Patents

Literature

35results about How to "Good fuel injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

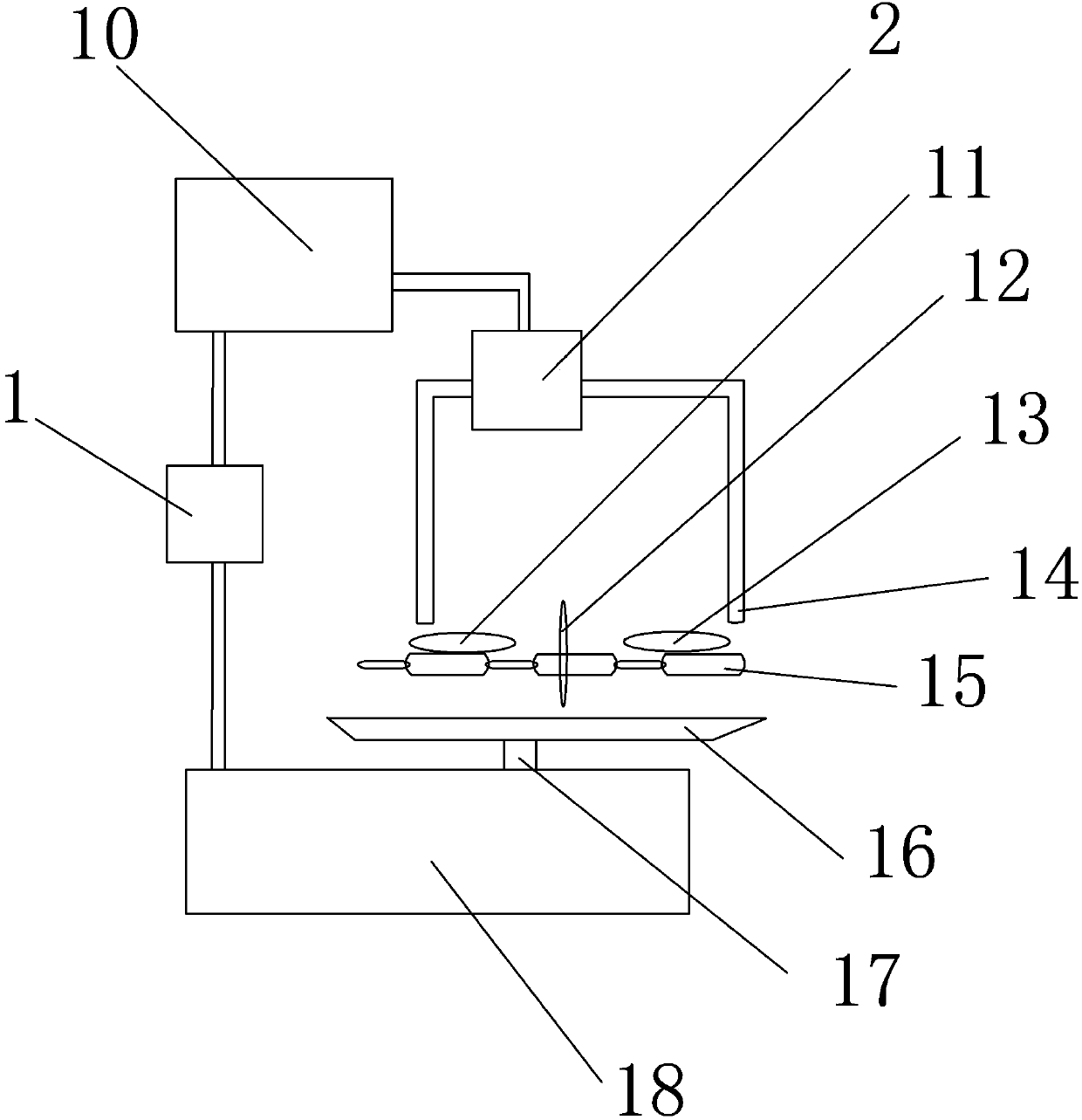

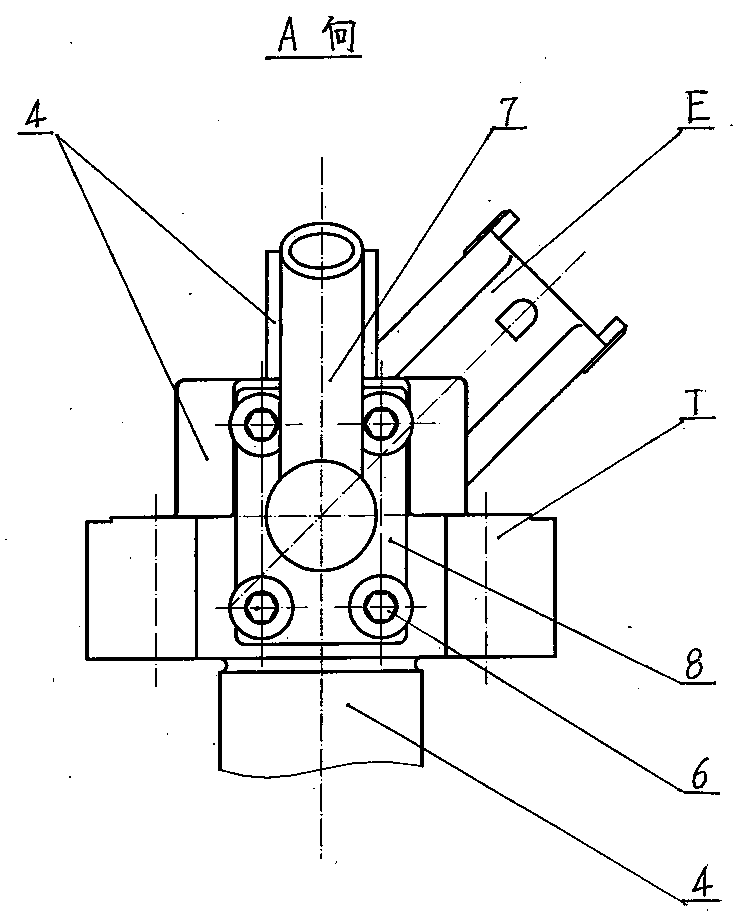

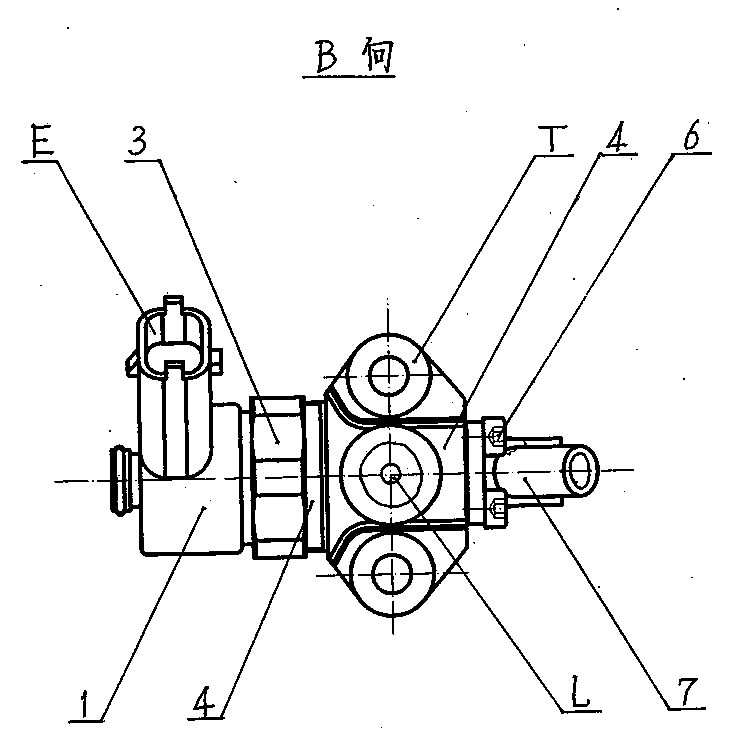

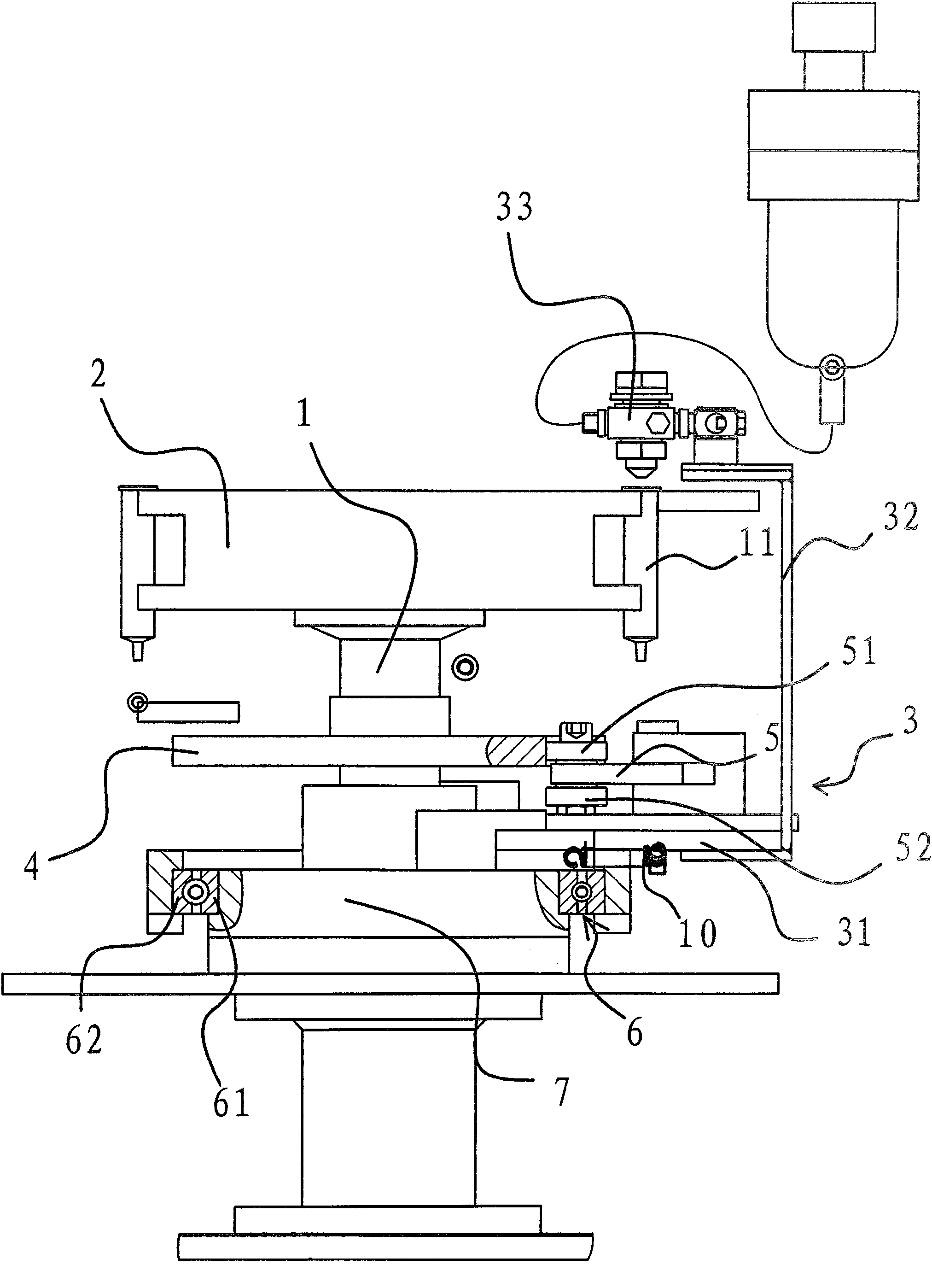

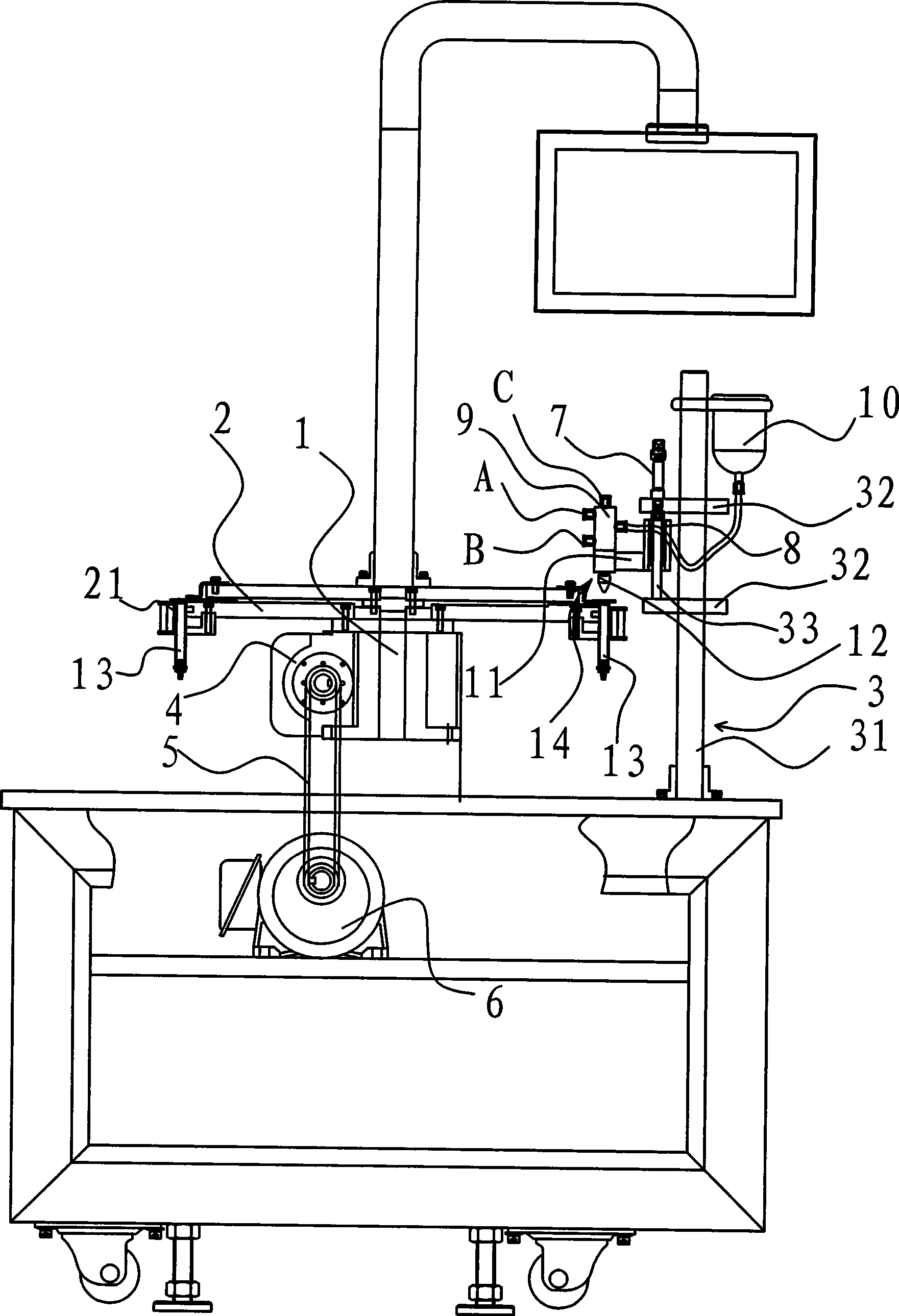

Silicone-oil coater for injector assembler

InactiveCN101073796AGood fuel injectionEasy to sprayLiquid surface applicatorsCoatingsInjectorSilicone oil

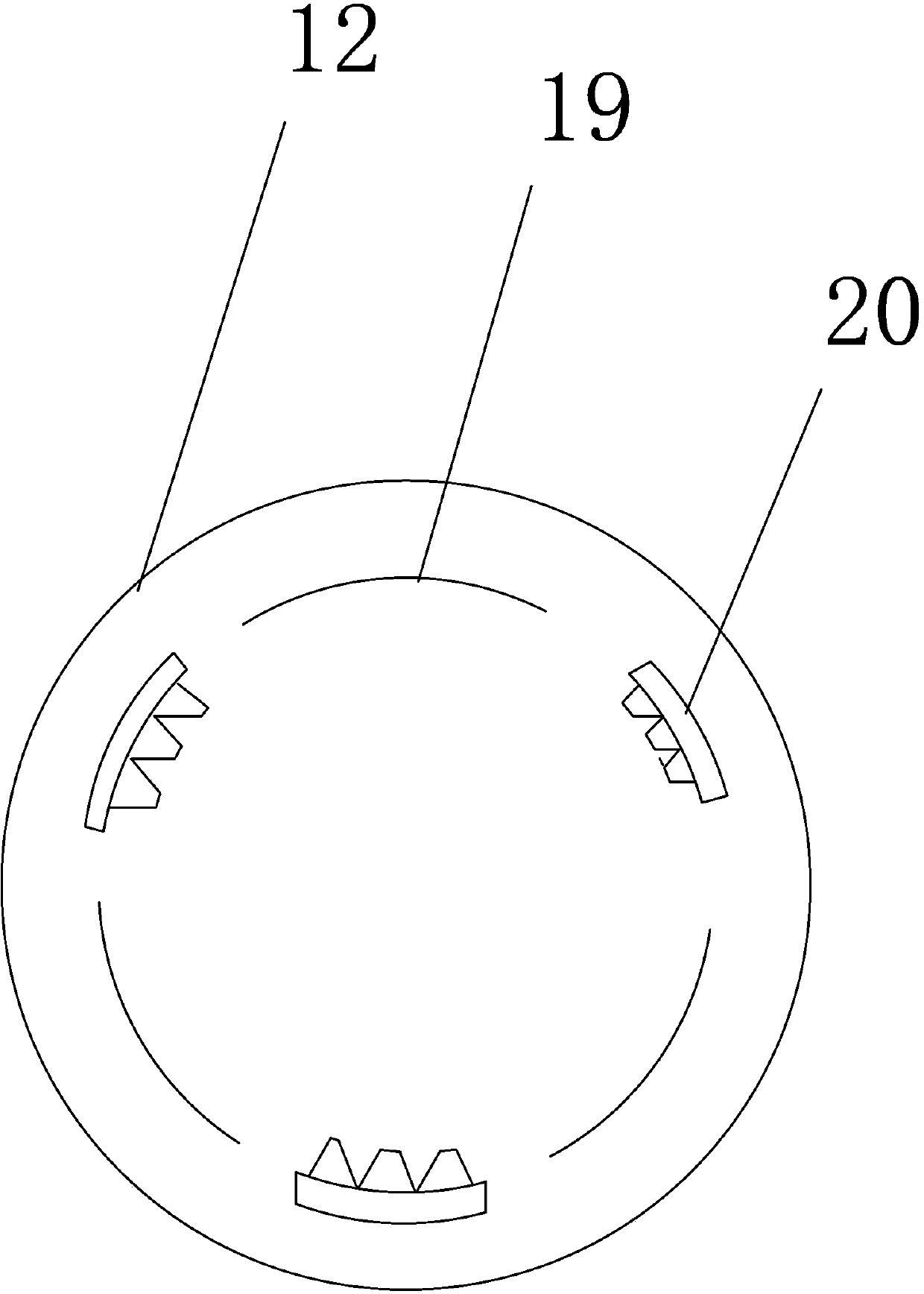

The invention is concerned with Silicone oil spreading equipment of injector assembly machine, belonging to machine technology. It solves the pollution on outside of canister and bad spraying effect of the existing Silicone oil spreading equipment. This equipment relates to a turning axis fixed with a turntable running with the turning axis. There are some blocks on the rim of turntable for fixing canister, and there is rack of spray oil on the side of turntable which having spray oil framework relating to head to spray oil, oil cup connecting with the head and spraying framework set on the head. There is driving framework between the head of spray oil and rack of spray oil to drive the spray framework on the top of block. This spray effect is good and the spray time is enough of this equipment and it can spray to the canister well and truly.

