism. The pallet fork device and the perpendicular lifting mechanism are installed on the self-walking carrier body. The pallet fork device has the functions of bidirectional transverse extending and precision locating for cargo box storing and taking. According to an external command, the self-walking carrier body automatically walks to a designated location or station under the guidance of the guide device, the laser ranging device automatically measures stop position errors of the carrier, and when the stop position errors exceed an allowable value and are within an adjustable range, the precision locating devices are started for precision locating of the carrier. After the stop position precision meets requirements, the pallet fork device conducts operation of storing and taking. The fork plate type carrier is simple in structure, small in occupied area, good in stress in the working process and free of bearing capsizing moment. The stop position precision is high, the pallet fork device can be used for taking cargos on the left and on the right, and positions of the cargos on a pallet fork can be located precisely.

Owner:山西东械自动化科技有限公司

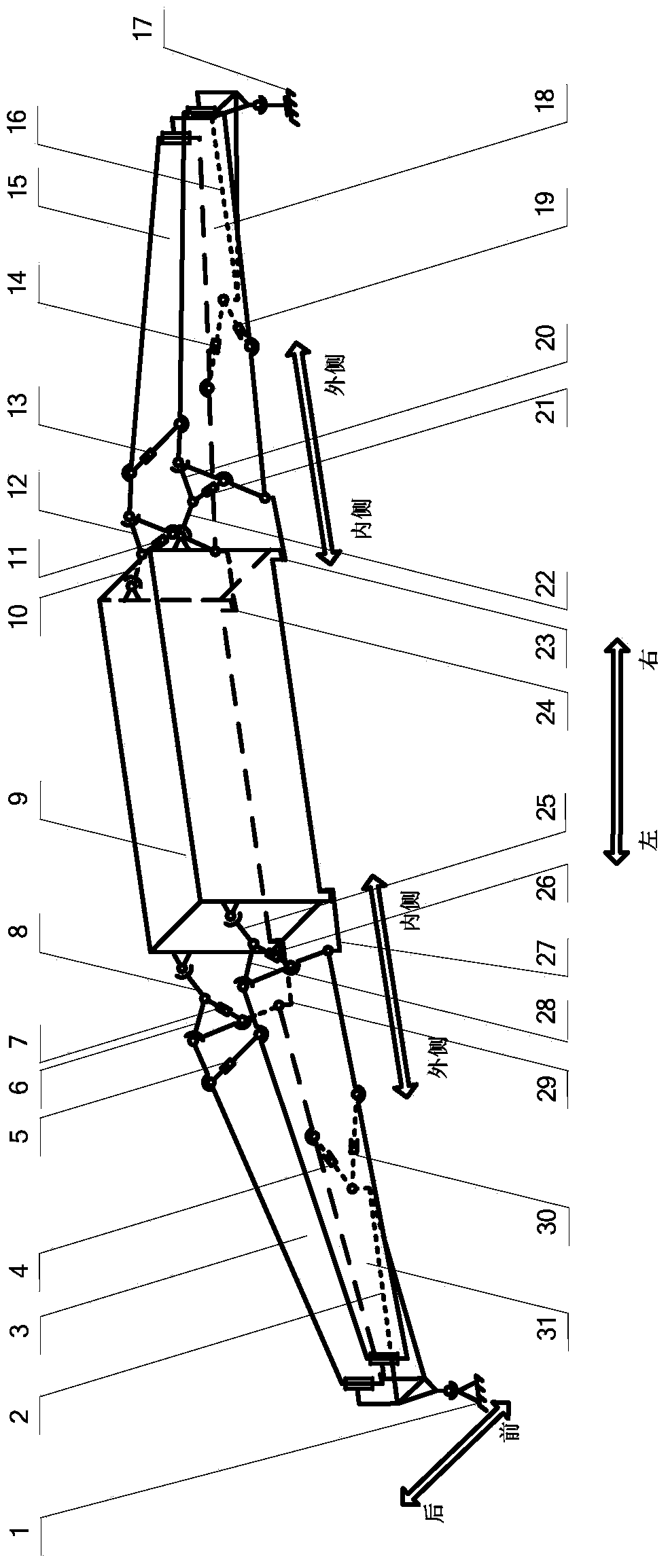

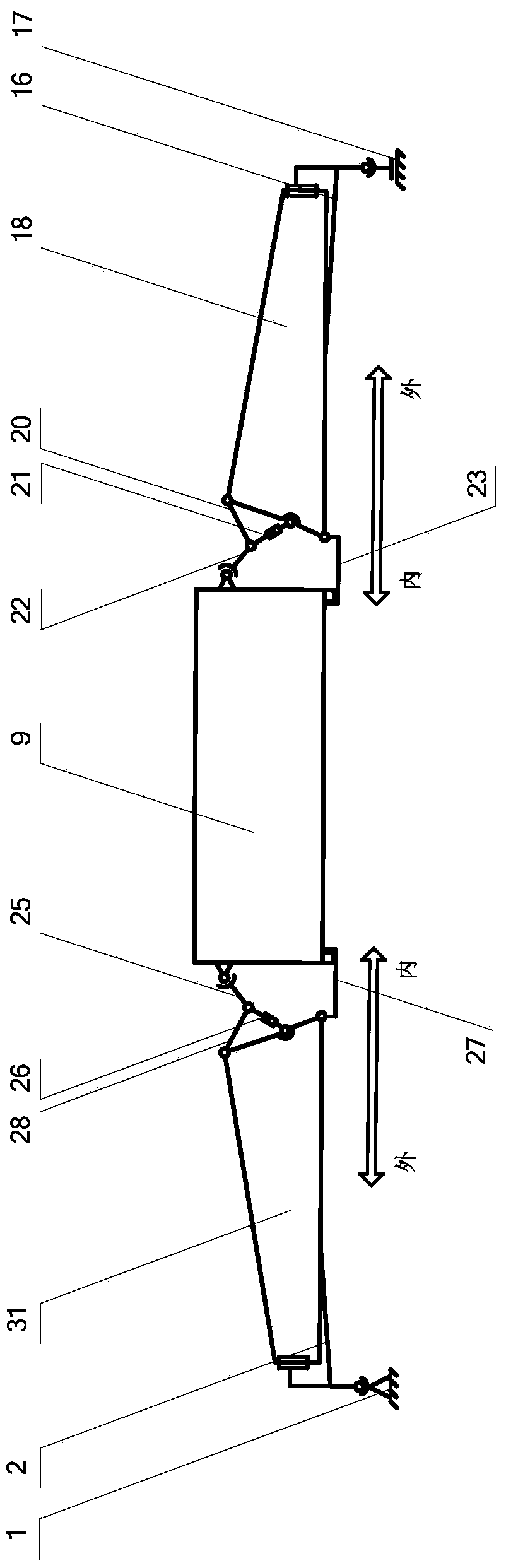

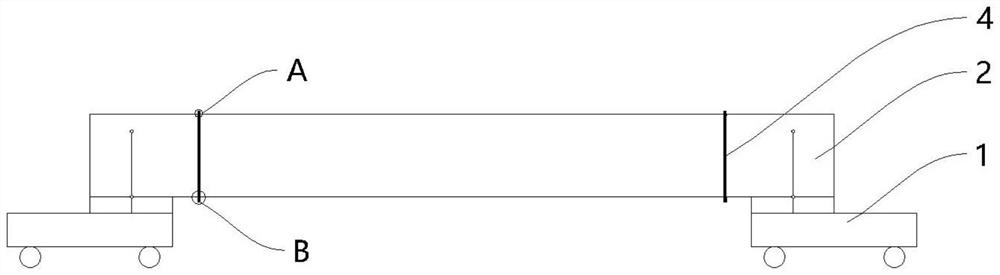

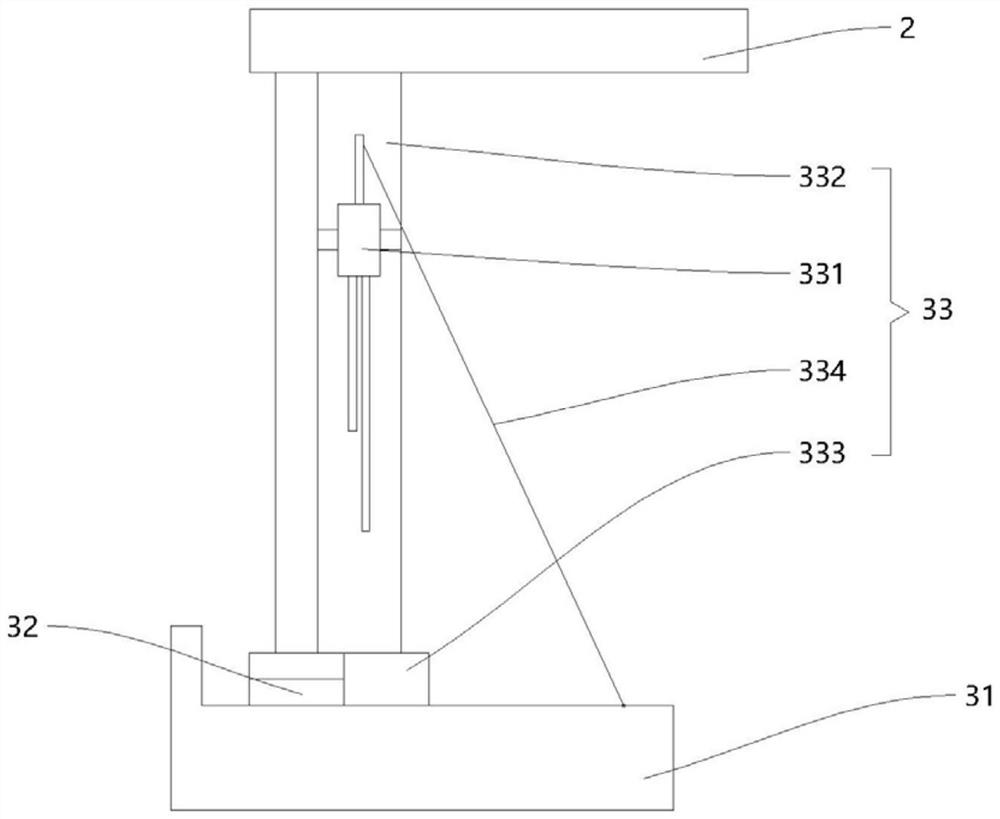

Lifting mechanism of schnabel car

InactiveCN104192155AGuaranteed boostGuarantee the stability of transportationWagons/vansCargo supporting/securing componentsEngineeringPiston rod

A lifting mechanism of a schnabel car is mainly characterized in that central disks of the outer ends of two half schnabel car lifting mechanisms are connected with the outer ends of guide beams through ball pairs, the outer end of each guide beam is hinged to the outer end of a front schnabel beam and the outer end of a rear schnabel beam, the upper portions of the inner ends of each front schnabel beam and the corresponding rear schnabel beam which are identical and connected in parallel are hinged to one end of a front outer connecting rod and one end of a rear outer connecting rod, the other end of the front outer connecting rod and the other end of the rear outer connecting rod are hinged to one end of a front inner connecting rod and one end of a rear inner connecting rod, the other end of the front inner connecting rod and the other end of the rear inner connecting rod are connected with the upper portions of goods, and a rotating pair of the front inner connecting rod, a rotating pair of the rear inner connecting rod, a rotating pair of the front outer connecting rod and a rotating pair of the rear outer connecting rod are respectively connected with a piston rod of a lifting oil cylinder, a cylinder body of each lifting oil cylinder is connected with the middle of the inner end of the corresponding schnabel beam, the lower portions of the inner ends of the two corresponding schnabel beams are hinged to one end of a front car lug and one end of a rear car lug, the other end of each front car lug and the other end of the corresponding rear car lug are connected with the lower ends of the goods, and a width regulating mechanism is installed between each front schnabel beam and the corresponding rear schnabel beam. According to the lifting mechanism of the schnabel car, small lifting force is exerted by the lifting oil cylinders so that the goods with the same weight can be lifted, and the lifting mechanism of the schnabel car has the advantage of saving labor.

