Aramid Fabric Skeleton Flame Retardant Conveyor Belt for Coal Mine

A fabric skeleton and conveyor belt technology, applied in the direction of conveyors, applications, closed-loop items, etc., can solve the problems of insufficient bonding strength between the metal skeleton and rubber, easy peeling of the skeleton and rubber, unfavorable long-term use of the conveyor belt, etc., to achieve quality Lightening, good safety performance, guaranteed effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

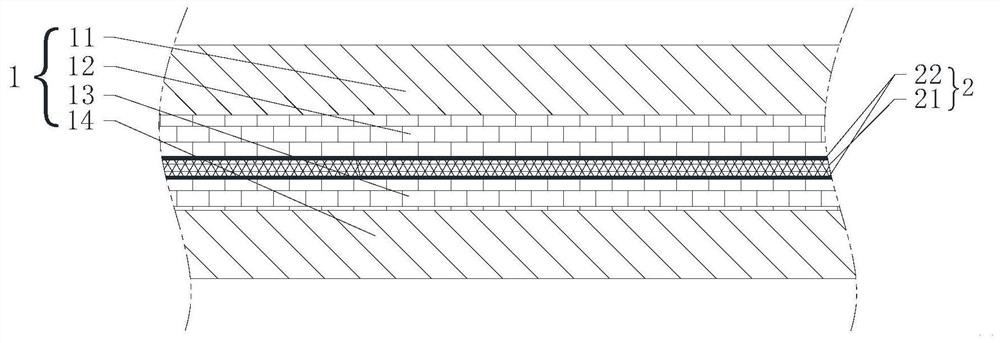

[0028] see figure 1, the flame-retardant conveyor belt with aramid fabric skeleton for coal mines of the present invention includes a belt body 1 made of neoprene; the belt body 1 includes an upper cover layer rubber 11, an A transition rubber layer 12, and B transition rubber layer 13 and lower cover layer rubber 14, the thickness of described upper cover layer rubber 11 is 8mm, the thickness of described lower cover layer rubber 14 is 4mm; The transition rubber layer 12 of described A, B transition rubber layer 13 A skeleton layer 2 is arranged between them; the skeleton layer 2 is composed of a layer of aramid canvas 21 and a dipping layer 22 coated on the outer surface of the aramid canvas 21, and the thickness of the skeleton layer 2 is 4mm; the upper covering The raw material components of the layer rubber 11 and the lower covering layer rubber 14 contain a flame retardant; the flame retardant is one or more of chlorinated paraffin, antimony oxide, zinc borate, and ammon...

Embodiment 2

[0030] Different from Example 1, in this embodiment, the thickness of the upper cover rubber 11 is 12mm, the thickness of the lower cover rubber 14 is 3mm; the thickness of the skeleton layer 2 is 2.5mm; The thickness of the A transition rubber layer 12 is 20% of the thickness of the upper cover layer rubber 11, and the thickness of the B transition rubber layer 13 is 15% of the thickness of the lower cover layer rubber 14; the square meter dry weight of the skeleton layer 2 is 1000g / ㎡; The raw material components of the upper cover layer rubber 11 and the lower cover layer rubber 14 are calculated in parts by weight: 100 parts of neoprene rubber, 2 parts of zinc oxide, 2 parts of magnesium oxide, 4 parts of sulfur, stearin 1 part of acid, 1 part of plasticizer TCP, 3 parts of aromatic oil, 5 parts of antioxidant, 30 parts of carbon black N110, 0.2 parts of nanosphere lubricant, 3 parts of ammonium polyphosphate, 3 parts of chlorinated paraffin, 1.5 parts of antimony oxide, 1...

Embodiment 3

[0032] The thickness of the upper cover rubber 11 is 7mm, the thickness of the lower cover rubber 14 is 5mm; the thickness of the skeleton layer 2 is 3mm; the thickness of the A transition rubber layer 12 is the upper cover rubber 11 thickness 40% of that, the thickness of the B transition rubber layer 13 is 30% of the thickness of the lower cover rubber 14; the square meter dry weight of the skeleton layer 2 is 2500g / ㎡; the upper cover rubber 11 and the lower The raw material components of the cover layer rubber 14 are calculated by weight: 100 parts of neoprene rubber, 4 parts of zinc oxide, 4 parts of magnesium oxide, 6 parts of sulfur, 2 parts of stearic acid, 3 parts of plasticizer TCP, 5 parts of aromatic oil , 7 parts of anti-aging agent, 50 parts of carbon black N110, 0.3 parts of nanosphere lubricant, 5 parts of ammonium polyphosphate, 5 parts of chlorinated paraffin, 2.5 parts of antimony oxide, 2 parts of zinc borate, 3 parts of accelerator TMTD, 3 parts of accelerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com