Owner:王兴章

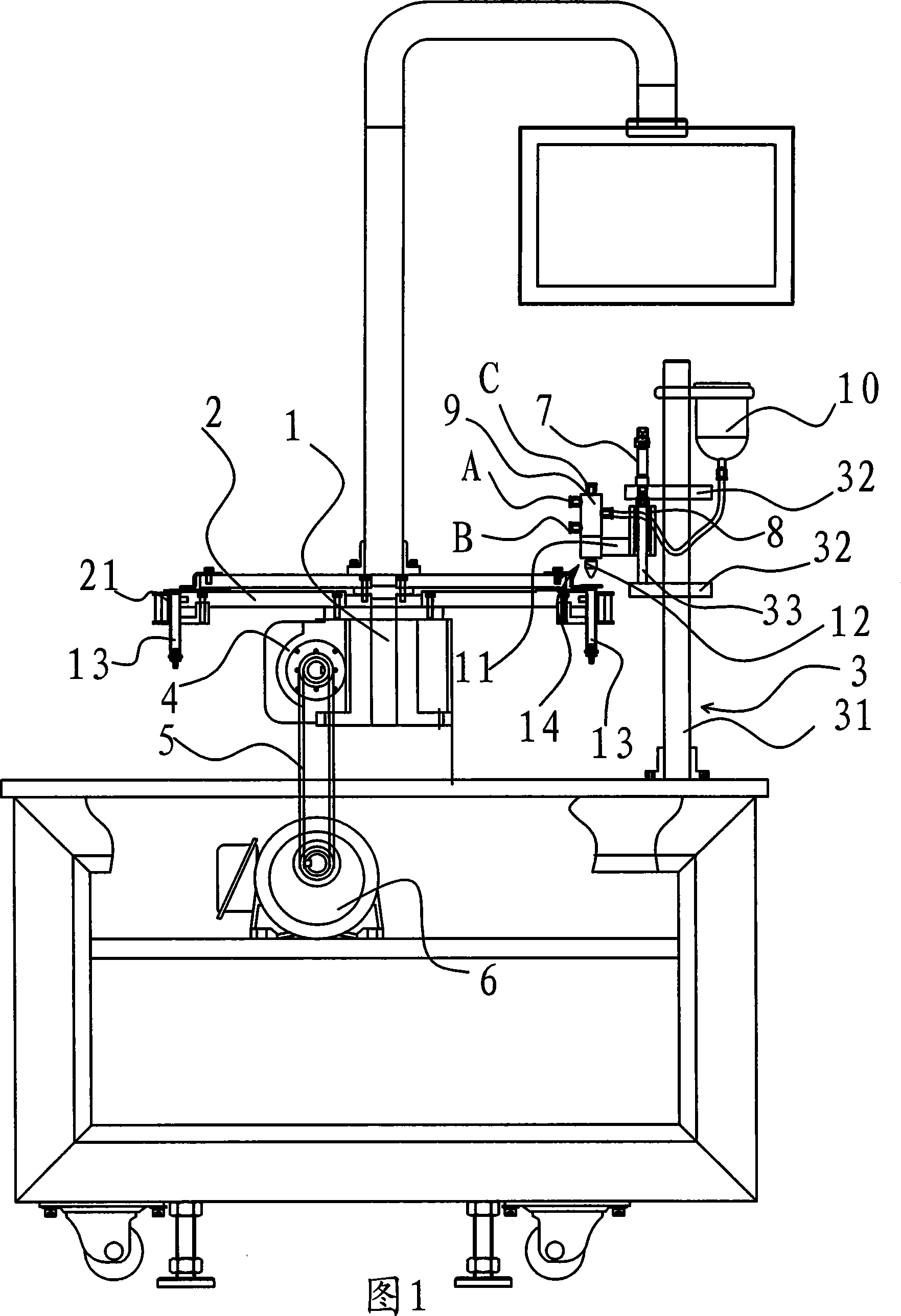

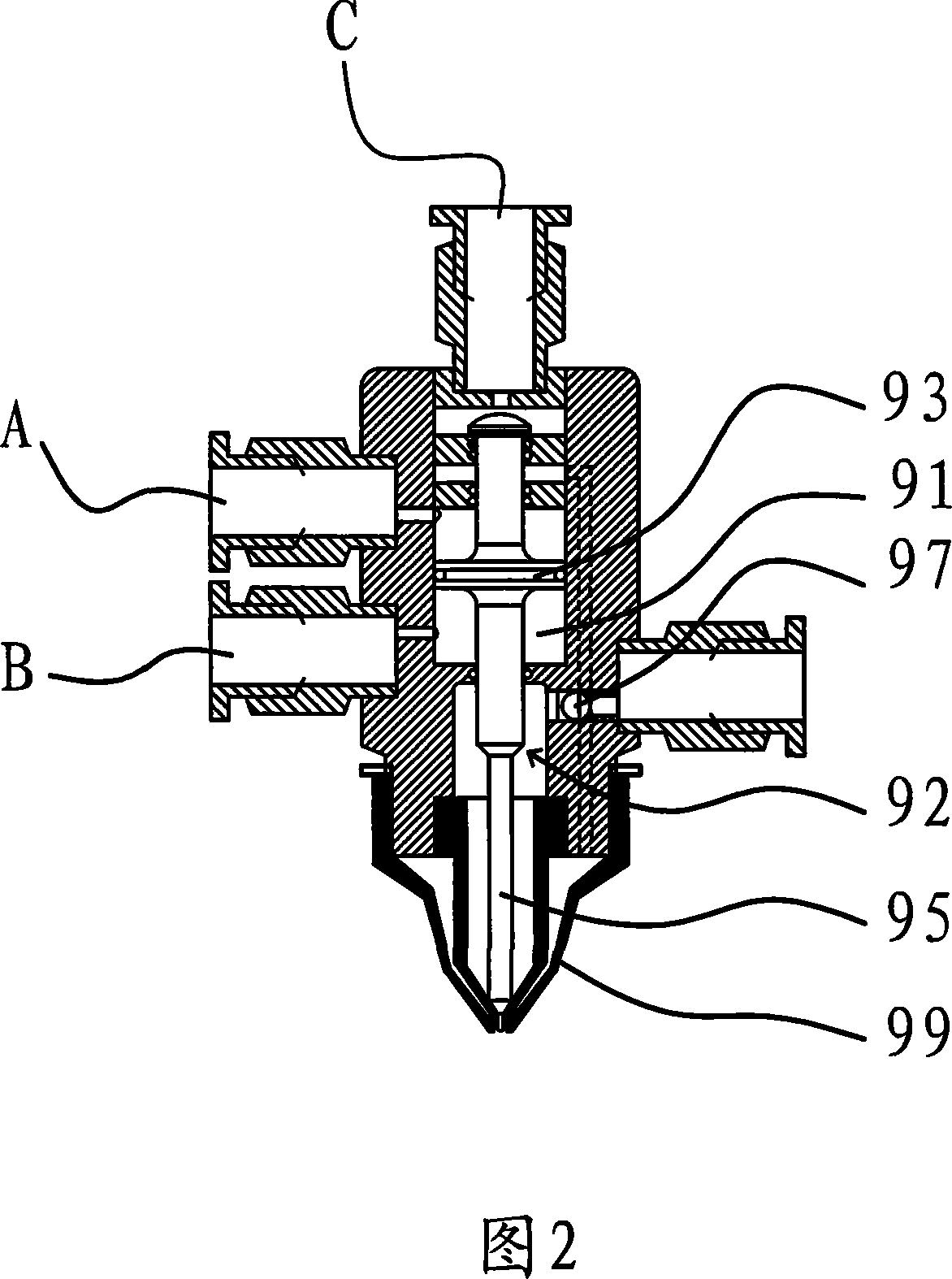

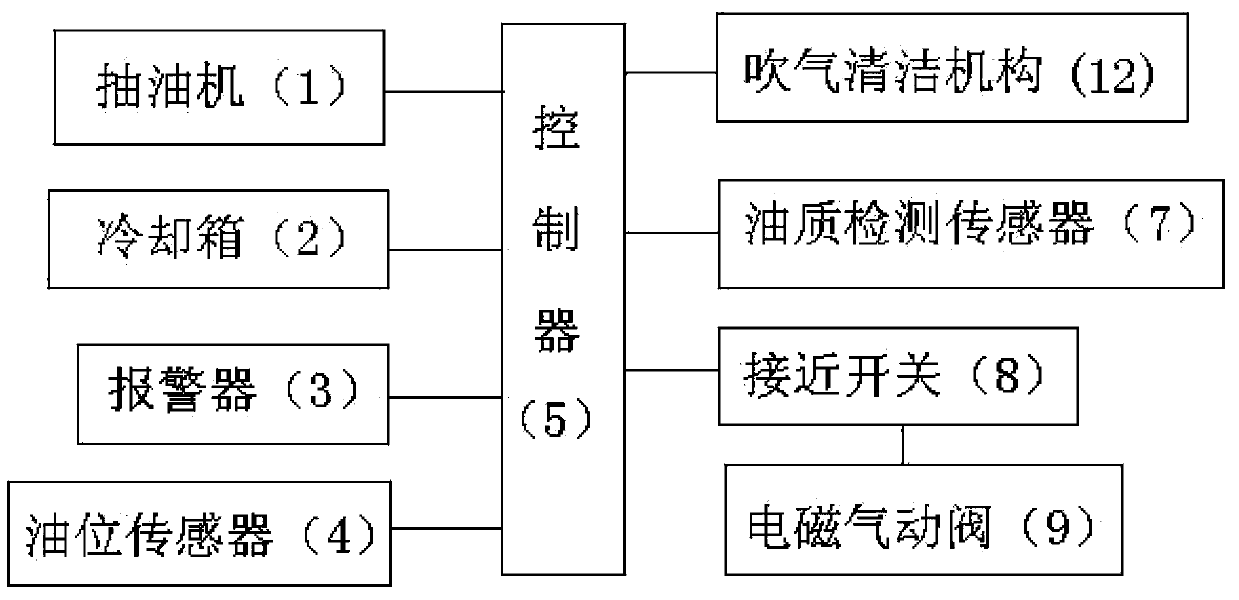

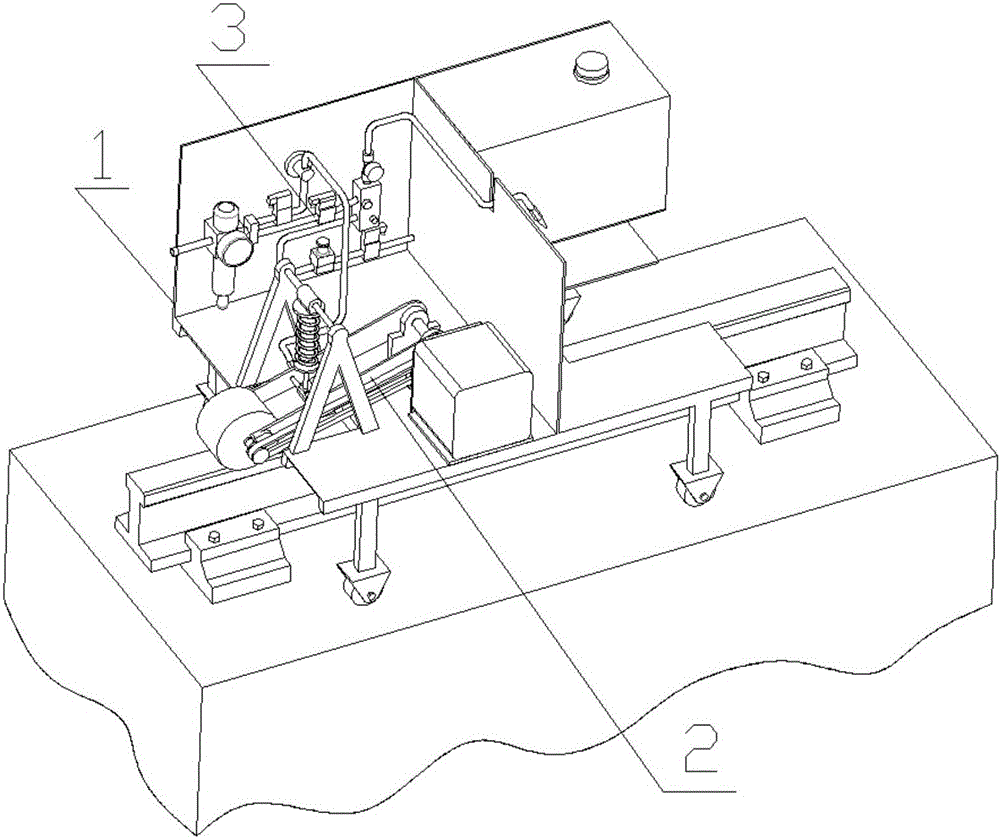

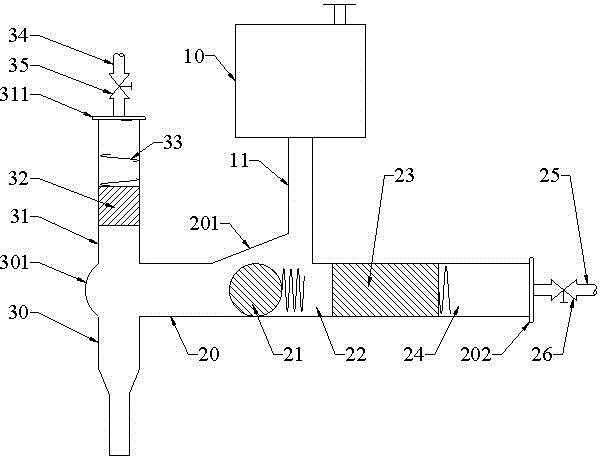

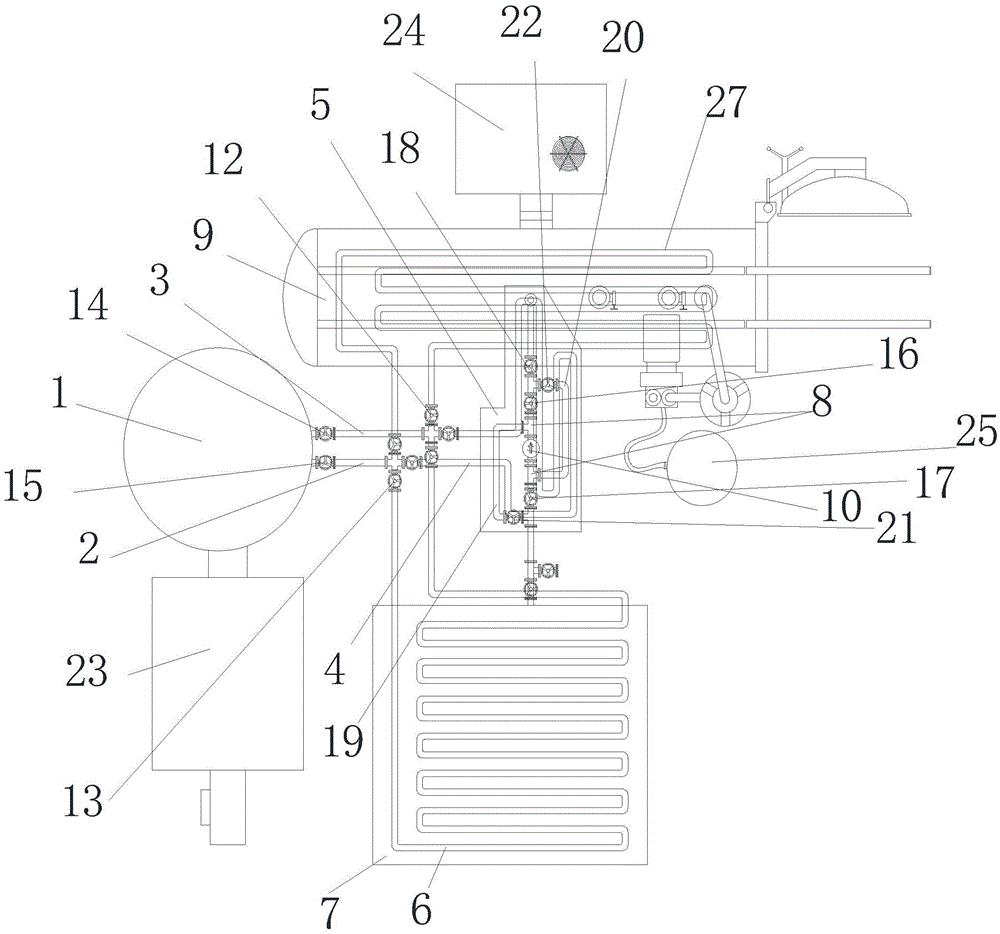

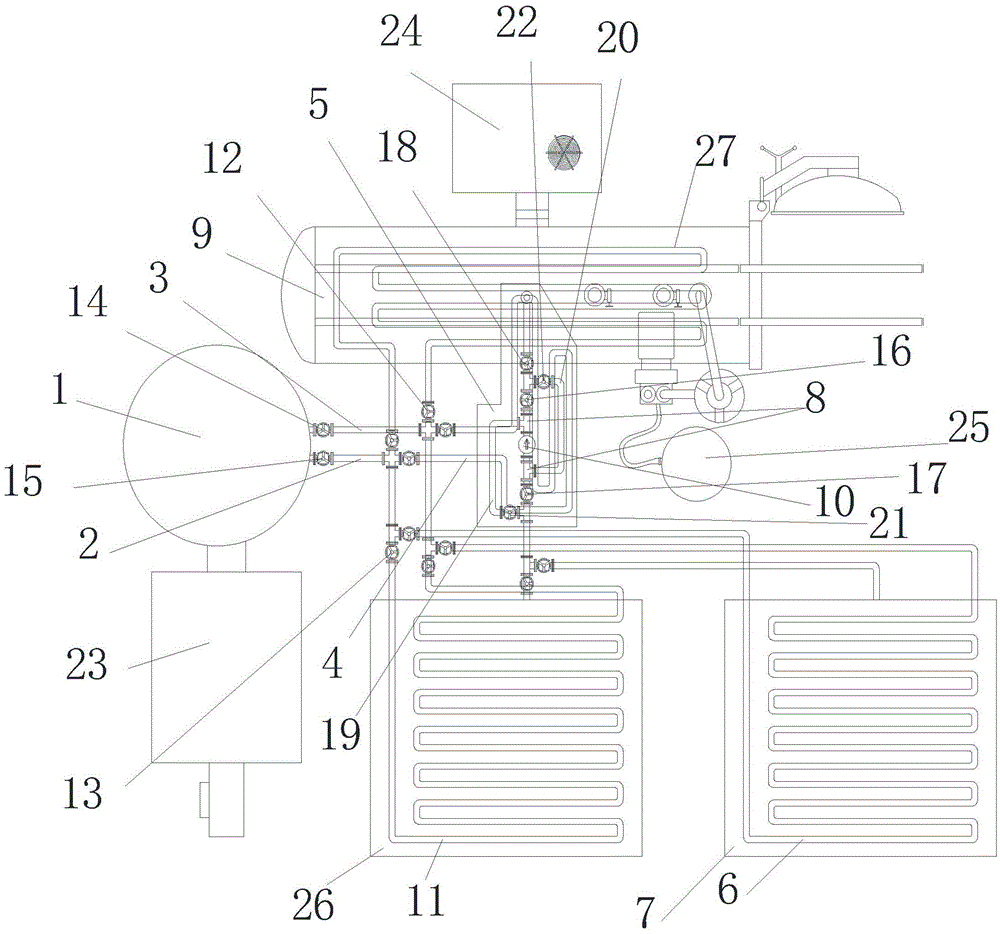

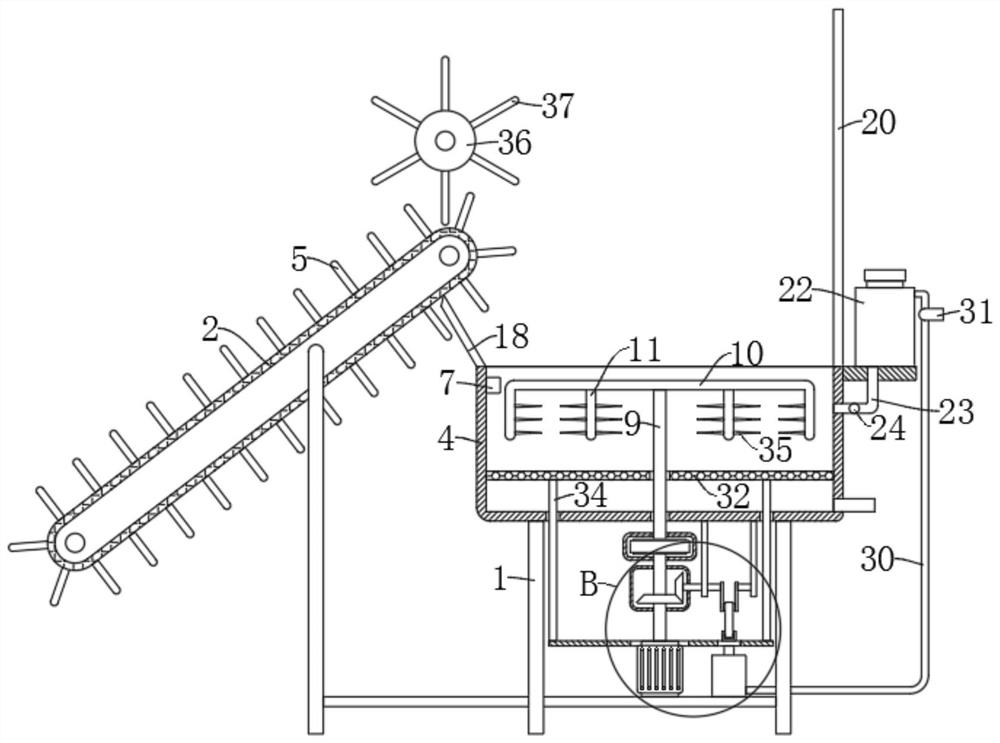

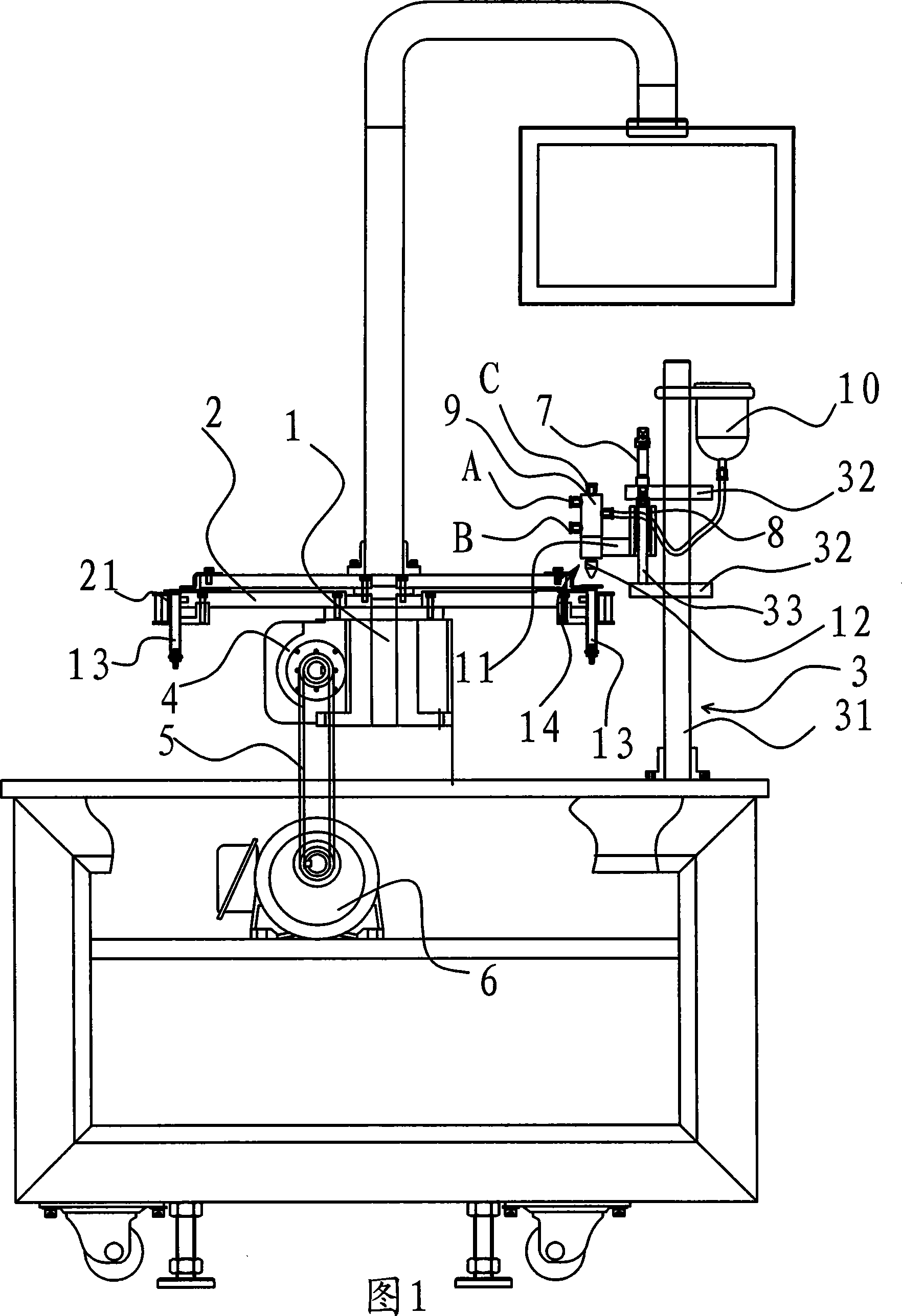

Intelligent automatic lubricating cleaning device for driving chain

InactiveCN103867873AHigh degree of intelligent automationImprove work efficiencyLubrication elementsCleaning using gasesSpray nozzlePneumatic valve

The invention discloses an intelligent automatic lubricating cleaning device for a driving chain, and belongs to the technical field of chain cleaning lubrication and aims at providing the intelligent automatic lubricating cleaning device for the driving chain with the advantages that a cleaning function is realized, the service lives of the driving chain and a main disc and a sub disc of a driving motor can be prolonged, and the lubricating effect is good. The intelligent automatic lubricating cleaning device comprises a support frame, an oil supply pipeline, a driving chain, a traction chain, a pulling claw, a driving motor, an air blowing cleaning mechanism, a controller, an electromagnetic pneumatic valve and a proximity switch, wherein the proximity switch is connected in series onto a power supply loop of the electromagnetic pneumatic valve, the electromagnetic pneumatic valve is connected onto the oil supply pipeline, an oil spray nozzle of the oil supply pipeline is arranged above the driving chain, the proximity switch is arranged above a chain wheel, an oil collecting disc is arranged under the driving chain, an air blowing opening of the air blowing cleaning mechanism is arranged in a direction facing the driving chain, and the control end of the air blowing cleaning mechanism and the control end of the proximity switch are respectively connected with the controller. The intelligent automatic lubricating cleaning device is mainly used in the automatic lubricating cleaning technology of the chain.