Owner:YANSHAN UNIV

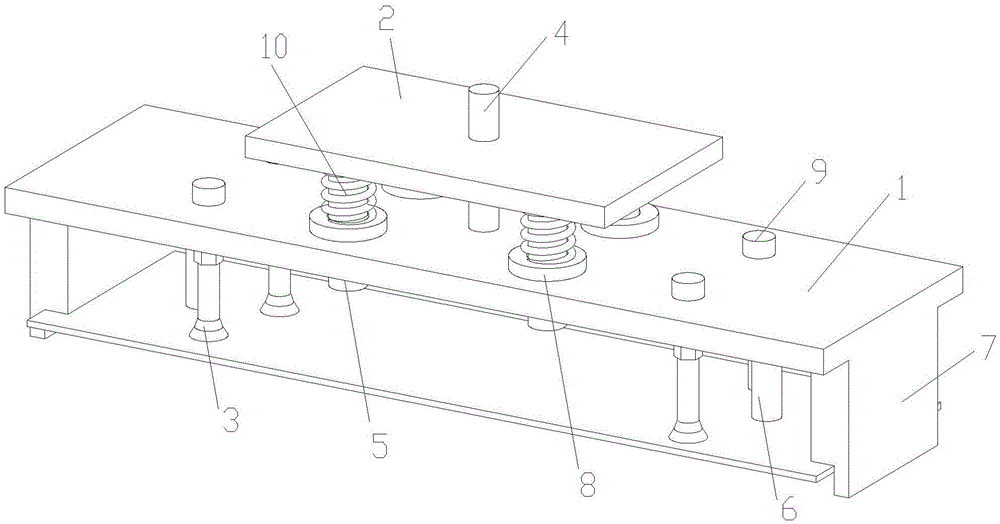

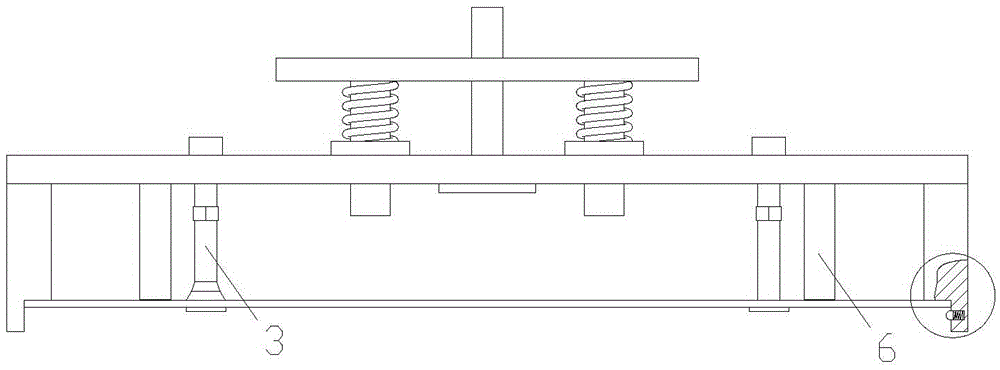

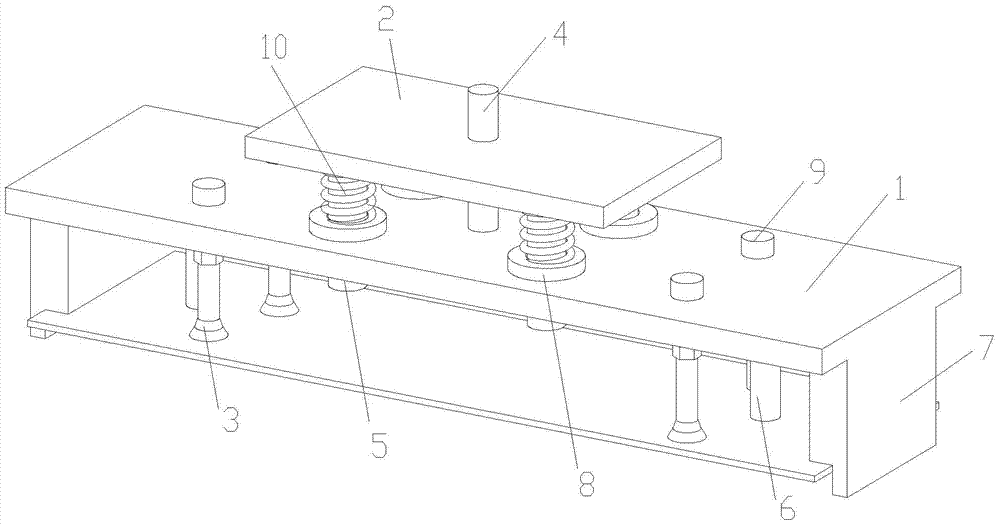

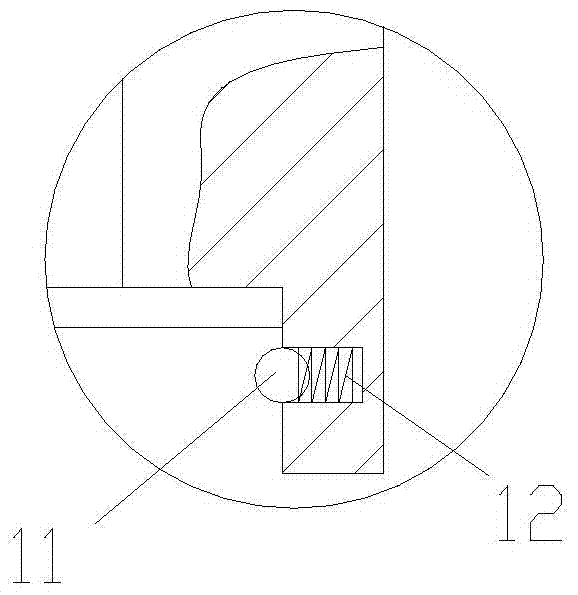

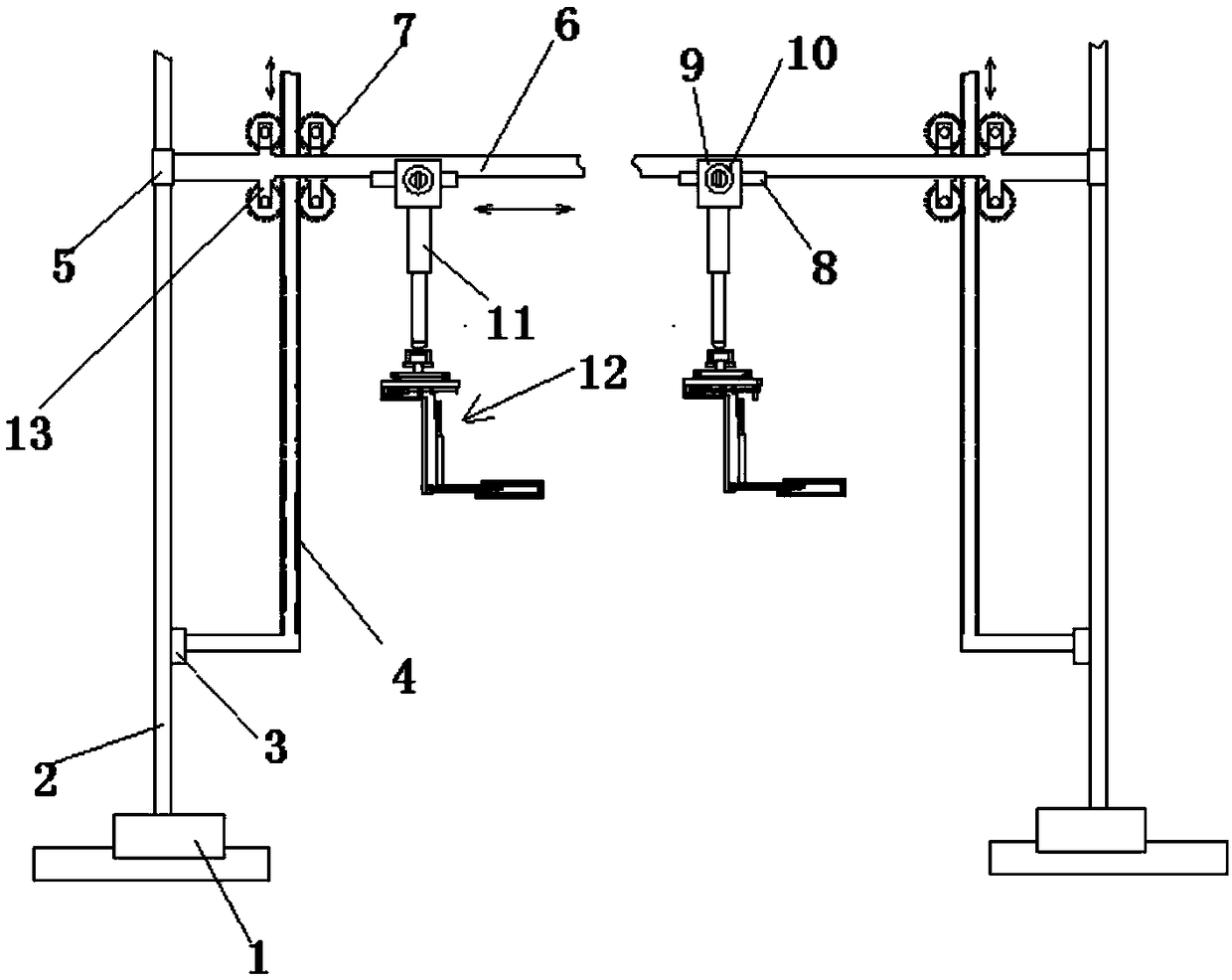

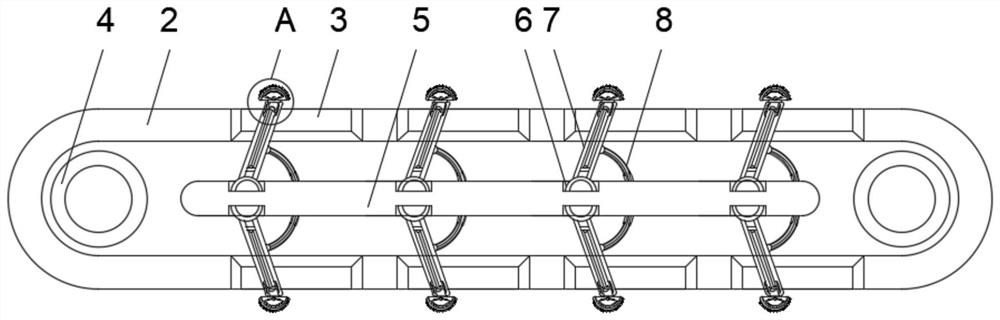

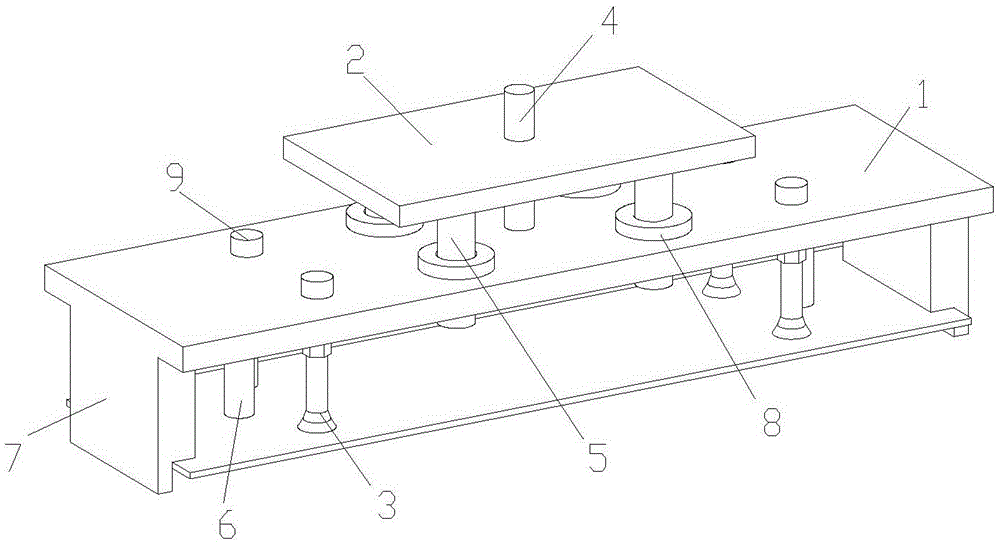

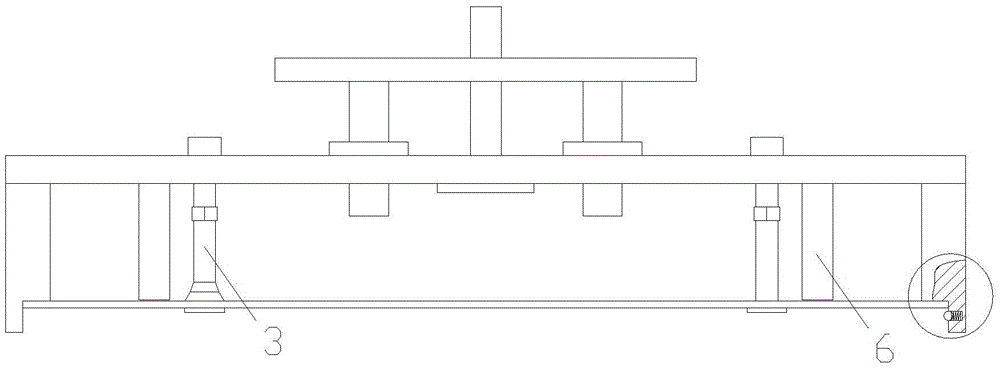

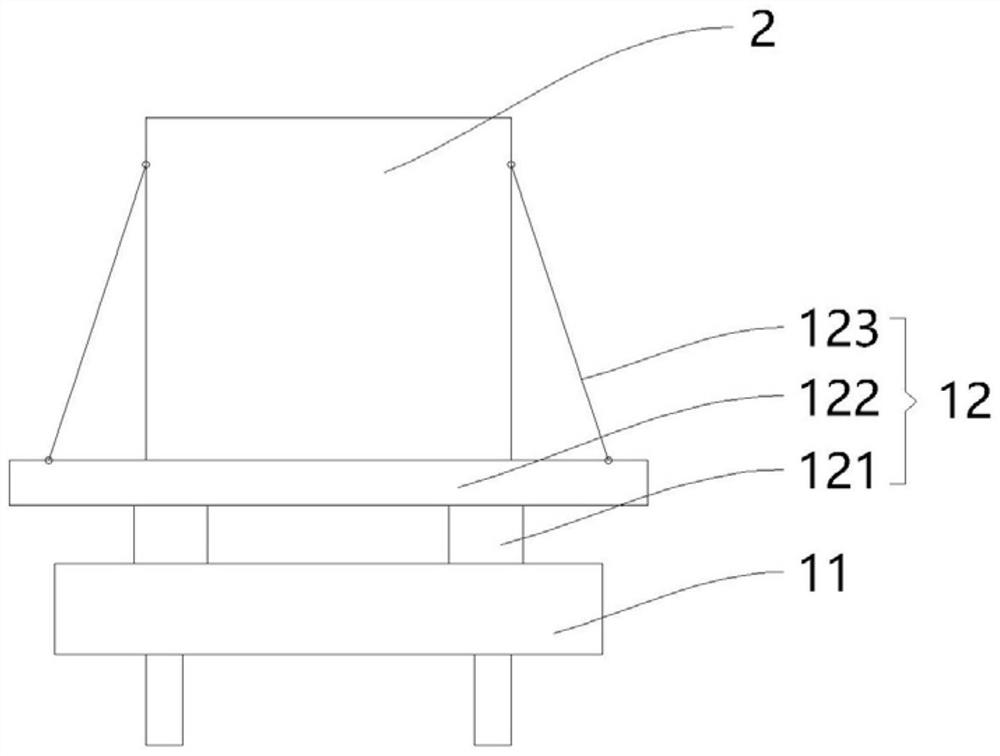

Sheet metal part elastic absorbing device with latch

ActiveCN105460615AReduce mistakesGuarantee the stability of transportationConveyor partsEngineeringMechanical engineering

The invention provides a sheet metal part elastic absorbing device with a latch. The sheet metal part elastic absorbing device with the latch comprises a fixing rack, a lifting seat and an absorbing head, wherein a supporting rod and guiding rods which are connected with the fixing rack are arranged on the lifting seat; the supporting rod is positioned in the center of the lifting seat and is connected with the fixing rack; the guiding rods are distributed on the periphery of the supporting rod and are matched with guide holes in the fixing rack; a damping spring is further arranged on each guiding rod in a matched manner; the absorbing head is arranged on the fixing rack and is axially parallel to the supporting rod; a limiting rod which is parallel to the absorbing head is further arranged on the fixing rack and is in threaded connection with the fixing rack; supporting ends which are perpendicular to end surfaces of the fixing rack are further arranged at two ends of the fixing rack; and a groove matched with a sheet metal part is formed in the bottom of each supporting end.

