System for lifting elevator shaft mold and construction method for cast-in-place wall of elevator shaft

A technology for elevator shafts and cast-in-place walls, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, and processing of building materials. It can solve the problem of large labor input for turnover materials and easy deviation of shaft size , slow construction speed and other problems, to achieve the effect of simple structure, fast construction speed and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

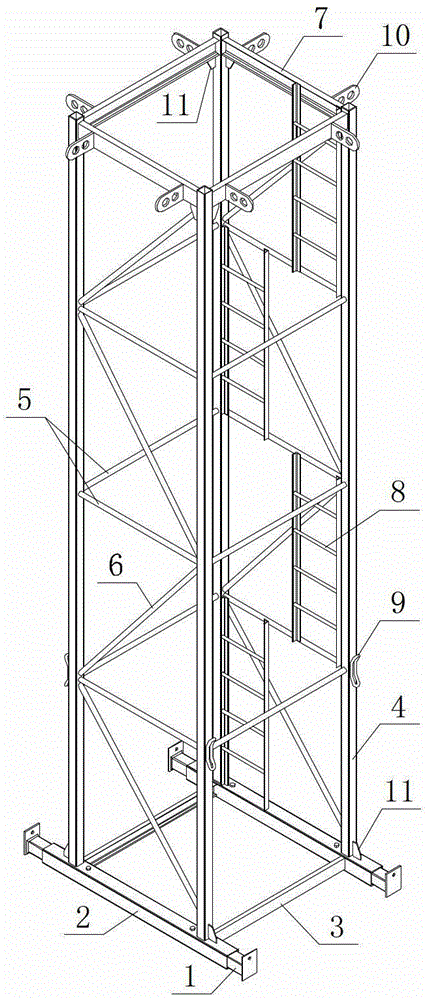

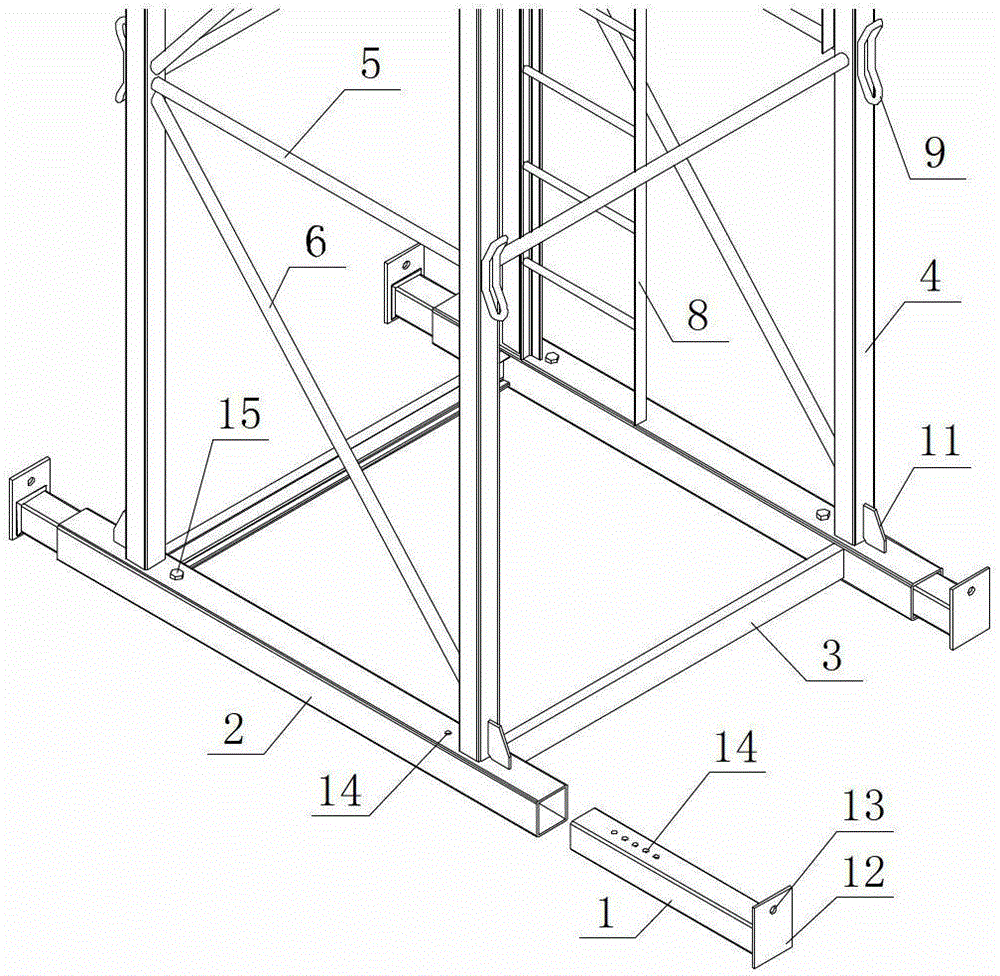

[0033] Example 1: A hoistway model system for lifting elevators, such as Figure 1-1~Figure 3-2 As shown, the hoisting elevator hoistway mold system includes a hoisting frame, a combined hoistway mold, and a hoisting device. The hoisting frame is composed of a base load-bearing beam 1, a main beam 2, a secondary beam 3, a column 4, an intermediate beam 5, and a diagonal brace. 6. The frame type operating platform composed of the top beam 7 and the climbing ladder 8. The lifting frame adopts the load-bearing high-strength bolts 16 and the embedded high-strength nuts on the elevator shaft wall through the reserved holes 13 on the connecting plate 12 at the end of the load-bearing beam 1 17 Connect to fix the hoisting frame on the elevator shaft wall;

