Anti-aging SBS modified asphalt

A modified asphalt, anti-aging technology, applied in the direction of building components, building insulation materials, construction, etc., can solve the problems of high production cost, large amount of SBS modifier, etc., to improve the aging point and good penetration , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

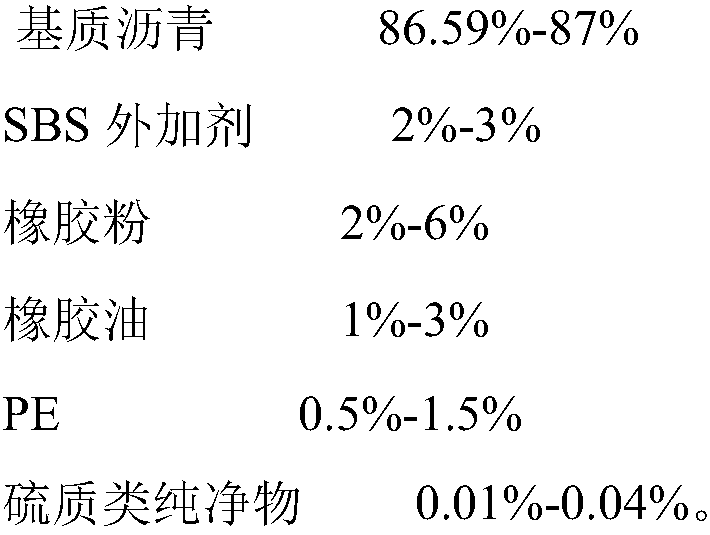

[0032] The invention discloses an anti-aging SBS modified asphalt, which comprises the following components by weight percentage:

[0033]

[0034] Among them, in this embodiment of the present invention, the base asphalt is SK asphalt with a penetration of 70-150 at 25°C and a softening point of 41-47. The reason is that after aging, the residual penetration ratio of SK asphalt is the largest, The residual ductility is the largest and the softening point rise rate is moderate, so its own aging resistance point is higher than that of Esso asphalt and Panjin asphalt;

[0035] In addition, the greater the molecular weight of SBS, the greater the viscosity of the solution and the higher the bonding strength. At the same time, as the ratio of styrene to butadiene increases, the viscosity of the polymer solution decreases, and the tensile strength and hardness increase. Therefore, in this embodiment of the present invention, the SBS admixture adopts a star structure SBS with a m...

Embodiment 2

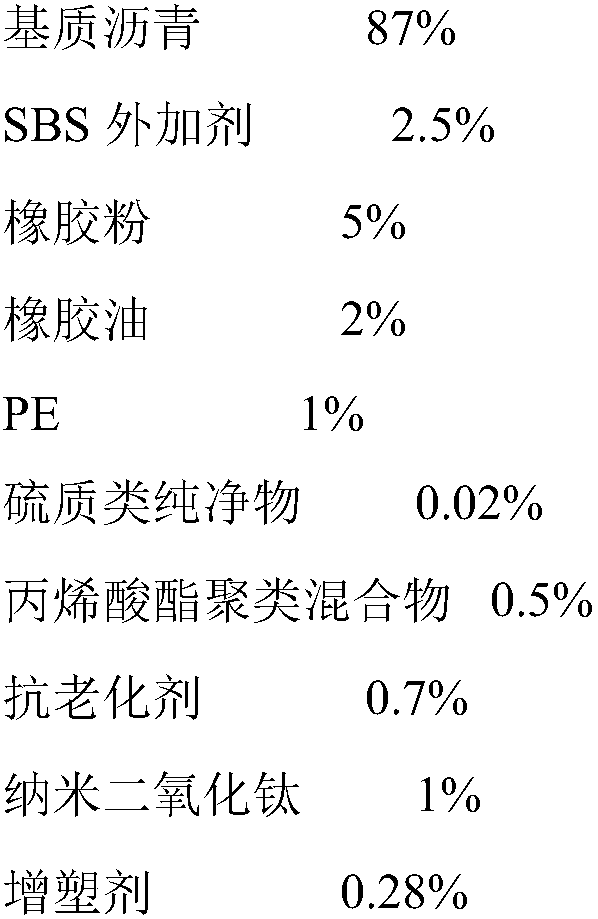

[0041] The invention discloses an anti-aging SBS modified asphalt, which comprises the following components by weight percentage:

[0042]

[0043] Among them, in this embodiment of the present invention, the base asphalt is SK asphalt with a penetration of 70-150 at 25°C and a softening point of 41-47. The reason is that after aging, the residual penetration ratio of SK asphalt is the largest, The residual ductility is the largest and the softening point rise rate is moderate, so its own aging resistance point is higher than that of Esso asphalt and Panjin asphalt;

[0044] In addition, the greater the molecular weight of SBS, the greater the viscosity of the solution and the higher the bonding strength. At the same time, as the ratio of styrene to butadiene increases, the viscosity of the polymer solution decreases, and the tensile strength and hardness increase. Therefore, in this embodiment of the present invention, the SBS admixture adopts a star structure SBS with a m...

Embodiment 3

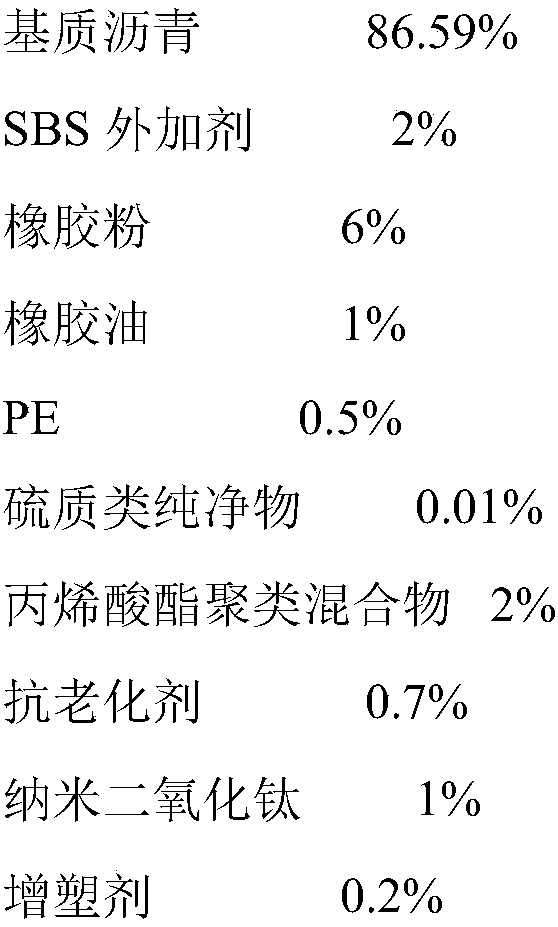

[0050] The invention discloses an anti-aging SBS modified asphalt, which comprises the following components by weight percentage:

[0051]

[0052] Among them, in this embodiment of the present invention, the base asphalt is SK asphalt with a penetration of 70-150 at 25°C and a softening point of 41-47. The reason is that after aging, the residual penetration ratio of SK asphalt is the largest, The residual ductility is the largest and the softening point rise rate is moderate, so its own aging resistance point is higher than that of Esso asphalt and Panjin asphalt;

[0053] In addition, the greater the molecular weight of SBS, the greater the viscosity of the solution and the higher the bonding strength. At the same time, as the ratio of styrene to butadiene increases, the viscosity of the polymer solution decreases, and the tensile strength and hardness increase. Therefore, in this embodiment of the present invention, the SBS admixture adopts a star structure SBS with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com