Owner:苏州恒泰精密钣金有限公司

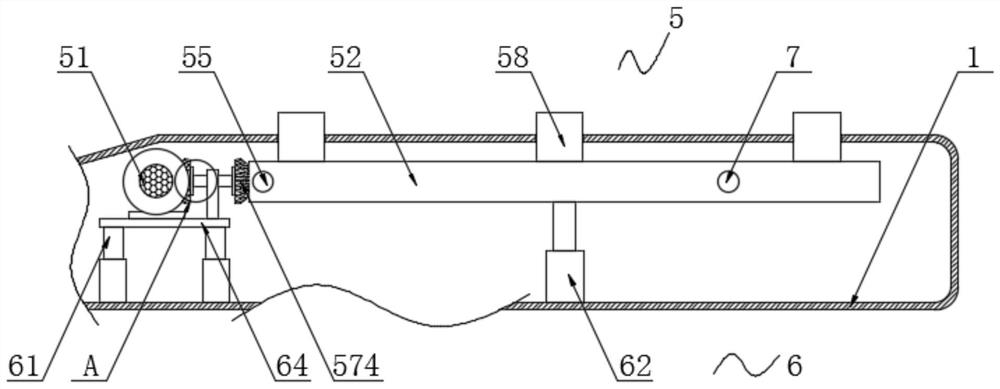

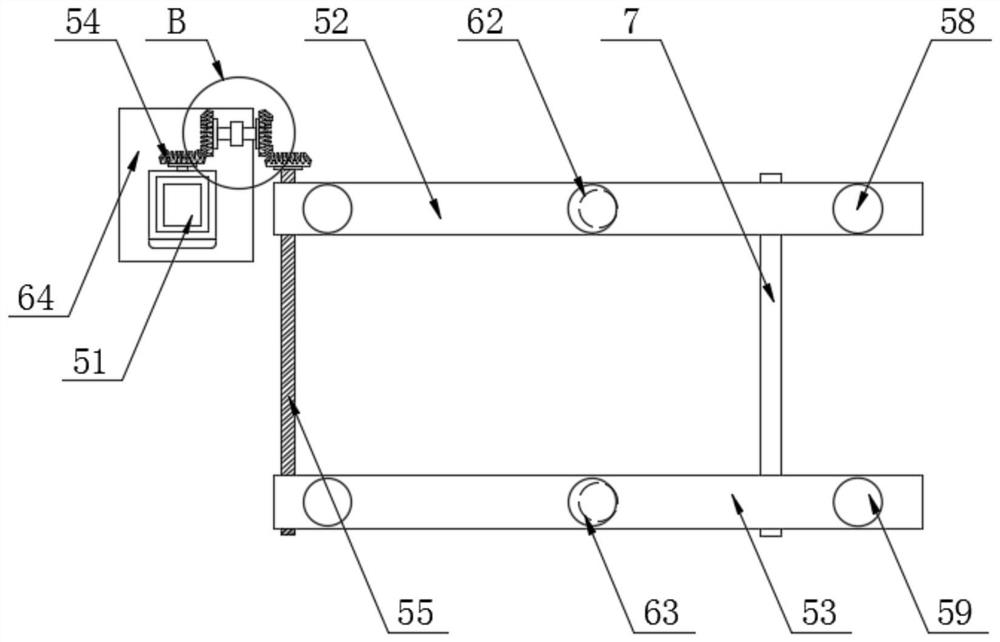

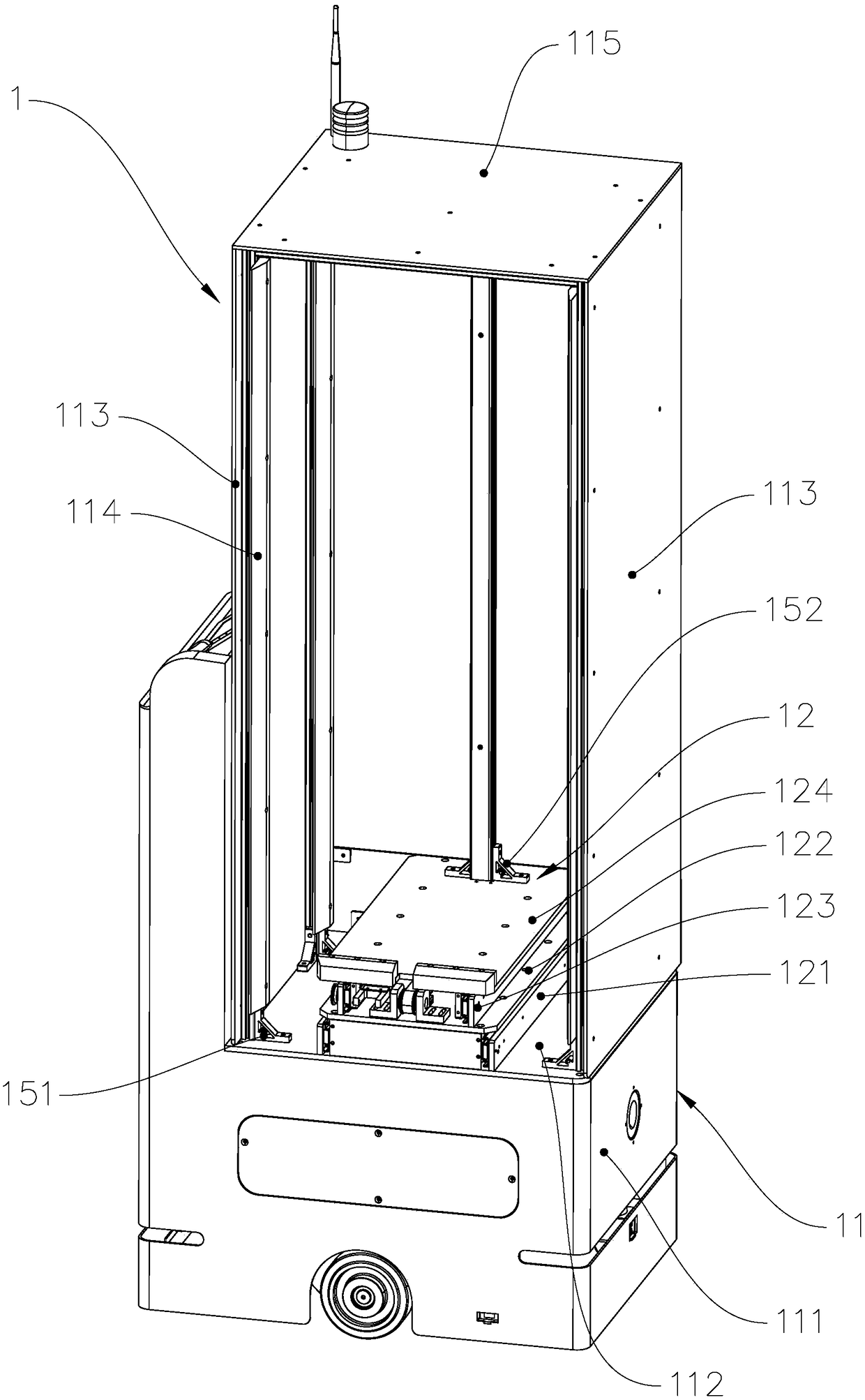

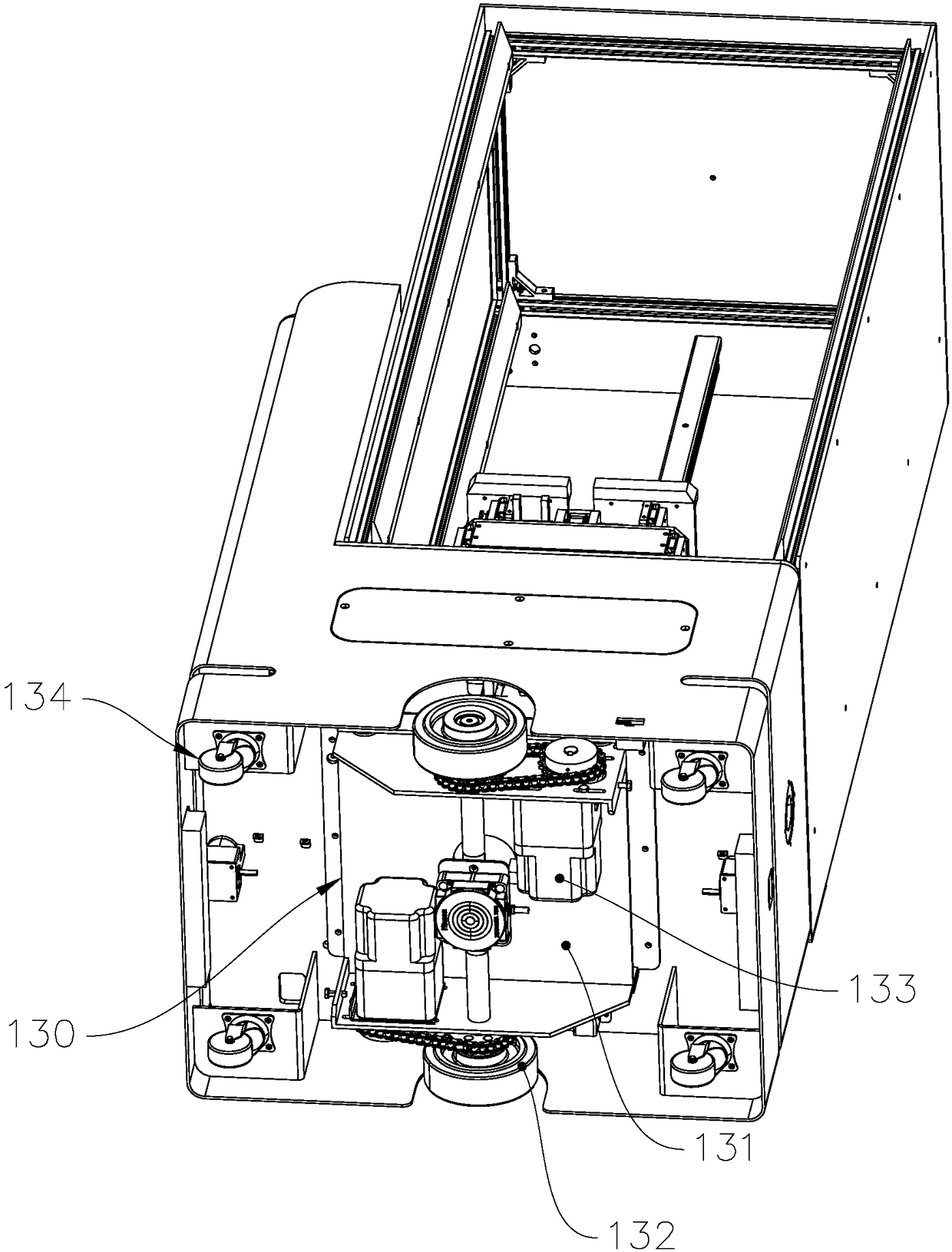

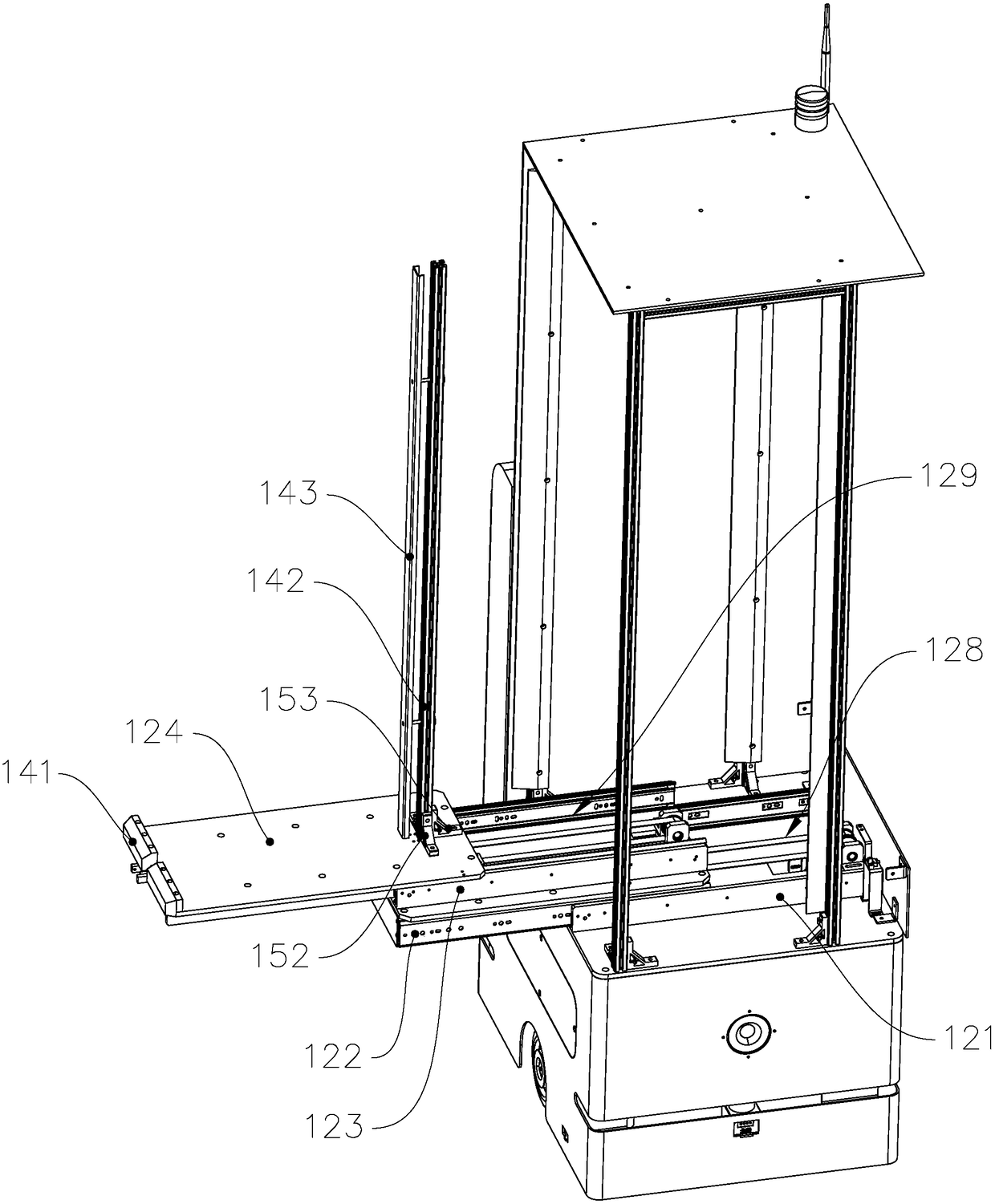

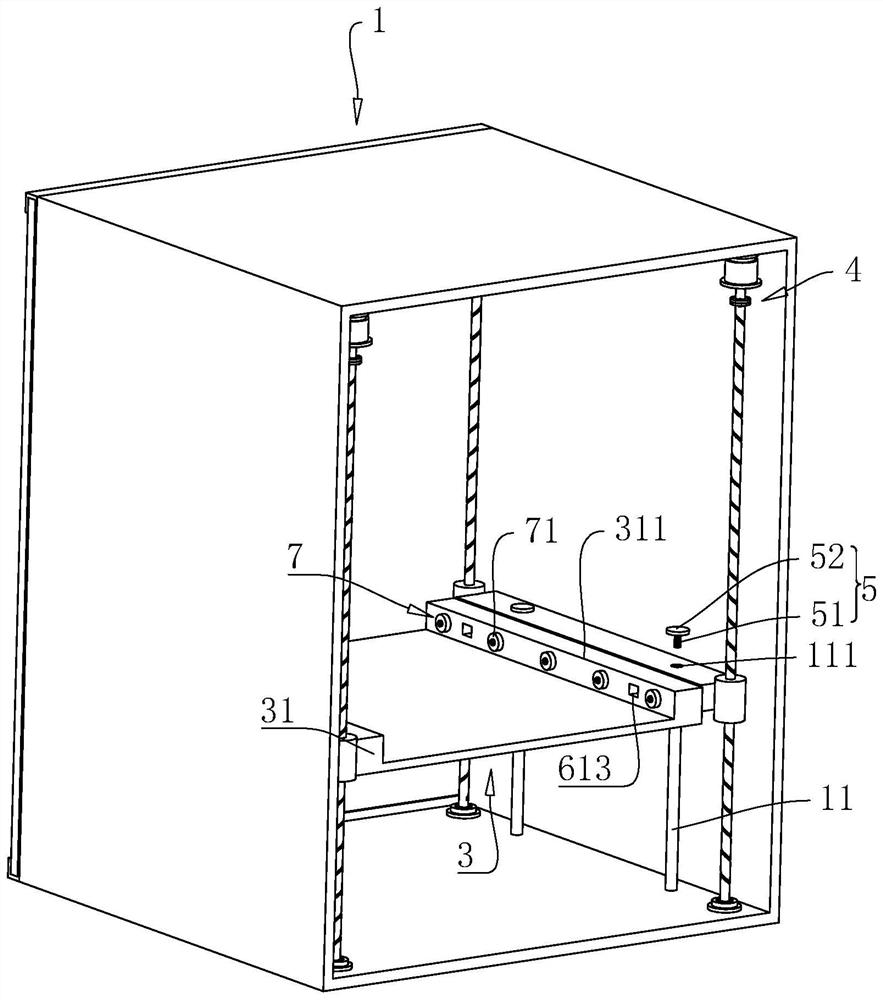

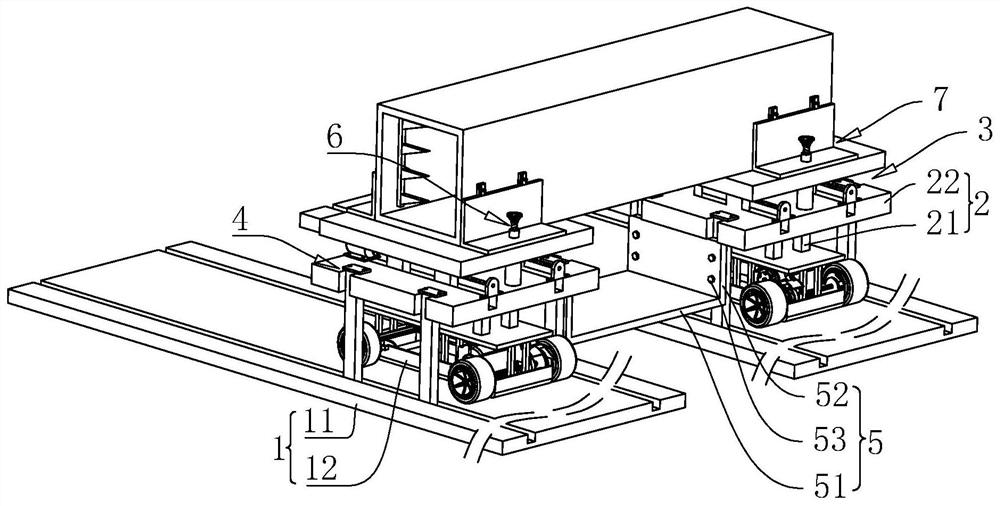

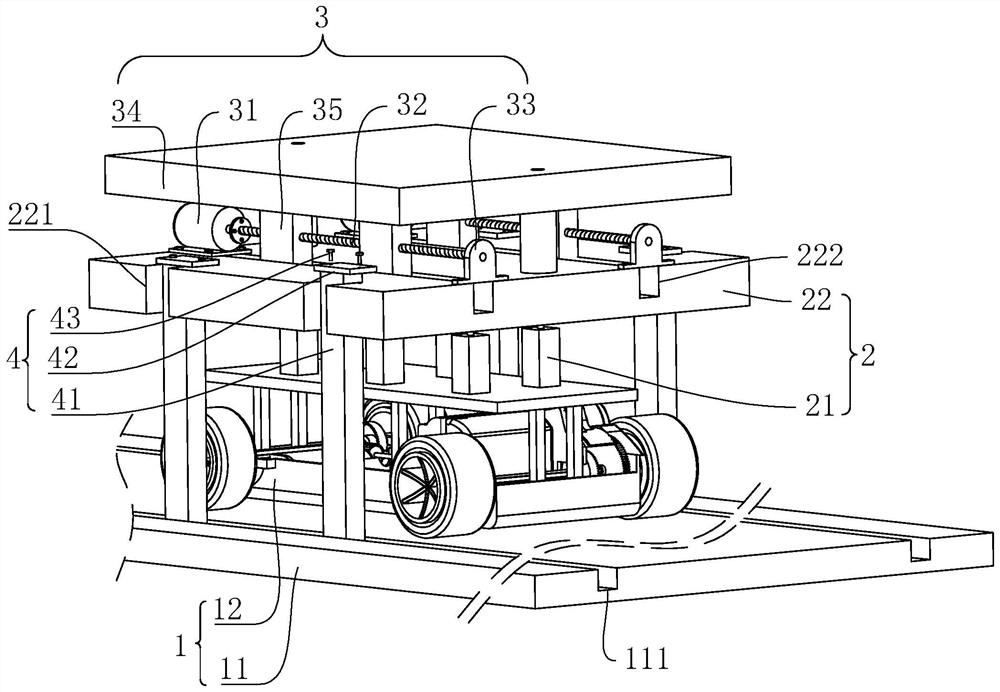

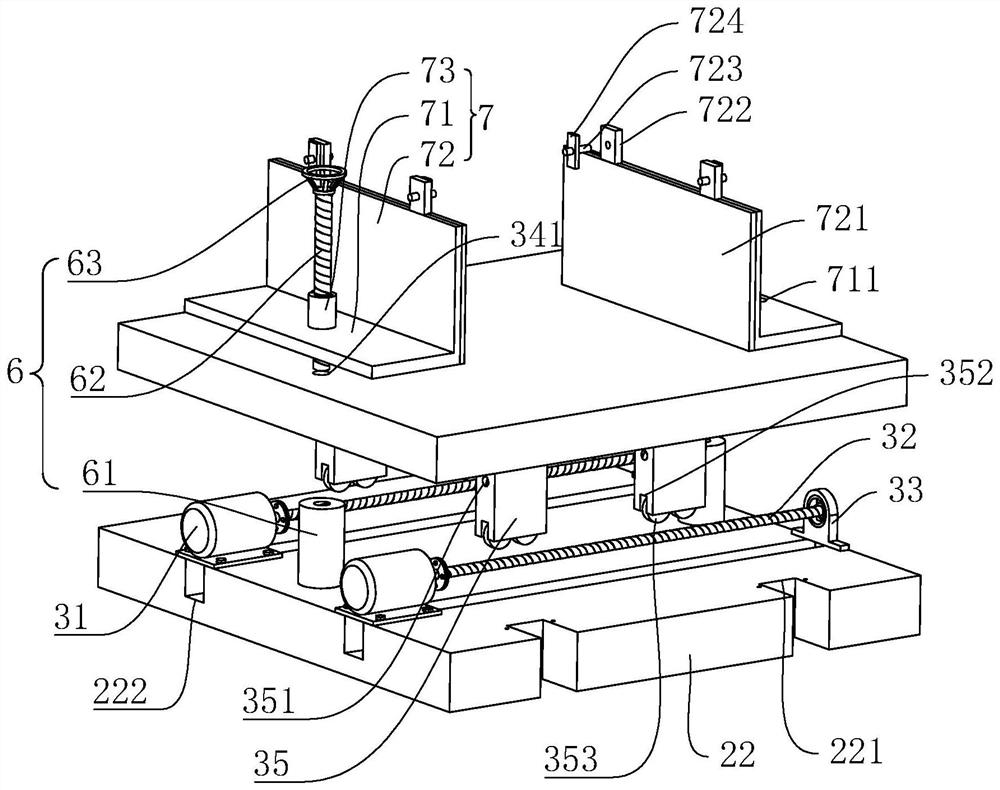

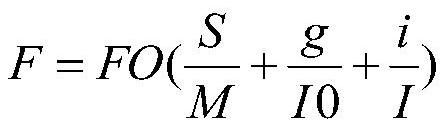

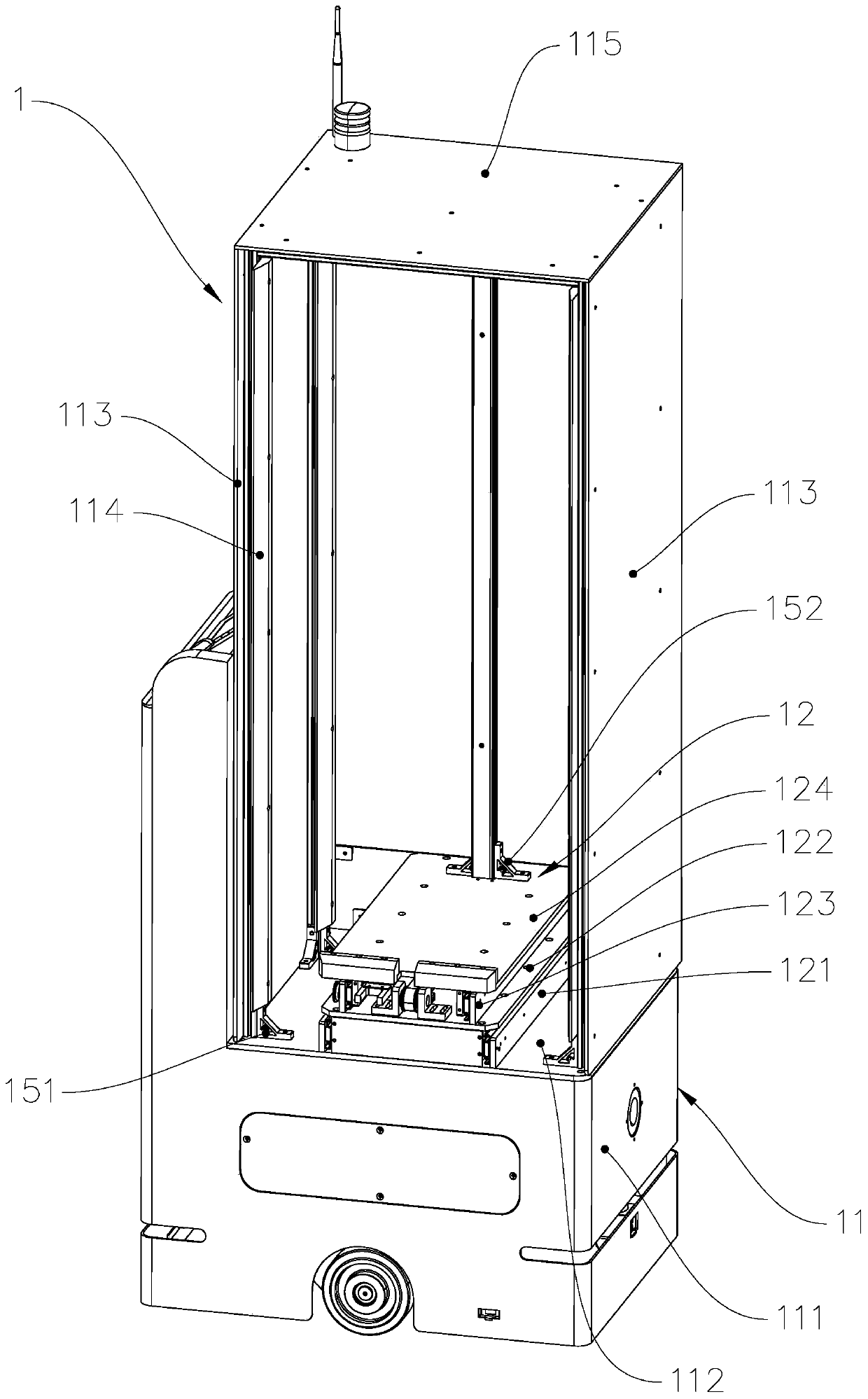

Material conveying system and material conveying method

ActiveCN108177939AWith lifting functionMiniaturizationConveyor partsMechanical conveyorsMechanical engineeringHandover

The invention provides a material conveying system and a material conveying method. The material conveying system comprises a material conveying robot and a vertical conveyer. The material conveying robot is provided with a telescopic platform assembly. A second sliding platform used for holding materials can completely extend out of a robot body. Two supporting seats are arranged on a lifting platform of the vertical conveyer. An insertion station is arranged between the two supporting seats. The material conveying method comprises the steps that the material conveying robot obtains materialcarriers, the second sliding platform and the material carriers extend out of the body and extend into the first lifting space from an overall opening, and the second sliding platform is located in the insertion station; the lifting platform rises, the supporting seats bear the material carrier, and the material carrier leaves the second sliding platform. The material conveying robot can achieve carrier handover without entering the vertical conveyer; the lifting platform achieves conveyance of the multiple material carriers, the multiple material carriers enter the material conveying robot orare recycled at the same time, so that the work frequency of the material conveying robot is lowered, and the conveyance capacity is increased; and conveyance is stable, the applicability is high, and the work efficiency is high.

Owner:ZHUHAI MAKERWIT TECH CO LTD

Bottom-through tie-bar arch bridge and its construction method

ActiveCN106592406BReduce investmentAvoid high-altitude constructionBridge erection/assemblyArch-type bridgeBridge deckArch bridge

The invention discloses a through tied arch bridge and a construction method thereof. The through tied arch bridge is composed of two single-piece arch rib units. Each single-piece arch rib unit comprises an arch rib and a tie beam, wherein a hanger rod is arranged between the arch rib and the tie beam. The two arch ribs are connected as a whole through transverse supports. The two tie beams are connected as a whole through transverse beams. A bridge deck slab is erected on the transverse beams. Each arch rib is formed by connecting arch rib sections, each tie beam is formed by connecting tie beam sections, and the arch-shaped arch rib sections and the tie beam sections are arranged correspondingly. Each transverse support is formed by connecting two transverse support sections, wherein the two transverse support sections are fixedly connected on the arch ribs of the two single-piece arch rib units correspondingly. Each transverse beam is formed by connecting two transverse beam sections, wherein the two transverse beam sections are fixedly connected on the tie beams of the two single-piece arch rib units correspondingly. By connecting each group of transverse beam sections and each group of transverse support sections on bridge location construction site, the erection work of a bridge main body can be completed, so that the construction period is shortened effectively, capital investment is reduced, and the construction method is especially suitable for bridge construction of crossing important riverways or important lines.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +1

