System and process for micro-power sewage treatment in plateau environment

A sewage treatment system and plateau environment technology, applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of high energy consumption, inconvenient sewage treatment, high cost, etc., and achieve the goal of installation project Simple, reduce heat loss and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

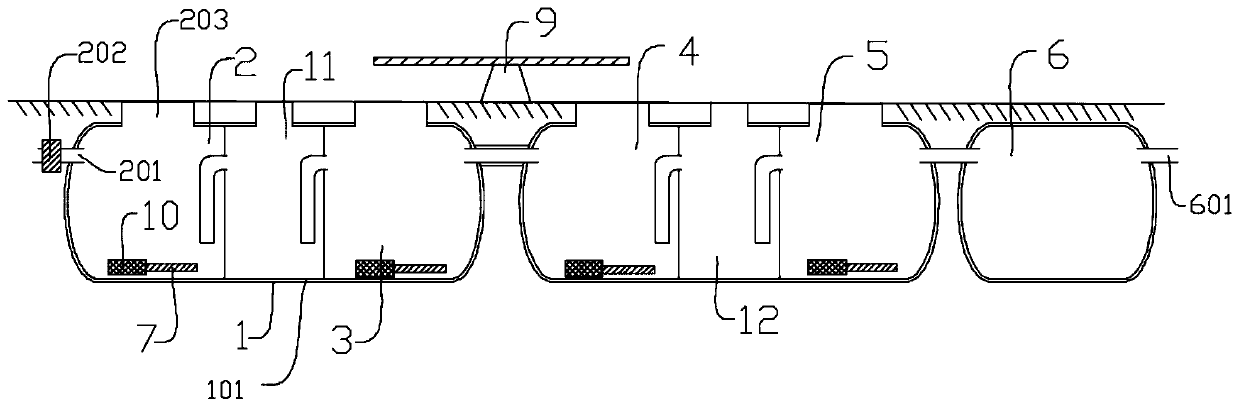

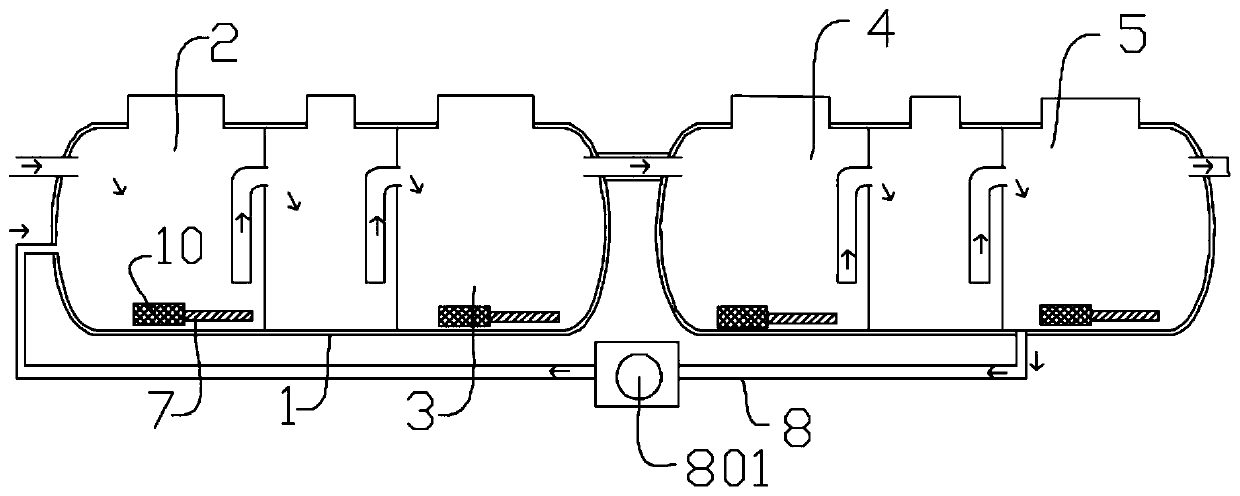

[0036] refer to figure 1 , figure 2 As shown, one embodiment of the present invention is, a kind of microdynamic sewage treatment system that is used in plateau environment, above-mentioned tank body 1 is placed in the low-temperature antifreeze layer of plateau surface, is provided with functional pool in above-mentioned tank body 1, and above-mentioned functional pool comprises Anaerobic pond 2, anoxic pond 3, aerobic pond 4, sedimentation pond 5, and purification pond 6, the above-mentioned anaerobic pond 2, anoxic pond 3, aerobic pond 4, sedimentation pond 5, and purification pond 6 are connected in sequence, and the above-mentioned The anaerobic tank 2, the anoxic tank 3, the aerobic tank 4, and the sedimentation tank 5 are provided with a heating element 7, and the bottom of the above-mentioned sedimentation tank 5 is provided with a return pipe 8, and the head end of the above-mentioned return pipe 8 is connected with the sedimentation tank 5, and the end Connected wi...