Owner:ZHEJIANG GEELY AUTOMOBILE +2

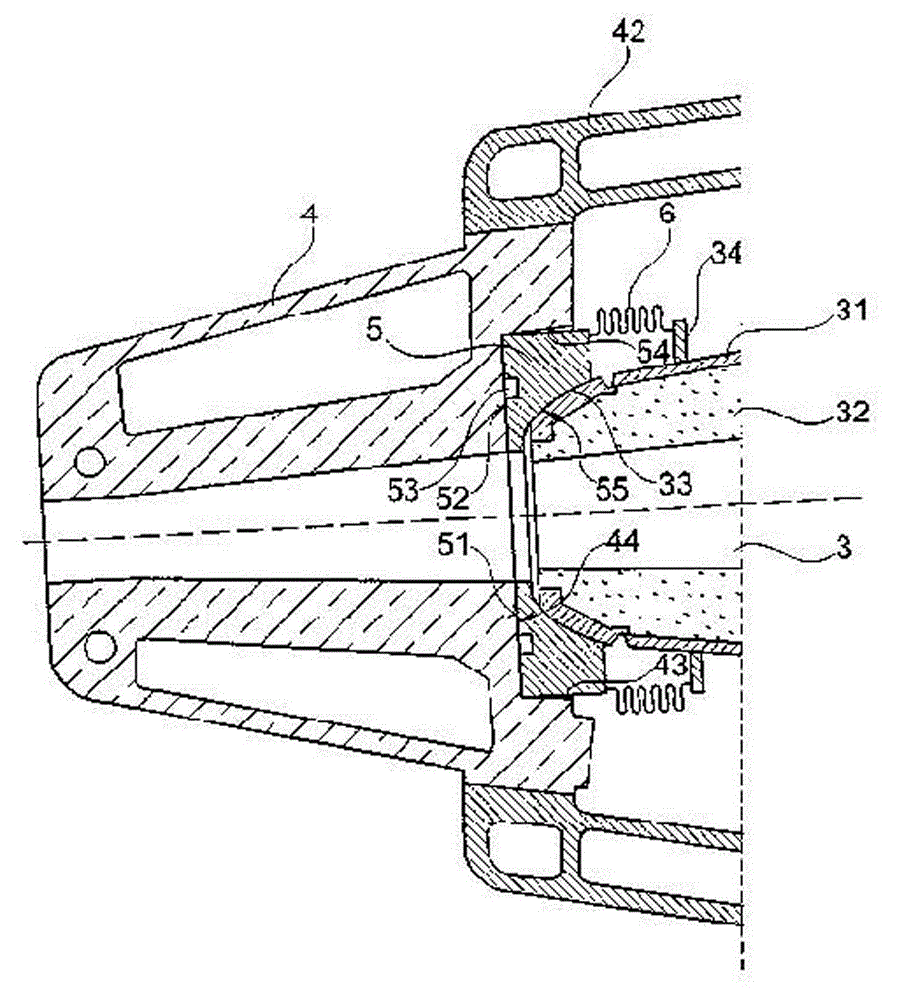

Method of starting a gas turbine helicopter engine, a fuel feed circuit for such an engine, and an engine having such a circuit

