Concrete composite anti-freezing agent and preparation method thereof

An antifreeze and concrete technology, which is applied in the field of concrete admixtures, can solve the problems that the antifreeze does not act as a coagulant and the strength of the antifreeze increases slowly in the concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

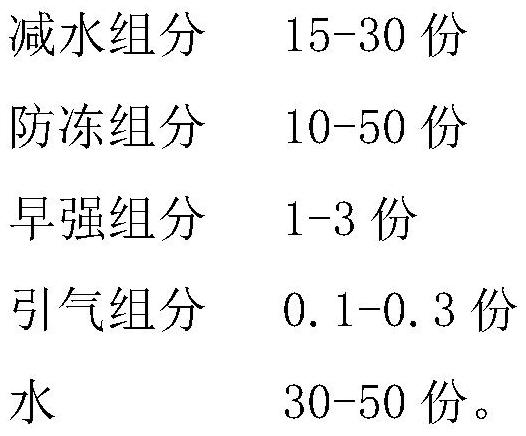

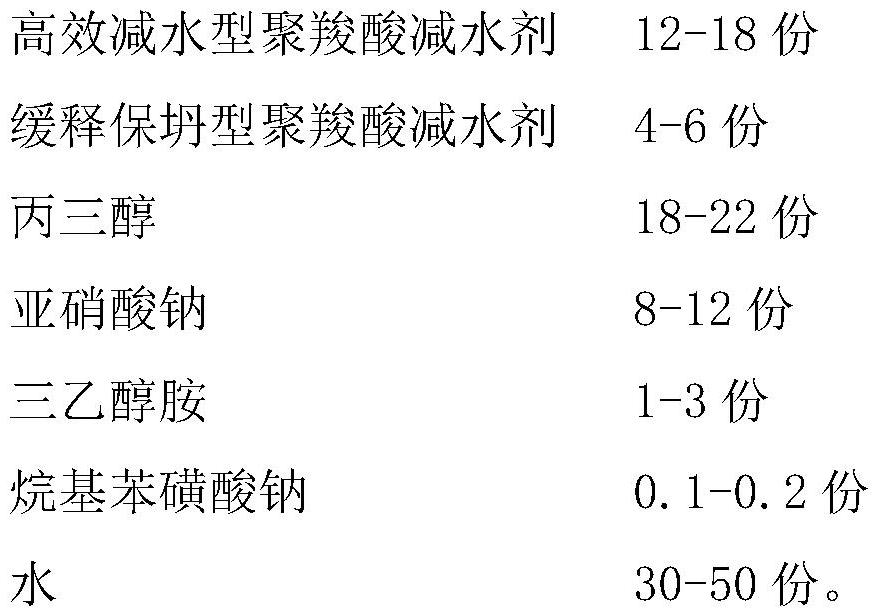

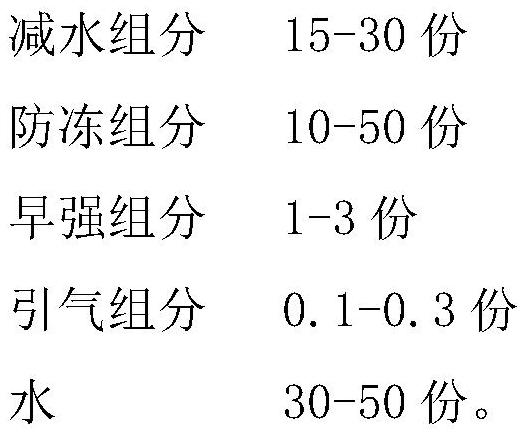

[0031] Present embodiment provides a kind of composite concrete antifreeze, the raw material of described concrete antifreeze comprises by mass parts:

[0032]

[0033] Its preparation method is as follows:

[0034] (1) Put 45g of deionized water, 15g of high-efficiency water-reducing polycarboxylate superplasticizer, and 5g of slow-release slump-proof polycarboxylate superplasticizer in the reactor, adjust the speed to 200rpm, and control the temperature at 27°C Stir for 10 minutes;

[0035] (2) 20g of glycerol (antifreeze component) is placed in the above-mentioned reaction kettle, keep temperature and rotating speed constant and stir for 10min;

[0036] (3) 10g of sodium nitrite (antifreeze component) is placed in the above-mentioned reaction kettle, keep the temperature and rotating speed constant and stir for 10min;

[0037] (4) Place measured 2 parts of early strength agent and 0.15 part of air-entraining agent in the above-mentioned reaction kettle, keep the temper...

Embodiment 2

[0039] This embodiment provides a concrete composite antifreeze, the composition and preparation method of the concrete composite antifreeze are basically the same as those in Example 1, the only difference is that glycerol is not added; the antifreeze component is selected as a single antifreeze component sodium nitrite.

Embodiment 3

[0041] The present embodiment provides a composite antifreeze for concrete, the composition and preparation method of the composite antifreeze for concrete are basically the same as in Example 1, the difference is only: replace glycerol with methanol in equal parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com