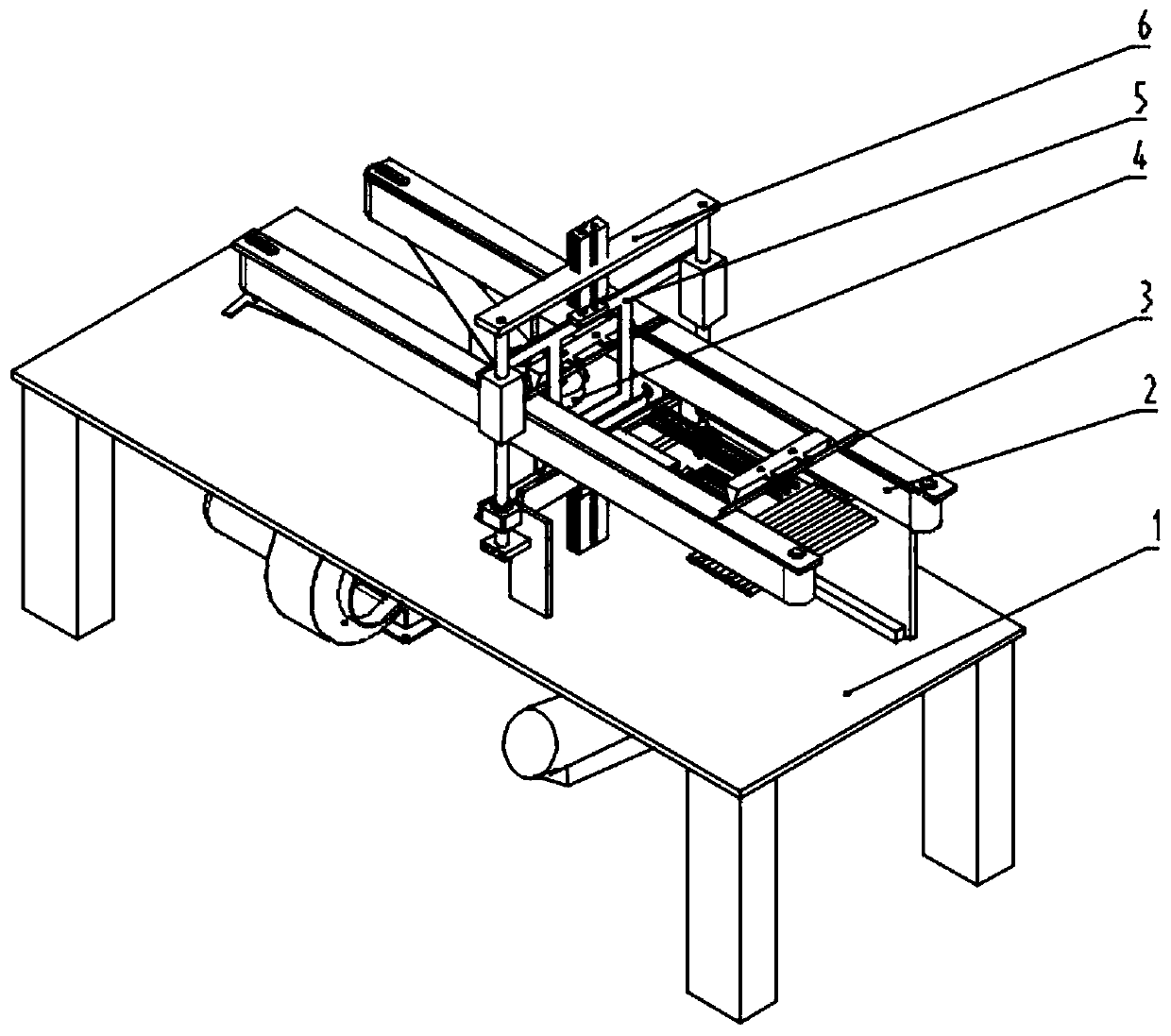

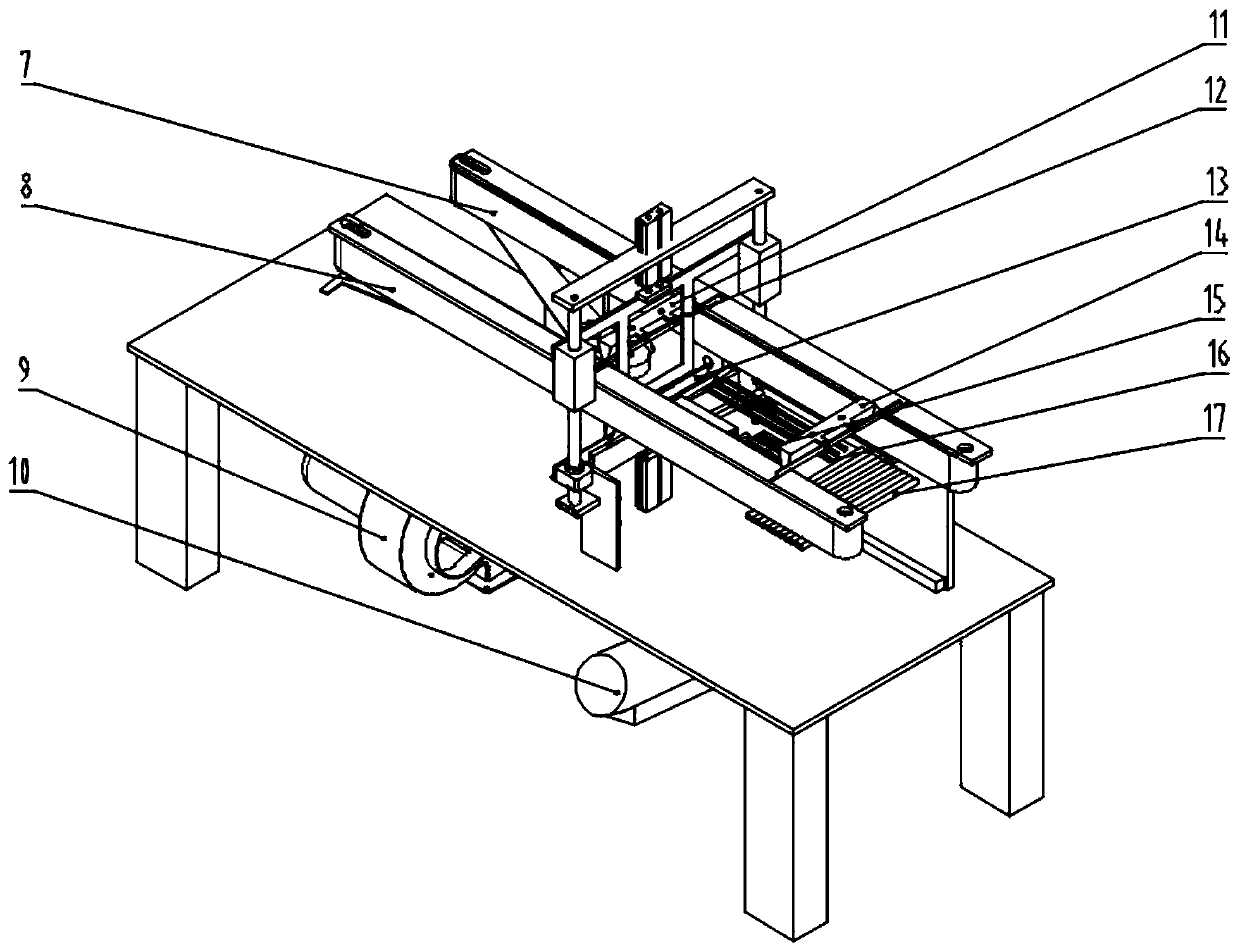

Cutting and sealing device of tray preservative film packing machine

PendingCN109866981ASimple structureReduce energy consumptionWrapper folding/bending apparatusWrapper twisting/gatheringEngineeringAir compressor

The invention relates to a cutting and sealing device of a tray preservative film packing machine. A cutter mechanism, a scraper, a transverse film sealing mechanism and a roller support belt are arranged on a worktable in sequence from left to right; a front air blowing box is fixed on a vertical material conveying unit through a bracket, and is positioned at the front end of the cutter mechanism; a back air blowing box is fixed on the vertical material conveying unit through a bracket, and is positioned at the back end of the transverse film sealing mechanism; a fan is mounted at the lower end of the worktable, and is connected with the front air blowing box and the back air blowing box through pipes; and an air compressor is mounted at the lower end of the worktable, and is connected with the cutter mechanism and the transverse film sealing mechanism through pipes. The device is scientific and reasonable in design and simple and skillful in structure; and a transverse cutting and sealing unit realizes front end sealing through the front air blowing box and the scraper, and realizes back end sealing through the back air blowing box and the transverse film sealing mechanism, so that a preservative film cutting and sealing device is simpler in structure, reduces the production cost and the energy consumption, and improves the packing quality of preservative films to achieve high working efficiency.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

An elastic suction device for sheet metal parts with snap lock

ActiveCN105460615BReduce mistakesGuarantee the stability of transportationConveyor partsEngineeringScrew thread

The invention provides a sheet metal part elastic absorbing device with a latch. The sheet metal part elastic absorbing device with the latch comprises a fixing rack, a lifting seat and an absorbing head, wherein a supporting rod and guiding rods which are connected with the fixing rack are arranged on the lifting seat; the supporting rod is positioned in the center of the lifting seat and is connected with the fixing rack; the guiding rods are distributed on the periphery of the supporting rod and are matched with guide holes in the fixing rack; a damping spring is further arranged on each guiding rod in a matched manner; the absorbing head is arranged on the fixing rack and is axially parallel to the supporting rod; a limiting rod which is parallel to the absorbing head is further arranged on the fixing rack and is in threaded connection with the fixing rack; supporting ends which are perpendicular to end surfaces of the fixing rack are further arranged at two ends of the fixing rack; and a groove matched with a sheet metal part is formed in the bottom of each supporting end.

