Preparation method for stainless steel fiber sintered felt

A fiber sintered mat and stainless steel technology, applied in the field of stainless steel materials, can solve the problems of inability to apply stainless steel fiber sintered felt, difficulty in manual direct compression, high compression resistance, etc., to achieve low-temperature short-term sintering, prevent rebound deformation, and firm metallurgical bonding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

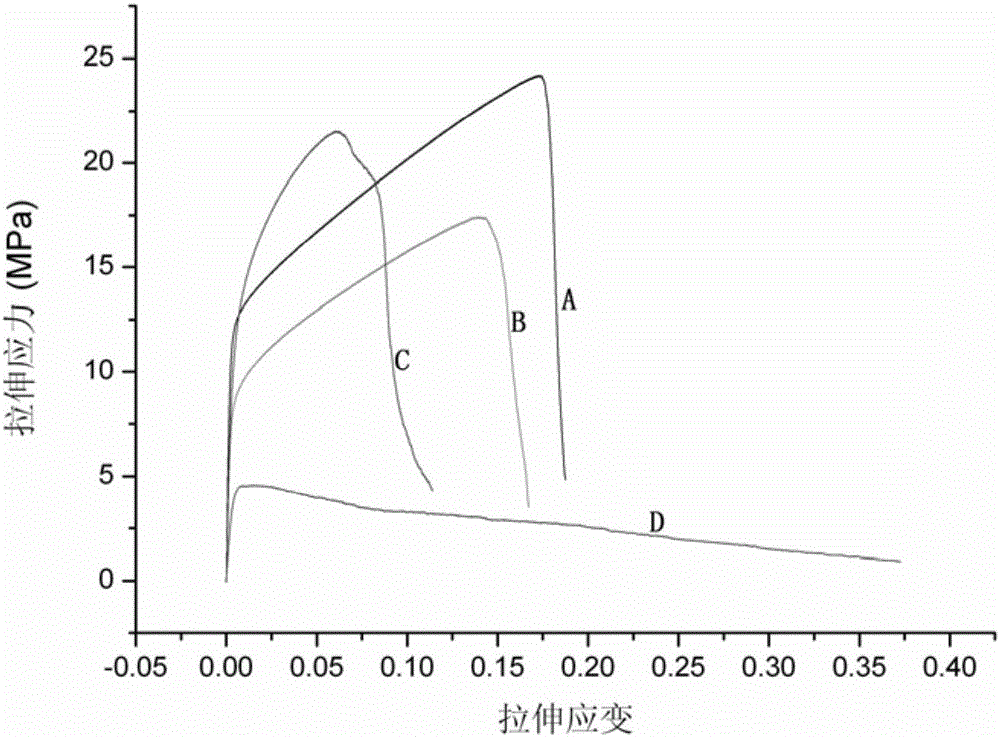

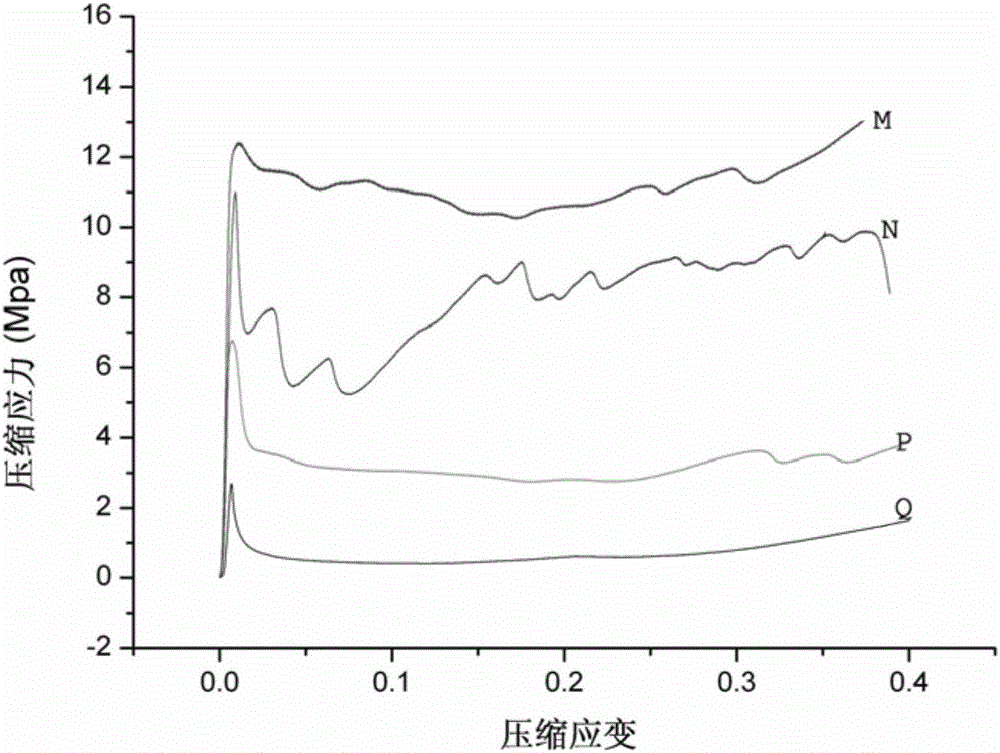

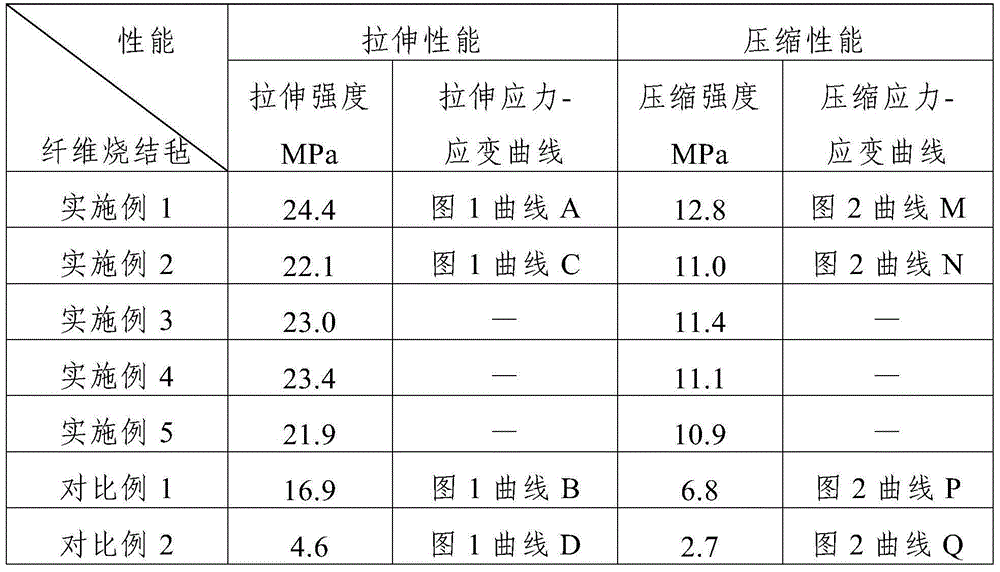

Examples

Embodiment 1

[0022] The preparation method of the present embodiment stainless steel fiber sintered felt comprises the following steps:

[0023] Step 1. Place the stainless steel fiber felt in a vacuum sintering furnace at a vacuum degree of ≤1×10 -2 Under the condition of Pa, the stainless steel fiber felt is heated up to 400°C at a heating rate of 10°C / min and then kept for 60 minutes for low-temperature sintering treatment, and the low-temperature sintered felt is obtained after natural cooling; the stainless steel fiber in the stainless steel fiber felt is preferably made of a bundled 316L stainless steel fiber prepared by drawing method, the fiber diameter is 28 μm;

[0024] Step 2. Use a hydraulic press to compress the low-temperature sintered felt in step 1 to a porosity of 83%, and then place the compressed low-temperature sintered felt in a vacuum sintering furnace at a vacuum degree ≤ 1×10 -2 Under the condition of Pa, the compressed low-temperature sintered felt was heated up t...

Embodiment 2

[0027] The preparation method of the present embodiment stainless steel fiber sintered felt comprises the following steps:

[0028] Step 1. Place the stainless steel fiber felt in a vacuum sintering furnace at a vacuum degree of ≤1×10 -2 Under the condition of Pa, the stainless steel fiber felt is heated up to 500°C at a heating rate of 10°C / min, and then kept for 30min for low-temperature sintering treatment, and the low-temperature sintered felt is obtained after natural cooling; the stainless steel fiber in the stainless steel fiber felt is preferably made of bundled 316L stainless steel fiber prepared by drawing method, the fiber diameter is 28 μm;

[0029] Step 2. Use a hydraulic press to compress the low-temperature sintered felt in step 1 to a porosity of 83%, and then place the compressed low-temperature sintered felt in a vacuum sintering furnace at a vacuum degree ≤ 1×10 -2 Under the condition of Pa, the compressed low-temperature sintered felt was heated up to 1000...

Embodiment 3

[0032] The preparation method of the present embodiment stainless steel fiber sintered felt comprises the following steps:

[0033] Step 1. Place the stainless steel fiber felt in a vacuum sintering furnace at a vacuum degree of ≤1×10 -2 Under the condition of Pa, the stainless steel fiber felt is heated up to 600°C at a heating rate of 20°C / min, and then kept for 30min for low-temperature sintering treatment, and the low-temperature sintered felt is obtained after natural cooling; the stainless steel fiber in the stainless steel fiber felt is preferably made of bundled 316L stainless steel fiber prepared by drawing method, the fiber diameter is 60 μm;

[0034]Step 2: Use a hydraulic press to compress the low-temperature sintered felt in step 1 to a porosity of 80%, and then place the compressed low-temperature sintered felt in a vacuum sintering furnace at a vacuum degree ≤ 1×10 -2 Under the condition of Pa, the compressed low-temperature sintered felt was heated up to 1000°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com