Fork plate type carrier

A technology for handling trolleys and fork plates, which is applied in the direction of lifting devices, etc., which can solve the problems of difficult to meet the requirements of high parking precision, such as cargo pick-and-place requirements, jamming, and large overturning moment of equipment, so as to reduce the need to return to the position, Improvement of parking accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

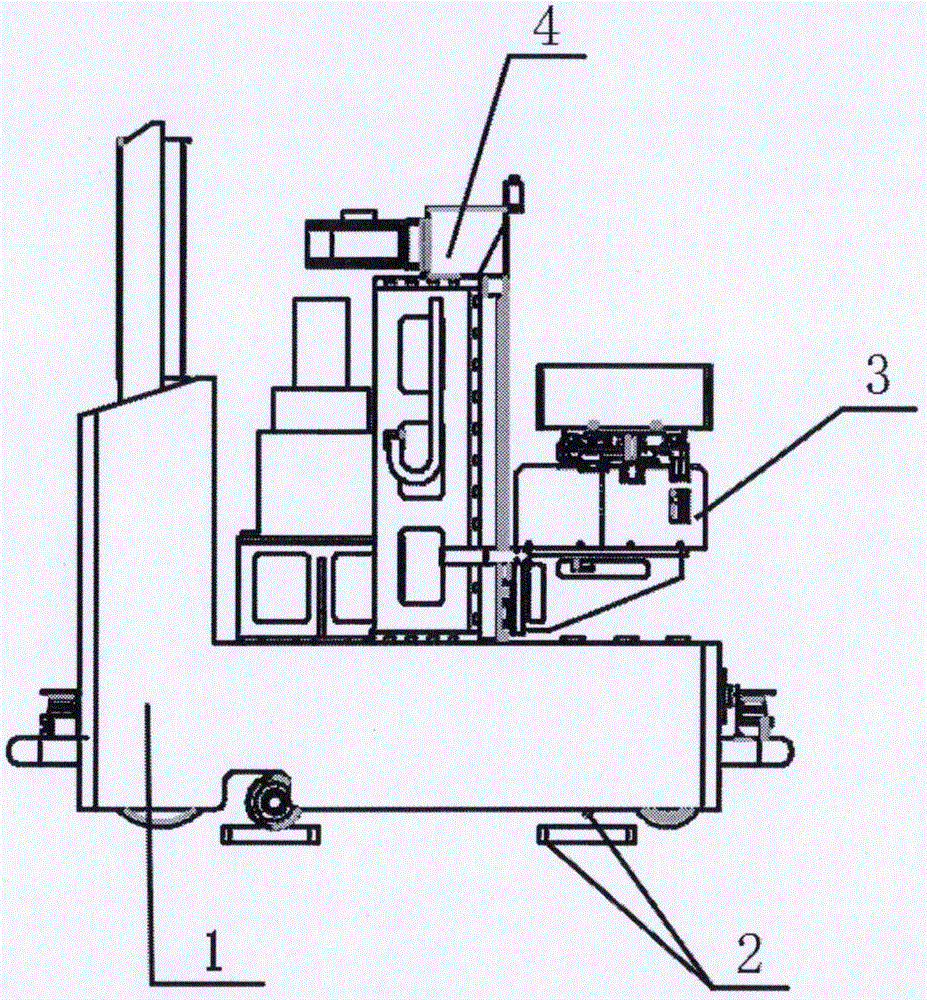

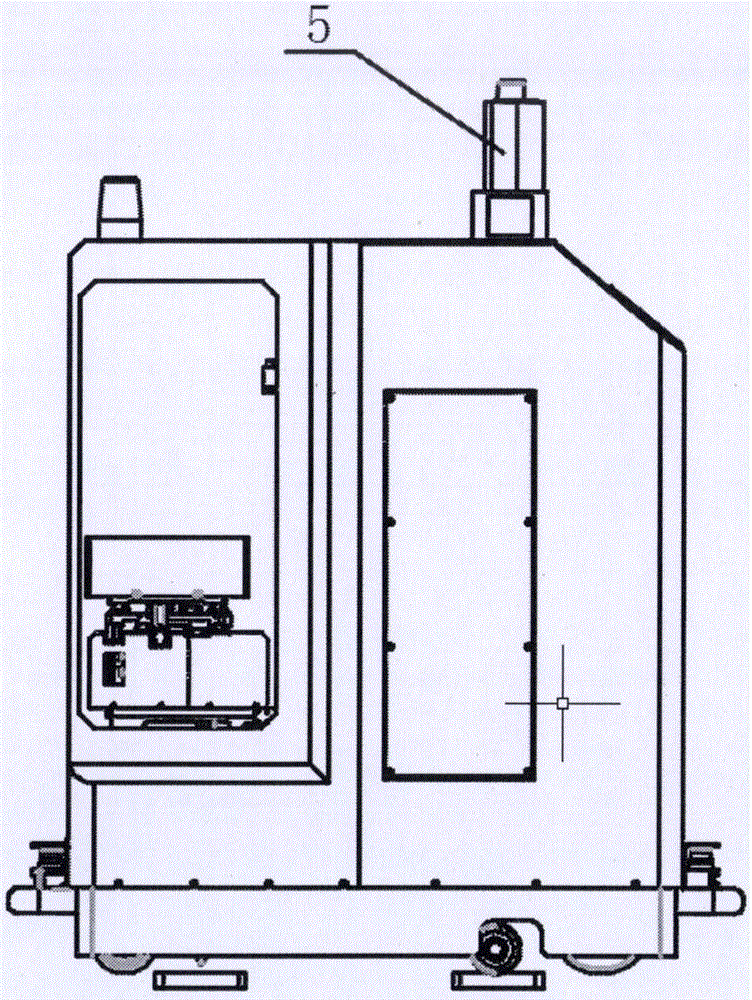

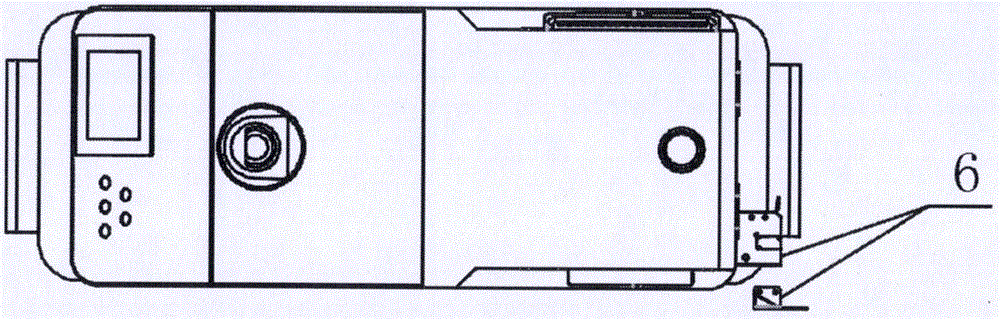

[0022] Such as figure 1 , figure 2 As shown, the fork-plate handling trolley includes a self-propelled vehicle body 1 that can automatically walk to a designated location or station according to external instructions, a guiding device 5, a laser distance measuring device 6, and a precise positioning device 2. The pallet fork device 3 and the vertical lifting mechanism 4 of the access positioning function. The self-propelled vehicle body 1 is connected with each part to be combined into an organic whole. The vertical lifting mechanism 4 and the fork device 3 are installed above the self-propelled vehicle body 1 . The vertical lifting mechanism 4 is rigidly connected with the self-propelled vehicle body 1, and the fork device 3 moves up and down and is installed on the vertical lifting mechanism 4. According to external instructions, the self-propelled vehicle body 1 automatically walks to the designated place or station under the guidance of the guiding device 5, and the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com