Owner:苏州恒泰精密钣金有限公司

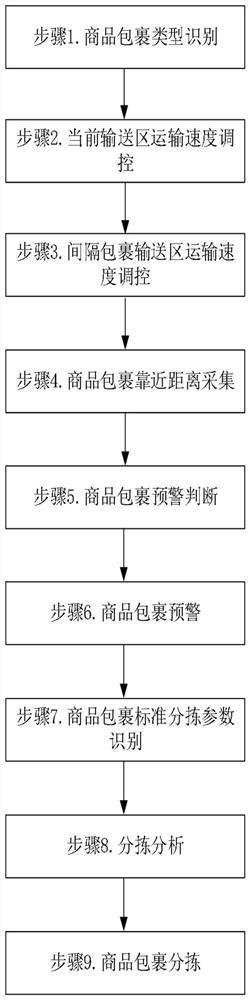

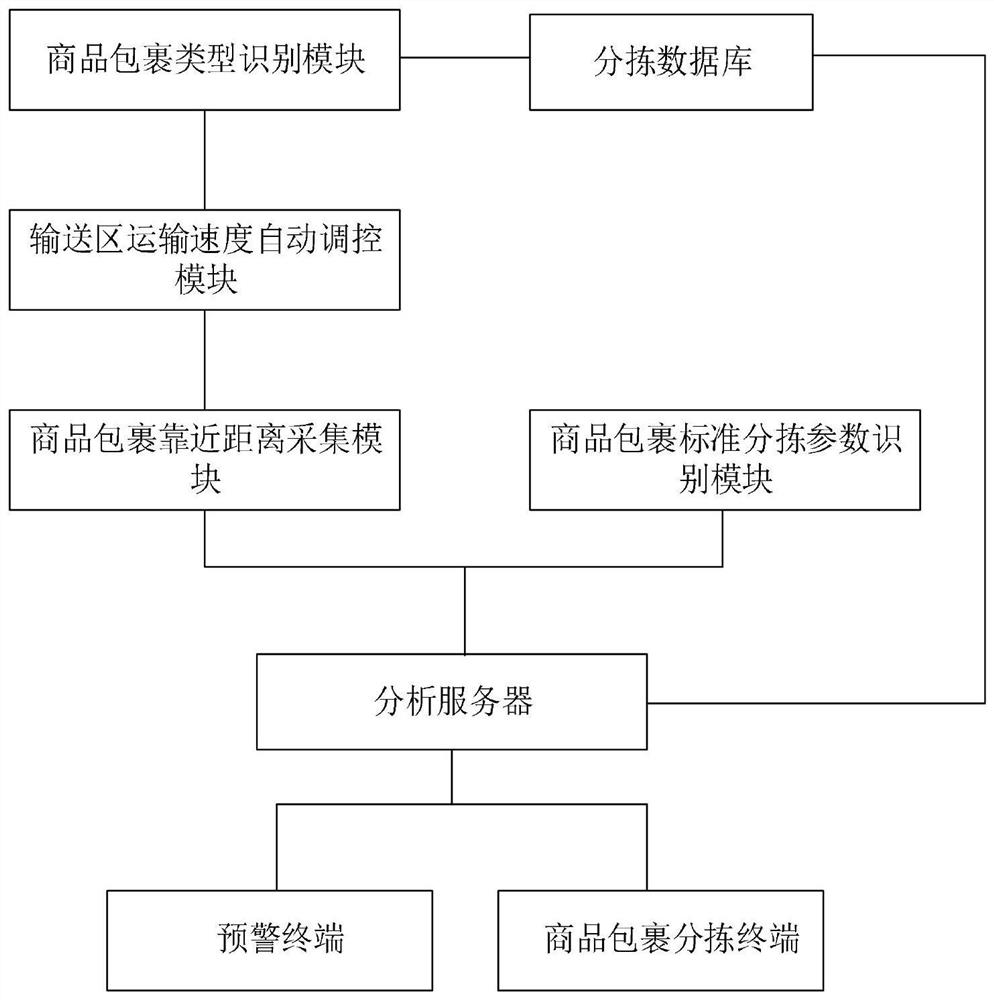

Intelligent commodity package sorting method and system based on machine vision and computer storage medium

ActiveCN113499996ARealize refined sortingAvoid unified loading and deliverySortingMachine visionSoftware engineering

The invention discloses an intelligent commodity package sorting method and system based on a machine vision and a computer storage medium. When commodity packages are conveyed in a conveying area corresponding to a package sorting machine, the conveying speed of the conveying area of the current package sorting machine is regulated and controlled in a targeted mode according to the package types corresponding to the commodity packages; an unloading channel is arranged at each sorting partition opening corresponding to the package sorting machine, so that transportation addresses and commodity types of the commodity packages are collected when the commodity packages are sorted, and target sorting partition openings corresponding to the commodity packages and specified unloading channels corresponding to the target sorting partition openings are analyzed according to the transportation addresses and the commodity types; therefore, the commodity packages are sorted to the designated unloading channels, so that flexible regulation and control over the conveying speed of the corresponding conveying area of the package sorting machine and refined sorting of the commodity packages are achieved, and the sorting efficiency is improved; on one hand, the conveying quality of fresh or fragile packages is guaranteed, and on the other hand, the conveying stability of large packages is guaranteed.

Owner:广州哆啦科技有限公司

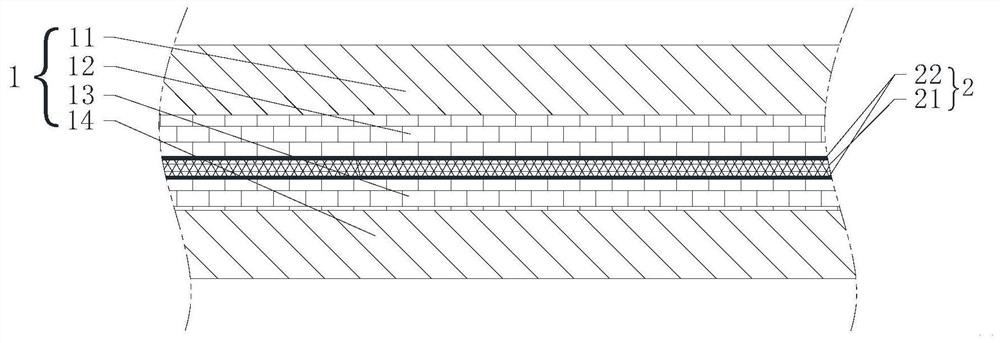

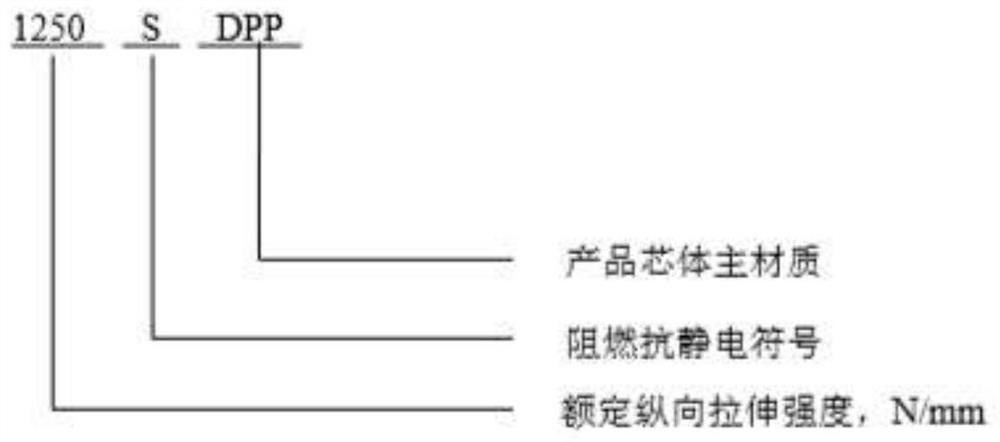

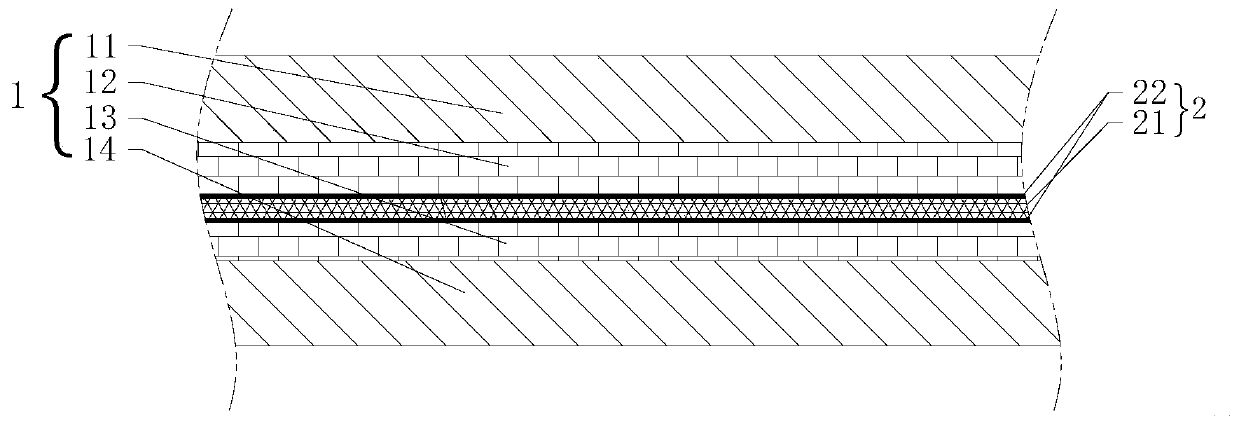

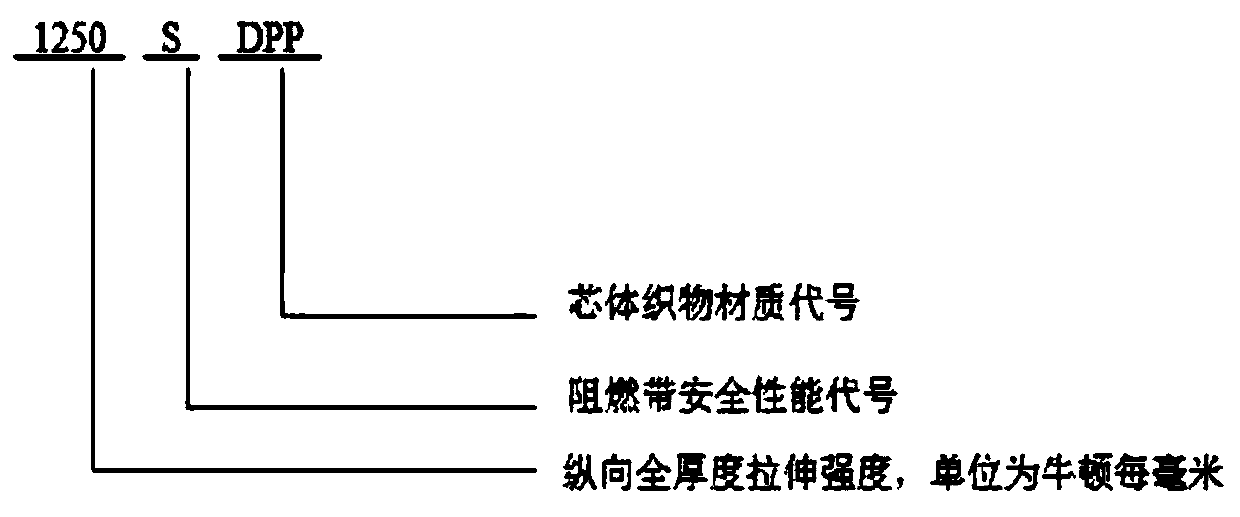

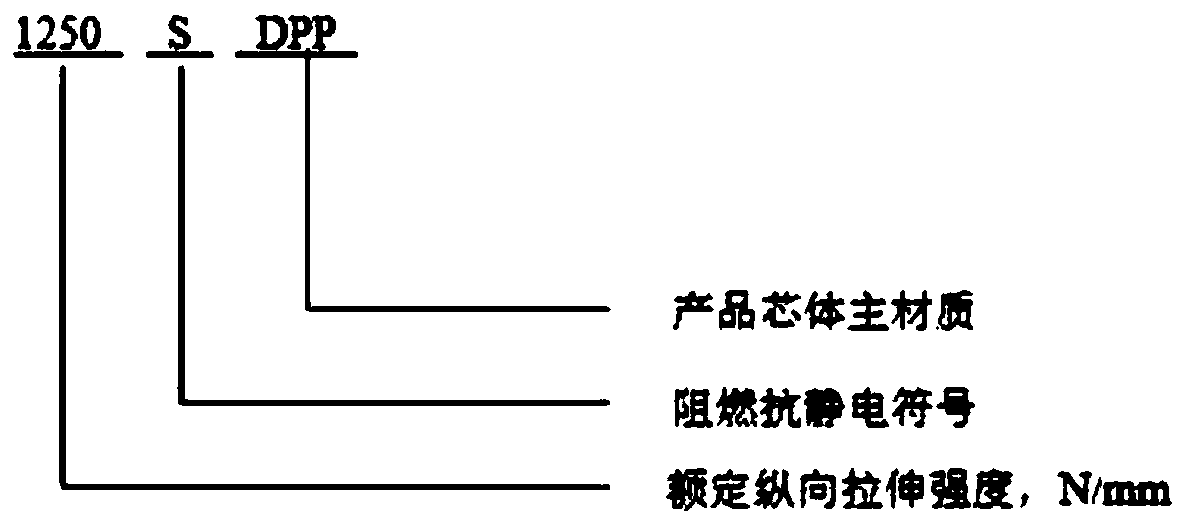

Aramid Fabric Skeleton Flame Retardant Conveyor Belt for Coal Mine

ActiveCN110127282BSignificant progressImprove impact resistanceConveyorsSynthetic resin layered productsZinc borateMining engineering

The invention relates to a flame-retardant conveyor belt with an aramid fabric skeleton used in coal mines, which includes a belt body made of neoprene; the belt body includes an upper covering rubber layer, an A transition rubber layer, a B transition rubber layer and a lower covering layer sequentially arranged from outside to inside. Layer rubber, the thickness of the upper cover layer rubber is 4-12mm, and the thickness of the lower cover layer rubber is 3-6mm; there is a skeleton layer between the A transition rubber layer and the B transition rubber layer; the skeleton layer is composed of a layer of aramid canvas and It is composed of a dipping layer wrapped on the outer surface of aramid canvas, and the thickness of the skeleton layer is 2.5-6mm; the raw material components of the upper cover rubber and the lower cover rubber contain flame retardants; the flame retardants are chlorinated paraffin, One or more of antimony oxide, zinc borate, and ammonium polyphosphate. The flame-retardant conveyor belt with aramid fiber fabric skeleton for coal mines of the present invention can transport materials in high-strength, long-distance, and large-capacity occasions, is suitable for use in the harsh environment of coal mine underground operations, and has high heat resistance and fire resistance. .