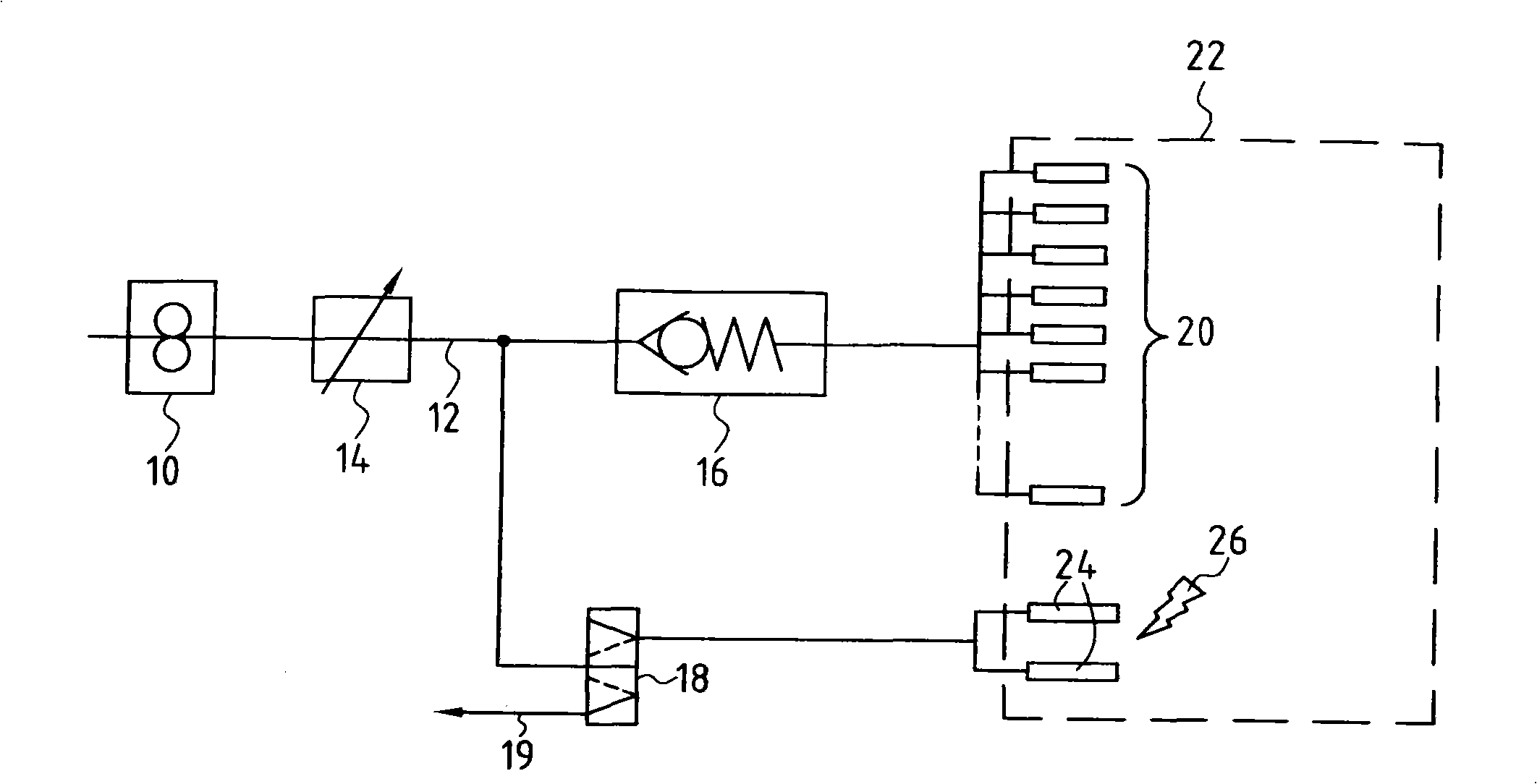

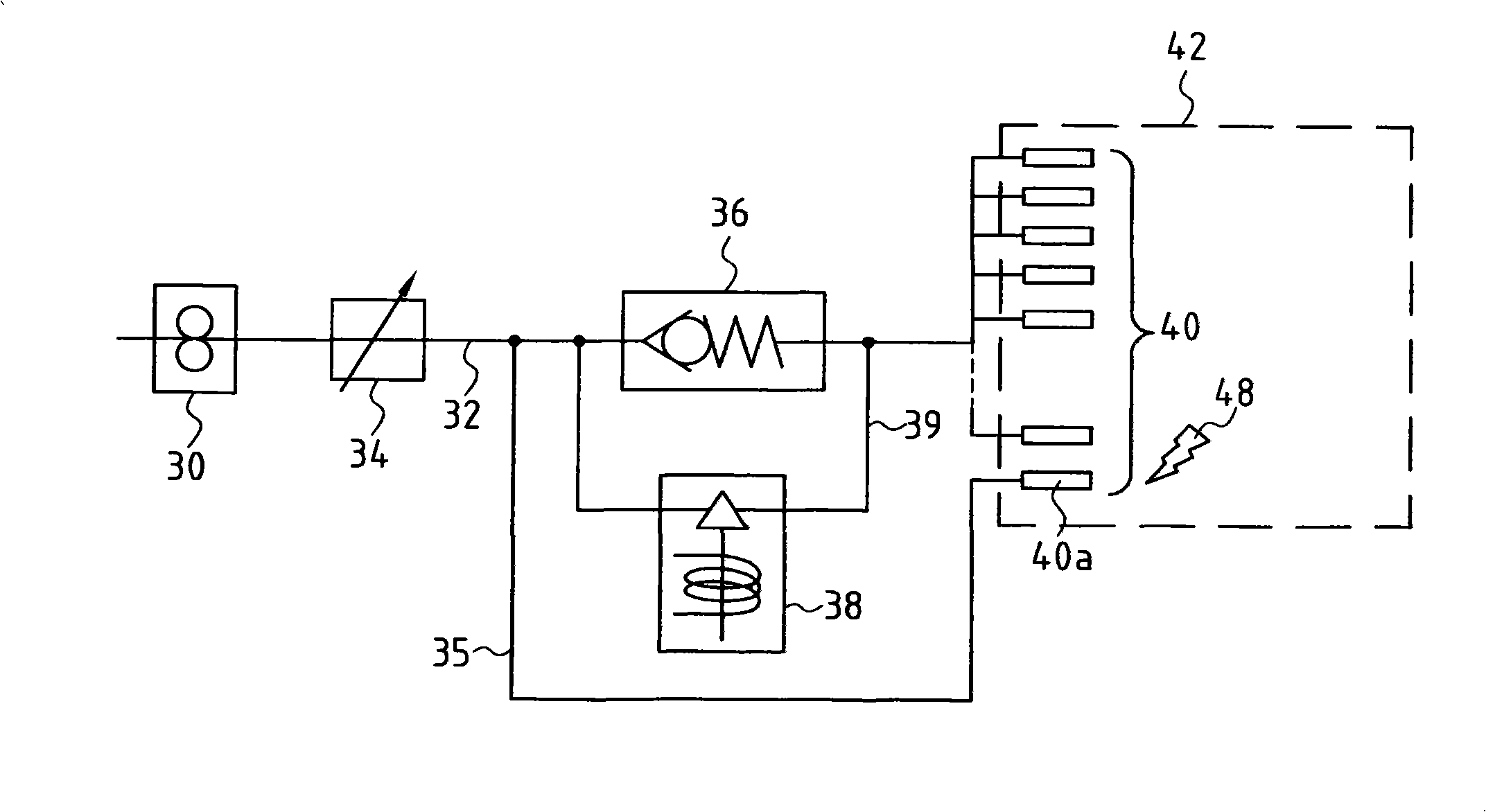

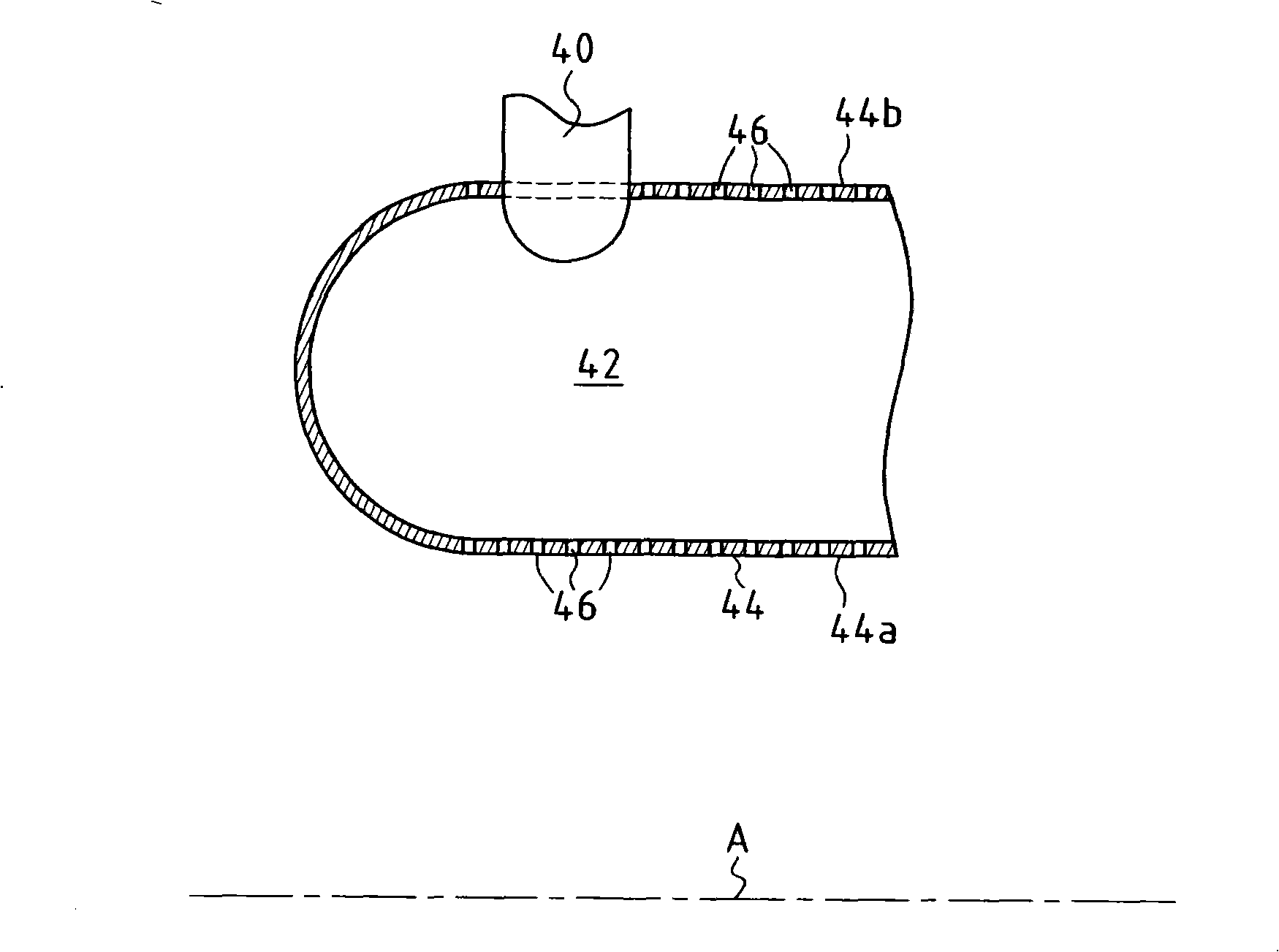

InactiveCN101255821AGood fuel injectionIncrease pressureContinuous combustion chamberTurbine/propulsion fuel supply systemsEngineeringTurbine

The present invention provides a method of starting a gas turbine helicopter engine. At least one of the main injectors of the engine, forming a starter main injector, is fed directly by the pressurized feed pipe, while a head loss is imposed between the pressurized feed pipe and the other main injectors. Ignition is caused to take place at the starter main injector, and after ignition, said head loss imposed between the feed pipe and the other main injectors is eliminated so that all of the main injectors are fed with fuel at substantially the same pressure, without any imposed head loss. The present invention also provides a fuel supply circuit for such an engine, and engine having such a circuit.

Owner:TURBOMECA SA

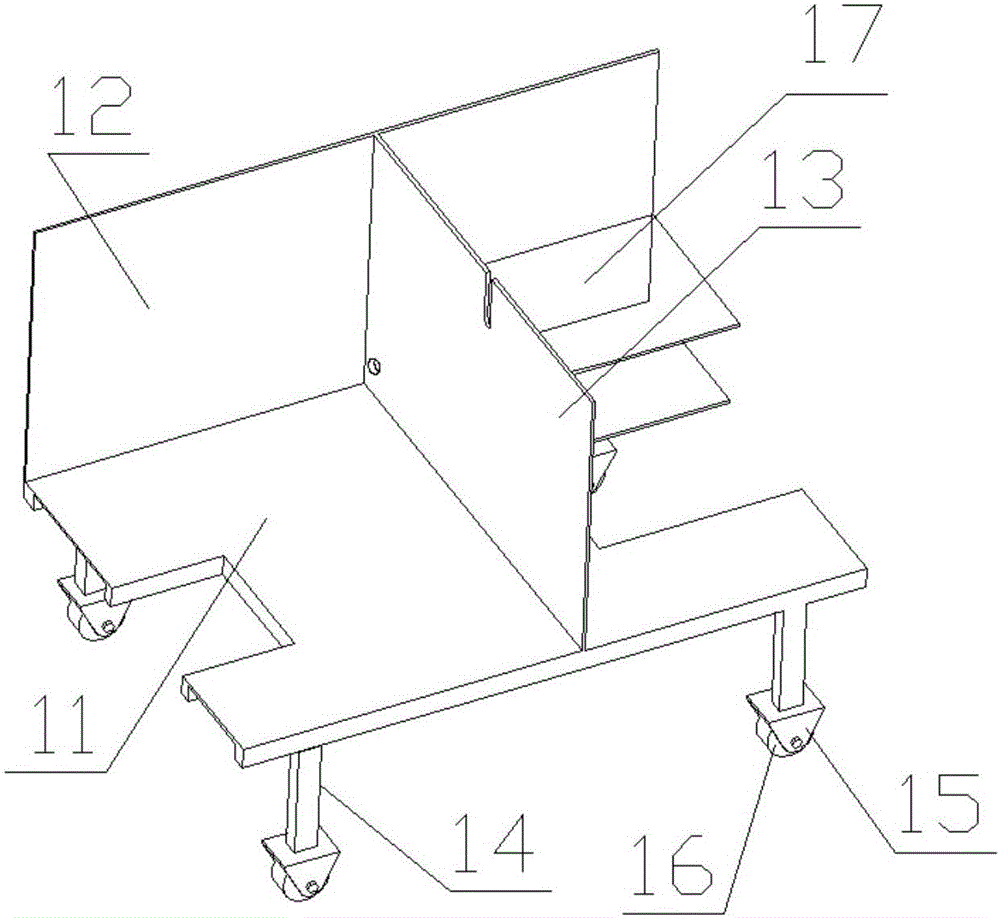

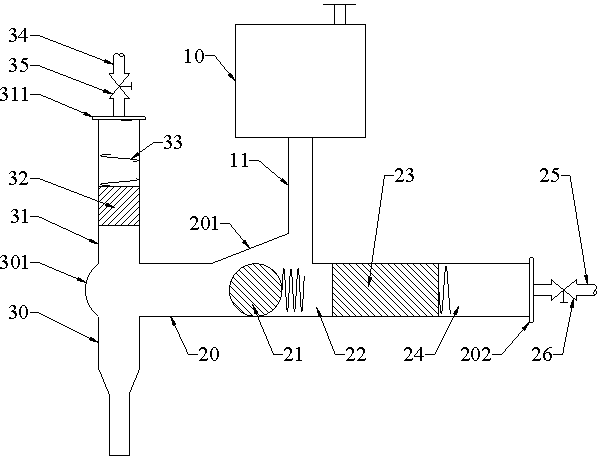

Oil spraying device for towing basin track cleaning

ActiveCN106076912AAvoid damageEasy to remove dustPretreated surfacesCleaning using toolsVehicle frameMotor drive

The invention discloses an oil spraying device for towing basin track cleaning. The oil spraying device comprises a vehicle frame. The vehicle frame is provided with a rolling brush cleaning device. The rolling brush cleaning device comprises a motor, a motor belt wheel and a rolling brush belt wheel. The motor is installed on the vehicle frame through a motor base, the motor drives the motor belt wheel to rotate, the motor belt wheel drives the rolling brush belt wheel through a belt to rotate, the rolling brush belt wheel and a rolling brush shaft coaxially rotate, the rolling rush shaft rotates so as to drive a rolling brush to rotate, and the rolling brush rotates so as to clean a track. The rolling brush shaft is installed on a rotating support through a rolling brush bearing pedestal. The rotating support is installed on a rotating support base through a rotating support main shaft. The rotating support base is installed on the vehicle frame. The oil spraying device for towing basin track cleaning is installed at the end in the forward motion direction of a trailer when in use, and is used when the trailer is in low-speed trial run; the rolling brush is adopted for cleaning the surface of the track, high-speed airflow is adopted for blowing brushed-up dirt away from the track, and then trace of oil is sprayed to the surface of the track.

Owner:JIANGSU UNIV OF SCI & TECH

Electric control uniset fuel injection pump for diesel engine

InactiveCN104061097AIncrease pressureEnsure supporting needsFuel-injection pumpsMachines/enginesElectric controlHigh pressure

Disclosed is an electric control uniset fuel injection pump for a diesel engine. According to the electric control uniset fuel injection pump for the diesel engine, a pump body plunger cavity is communicated with a high-pressure oil hole, an electromagnetic installation hole and a low-pressure oil supply cavity are formed in the two lateral sides, are communicated through a middle connection hole and are perpendicularly communicated with the high-pressure oil hole, the front section of a plunger is assembled in a plunger cavity, the rear section of the plunger is sleeved with a plunger spring and connected with a lower spring base which is embedded in a push rod body, an armature is movably installed in an armature hole of an electromagnet in a sleeved mode, the electromagnet is installed in an electromagnet installation hole, one end of a valve element fixedly installed in the armature hole penetrates through the middle connection hole to extend into the low-pressure oil supply cavity and abut against a lift check block, and the lift check block is connected with an oil inlet pipe. An electric control system is communicated with the electromagnet to control the action of the armature and the valve element, an oil supply system of a traditional fuel injection pump is converted into a fuel injection system featured in time, oil supply timing and quantity are controlled and adjusted precisely, the pressure of the end of the pump is high, oil consumption is low, and noise is low.

