Auxiliary cementing material utilizing circulating fluidized bed fly ash and preparation method thereof

A technology of auxiliary cementitious material and circulating fluidized bed, which is applied in cement production and other directions, can solve the problem of difficulty in effectively utilizing circulating fluidized bed fly ash, etc., and achieves the effect of eliminating adverse effects, obvious effect and good volume stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

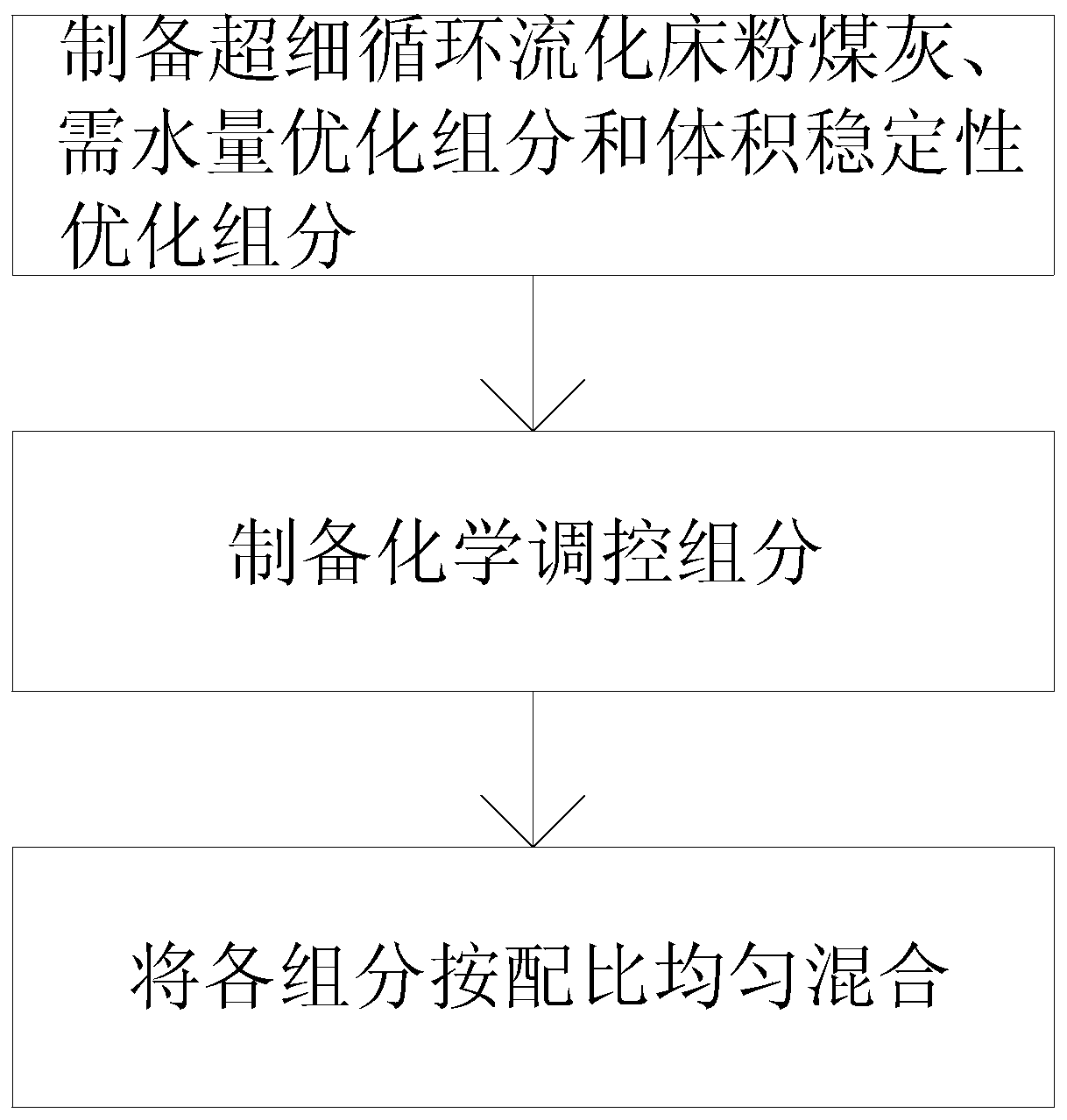

[0028] And in order to make above-mentioned auxiliary gelling material, the present invention also provides a kind of preparation method of auxiliary gelling material, such as figure 1 shown, including the following steps:

[0029] Step S1, using a grinding process to grind or separate the corresponding ultrafine circulating fluidized bed fly ash, water demand optimization components and volume stability optimization components; and the particles of ultrafine circulating fluidized bed fly ash Particle size < 17 μm, median particle size D50 = 5 ± 1 μm; particle size of the component optimized for water demand < 10 μm, median particle size D50 = 4 ± 1 μm; median particle size D50 of the component optimized for volume stability = 15~20μm;

[0030] Step S2, preparing a chemical control component, which is a liquid additive with a solid content of 30% to 50%;

[0031] Step S3, uniformly mixing ultrafine circulating fluidized bed fly ash, water demand optimization components, volu...

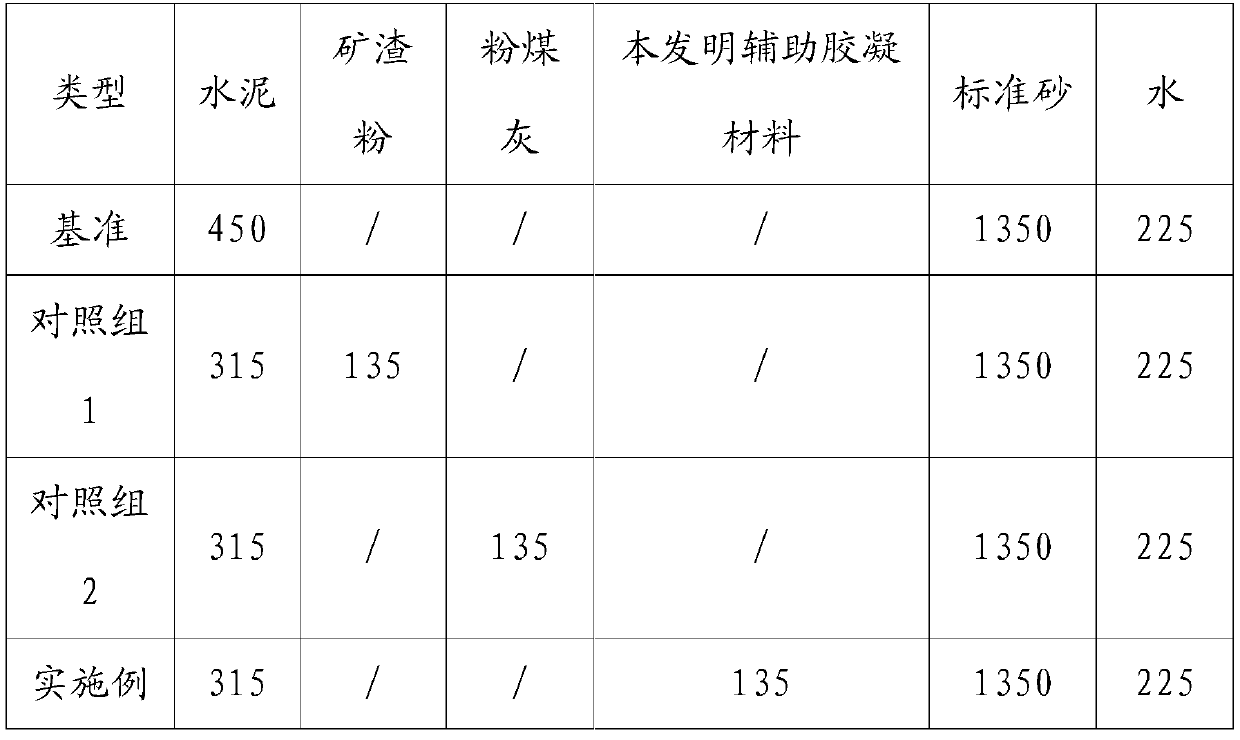

Embodiment 1

[0043] First of all, use the grinding process to grind or sort ultrafine circulating fluidized bed fly ash with a particle size of <17 μm and a median particle size of D50=5±1 μm, with a particle size of <10 μm and a median particle size of D50=4±1 μm 1μm ultrafine slag powder, limestone powder and tailings slag powder with median particle size D50=15-20μm; secondly, 65% water, 10% triethanolamine acetate, 5% triethylene glycol, 15% nitric acid Calcium and 5% molasses are mixed evenly to make chemical control components; finally, 