Owner:ZHEJIANG FENFEI RUBBER & PLASTIC PROD CO LTD +1

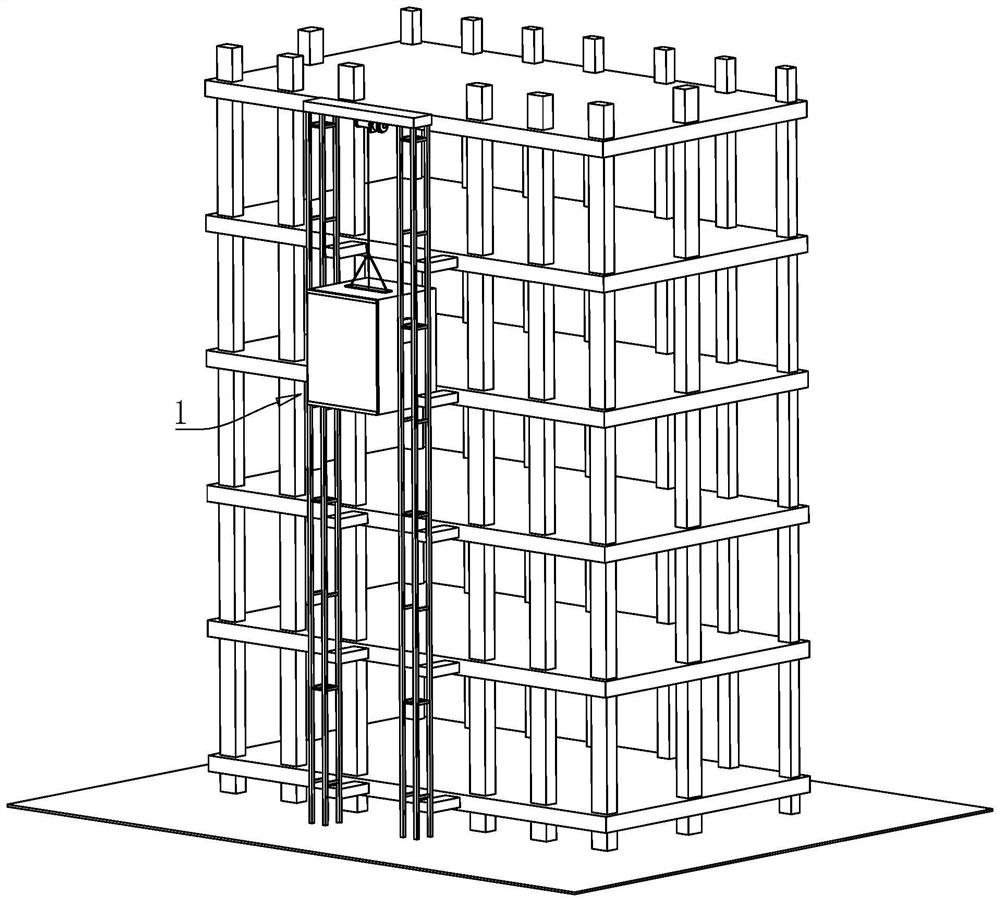

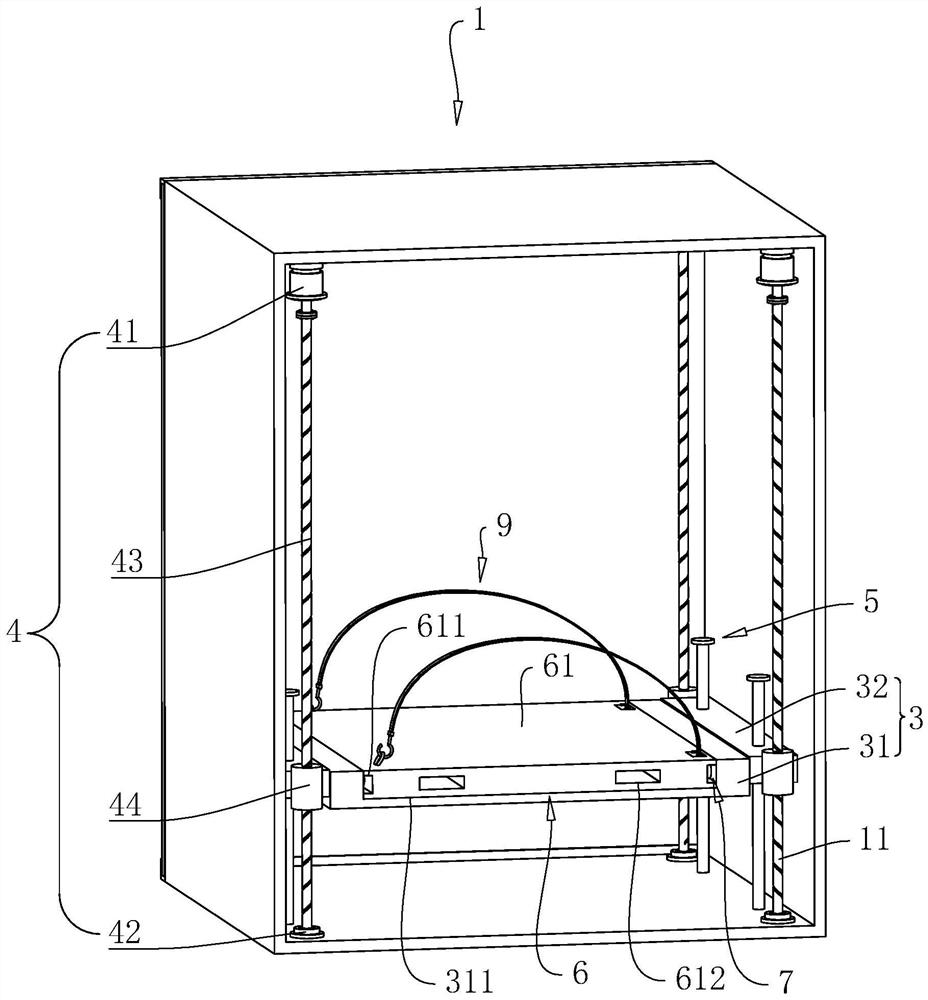

Efficient BIM-based super high-rise housing construction freight structure

PendingCN114261867AImprove unloading efficiencyImprove positional stabilityBuilding liftsConstruction schedulingPallet fork

The invention relates to an efficient BIM-based super high-rise building freight structure, and relates to the technical field of super high-rise building, the efficient BIM-based super high-rise building freight structure comprises a lifting car and further comprises a freight mechanism, the freight mechanism comprises a fixed device and a movable device, the fixed device is arranged in the lifting car, and the movable device is arranged on the fixed device; the fixing device comprises a bearing plate, and the bearing plate is arranged in the lifting car. The movable device comprises a movable plate, and the movable plate is arranged on the bearing plate in a sliding mode; a plurality of inserting channels are formed in the movable plate in a penetrating mode, and the inserting channels are used for allowing pallet forks of a forklift to be connected in an inserting mode so as to move the movable plate and goods. The method has the effects that the cargo unloading efficiency is improved, and the construction progress of a building is guaranteed.

Owner:苏州江南意造建筑设计有限公司

Transportation system for assembly type standard knot construction of comprehensive pipe gallery

ActiveCN113104764AReduce construction difficultyImprove convenienceLifting framesTransit systemArchitectural engineering

The invention relates to a transportation system for assembly type standard knot construction of a comprehensive pipe gallery. The transportation system comprises two groups of transferring assemblies, wherein each group of transferring assemblies comprises a guide plate and a transferring vehicle; each transferring vehicle is provided with a jacking assembly; each jacking assembly comprises a jacking plate and a plurality of jacking oil cylinders; all the jacking oil cylinders are arranged on the transferring vehicles; each jacking plate is arranged at one end of a piston rod of the corresponding jacking oil cylinder; each jacking plate is provided with a translation assembly; each translation assembly comprises a driving motor, a propelling screw rod, a positioning seat, a carrying plate and a plurality of supporting plates; all the supporting plates are arranged on the lower surface of the carrying plate; a sliding groove is formed in the upper surface of each jacking plate along the length direction; the driving motors and the positioning seats are arranged on the upper surfaces of the jacking plates; and an adaptive groove, which is in thread match with the corresponding propelling screw rod, is formed in an outer side wall of each supporting plate in a penetrating manner. The transportation system provided by the invention has the effects of effectively reducing the working difficulty of controlling standard part alignment and installation in a foundation pit by operators.

Owner:湖南路港建设有限公司

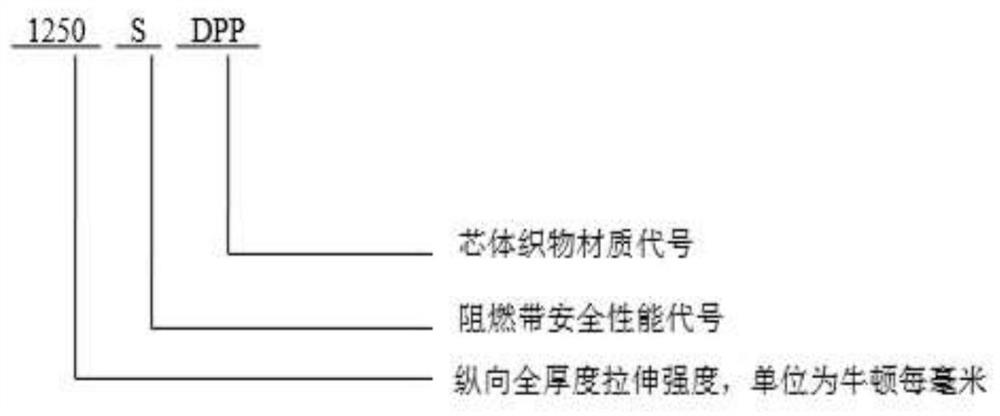

Aramid fiber framework flame-retardant conveyor belt for coal mines

ActiveCN110127282ASignificant progressImprove impact resistanceConveyorsSynthetic resin layered productsZinc borateEngineering

The invention relates to an aramid fiber framework flame-retardant conveying belt for the coal mines. The aramid fiber fabric framework flame-retardant conveying belt comprises a belt body made of chloroprene rubber, wherein the belt body comprises upper covering layer rubber, a transition rubber layer A, a transition rubber layer B and a lower covering layer rubber which are sequentially arrangedfrom outside to inside, the thickness of the upper covering layer rubber is 4-12 mm, and the thickness of the lower covering layer rubber is 3-6 mm. A framework layer is arranged between the transition rubber layer A and the transition rubber layer B, and the framework layer is composed of a layer of aramid canvas and a glue dipping layer wrapping the outer surface of the aramid canvas, with thethickness of the framework layer being 2.5mm-6mm. A flame retardant is contained in raw material components of the upper covering layer rubber and the lower covering layer rubber, and the flame retardant is one or more of chlorinated paraffin, antimony oxide, zinc borate and ammonium polyphosphate. The aramid fiber fabric framework flame-retardant conveyor belt for the coal mines is capable of conveying materials under the conditions of high strength, long distance and large capacity, suitable for severe environments of underground coal mine operation, and has high heat resistance and fireproof performance.

Owner:ZHEJIANG FENFEI RUBBER & PLASTIC PROD CO LTD +1

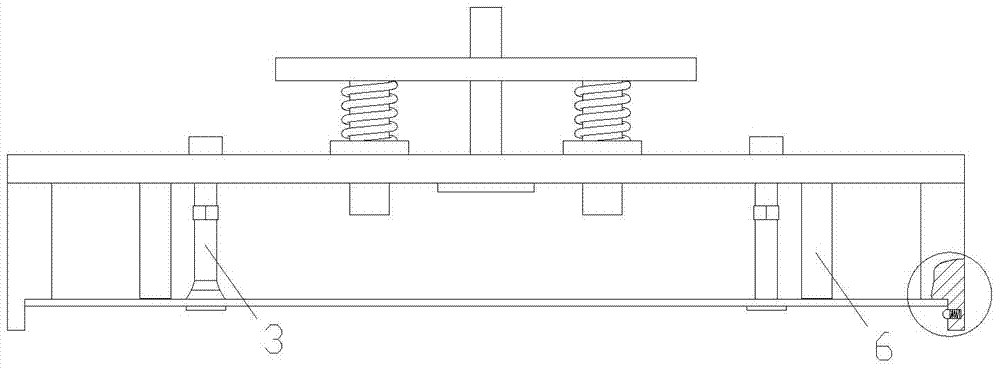

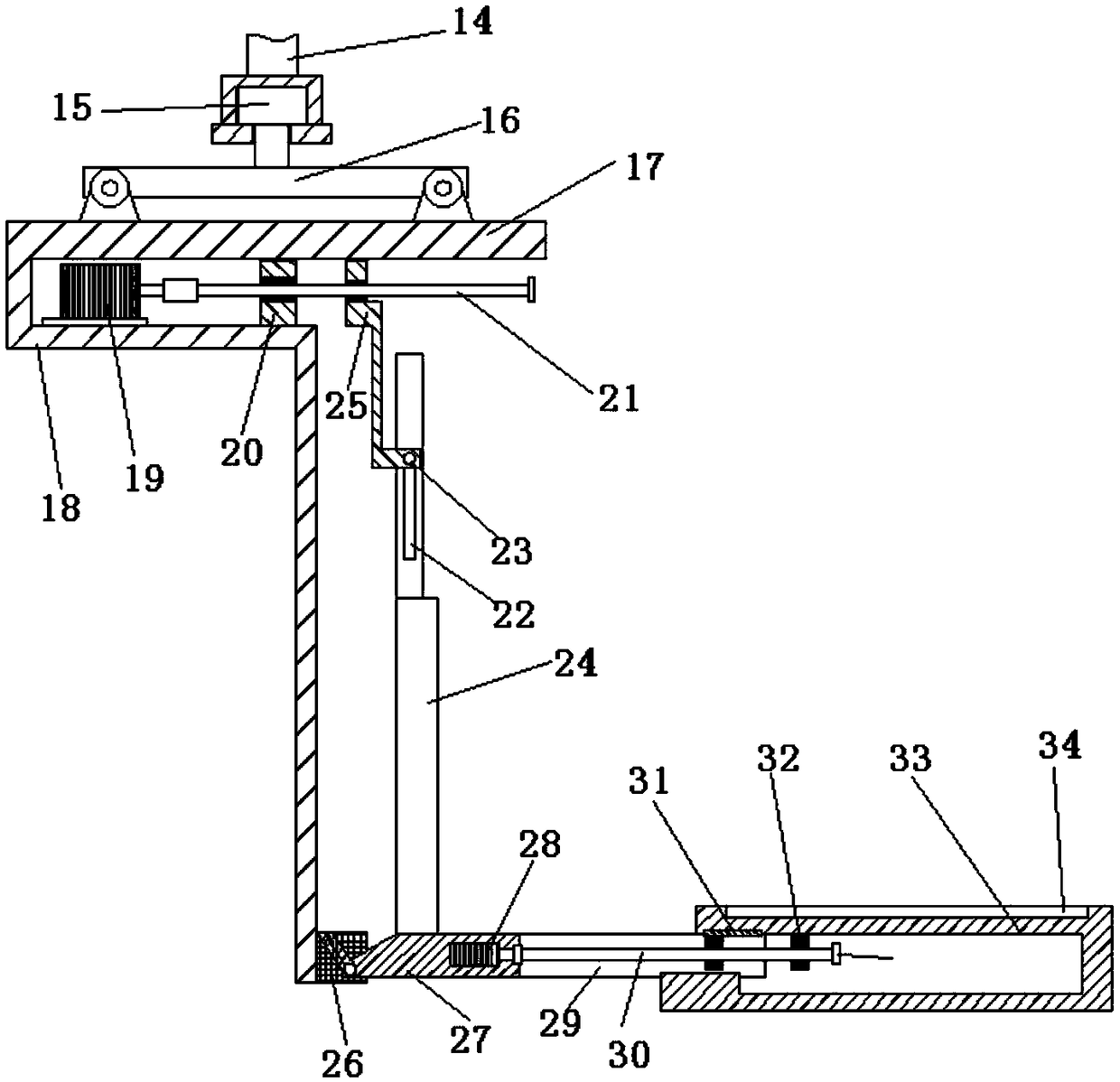

Garment production material lifting device

InactiveCN108793021AImprove lifting efficiencyEasy transferLifting devicesEngineeringMaterial transport

The invention discloses a garment production material lifting device. According to the garment production material lifting device, the garment material lifting efficiency can be greatly improved, garment materials are lifted step by step through a primary lifting assembly and a secondary lifting assembly, and material conveying during garment machining is facilitated; material conveying is conducted in the lifting and action moving modes, and the occupied space of a garment production factory can be effectively saved; and meanwhile, a first bearing seat and a second bearing seat are adjustablein angle and thus can be obliquely arranged upwards or downwards, and the transport stability and the loading and unloading convenience are ensured. In addition, the garment production material lifting device is smooth, steady and reliable in lifting operation, and the material transport stability is ensured.

Owner:宿州学院

Mechanical conveying device convenient and fast to use

ActiveCN113104548AIncrease frictionGuarantee the stability of transportationConveyorsConveyor partsPhysicsEngineering

Owner:常山县永达轴承有限公司

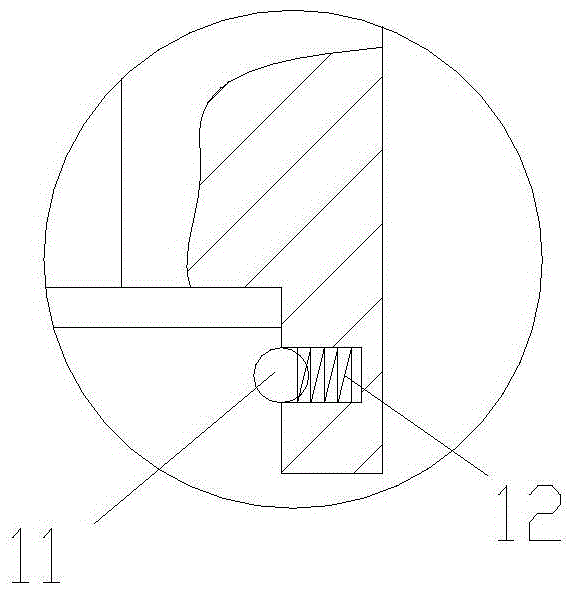

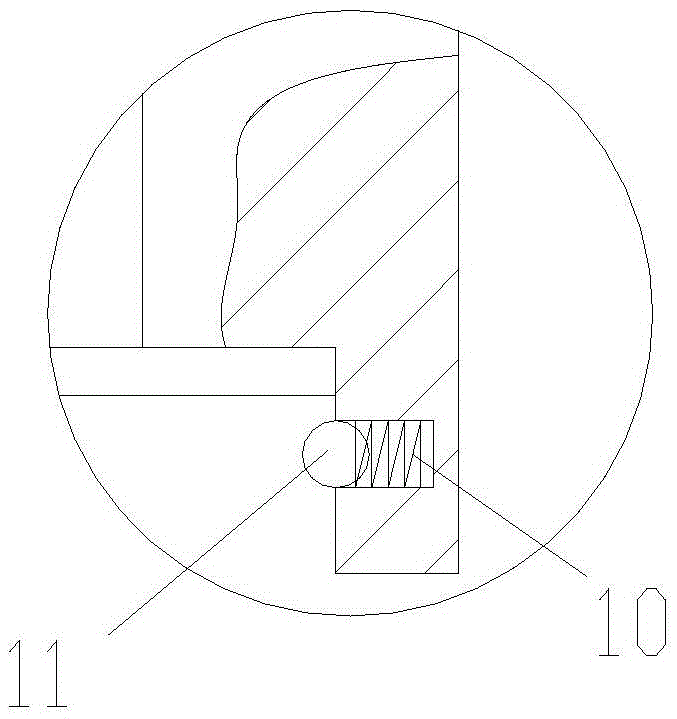

Sheet metal part sucking device with clamping lock

InactiveCN105480719AGuarantee the stability of transportationSimple structureConveyorsConveyor partsEngineeringMechanical engineering

The invention discloses a sheet metal part sucking device with a clamping lock. The sheet metal part sucking device comprises a fixing frame, a lifting seat and adsorbing heads. The lifting seat is provided with a supporting rod and guide rods of the fixing frame. The supporting rod is located in the center of the lifting seat and is connected with the fixing frame. The guide rods are distributed on the periphery of the supporting rod and are matched with guide holes in the fixing frame. The fixing frame is provided with the adsorbing heads which are parallel to the axial direction of the supporting rod. The fixing frame is further provided with limiting rods parallel to the adsorbing heads. The limiting rods are in threaded connection with the fixing frame. The two ends of the fixing frame are further provided with supporting ends perpendicular to the end face of the fixing frame. The supporting ends are provided with grooves sucking sheet metal parts in a matched manner. Containing cavities are formed in the grooves. Outlets of the containing cavities are located in the inner walls of the grooves. Balls and springs are arranged in the containing cavities. The springs eject the balls to the outlets of the containing cavities. Part of ball bodies of the balls are exposed out of the outlets of the containing cavities.

