Multiple-gear-train lifting driving system

A technology of lifting drive and multi-wheel trains, which is applied in the direction of transmission, transmission parts, belts/chains/gears, etc., can solve the problems that the synchronous lifting of the tank cannot be guaranteed, so as to save labor costs, ensure production efficiency, and reduce length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

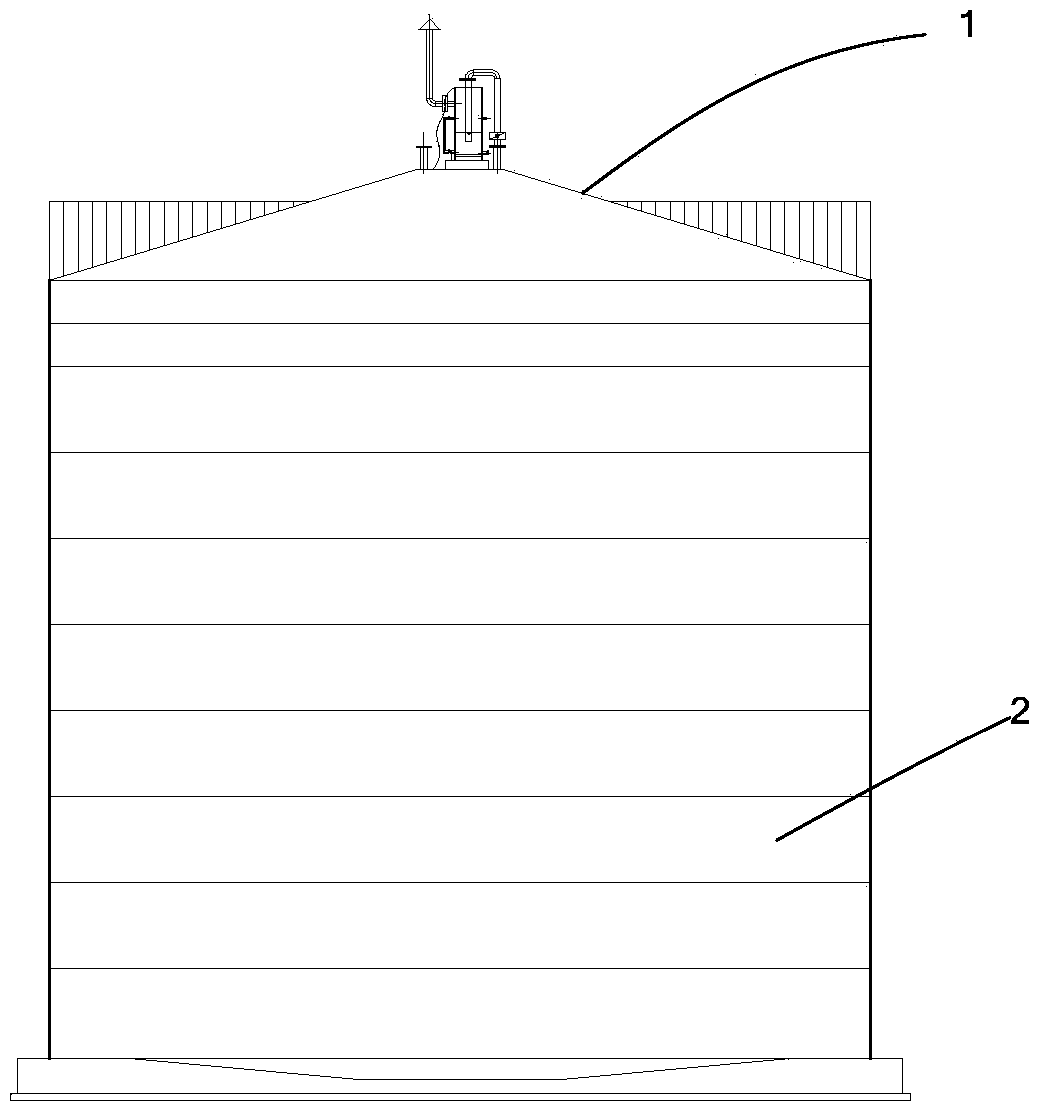

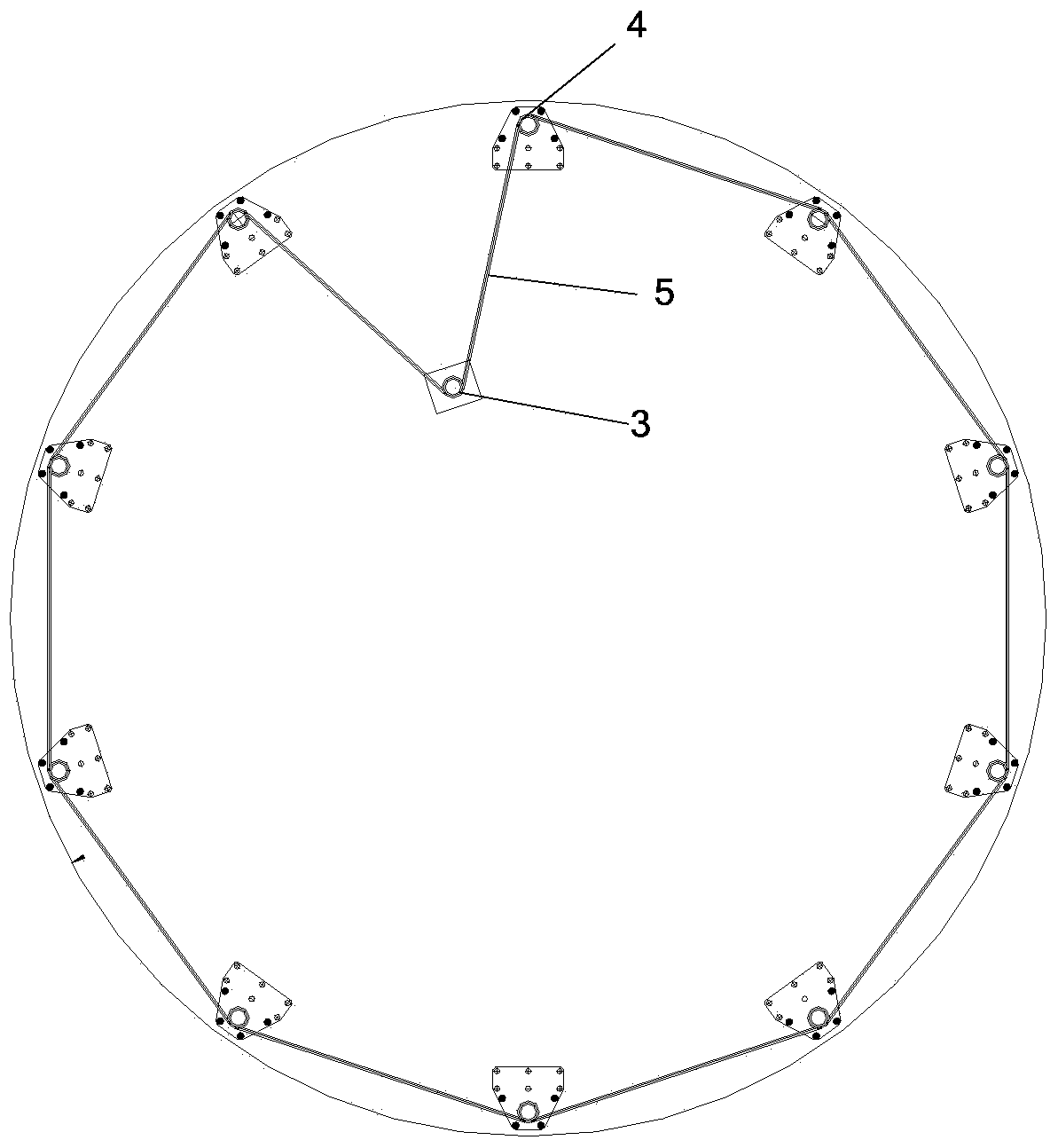