Owner:SHANDONG XINYA IND

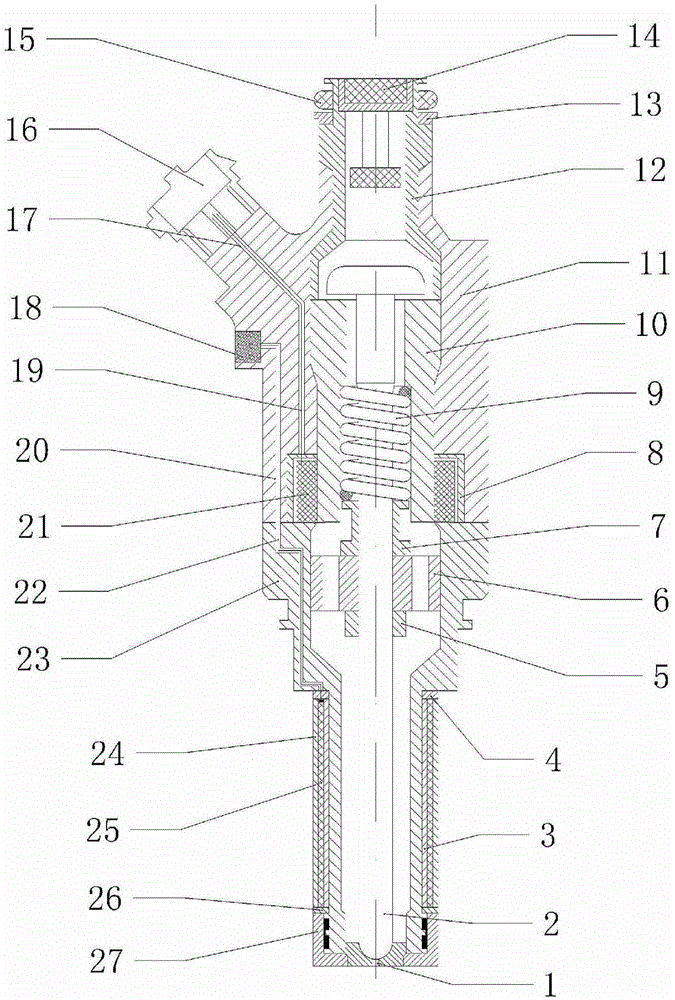

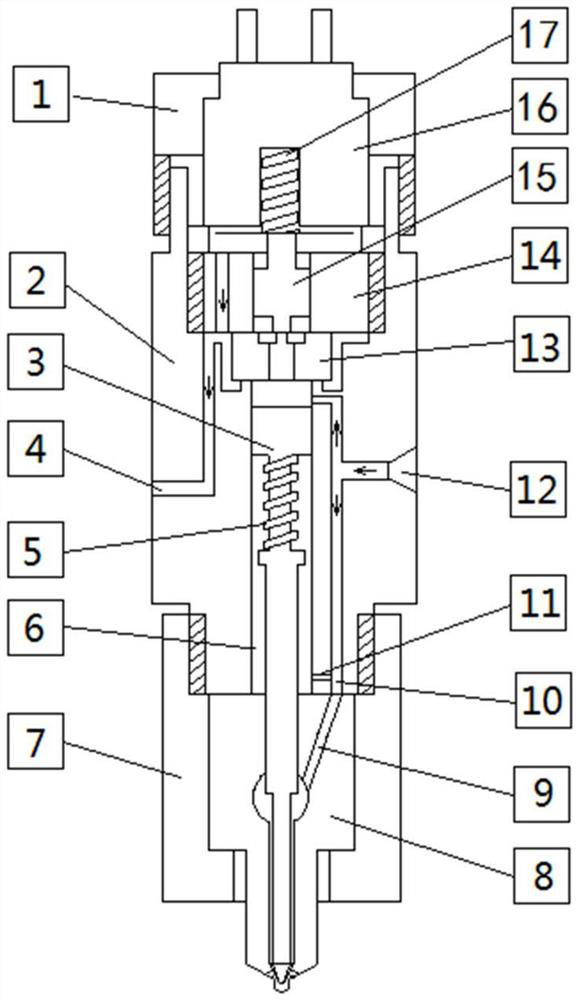

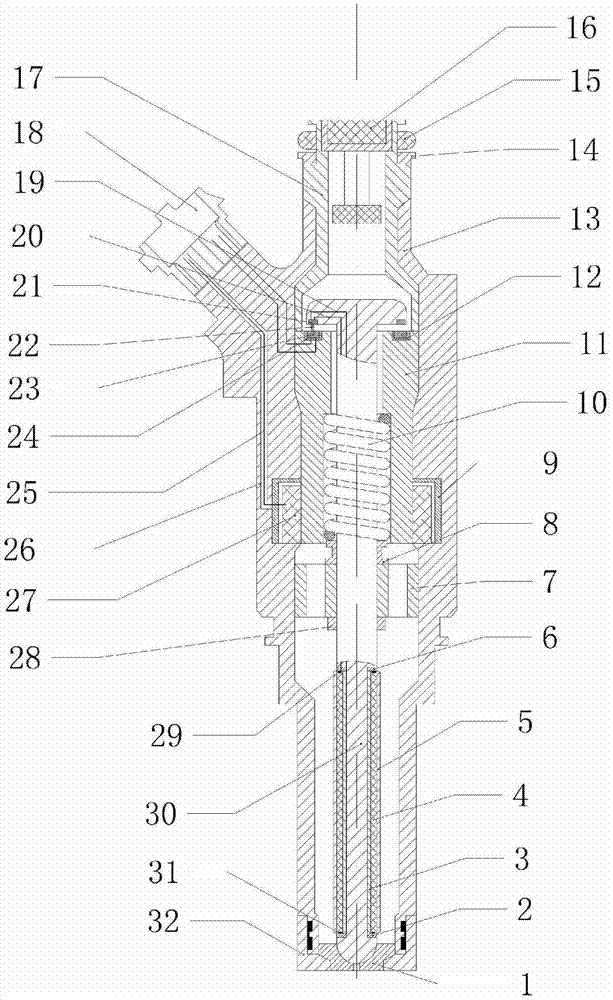

GDI fuel injector utilizing PTC thermal sensitive ceramic for heating

InactiveCN105484917ATemperature controlControl heating effectFuel injection apparatusMachines/enginesGasoline direct injectionEngineering

The invention belongs to the technical field of fuel injection systems of gasoline engines, and relates to a GDI fuel injector utilizing PTC thermal sensitive ceramic for heating. An insulation sheath, a PTC thermal sensitive ceramic pipe and a heat conduction round pipe in the GDI fuel injector sequentially wrap the outer ring of the lower portion of a needle valve, and insulation gaskets are arranged between the upper end of the PTC thermal sensitive ceramic pipe and a boss of the needle valve of the fuel injector and between the lower end of the PTC thermal sensitive ceramic pipe and the boss of the needle valve of the fuel injector respectively. The upper end of a positive wire and the upper end of a negative wire are connected with a wiring harness plug through electric conduction carbon rings and an electric conduction spring, the lower end of the positive wire and the lower end of the negative wire are connected with the positive pole and the negative pole of a heating electrode respectively, and the electric conduction carbon ring I and the electric conduction carbon ring II are connected through the electric conduction spring. The GDI fuel injector belongs to internal heating, fuel in the fuel injector can be heated to high temperature within short time, the fuel injection effect is good, the spraying effect in an air cylinder of a gasoline direct injection engine is greatly improved, cold start combustion efficiency is improved, and cold start tail gas emission is reduced. The GDI fuel injector is simple in structure, and other systems of an internal combustion engine do not need to be greatly modified.

Owner:JILIN UNIV

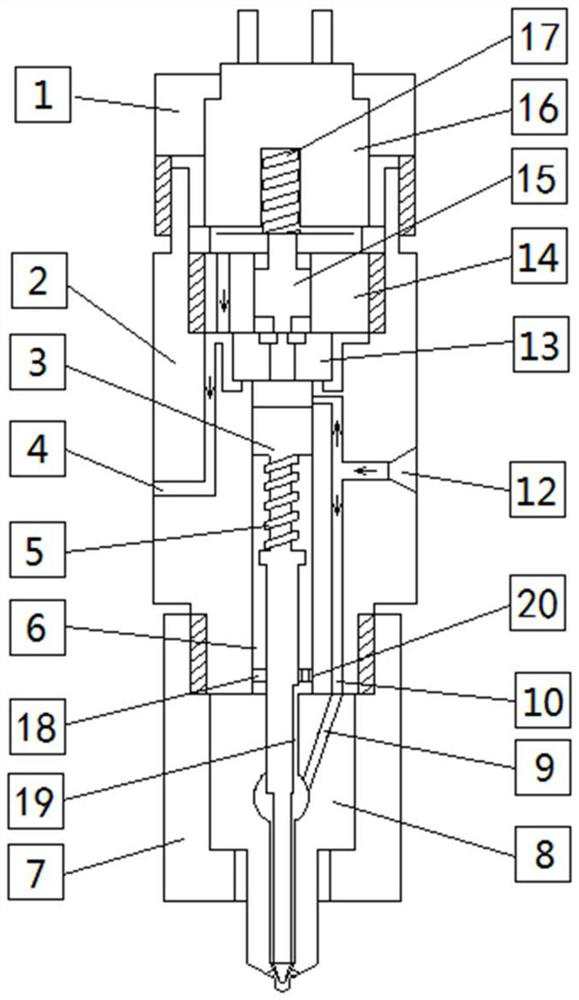

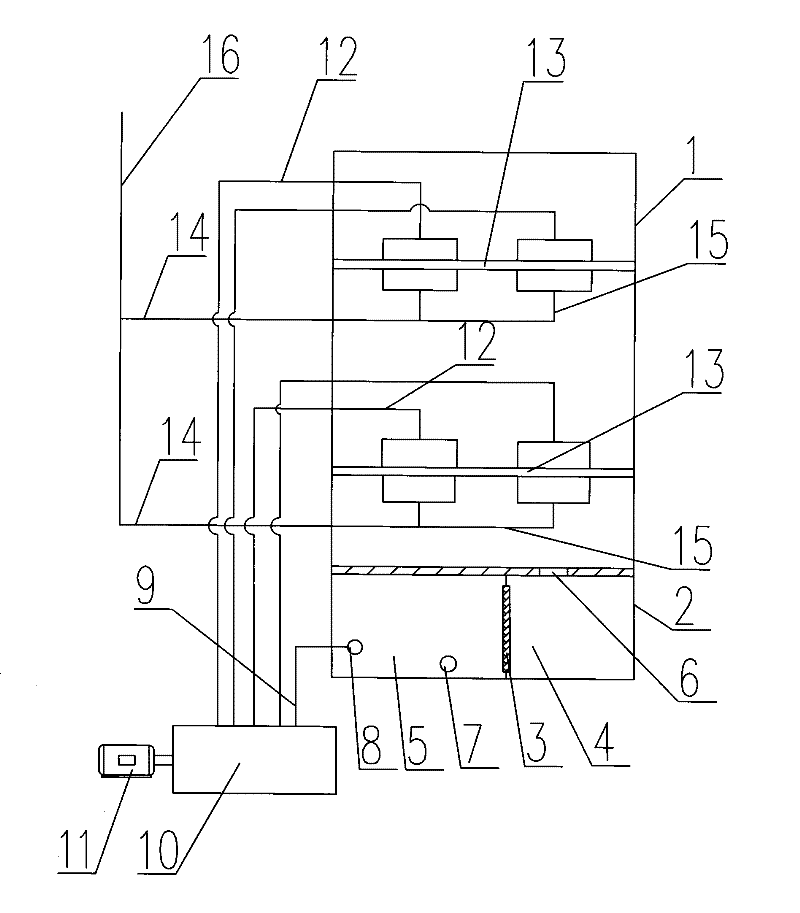

Gasoline direct injection (GDI) oil sprayer for utilizing electromagnetic heating coil for heating

InactiveCN105464866AHeating effect controlImprove heating efficiencyFuel injection apparatusMachines/enginesGasoline direct injectionSprayer

The invention provides a gasoline direct injection (GDI) oil sprayer for utilizing an electromagnetic heating coil for heating and belongs to the technical field of gasoline engine fuel injection systems. According to the GDI oil sprayer, an insulating sheath I, the electromagnetic heating coil and an insulating sheath II wrap the outer circle of the lower portion of a lower shell from inside to outside. Insulating gaskets are arranged between the upper end and the lower end of the insulating sheath I and a boss of the lower shell and a bottom end limiting sleeve II respectively, insulating gaskets are arranged between the upper end and the lower end of the electromagnetic heating coil and the boss of the lower shell and the bottom end limiting sleeve II respectively, and insulating gaskets are arranged between the upper end and the lower end of the insulating sheath II and the boss of the lower shell and the bottom end limiting sleeve II respectively. A heating coil wire connected with the electromagnetic heating coil is arranged in the sleeve II. The upper end of the heating coil wire is connected with a wire groove. The electromagnetic heating coil is connected with an inducting heating power source externally arranged through the wire groove. Fuel oil in the oil sprayer can be heated to certain temperature within a short time, the fuel oil spraying effect is good, the spraying effect of a direct injecting gasoline engine in a cylinder is greatly improved, cold-start combustion efficiency is improved, and cold-start tail emission is reduced. The oil sprayer is simple in structure, and it is unnecessary to modify other systems of an internal combustion engine greatly.

