Steel wire rope greasy filth cleaning device

A cleaning device and wire rope technology, which is applied in the direction of transportation, packaging, elevators, etc., can solve the problems that affect the integrity of the pads, take a long time to clean the sludge, and cannot check the wire rope correctly, so as to improve the efficiency of daily maintenance and save daily maintenance time , Guarantee the effect of daily maintenance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

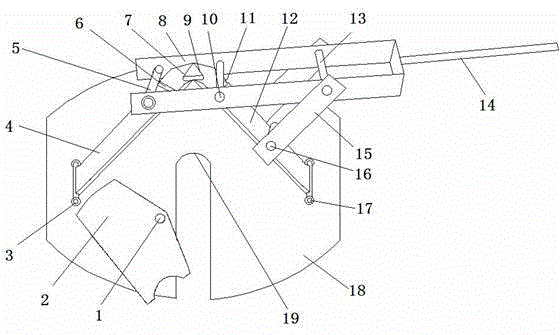

[0025] See Figure 1-5 , the specific structure is as follows: a bottom plate 18 for connecting oil sludge is provided, a gap 19 passing through a steel wire rope is set on the bottom plate connecting oil sludge 18, and the baffle plate 2 is hinged by a hinge shaft 1 on the side of the gap 19 to block the scraped oil sludge to prevent The scraped greasy sludge falls from the rectangular gap 19 .

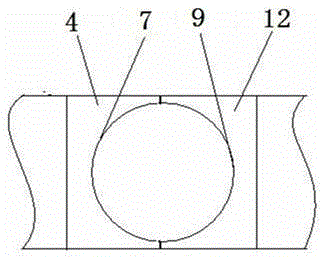

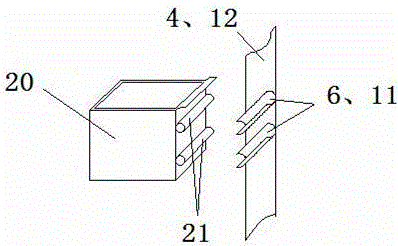

[0026] On the left and right sides of the oil sludge bottom plate 18, the opposite left scraper 4 and right scraper 12 are respectively connected by hinge shafts 3 and 17; the upper ends of the left scraper 4 and the right scraper 12 are respectively provided with circular arc-shaped concave knife edges 7 , 9, the two are relatively joined to form a round knife edge for scraping oil mud (see figure 2 ), the steel wire rope passes through the scraping mud round knife edge; the connecting shaft 16 is welded on the right scraper plate 12, and the connecting plate 15 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com