70% ultrafine circulating fluidized bed fly ash, 15% ultrafine slag powder, 5% limestone powder and 10% tailings powder are evenly mixed , 0.15 parts of chemical adjustment admixture is sprayed on the surface of particles by spraying, so as to obtain an auxiliary cementitious material using circulating fluidized bed fly ash.

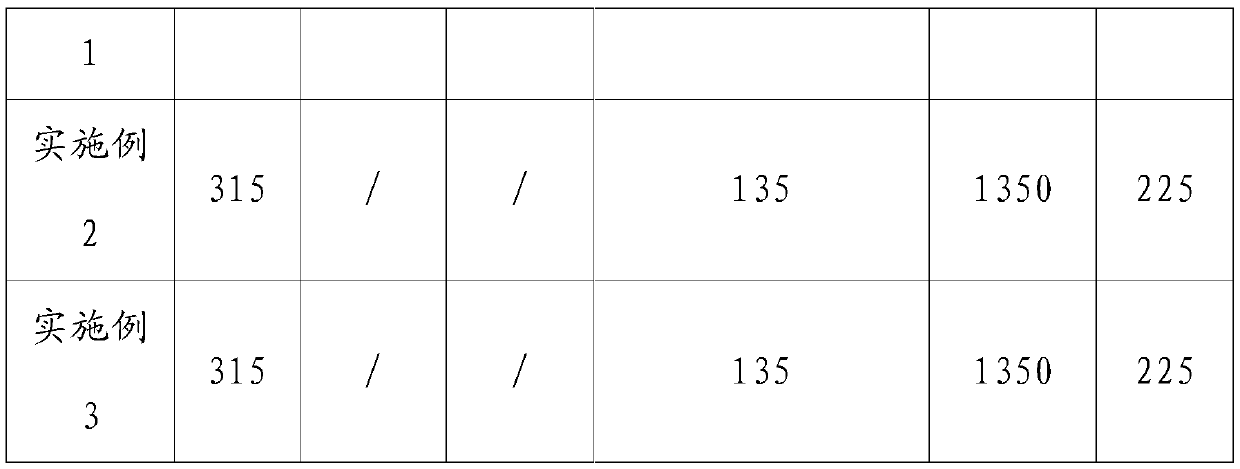

Embodiment 2

[0045] First of all, use the grinding process to grind or sort ultrafine circulating fluidized bed fly ash with a particle size of <17 μm and a median particle size of D50=5±1 μm, with a particle size of <10 μm and a median particle size of D50=4±1 μm 1μm ultrafine pulverized coal furnace fly ash, median particle size D50=15-20μm tailings slag powder; secondly, 70% water, 10% calcium nitrate, 5% triethanolamine acetate, 10% triethylamine Glycol, 5% diethanol monoisopropanolamine are mixed evenly to make chemical control components; finally, 75% ultrafine circulating fluidized bed fly ash, 15% ultrafine pulverized coal furnace fly ash and 10% tailings While the ore powder is uniformly mixed, 0.15 parts of the chemical adjustment admixture is sprayed on the surface of the particles in a spray mode, so as to obtain an auxiliary cementitious material using circulating fluidized bed fly ash.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com