Embodiment 2

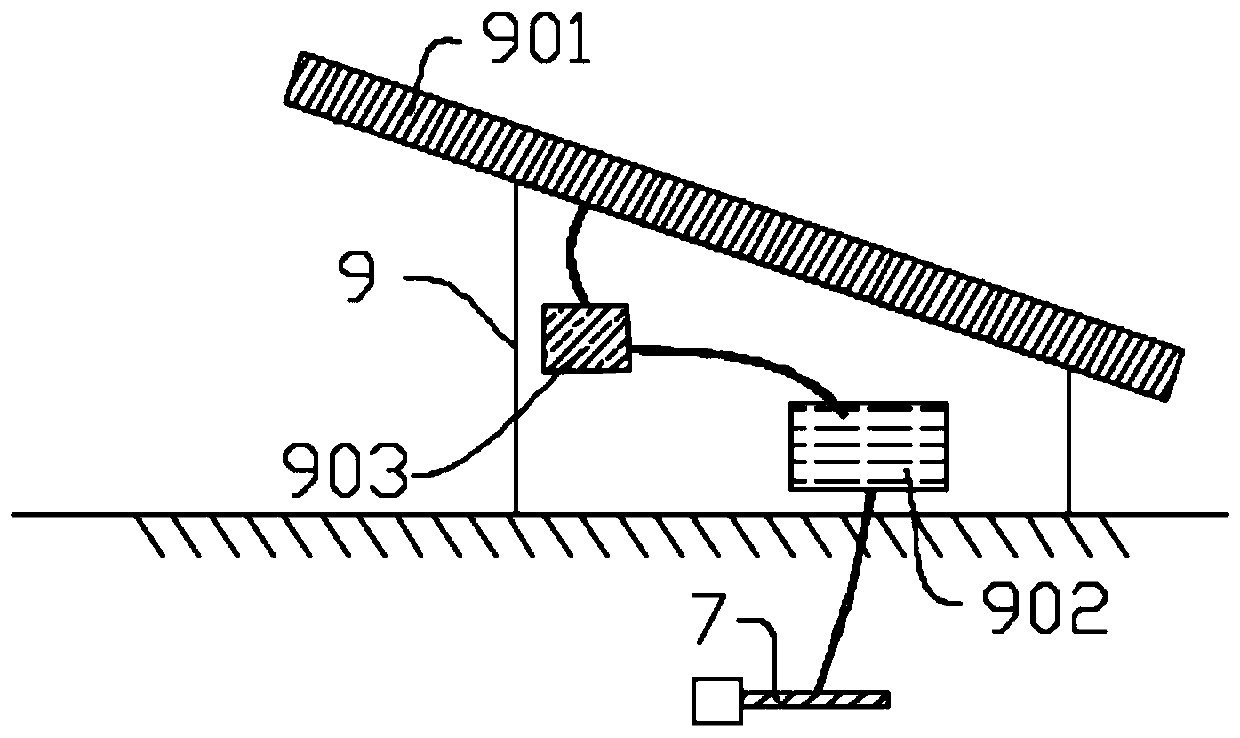

[0038] Based on the above-mentioned sewage treatment system, the present invention also provides a micro-dynamic sewage treatment process, the steps of which include: S1 tank installation, digging an installation pit under the surface of the selected plateau area, the above-mentioned installation pit is 40 cm below the surface and install a solar power supply device 7 on the ground surface for obtaining energy from the solar power supply device 7; S2 adjusts the temperature of the tank body, injects water into the tank body 1, and then heats up the water inside the tank body 1 through the heating element 6, Keep its temperature at 15-25 degrees Celsius to ensure the activity of nitrifying bacteria; S3 sewage treatment, continuously input sewage into tank 1, the sewage is input from anaerobic tank 2, and put matching compound nitrifying bacteria into the tank according to the characteristics of sewage In the anaerobic pool 2, the sewage flows through the entire sewage treatment ...

Embodiment 3

[0040] On the basis of the above-mentioned embodiments, in order to save equipment energy consumption and reduce the overall energy consumption of the heating element 7, the thickness of the above-mentioned thermal insulation cotton 101 is not less than three centimeters, and the above-mentioned anaerobic pool 2, anoxic pool 3, aerobic pool 4, All be provided with the temperature sensor 10 corresponding with heating element 7 in the settling tank 5, above-mentioned temperature sensor 10 is connected with heating element 7 control unit signal, and wherein temperature sensor 10 is existing commodity, can be temperature transmitter or thermocouple, And installed in the desired position of anaerobic pool 2, anoxic pool 3, aerobic pool 4, and sedimentation tank 5 through conventional installation methods, the temperature signal is collected by the temperature sensor 10, transmitted to the controller of the heating element 7, and sent to the controller The thyristor signal is output,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com