Method for calibrating industry robot

A technology of industrial robot and calibration method, which is applied in the field of calibration of industrial robots and can solve the problem of insufficient positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the calibration method of a kind of industrial robot of the present invention is described below, and it comprises the following steps:

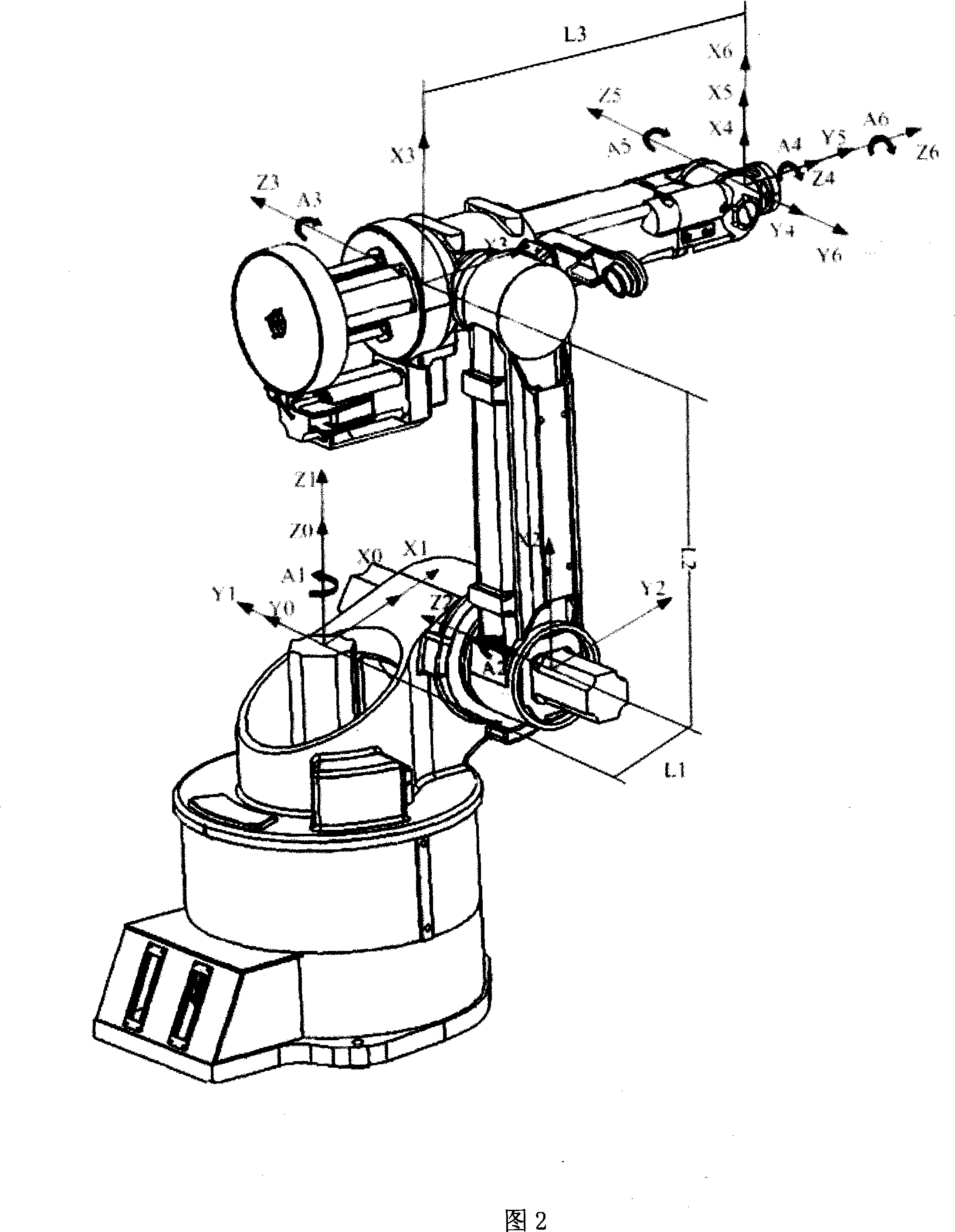

[0017] (a) In the Cartesian coordinate system, establish the kinematics model of the robot, and obtain the pose transformation matrix of the coordinate system of the end effector of the robot relative to the base coordinate system.

