Steel plate superposed beam erecting system and erecting method

A technology of superimposing beams and steel plates, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve problems such as easy unbalanced connection of steel plate composite beams, difficulty in prefabricated steel plate composite beams, and easy deviation of lateral connection of steel plate composite beams. Achieve the effect of ensuring transportation stability, solving biased dumping, and avoiding suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

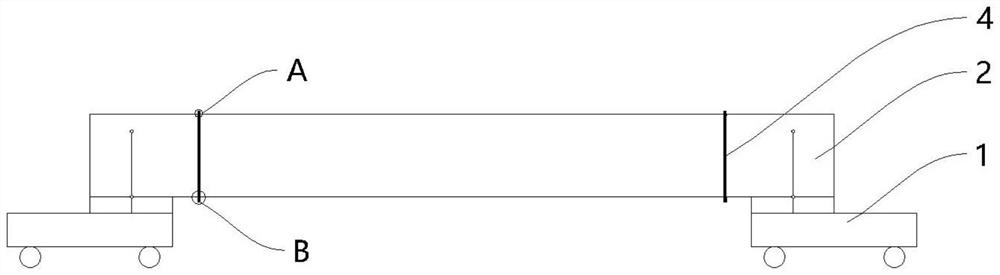

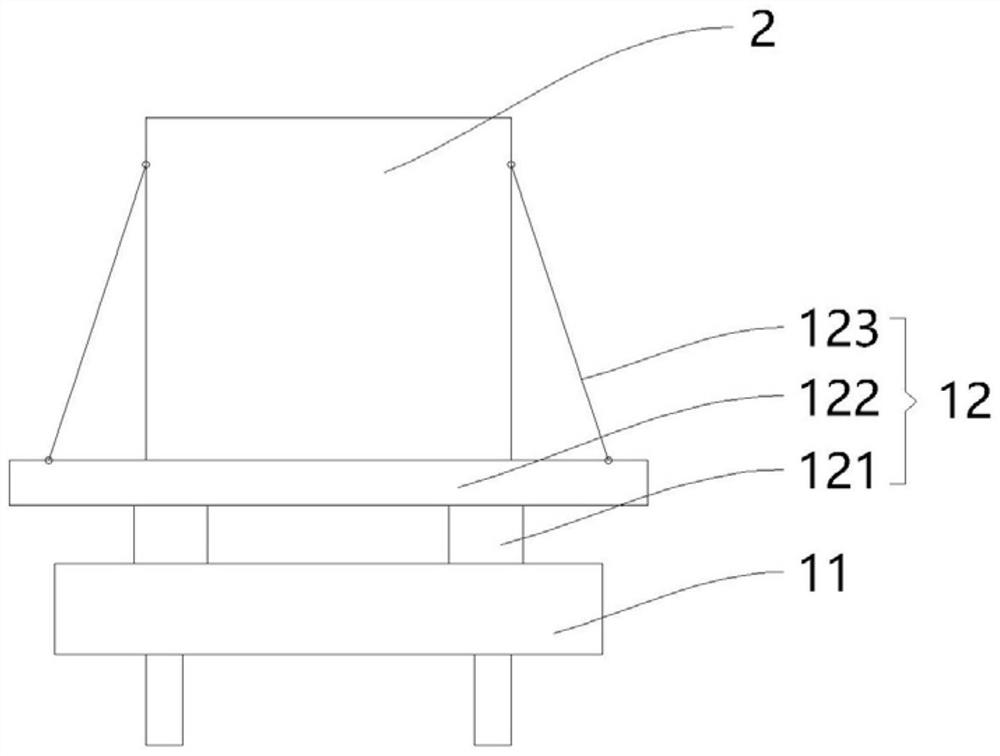

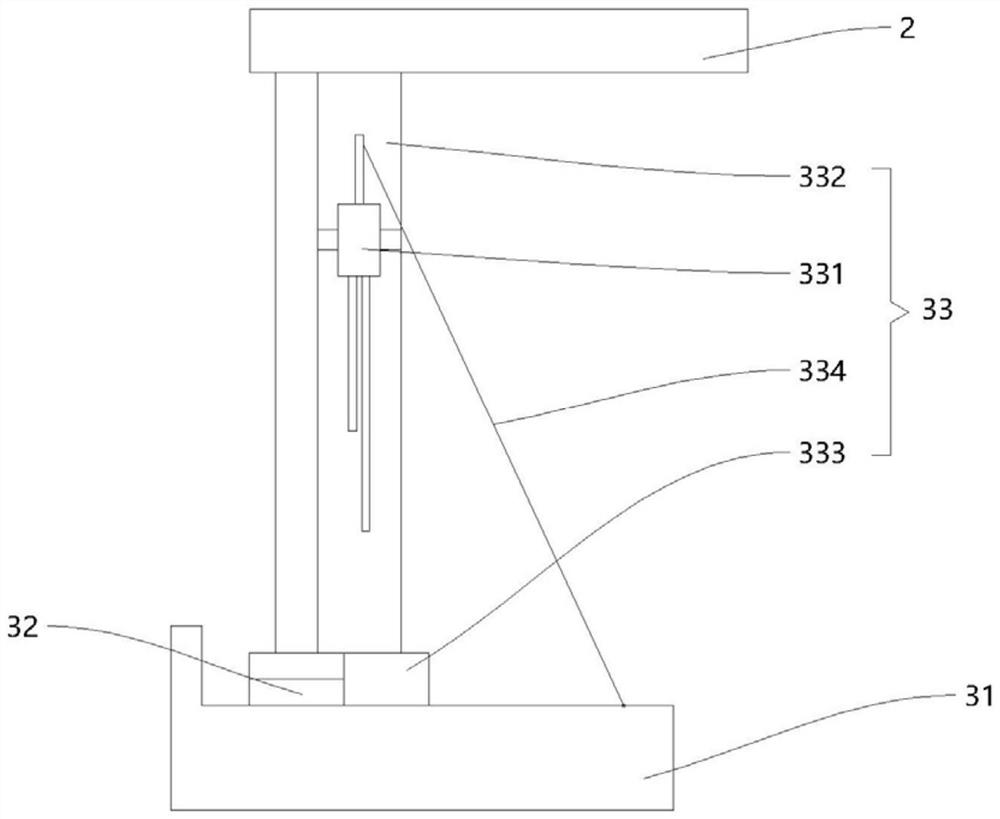

[0038] A steel plate composite beam erection system, which is used for the elevated construction of multi-section asymmetric steel plate composite beams, comprises a carrier device 1 for transporting a prefabricated steel plate composite beam 2; a support device 3, arranged along the direction of the pier, and Located below the laminated steel plate beam 2, it is used to support and fix the laminated steel plate beam 2; the lifting device 4 is used to lift the prefabricated laminated steel plate beam 2 to the installation position on the bridge pier; the bridging device 5 is located on the roadbed and the bridge pier On the upper side, it is used to hoist the steel plate superposed beam 2 with the hoisting device 4 .

[0039] Specifically: due to the long length of the prefabricated steel plate laminated beam 2, conventional transport vehicles cannot be transported. At the same time, during the transportation process, the stability of the steel plate laminated beam 2 should be ...

no. 2 example

[0049] like Figure 7-Figure 9 As shown in the figure, the present invention discloses a method for erecting a steel plate superimposed beam, which adopts a bundled hoisting method to transport the steel plate superimposed beam 2, which reduces the difficulty of transportation and improves the flexibility of transportation; The hoisting process of the composite beam 2 reduces the influence of wind speed on the construction process, and improves the stability and safety of the erection; the rigid plate composite beam erected is fixed by the combination fixing method, which improves the horizontal connection of the steel plate composite beam 2. accuracy.

[0050] A method for erecting a steel plate composite beam, comprising the following steps:

[0051] S1: Prefabricated steel plate composite beams and transported to temporary supports;

[0052] Specifically, due to the shape and structure of the prefabricated steel plate laminated beam, and at the same time to facilitate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com