Cement grinding aid for cement grinding and preparation method thereof

A technology of cement grinding aid and cement powder, applied in the field of cement grinding aid, can solve the problems of large dosage, poor stability of cement quality, unstable quality of grinding aid, etc. The effect of increasing cement production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

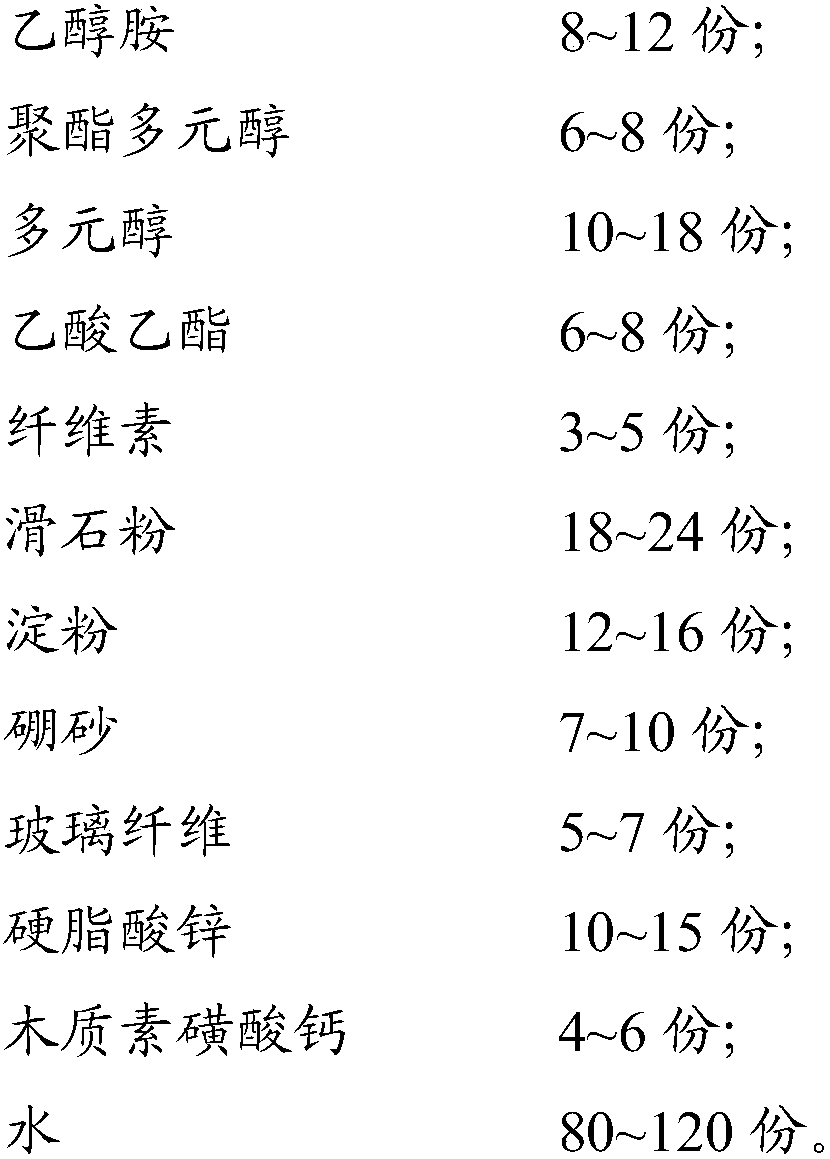

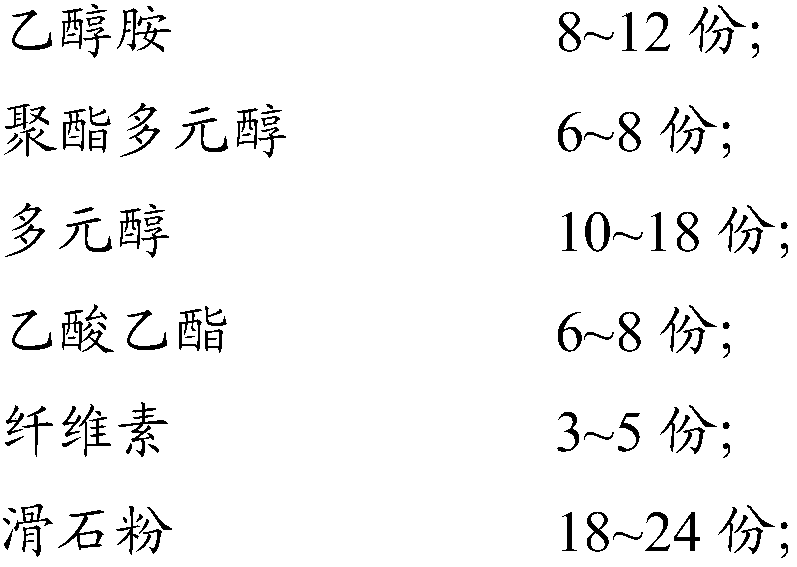

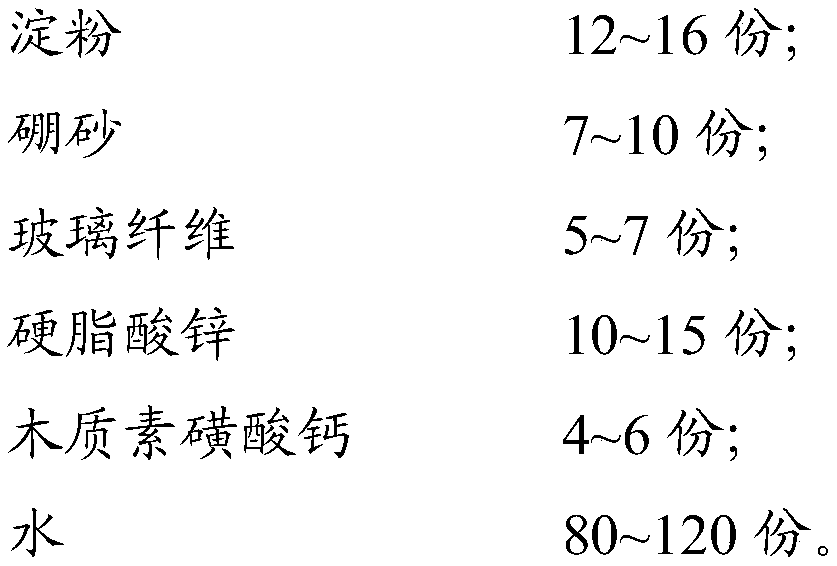

[0033] The present invention also provides a preparation method of a cement grinding aid for cement grinding, comprising the following steps:

[0034] Weigh ethanolamine, polyester polyol, polyol, ethyl acetate, cellulose, talcum powder, starch, borax, glass fiber, zinc stearate, calcium lignosulfonate and add it to water, and put it under 40~50℃ Stir for 50-70 minutes, and cool down to room temperature to obtain the cement grinding aid for cement grinding.

[0035] Wherein, ethanolamine, polyester polyol, polyol, ethyl acetate, cellulose, talcum powder, starch, borax, glass fiber, zinc stearate, calcium lignosulfonate and water are all the same as above, no longer repeat.

[0036] In the above technical scheme, the process is simple and the processing is convenient, and the prepared grinding aid can improve the early strength of cement and shorten the setting time of cement, thereby realizing the improvement of grinding efficiency and output of the mill and reduction of ener...

Embodiment 1

[0039] The cement grinding aid used for cement grinding comprises the following raw materials in parts by weight:

[0040] 9 parts of triethanolamine, 6.8 parts of polyethylene adipate diol, 13 parts of ethylene glycol, 6.5 parts of ethyl acetate, 3 parts of hydroxyethyl cellulose, 19 parts of talc, 13.5 parts of carboxymethyl starch, 7.5 parts borax, 5.4 parts glass fiber, 12 parts zinc stearate, 4.4 parts calcium lignosulfonate and 105 parts water.

[0041] The preparation method of the cement grinding aid for cement grinding, comprises the following steps:

[0042] Weigh triethanolamine, polyethylene adipate glycol, ethylene glycol, ethyl acetate, hydroxyethyl cellulose, talcum powder, carboxymethyl starch, borax, glass fiber, zinc stearate, lignin Calcium sulfonate is added to water, stirred at 45°C for 60 minutes, and cooled to room temperature to obtain cement grinding aid for cement grinding.

Embodiment 2

[0044] The cement grinding aid used for cement grinding comprises the following raw materials in parts by weight:

[0045] 11 parts of N-methyldiethanolamine, 7.2 parts of polycaprolactone diol, 15 parts of diethylene glycol, 7.5 parts of ethyl acetate, 3.5 parts of hydroxypropyl methylcellulose, 20 parts of talc, 12 parts Octenylsuccinate starch, 7 parts borax, 5 parts glass fiber, 10 parts zinc stearate, 5.6 parts calcium lignosulfonate and 95 parts water.

[0046] The preparation method of the cement grinding aid for cement grinding, comprises the following steps:

[0047]Weigh N-methyldiethanolamine, polycaprolactone glycol, diethylene glycol, ethyl acetate, hydroxypropyl methylcellulose, talcum powder, octenyl succinic esterified starch, borax, glass Fiber, zinc stearate, and calcium lignosulfonate were added to water, stirred at 50°C for 50 minutes, and cooled to room temperature to obtain a cement grinding aid for cement grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com