High-performance electric-control bypass valve for turbocharger

A turbocharger, high-performance technology, used in machines/engines, combustion engines, internal combustion piston engines, etc., can solve problems that affect engine performance and power, affect valve body response time, and poor valve body sealing effect. To achieve the effect of ensuring the turbocharger effect, preventing the delay of the response, and reducing the noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

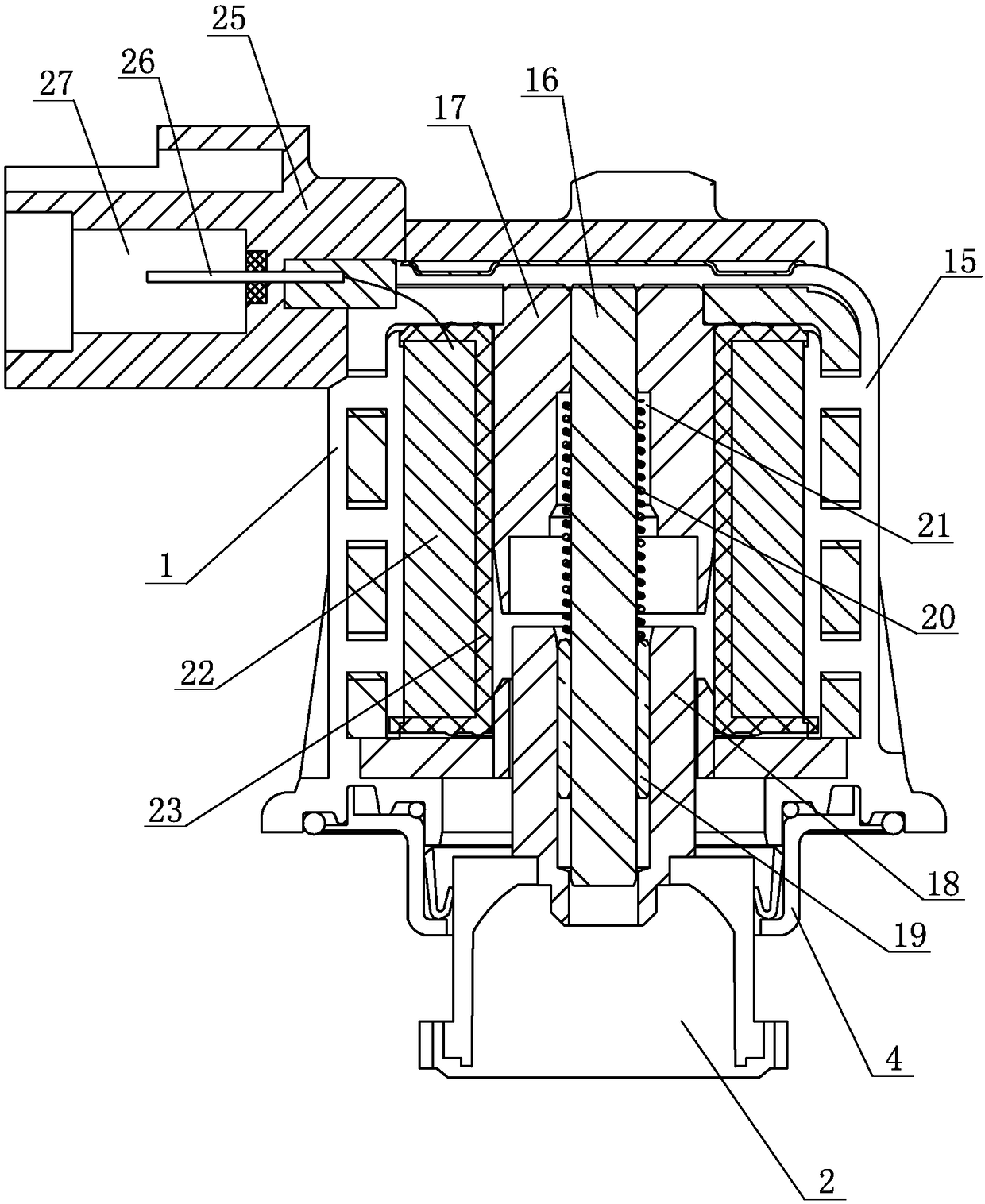