Owner:SUZHOU HENGTAI METAL PROD

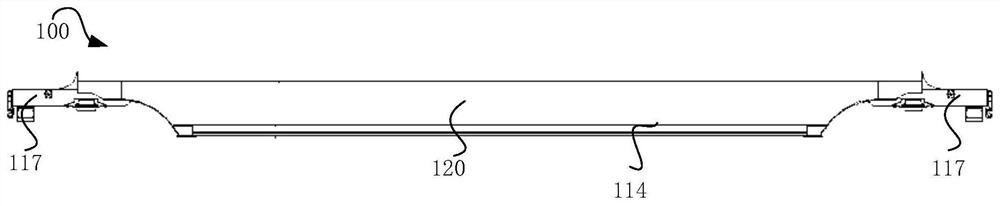

Car bodies for railway freight cars and railway freight cars

ActiveCN111301454BGuarantee the stability of transportationEvenly loadedAxle-box lubricationRailway bodiesTransport timeTruck

The invention provides a wagon body for a railway wagon. The wagon body comprises a middle underframe, two opposite sides of the middle underframe are respectively provided with a side wall, and the two side walls and the middle underframe jointly form an accommodating cavity for accommodating a road wagon, wherein two ends of each side wall are respectively used for being connected with a bogie of the railway wagon. Compared with wagon bodies in the prior art, the wagon body for the railway wagon of the invention has the following advantages: on one hand, the wagon body provides the accommodating cavity for the road wagon, so that the road wagon loaded with goods can be stably loaded on the railway wagon; and on the other hand, in the cargo transportation process of the wagon body, the process of unloading cargoes on the railway wagon to the road wagon can be omitted, so that the transportation time is shortened, and the transportation efficiency is improved.

Owner:CHINA RAILWAYS CORPORATION +1

Forming positioning device for copper strip manufacturing

ActiveCN113334089ARapid responseImprove stabilityMeasurement/indication equipmentsShearing machinesCopper tapeManufacturing engineering

The invention relates to the technical field of copper strip manufacturing, and discloses a forming positioning device for copper strip manufacturing. The forming positioning device for copper strip manufacturing comprises two inverted-L-shaped fixing blocks, the two fixing blocks correspond to each other left and right, air cushions are fixedly connected to the bottom ends of the corresponding faces of the two fixing blocks, and touch plates are fixedly connected to the corresponding ends of the two air cushions. Through the arrangement of the touch plates, a spraying rod is triggered in a pneumatic mode to mark the protruding position of a copper strip, compared with an existing sensor detection mode, the beneficial effects of being rapid in response and high in stability are achieved, the device is suitable for being used for a long time, the two touch plates can change the distance according to the shape of the copper strip, and conveying of the copper strip is prevented from being hindered; and ink is sprayed only when the spraying rod corresponds to the protruding position of the copper strip, the ink is stored in a closed space in a sleeve at ordinary times, and therefore the problems that in existing spraying, the spraying effect is poor after drying, and cleaning is difficult due to dirt and ink dripping caused by continuous attaching of the copper strip are solved.

Owner:江苏兴成新材料有限公司

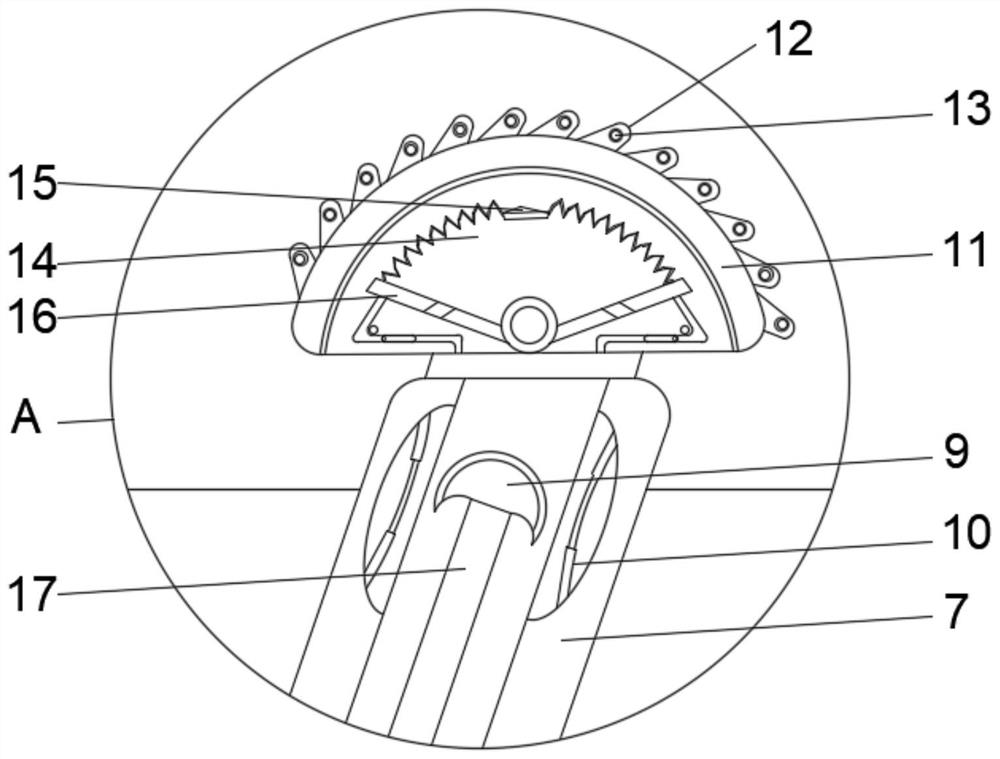

An automatic quantitative weighing device for liquid canning

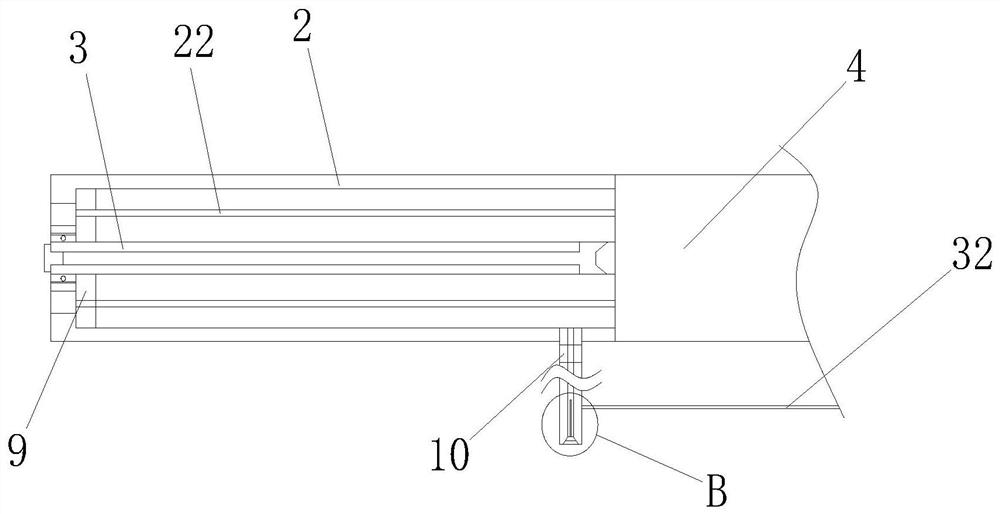

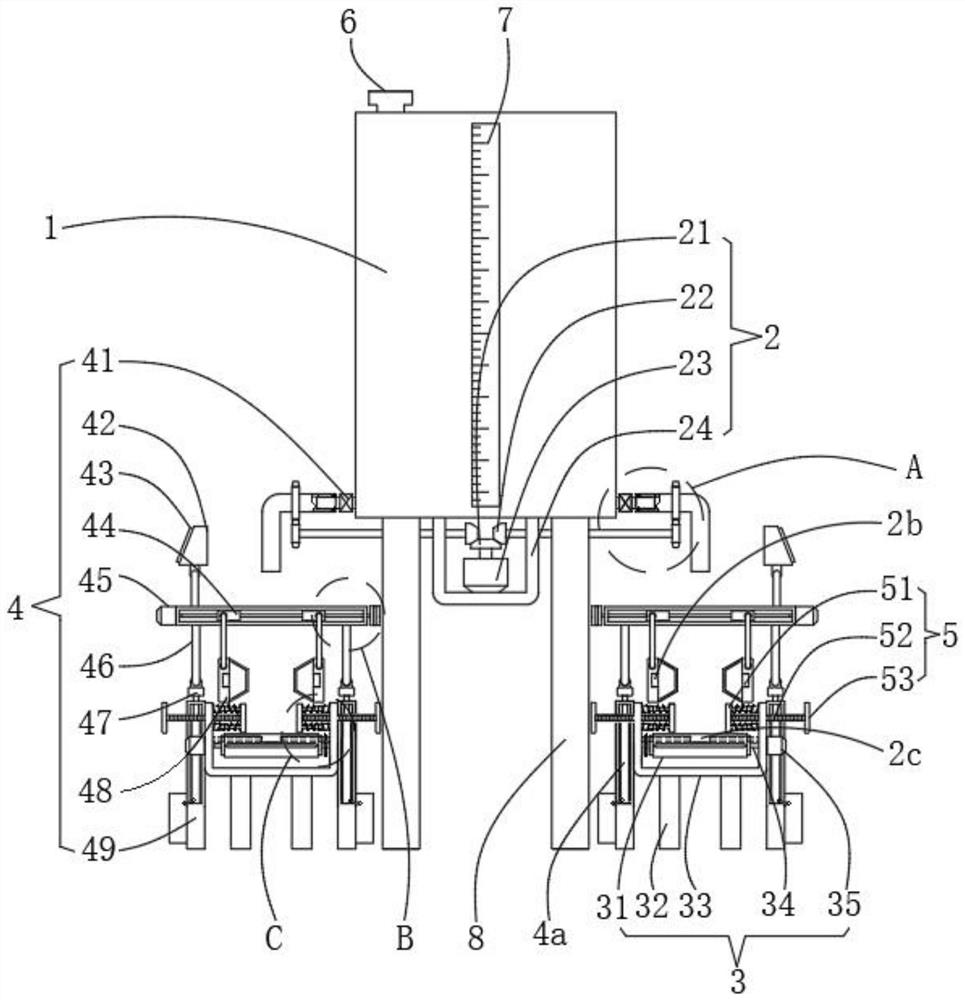

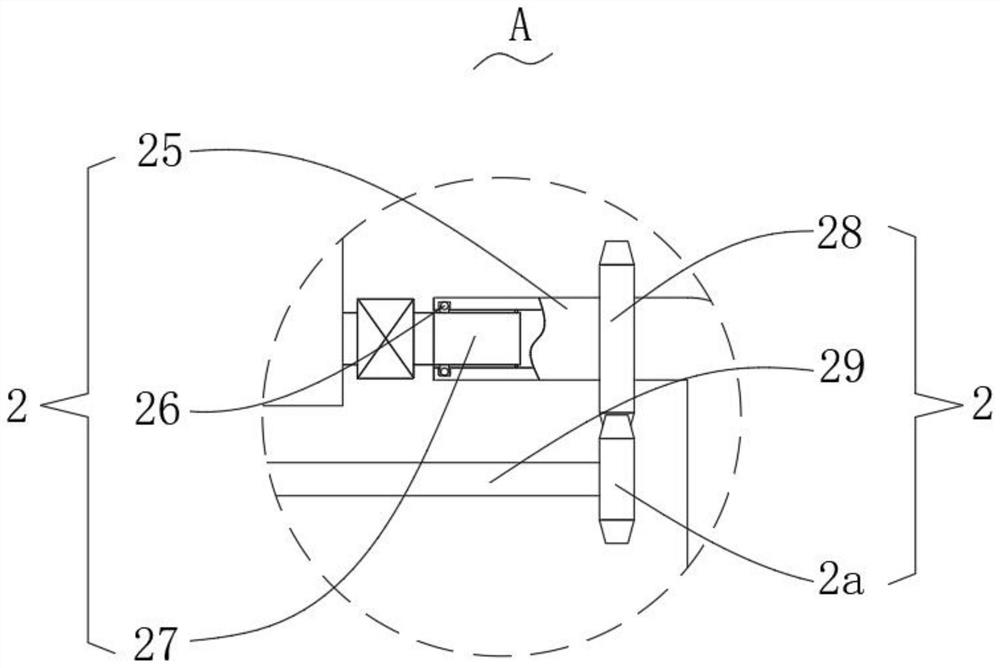

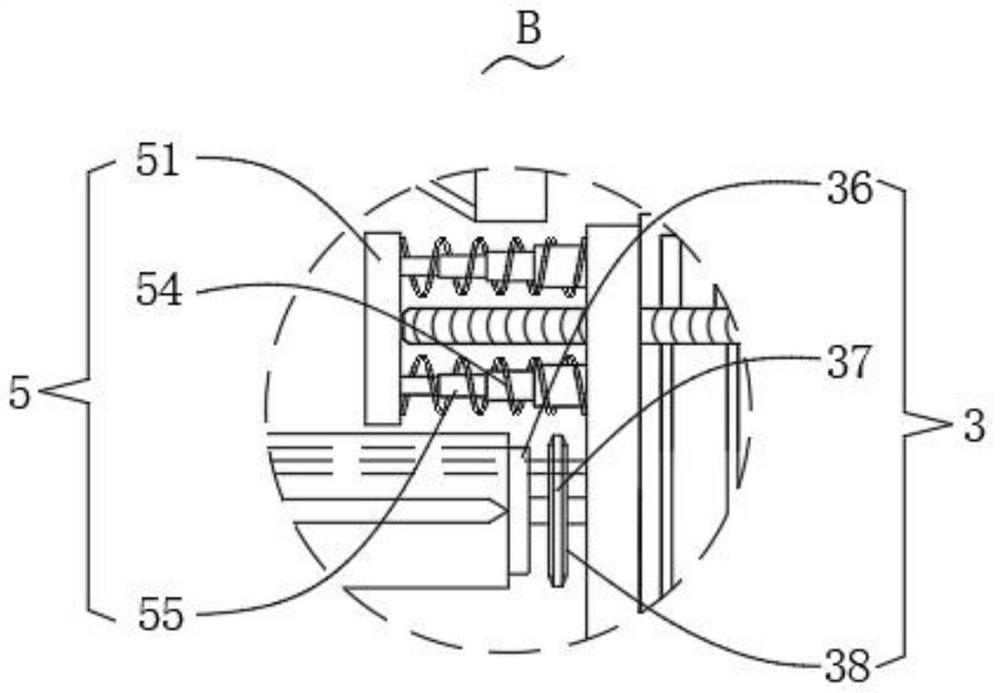

ActiveCN110950288BAvoid drippingAvoid problemsSafety device in filling machineryMarine engineeringElectric machine

The invention provides an automatic quantitative weighing device for liquid canning. The liquid canned automatic quantitative weighing device includes an oil storage tank, an oil leakage-proof discharge structure, a transport structure, and a clamping lifting quantitative weighing structure. The structure is connected to the oil storage tank, and the anti-leakage oil discharge structure includes a first helical gear, a second helical gear, a rotating motor, a U-shaped mounting plate, an L-shaped oil discharge pipe, an oil outlet pipe, a first gear, a rotating shaft and a second gear, The outer wall of the bottom of the oil storage tank is connected to two symmetrical and horizontal oil outlet pipes, the other end of the oil outlet pipe is connected to the L-shaped oil discharge pipe, the center of the bottom surface of the oil storage tank is connected to the U-shaped mounting plate, and the inner part of the U-shaped mounting plate The rotating motor is installed at the bottom, and the insides of the two sides of the U-shaped mounting plate are respectively rotated and connected to the rotating shafts. The automatic quantitative weighing device for liquid canning provided by the present invention has intelligent control and can effectively prevent oil from dripping and cause resource phenomena to occur.