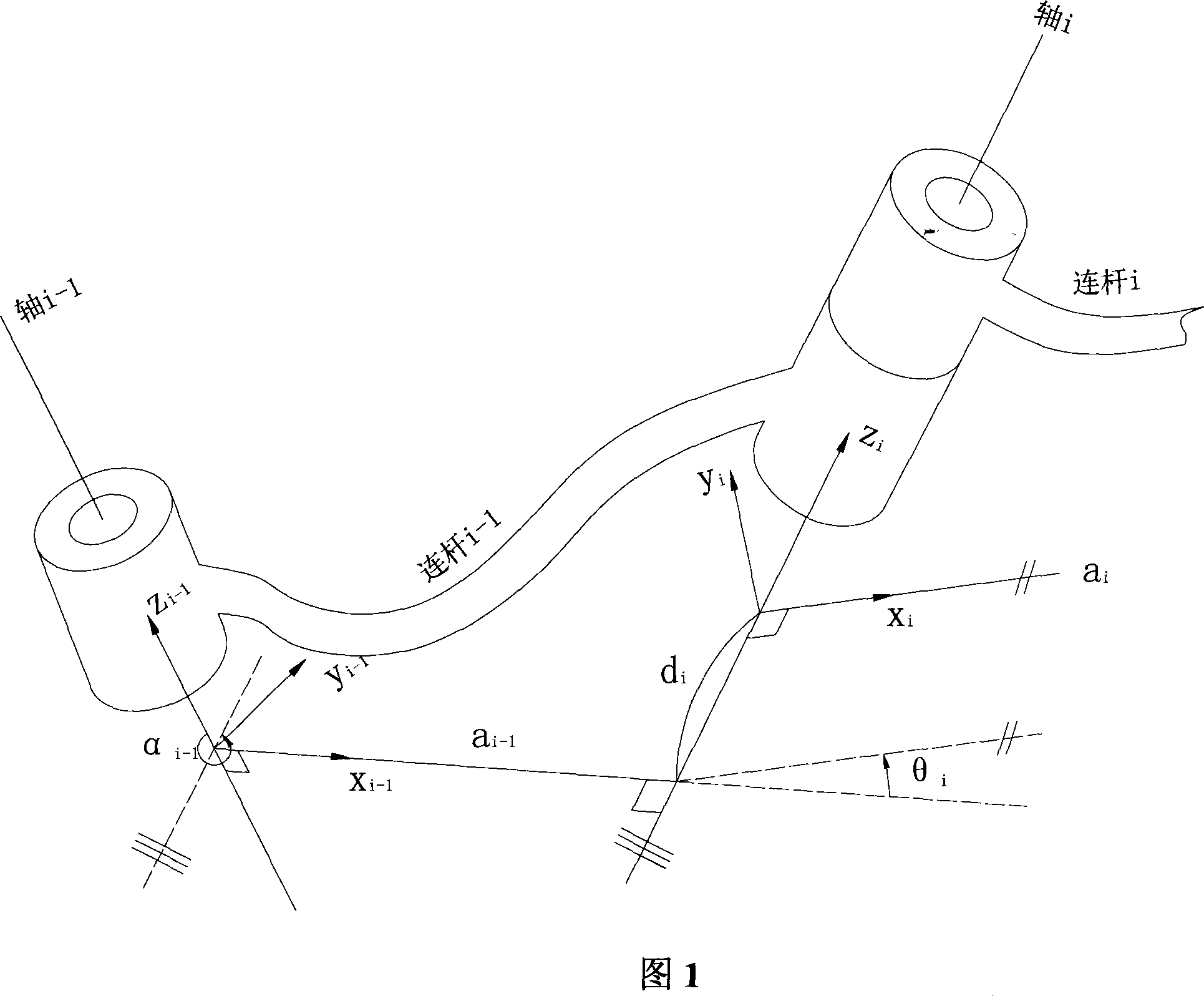

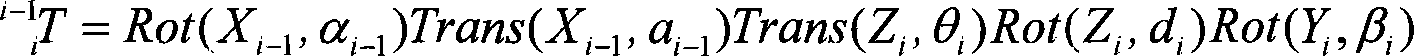

[0018] Selecting the kinematic model of the robot is a key process of calibration, because the kinematic model is an important factor that determines the various accuracy of the robot. The most basic and most general kinematics model of a robot is the Denavit-Hartenberg (D-H for short) model. In this model, the relationship between adjacent joints can be expressed by 4 independent D-H parameters, one of which is the joint variable θ i , and the other three are member structural parameter constants d i 、a i 、α i (See the definition of the 4 parameters later).

[0019] De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com