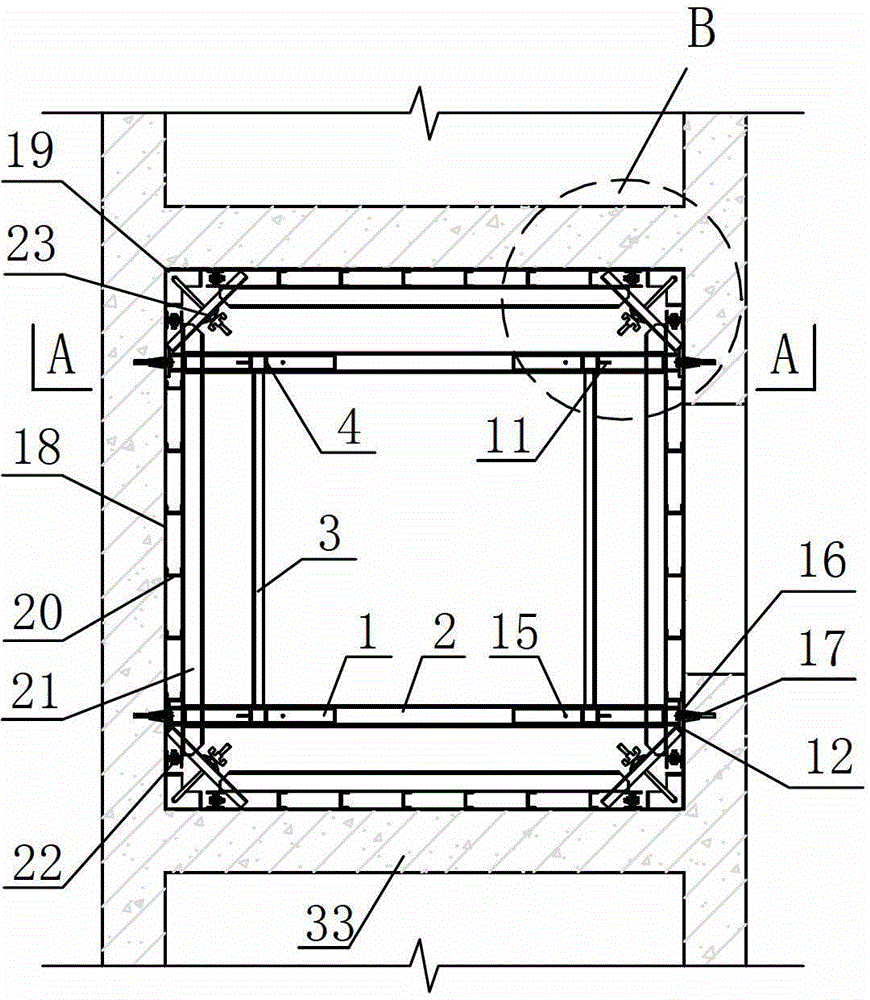

[0034] The combined hoistway mold includes a large steel template 18 and a female corner die 19. The template panel of the steel large template 18 is made of steel plate, the vertical flute 20 is made of channel steel, and the horizo...

Embodiment 2

[0039] Embodiment 2: A method for construction of cast-in-place walls of elevator shafts.

[0040] The method is to use the elevator hoistway mold system described in the first embodiment to carry out the construction of the cast-in-place wall of the elevator hoistway. During the hoisting construction, the steel large template of the combined hoistway mold and the hoisting frame are mutually supporting points, and the hoisting frame It is lifted into place as a whole with the large steel formwork, and lifted once every floor is completed; it includes the following steps:

[0041] A. Hoisting frame approach installation: use a tower crane or truck crane to hoist the hoisting frame into the elevator shaft, adjust the length of the base bearing beam 1 extending into the main beam 2, and install a limit pin 15 through the pin hole 14 to limit the position, and then pass the base The reserved holes 13 on the end connecting plate 12 of the load-bearing beam 1 are connected with the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com