Light thermal insulation material and preparation method of light thermal insulation material

A kind of insulation material and lightweight technology, which is applied in the preparation of lightweight insulation materials and the field of lightweight insulation materials, can solve the problems of difficult construction, large deformation coefficient, poor safety, etc., achieve good economic and environmental benefits, improve resistance Improving performance and reducing economic burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

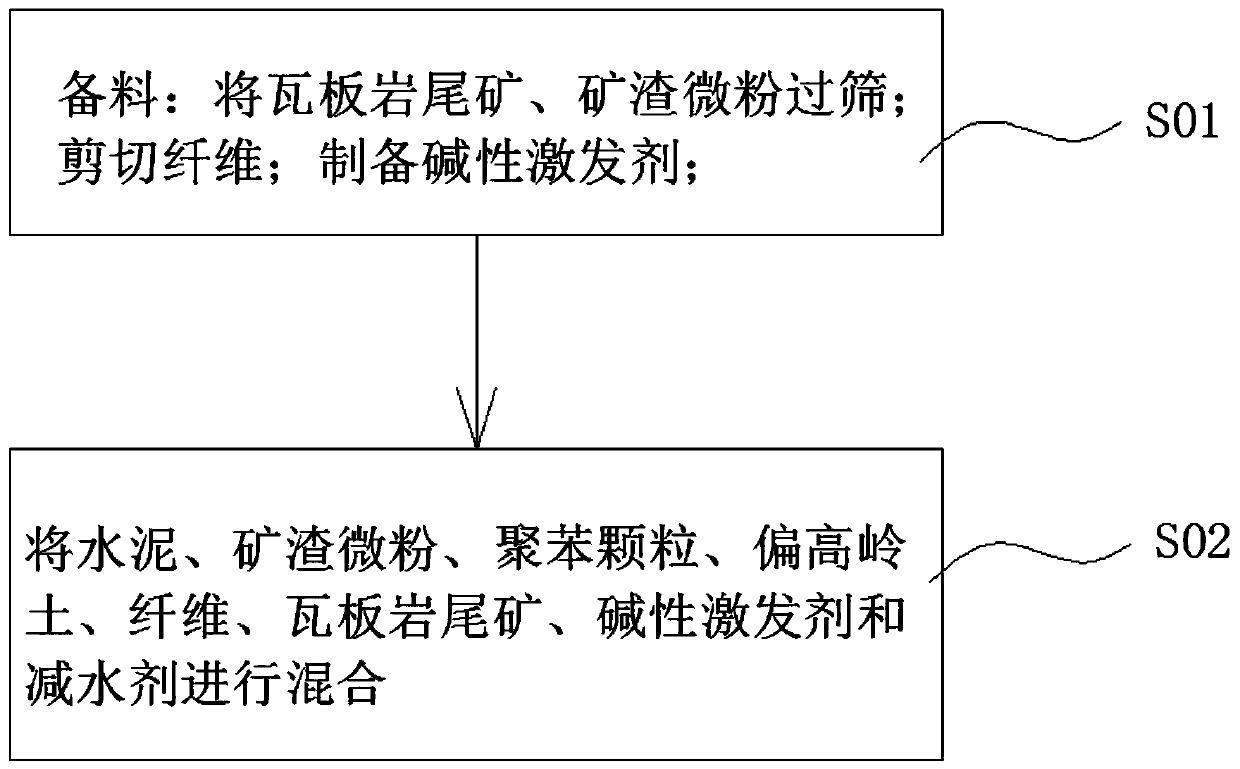

[0030] Such as figure 1 As shown, the second aspect of the present invention also provides a kind of preparation method of lightweight thermal insulation material, comprises the following steps:

[0031] First, material preparation: sieve the slate tailings and slag powder to make the slate tailings and slag powder meet the particle size requirements; use hemp rope as the fiber, and cut it into hemp rope fine fibers; prepare an alkaline activator in proportion ;

[0032] Second, dry mix cement, slag micropowder, polyphenylene particles, metakaolin, fiber, slate tailings and alkaline activator to obtain a mixture;

[0033] Among them, the amount of each raw material is calculated in parts by mass: 25-40 parts of cement, 5-15 parts of slag powder, 1-5 parts of polyphenylene particles, 10-25 parts of metakaolin, 1-10 parts of fiber, and slate tailings 5-15 parts, 5-10 parts of alkaline activator and 1-5 parts of water reducer.

[0034] Preferably, the basic activator includes ...

Embodiment 1

[0053] (1) Grinding 100kg of slate tailings and sieving to obtain slate tailings powder with a particle size distribution of 0.5-25 μm and not less than 90%;

[0054] Grinding and sieving 50kg of fine slag powder to obtain fine slag powder with a particle size distribution of 0.5-25 μm and no less than 80%;

[0055] The fibers are cut into thin fibers with a length of 15 mm and a diameter of 0.2-0.4, usually by manual cutting, or by machine cutting.

[0056] Take 2kg of sodium hydroxide, 5kg of sodium silicate and 1kg of calcium oxide and mix them uniformly to prepare an alkaline activator;

[0057] (2) 400kg of cement, 50kg of slag powder, 2kg of polyphenylene particles, 125kg of metakaolin, 2kg of fiber, 100kg of tile slate tailings, 8kg of alkaline activator and 1kg of water reducing agent are mixed uniformly to obtain the light heat insulating material of the present invention Material;

[0058] (3) Take 100kg of uniformly mixed light insulation material, add 64kg of wat...

Embodiment 2

[0063] (1) Grinding 150kg of slate tailings and sieving to obtain slate tailings powder with a particle size distribution of 0.5-25 μm and not less than 90%;

[0064] Grinding and sieving 50kg of fine slag powder to obtain fine slag powder with a particle size distribution of 0.5-25 μm and no less than 80%;

[0065] The fibers are cut into thin fibers with a length of 15 mm and a diameter of 0.2-0.4, usually by manual cutting, or by machine cutting.

[0066] Take 2kg of sodium hydroxide, 5kg of sodium silicate and 1kg of calcium oxide and mix them uniformly to prepare an alkaline activator;

[0067] (2) Mix 300kg cement, 50kg slag micropowder, 2kg polyphenylene particles, 125kg metakaolin, 3kg fiber, 150kg tile rock tailings, 8kg alkaline activator and 1kg water reducing agent to obtain the light heat insulating material of the present invention Material;

[0068] (3) Take 100kg of uniformly mixed light insulation material, add 64kg of water, pour the material into a mortar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com