Spraying device for cast iron tube

A technology of spraying device and cast iron pipe, applied in furnaces, heat treatment equipment, heat treatment furnaces and other directions, can solve problems such as hidden dangers to the safety of workers, obstacles to the production and processing of cast iron pipes, burnout of processing equipment of cast iron pipes, etc., and achieves good cooling effect, Guarantee the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

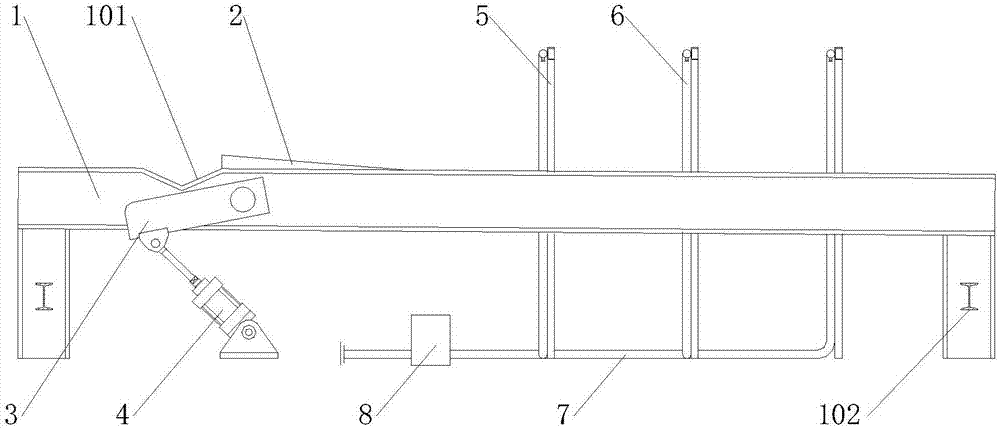

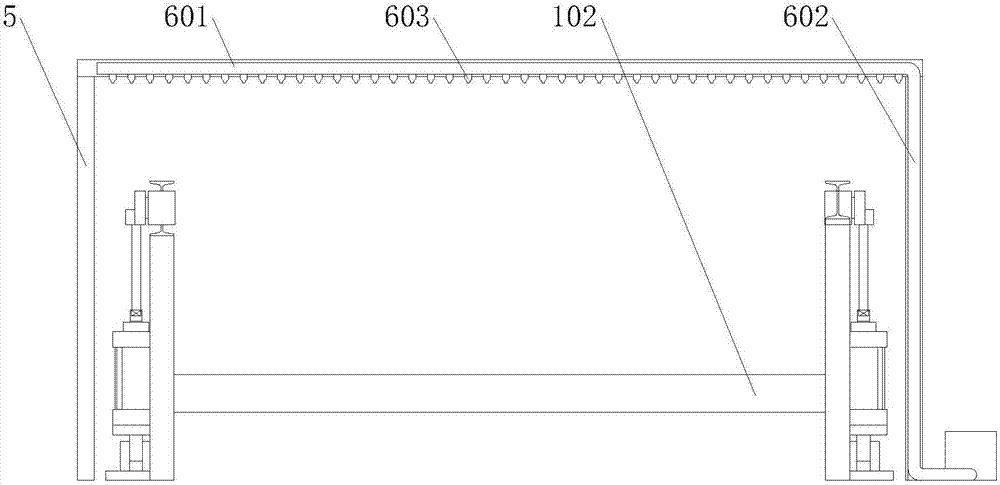

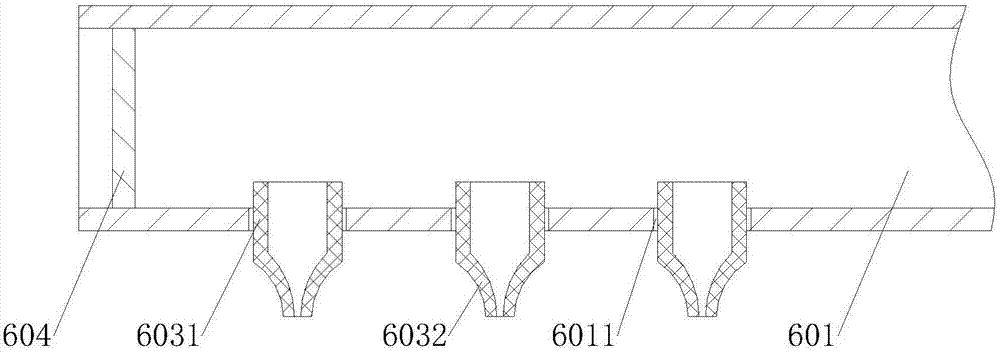

[0014] Example. A cast iron pipe spraying device, constituted as figure 1 As shown, the conveying track 1 is included, and one end of the conveying track 1 is provided with a group of symmetrically arranged V-shaped grooves 101, one end of the V-shaped groove 101 is provided with a diagonal brace 2, and the lower end of the V-shaped groove 101 is provided with a push plate 3, and one end of the push plate 3 is connected to There is a jacking cylinder 4; the outside of the conveying track 1 is provided with a plurality of mounting frames 5 placed side by side, and each mounting frame 5 is provided with an L-shaped spray pipe 6, and the spray pipe 6 includes interconnected A horizontal pipe 601 and a vertical pipe 602, the bottom of the horizontal pipe 601 is evenly distributed with a number of nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com