Owner:ZHONGSHAN TO U INTELLIGENT EQUIP TECH CO LTD

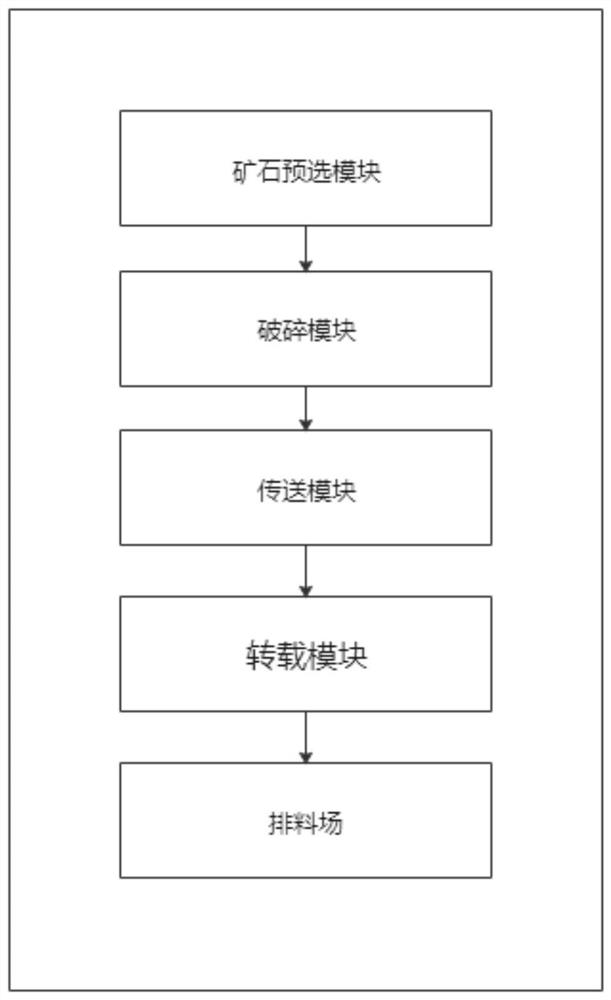

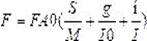

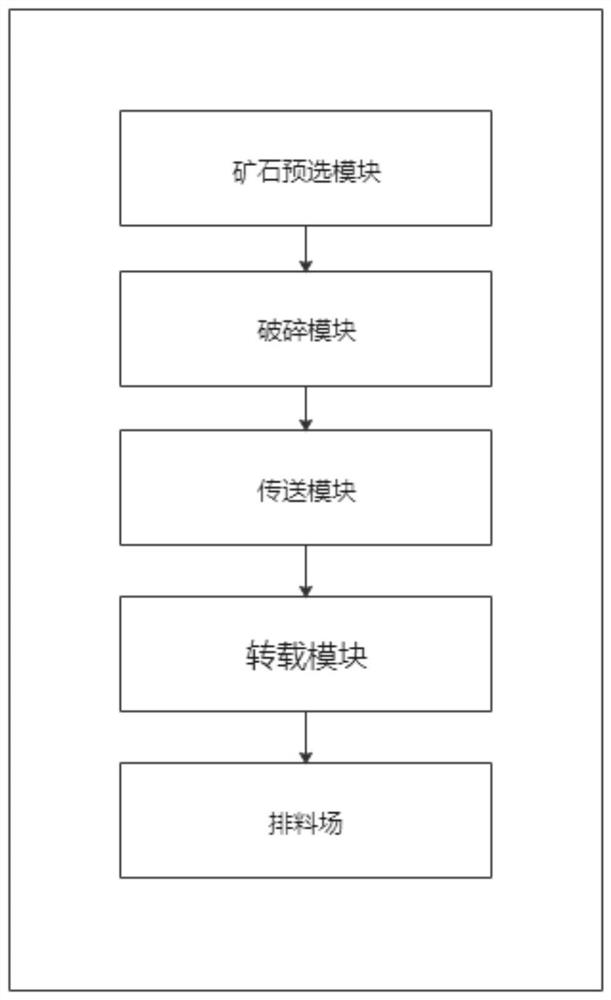

An Intelligent Control System for Surface Mining

ActiveCN111810160BGuaranteed transportation efficiencyGuarantee the stability of transportationOpen-pit miningGrain treatmentsMining engineeringCrusher

The invention relates to an intelligent control system for open-pit mining, which includes an ore pre-selection module, a crushing module, a transmission module, a reloading module, and a discharge field; Equipment, select the most suitable mining equipment, reduce costs and improve mining efficiency. Correspondingly, in the crushing stage, different crusher strengths are adopted according to different ore types and needs, and then the crushed ore fragments are loaded into different compartments , after measuring its weight density, it is released to the conveyor belt, and the crushed ore is classified to facilitate subsequent processing. The conveying speed of the conveyor belt is adjusted in real time according to its load, and the load is calculated in real time to ensure the conveying efficiency and stability of the conveyor belt. The module puts the ore fragments on the conveyor belt into different discharge yards according to different densities and diameters to meet different needs, reduce labor costs and improve efficiency.

Owner:内蒙古智矿环保高新科技有限责任公司

Multifunctional Emergency Rescue and Disaster Relief Drainage Vehicle

ActiveCN104943599BAvoid inconvenienceSave spaceSearchlight transportationItem transportation vehiclesEmergency rescueOn board

The invention discloses a multi-functional emergency rescue and disaster relief vehicle, which comprises a carrier vehicle chassis and a driver's cab and a carriage on the chassis. A backpack hydraulic oil tank and a fire extinguisher are arranged in the gap between the driver's cab and the carriage. Chassis power take-off hydraulic power station connected with the hydraulic oil tank; there are power generation compartment, equipment compartment and tool compartment in the compartment, vehicle-mounted generator set and hidden vehicle-mounted lifting and rotating lighting device are installed in the power generation compartment, and vehicle-mounted Cantilever crane, the other side is equipped with a hydraulic saw and a hydraulic pick through the bracket, and a cable winch, an integrated vehicle cleaning machine and a telescopic ladder are hoisted at the bottom of the compartment. In a limited space, through a reasonable and compact layout design, it integrates many functions. The generator set is installed at the front of the carriage, which is the center of gravity of the vehicle's load, thus effectively ensuring the transportation stability of the vehicle. , more effectively guarantee the driving safety of the car.

Owner:河南宜和城保装备科技实业有限公司

Steel plate superposed beam erecting system and erecting method

PendingCN114508051AGuarantee the stability of transportationPrevent floatingBridge erection/assemblyClassical mechanicsEngineering

The invention discloses a steel plate superposed beam erecting system, which is applied to the construction process of crossing a swivel bridge section in a high-speed railway bridge, and comprises a carrying device for transporting a prefabricated steel plate superposed beam; the supporting device is arranged in the direction of the pier, located below the steel plate superposed beam and used for supporting and fixing the steel plate superposed beam; the hoisting device is used for hoisting the prefabricated steel plate superposed beam to a mounting position on the pier; and the bridging device is arranged on the roadbed and the piers and used for being matched with the hoisting device to hoist the steel plate superposed beam. According to the steel plate superposed beam erecting system, the carrying device of a unique structure is adopted, the transportation stability of the steel plate superposed beam is ensured, the supporting device and the steel plate superposed beam are matched, connected and fixed, supporting force is provided for the steel plate superposed beam in the vertical direction, and the problem that the steel plate superposed beam is suspended in the air is solved; meanwhile, the phenomenon that the steel plate superposed beam deviates and topples due to the mass center is avoided; the bridge erecting device can be better matched with a roadbed and a bridge pier to erect the steel plate superposed beam.

Owner:中铁二十五局集团第二工程有限公司

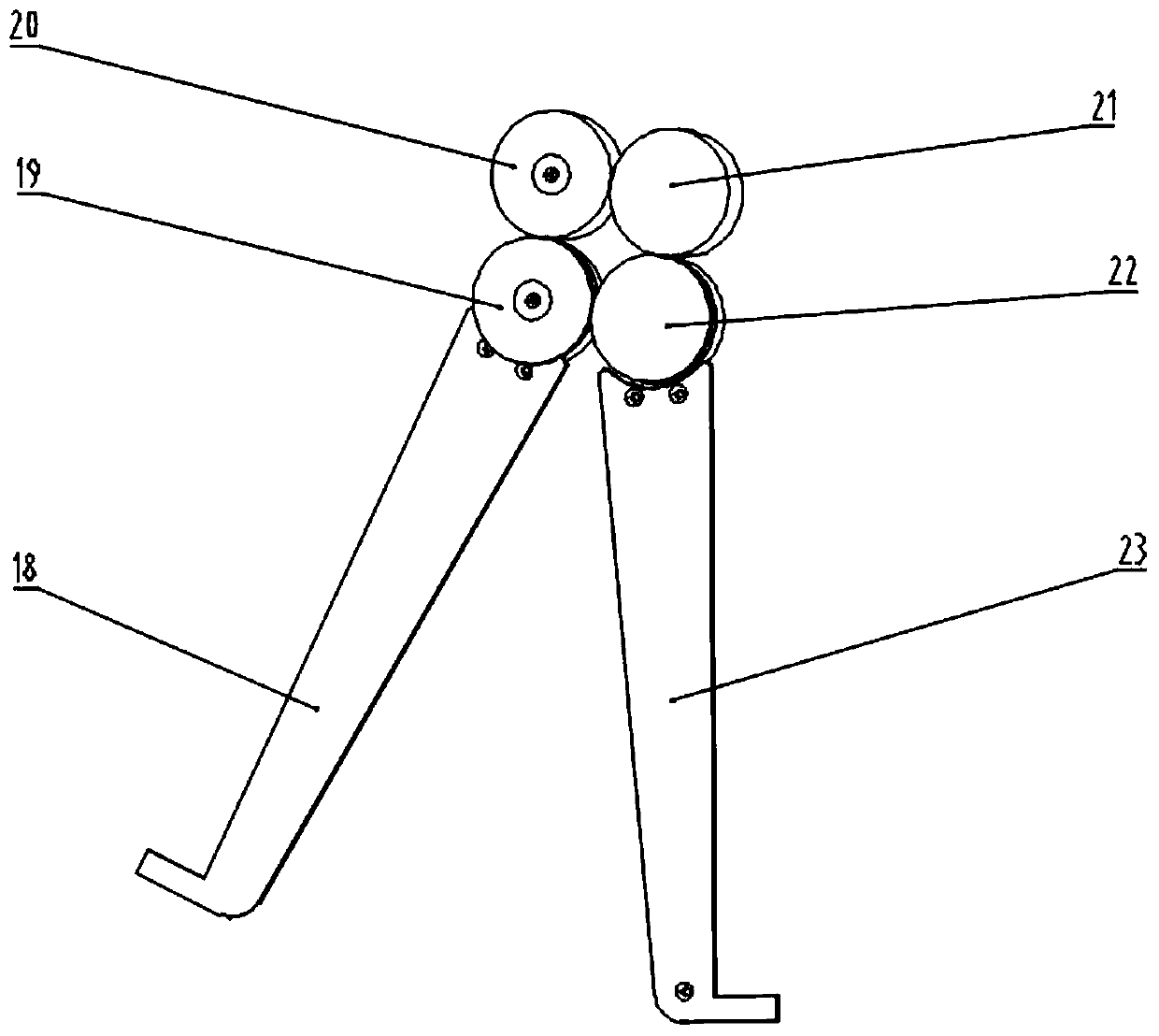

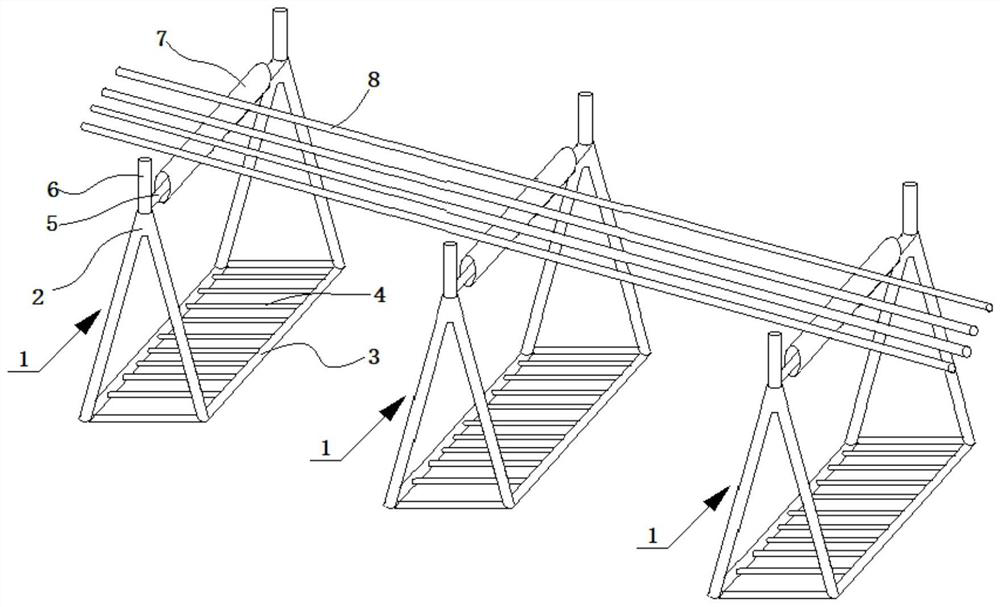

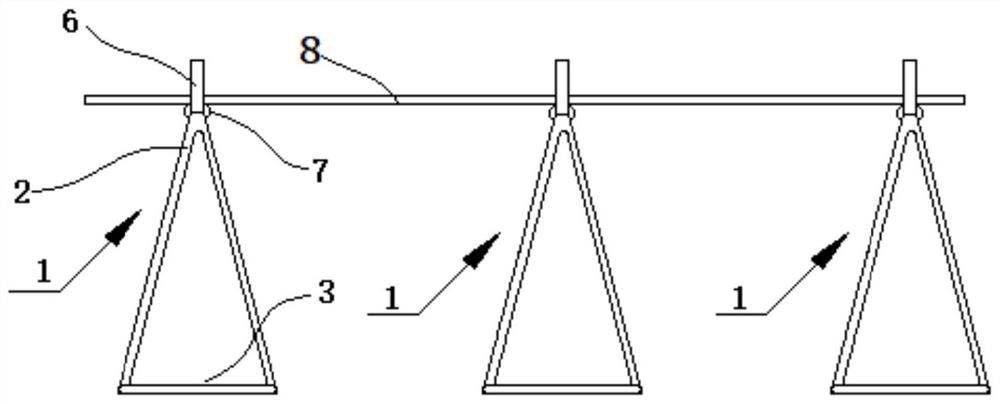

Simple and convenient short-distance transportation device for steel bars and using method

The invention discloses a simple and convenient short-distance transportation device for steel bars and a using method. Multiple transport assemblies are placed in the transport direction of the steel bars, so that the purpose of transporting the steel bars without manual carrying is achieved. Each transport assembly comprises a conveying mechanism and a supporting mechanism, wherein each conveying mechanism comprises a pressure bearing roller and a roller, each roller sleeves one pressure bearing roller, the steel bars are placed on the rollers, the pressure-bearing rollers provide supporting force for transporting the steel bars, and the steel bars are transported through rolling and sliding of the rollers, so that manpower is reduced, and the problem of personnel casualties caused by manual carrying is solved; and meanwhile, the steel bars can be transported on a large scale, so that the efficiency of steel bar transportation work is effectively improved.

Owner:中国葛洲坝集团第三工程有限公司

Intelligent control system for strip mining

ActiveCN111810160AGuaranteed transportation efficiencyGuarantee the stability of transportationOpen-pit miningGrain treatmentsMining engineeringProcess engineering

The invention relates to an intelligent control system for strip mining. The intelligent control system comprises an ore preselecting module, a crushing module, a conveying module, a transshipment module and material discharge fields. The intelligent control system has the technical effects that different kinds of mining equipment are determined according to the kind of ore which is mined in advance first, the optimum mining equipment is selected, the cost is reduced, the mining efficiency is improved, correspondingly, different forces of a crushing machine is adopted according to different kinds of ore and requirements at a crushing stage, then the crushed ore fragments are put in different compartments, the crushed ore fragments are released to a conveying belt after the weight density is determined, the crushed ore is sorted, the later processing is facilitated, the conveying speed of the conveying belt is adjusted in real time according to the load, the load is calculated in real time, the conveying efficiency and stability of the conveying belt are guaranteed, the ore fragments on the conveying belt are put in different material discharge fields according to different densities and diameters by the transshipment module, different requirements are met, the human cost is reduced, and the efficiency is improved.

Owner:内蒙古智矿环保高新科技有限责任公司

Material transportation system and material transportation method

ActiveCN108177939BWith lifting functionMiniaturizationConveyor partsMechanical conveyorsEngineeringHandover

The invention provides a material conveying system and a material conveying method. The material conveying system comprises a material conveying robot and a vertical conveyer. The material conveying robot is provided with a telescopic platform assembly. A second sliding platform used for holding materials can completely extend out of a robot body. Two supporting seats are arranged on a lifting platform of the vertical conveyer. An insertion station is arranged between the two supporting seats. The material conveying method comprises the steps that the material conveying robot obtains materialcarriers, the second sliding platform and the material carriers extend out of the body and extend into the first lifting space from an overall opening, and the second sliding platform is located in the insertion station; the lifting platform rises, the supporting seats bear the material carrier, and the material carrier leaves the second sliding platform. The material conveying robot can achieve carrier handover without entering the vertical conveyer; the lifting platform achieves conveyance of the multiple material carriers, the multiple material carriers enter the material conveying robot orare recycled at the same time, so that the work frequency of the material conveying robot is lowered, and the conveyance capacity is increased; and conveyance is stable, the applicability is high, and the work efficiency is high.

Owner:ZHUHAI MAKERWIT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com