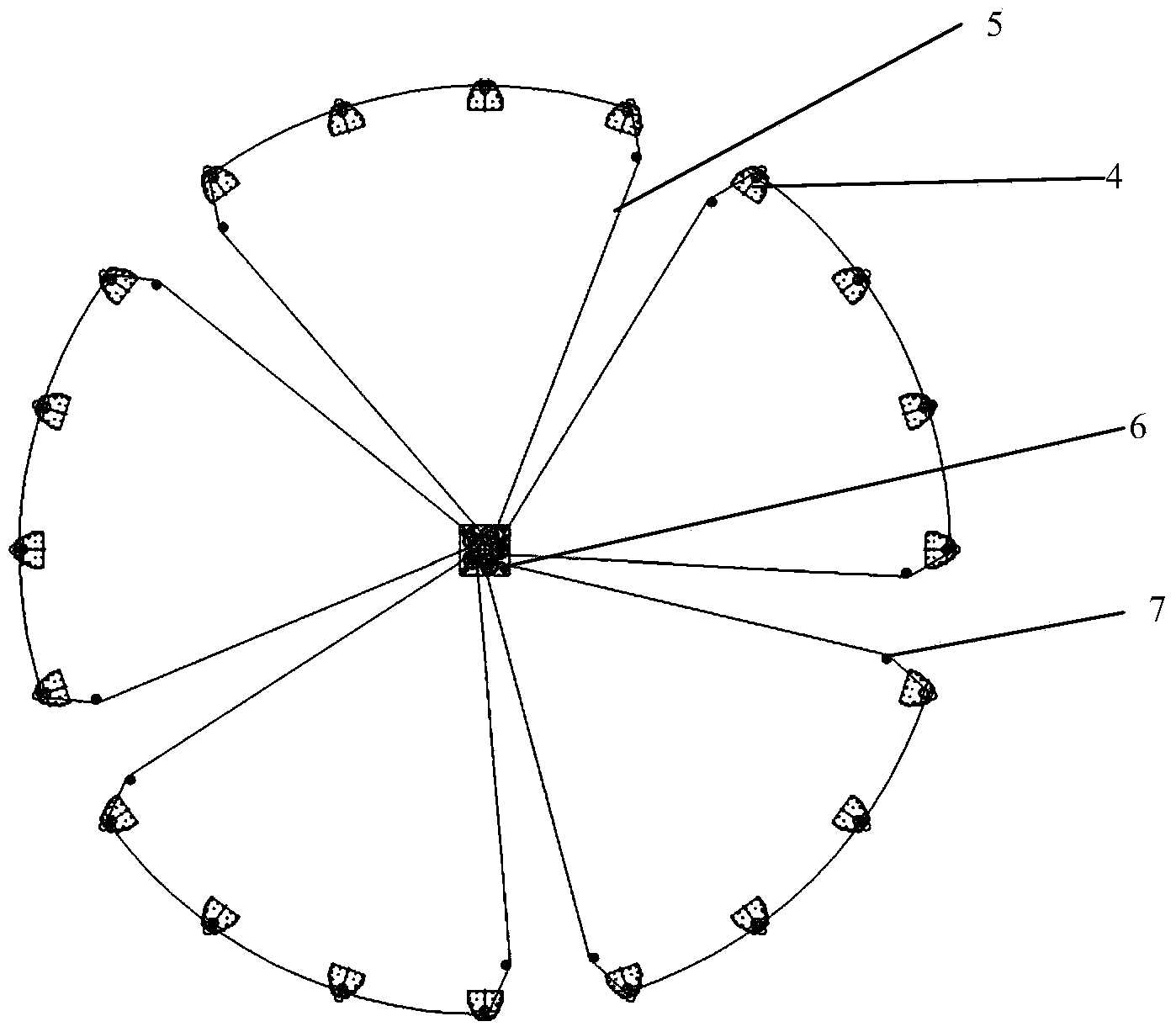

[0026] like image 3 and Figure 4 As shown, this embodiment provides a multi-wheel train lifting drive system, including a drive device 6 and a plurality of sprockets 10; the drive device 6 includes a speed reducer 3 and a gear transmission mechanism; the speed reducer 3 passes through the gear The transmission mechanism drives the plurality of sprockets 10; the lifting mechanism adopts the elevator 4 to lift the assembled board. The reducer 3 is generally arranged in the middle of the assembled tank body; each sprocket 10 is correspondingly connected with one or several elevators 3 through a chain 5 . The invention cooperates with the sprocket through the gear transmission mechanism, and drives a lifting mechanism through a single chain, so that during the installation process of the assembled panels around the biogas tank bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com