An automatic quantitative weighing device for liquid canning

A quantitative weighing and automatic technology, applied in liquid bottling, liquid handling, safety devices of filling devices, etc., can solve the problems of oil pollution, oil dripping, waste of resources, etc., to prevent oil dripping and reduce the distance. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The present invention will be further described below with reference to the accompanying drawings and embodiments.

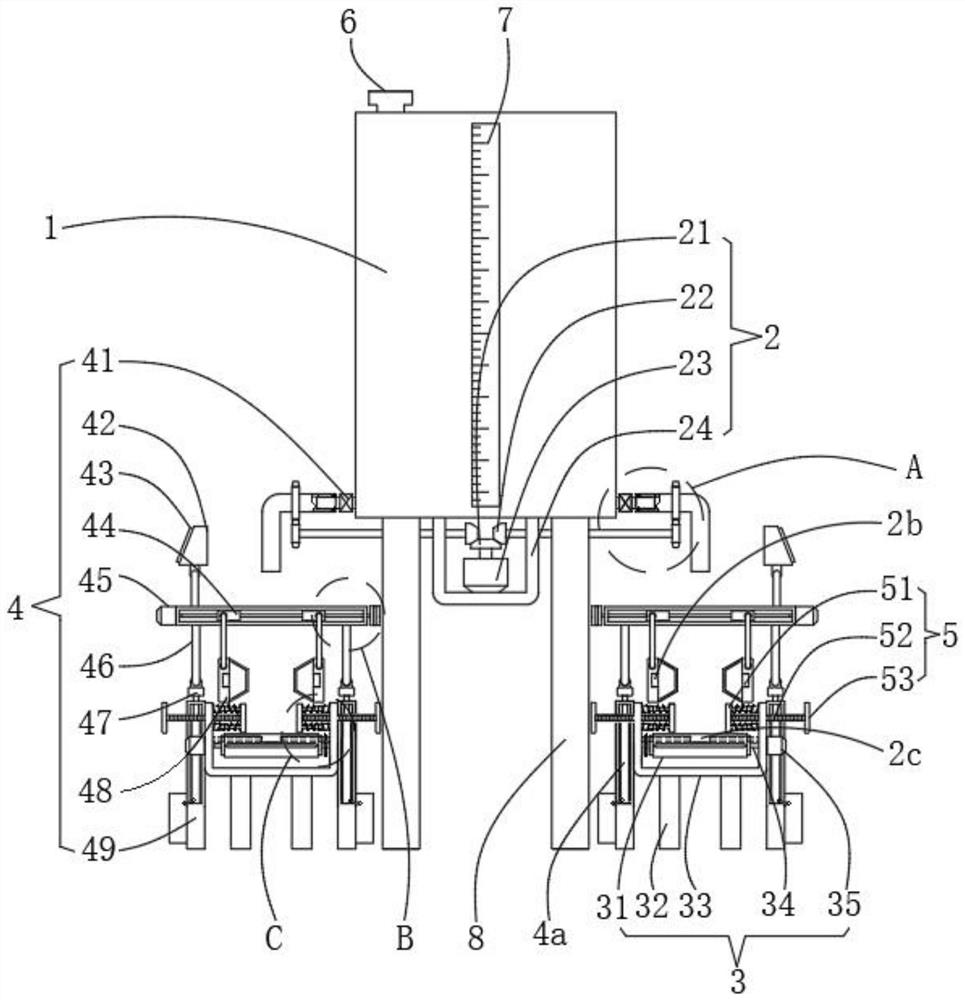

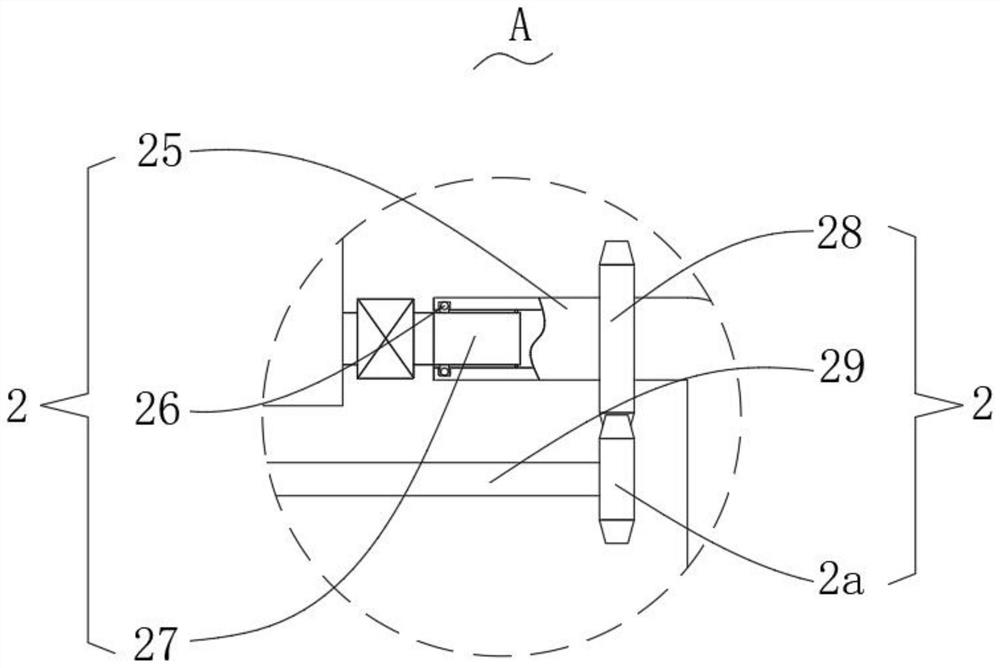

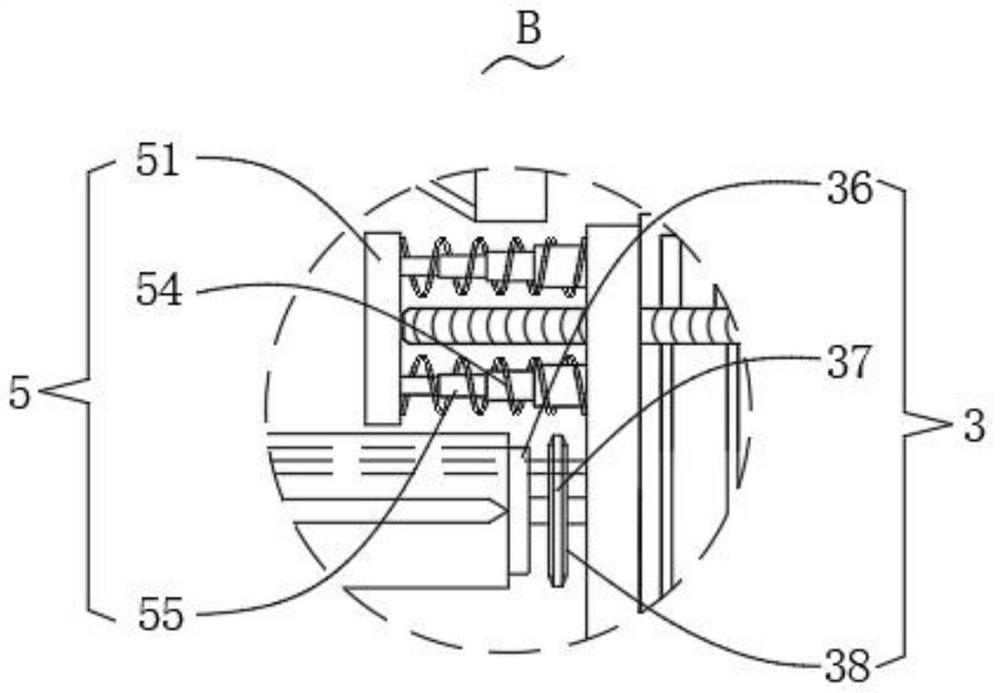

[0028]Please refer tofigure 1 ,figure 2 ,image 3 ,Figure 4 withFigure 5,among them,figure 1 A structural diagram of a preferred embodiment of a liquid canned automatic quantitative weighing device provided by the present invention;figure 2 forfigure 1 A partial enlarged structure shown in the A is shown inimage 3 forfigure 1 Local enlargement structure shown in B.Figure 4 forfigure 1 A partial enlarged structure shown in C is shown inFigure 5A structural diagram of the control module of the liquid canned automatic quantitative weighing device provided by the present invention. Liquid canned automatic quantitative weighing devices include: oil storage tank 1, leak-proof discharge structure 2, transport structure 3, and clamped starting quantitative structure 4.

[0029]In the specific implementation process, iffigure 1 withfigure 2 Design, the top surface of the oil co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com