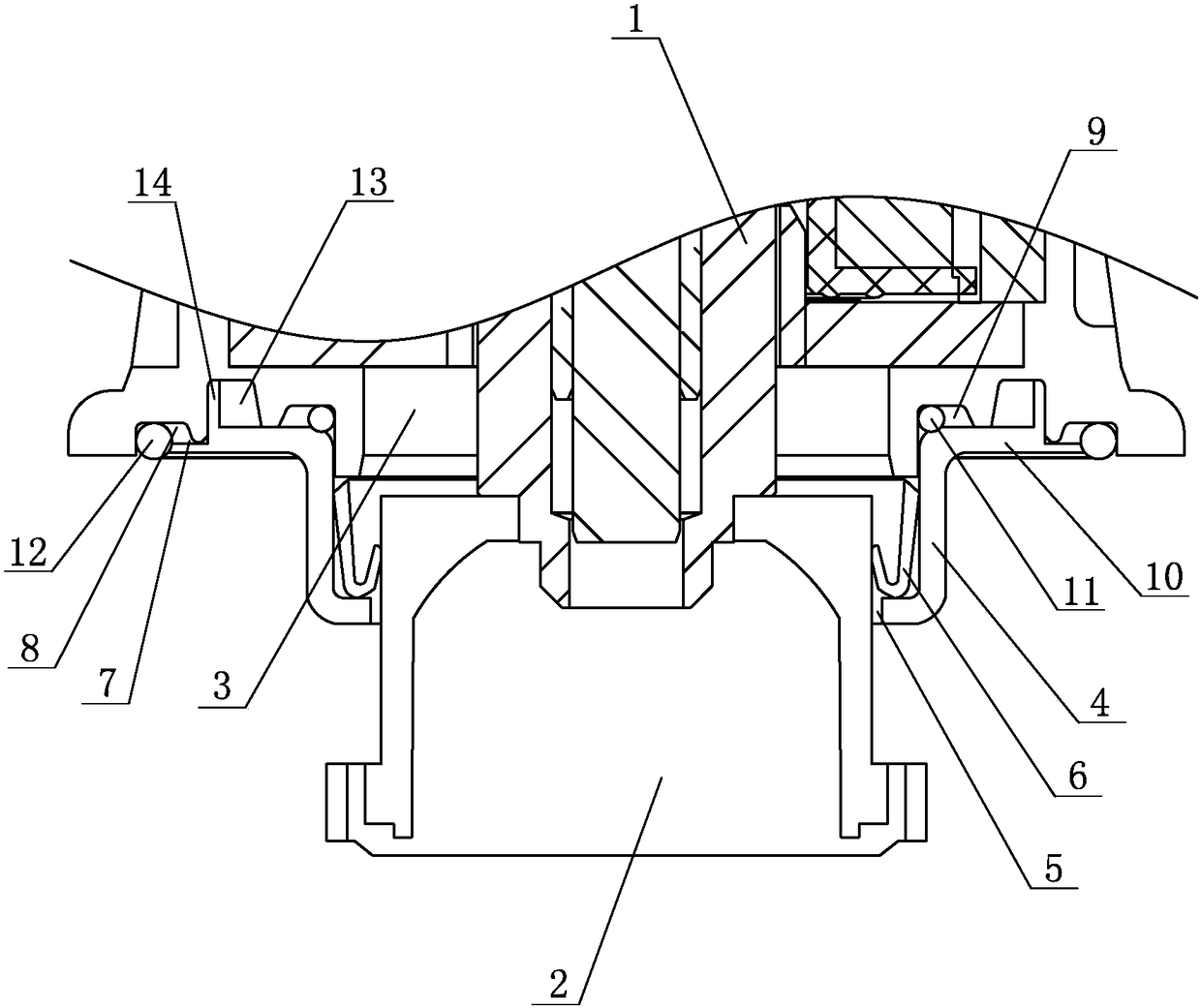

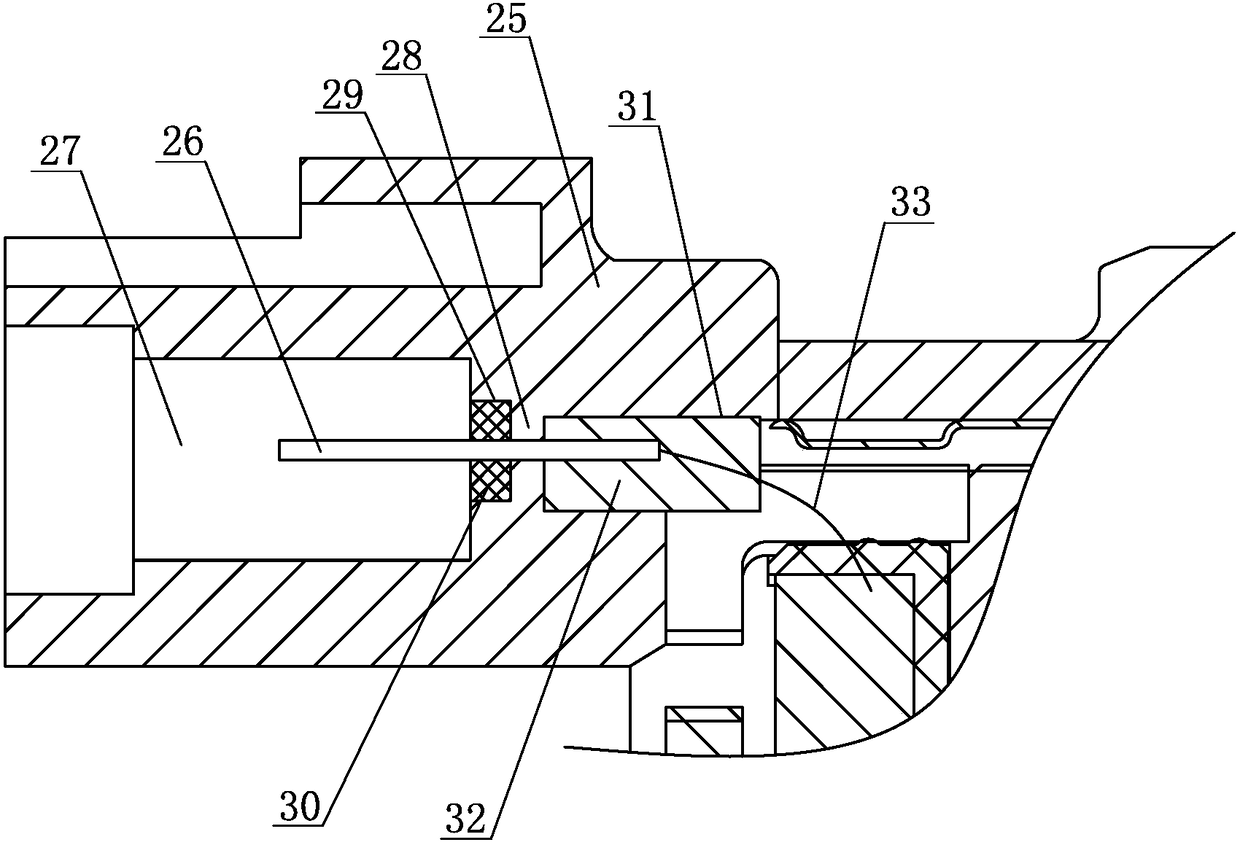

[0026] Embodiment one: see Figure 1~4 As shown, a high-performance electronically controlled bypass valve for a turbocharger includes a valve body 1 and a valve body seal 2 arranged at the bottom of the valve body 1, the bottom of the valve body 1 is provided with an outlet 3, and the valve The body seal 2 is moved and arranged in the outlet 3; the outlet 3 is also provided with a column cover 4, the column cover 4 is a hollow structure with an opening at the top, and the opening of the column cover 4 The mask is arranged on the outlet 3, and a through hole 5 is provided on the bottom surface of the column cover plate 4, the through hole 5 is arranged facing the outlet 3, and the valve body seal 2 is moved and inserted in the In the through hole 5, a first sealing ring 6 is arranged inside the columnar cover plate 4, and the first sealing ring 6 is arranged at the junction of the valve body seal 2 and the through hole 5; The bottom surface of the valve body 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com