Cutting and sealing device of tray preservative film packing machine

A technology for a fresh-keeping film and a packaging machine, which is applied in the directions of packaging paper bending device, packaging sealing/fastening, packaging, etc., can solve the problems of complex structure of transverse cutting and sealing device, large workload and energy consumption, and high manufacturing cost of packaging machine , to achieve the effect of ensuring transportation stability, improving packaging quality, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

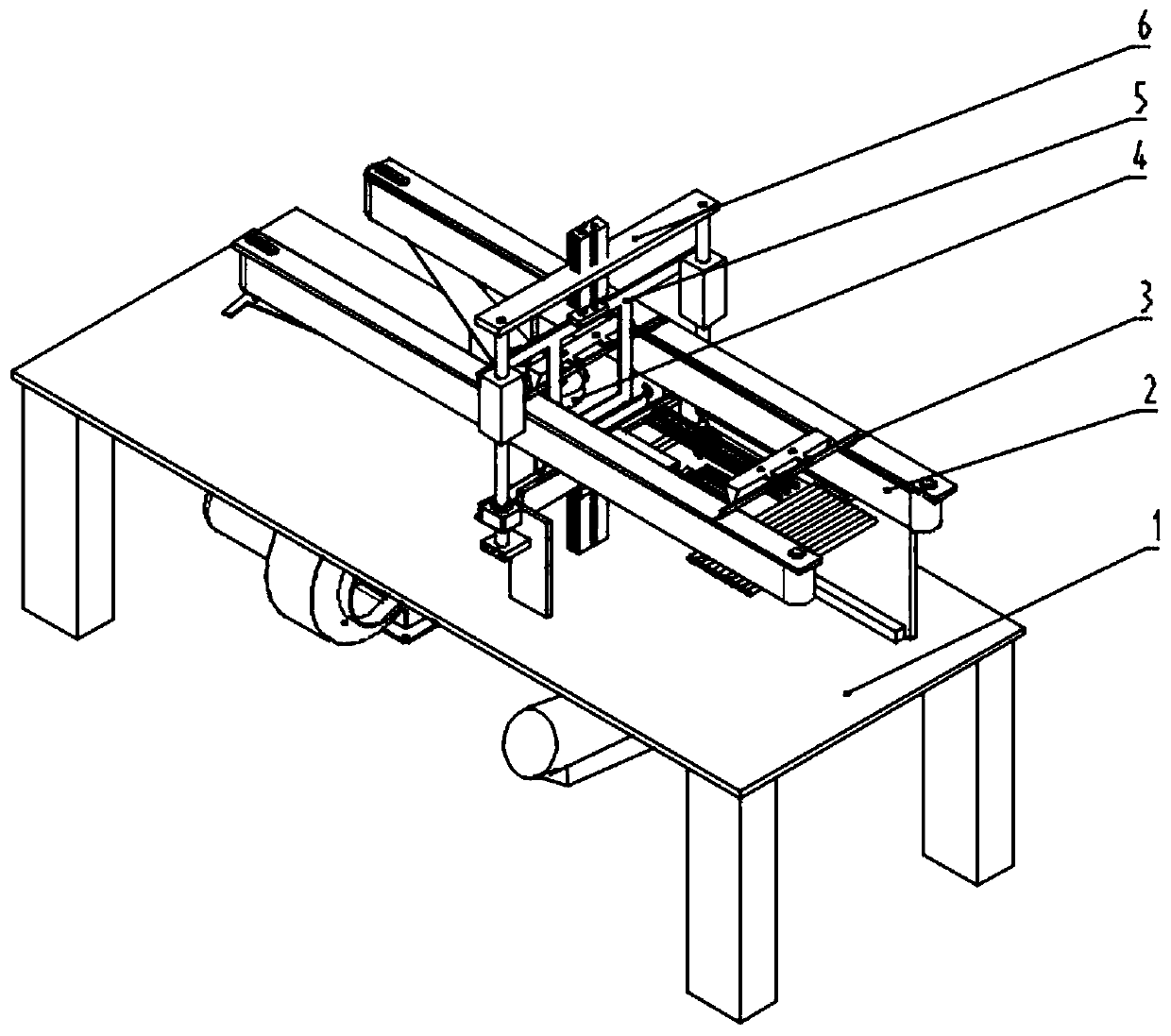

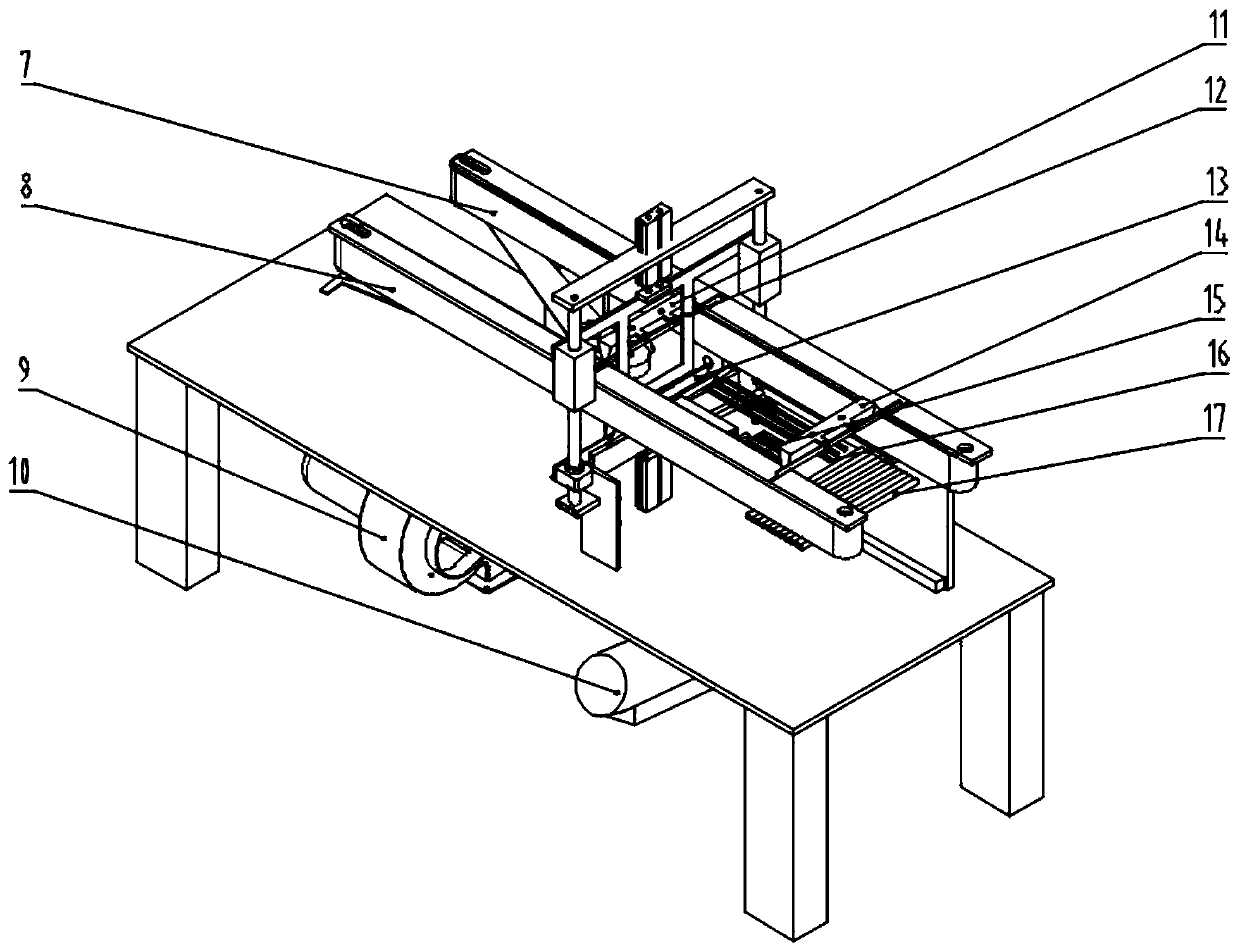

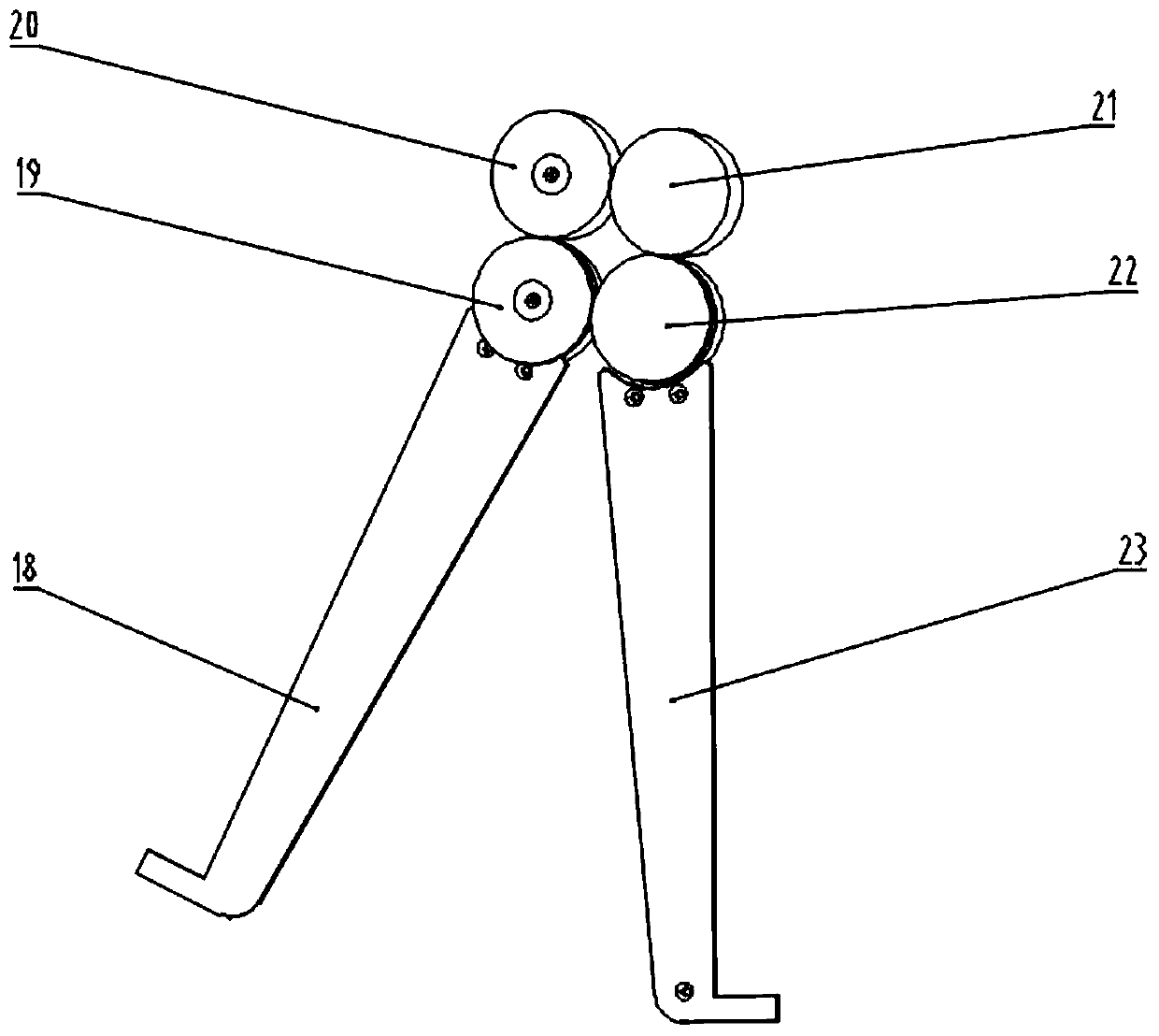

[0026] Such as Figure 1 to Figure 5 , a cutting and sealing device of a tray plastic wrap packaging machine, including a vertical material conveying unit 2 installed on a workbench 1, a longitudinal sealing unit 4 and a transverse cutting and sealing unit 5, and its innovation lies in: the transverse cutting and sealing unit Including cutter mechanism 12, front blowing box 11, rear blowing box 14, scraper 13, fan 9, transverse sealing mechanism 15, roller support belt 17 and air compressor 10, cutter mechanism, scraper, transverse sealing mechanism , and roller support belts are arranged on the workbench from left to right. The front blowing box is fixed on the vertical material conveying unit through the bracket 3 and is located at the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com