Low-dosage asphalt regenerant and preparation method and application method thereof

An asphalt regenerating agent and a technology for reclaiming asphalt, which are applied in building components, building thermal insulation materials, buildings, etc., can solve the problem of high cost of raw materials, reduce the amount of mixing, save production costs, and be conducive to environmental protection and sustainable development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

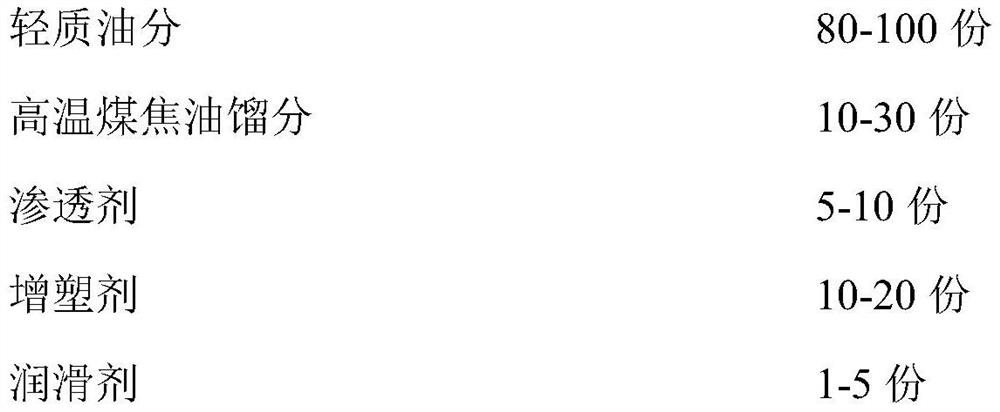

[0039] The asphalt regenerant consists of the following raw materials in percentage by mass: 100 parts of rubber oil, 20 parts of anthracene oil, 5 parts of turpentine, 15 parts of butyl epoxy fatty acid, 2 parts of calcium stearate and 5 parts of organic nano-montmorillonite.

[0040] According to the above proportion, the preparation steps of the asphalt regenerant are as follows:

[0041] Heating rubber oil to 60-80℃, adding anthracene oil, turpentine and epoxy fatty acid butyl ester, stirring at a speed of 50-100r / min for 10-20min, and uniformly mixing; Heating to 100-120℃, further adding calcium stearate and organic nano-montmorillonite and shearing for 20-30 min with a high-speed shearing machine at a speed of 2000-3000r / min; After natural cooling, the asphalt regenerant is obtained.

Embodiment 2

[0043] The asphalt regenerant consists of the following raw materials in percentage by mass: 90 parts of aromatic oil, 10 parts of anthracene oil, 7 parts of rosin water, 13 parts of epoxidized soybean oil, 5 parts of barium stearate and 1 part of organic nano montmorillonite.

[0044] According to the above proportion, the preparation steps of the asphalt regenerant are as follows:

[0045] Heating aromatic oil to 60-80℃, adding anthracene oil, rosin water and epoxidized soybean oil, keeping the temperature at 50-100r / min, stirring for 10-20min, and uniformly mixing; Heating to 100-120℃, further adding barium stearate and organic nano montmorillonite, and shearing for 20-30min; at a speed of 2000-3000r / min with a high-speed shearing machine; After natural cooling, the asphalt regenerant is obtained.

Embodiment 3

[0047] The asphalt regenerant consists of the following raw materials in percentage by mass: 80 parts of waste engine oil, 15 parts of anthracene oil, 10 parts of ethyl acetate, 10 parts of octyl epoxy fatty acid, 1 part of barium stearate and 3 parts of organic nano-montmorillonite.

[0048] According to the above proportion, the preparation steps of the asphalt regenerant are as follows:

[0049] Heating waste engine oil to 60-80℃, adding anthracene oil, ethyl acetate and octyl epoxy fatty acid, stirring at a speed of 50-100r / min for 10-20min, and mixing evenly; Heating to 100-120℃, further adding barium stearate and organic nano montmorillonite, and shearing for 20-30min; at a speed of 2000-3000r / min with a high-speed shearing machine; After natural cooling, the asphalt regenerant is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com