Material conveying system and material conveying method

A technology of transportation system and transportation method, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., and can solve problems such as damaged materials, materials overturned, and unstable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

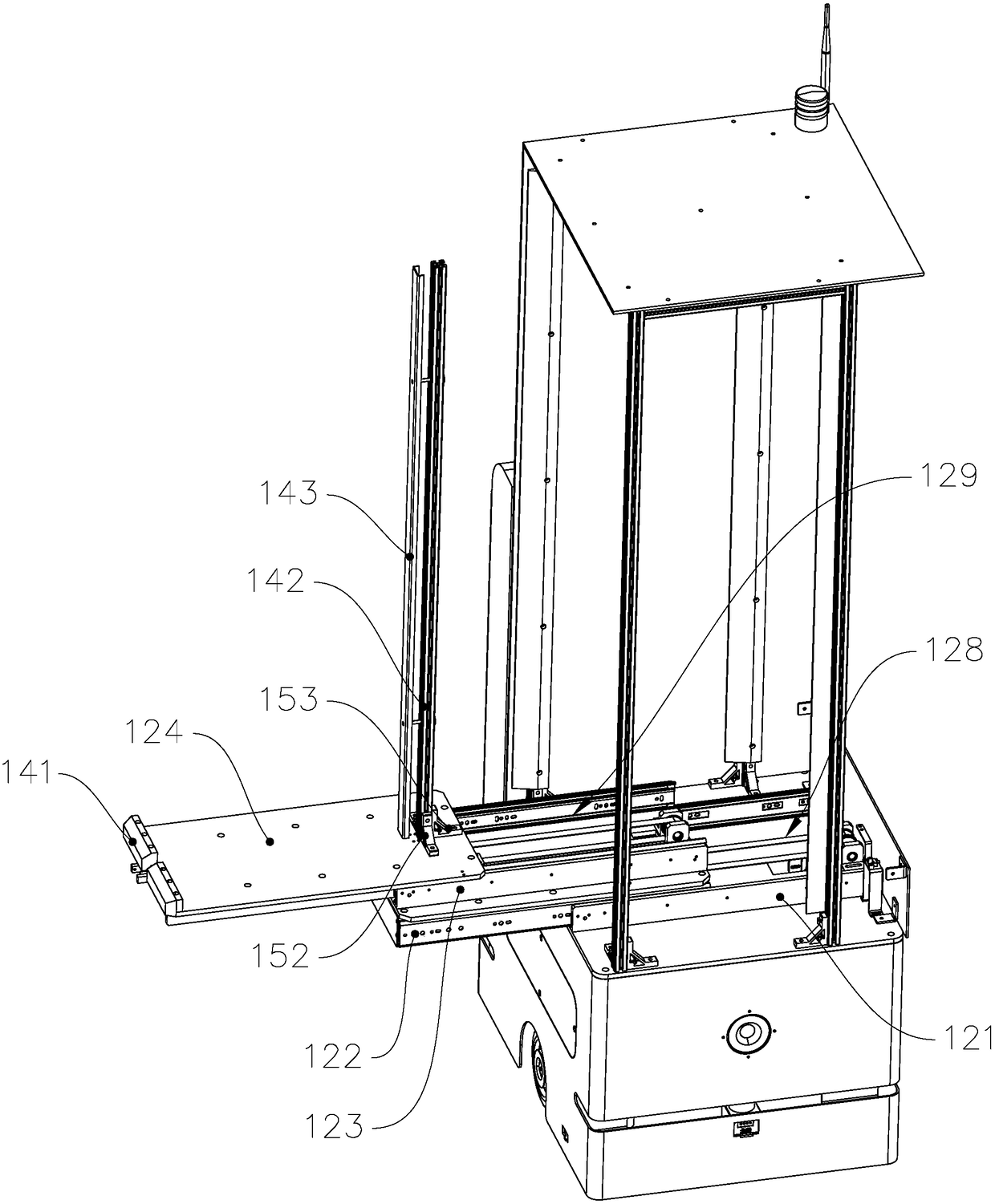

[0044] see Figure 4 and Figure 5 , Figure 4 It is the structural diagram of the first embodiment of the upper and lower conveyors, Figure 5 for Figure 4 Enlarged image at A. Up and down conveyor 2 comprises frame 21, two elevating devices 22 and translation device 23 arranged in frame 21; A lifting device 22 is arranged in the second lifting space 202, and the translation device 23 extends between the top of the first lifting space 201 and the top of the second lifting space 202; the frame 21 is on the front side of the first lifting space 201 An integral opening 203 and an integral opening 204 are respectively provided on the front side of the second lifting space 202 .

[0045] The lifting device 22 includes a screw mandrel assembly and a lifting table 221 installed on the screw mandrel assembly. The screw mandrel assembly includes a drive device and a drive device connected to the output end of the drive device. Two vertical screw mandrels 220, the elevating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com