Owner:JILIN UNIV

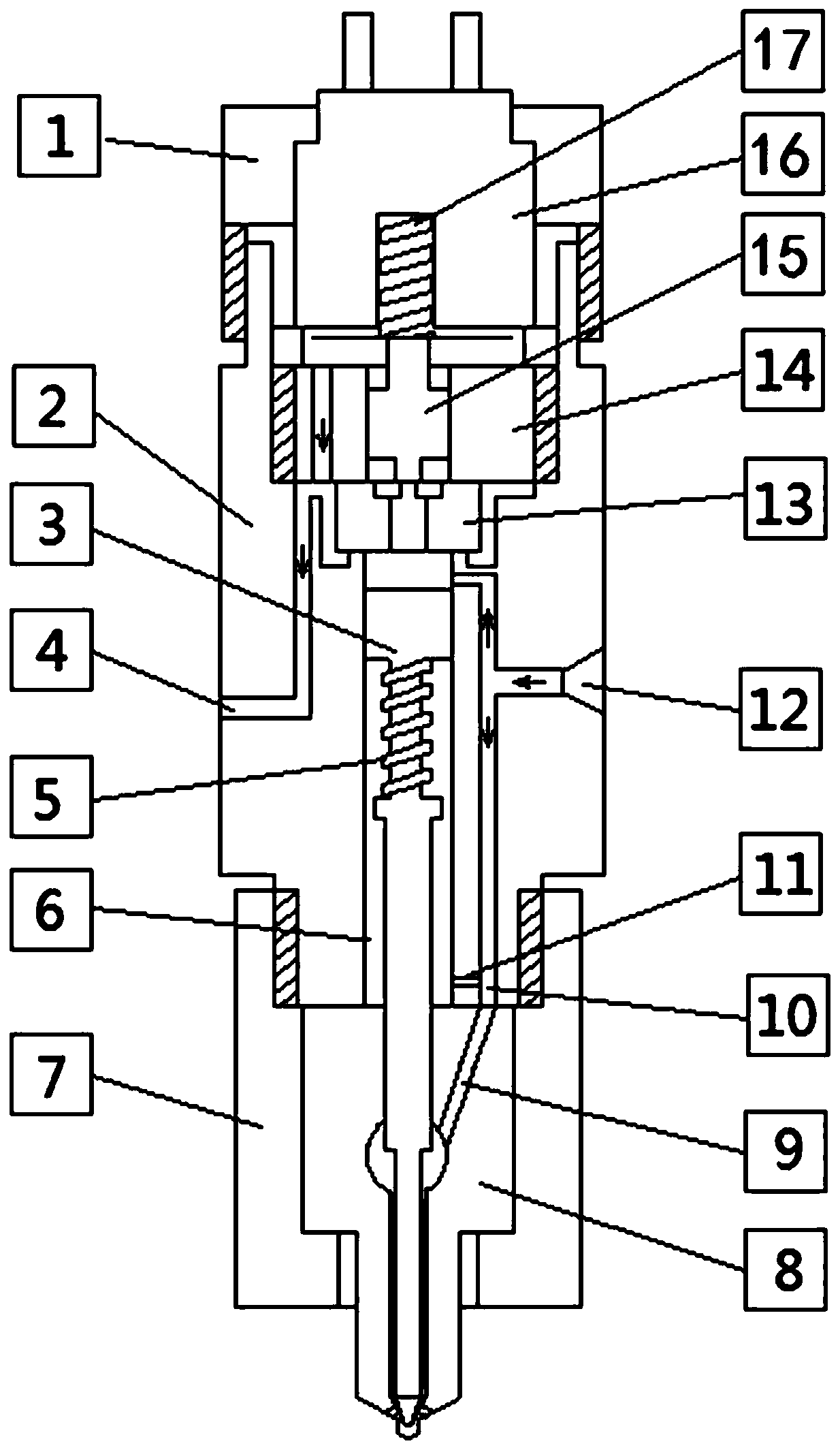

Variable spray hole type electric control oil sprayer

InactiveCN103362710AImprove powerImprove economyFuel injection apparatusMachines/enginesElectric controlActuator

The invention aims at providing a variable spay hole type electric control oil sprayer which comprises an electric control actuator part, an oil nozzle and an oil sprayer body, wherein the electric control actuator part and the oil nozzle are mounted at the upper end and the lower end of the oil sprayer body respectively; the oil nozzle comprises a needle valve and a needle valve base; the needle valve is mounted in the needle valve base; an oil containing groove is formed by the needle valve and the needle valve base; main oil spray holes and auxiliary oil spray holes are formed at the lower end part of the needle valve base from the bottom up sequentially; a double sealing surface structure is arranged at the lower end part of the needle valve; a bevelled sealing surface and a cylindrical sealing surface are arranged at the lower end part of the needle valve from the top down sequentially; when the needle valve is positioned at the undermost end of a stroke, the cylindrical sealing surface seals the main oil spray holes, and the bevelled sealing surface seals the auxiliary oil spray holes; and when the needle valve ascends, the auxiliary oil spray holes are communicated with the oil containing groove earlier than the main oil spray holes. The oil sprayer facilitates controlling small oil quantity spray in a multi-spray process, and can allow main spray to be combined with boot type spray, so that an oil spray effect is improved, the power performance and the economical efficiency of an engine are improved, and stricter discharge laws and regulations are met.

Owner:HARBIN ENG UNIV

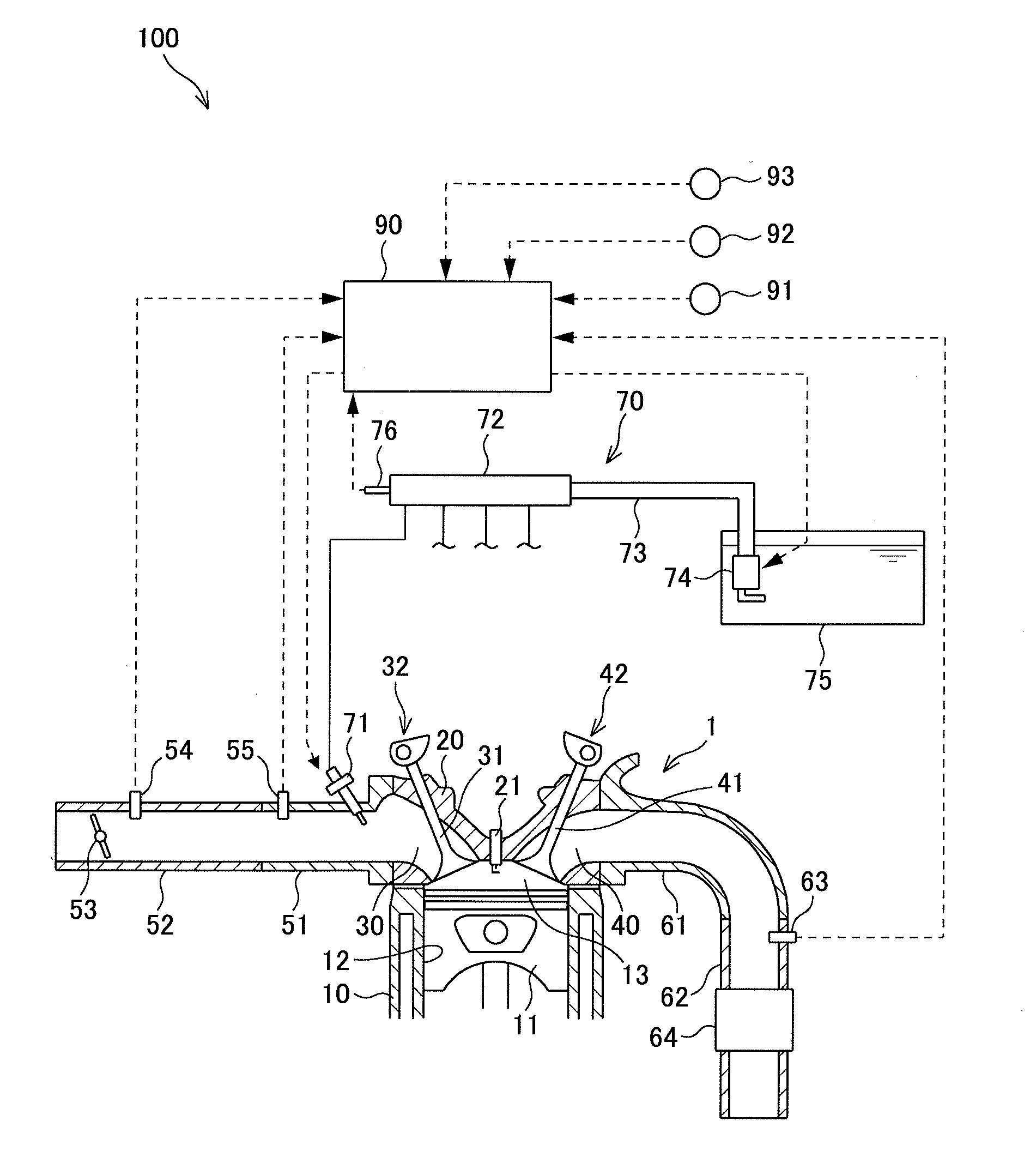

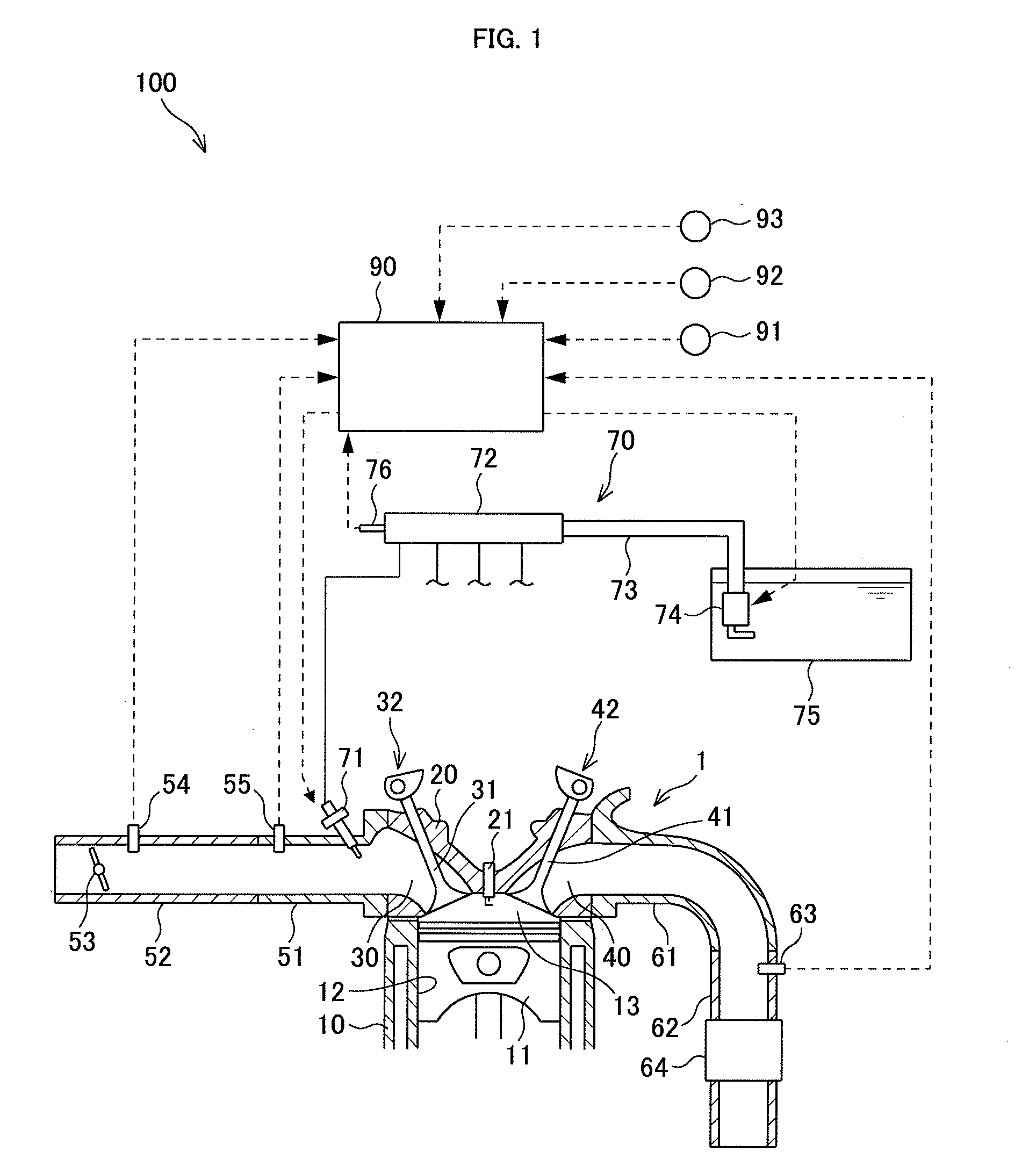

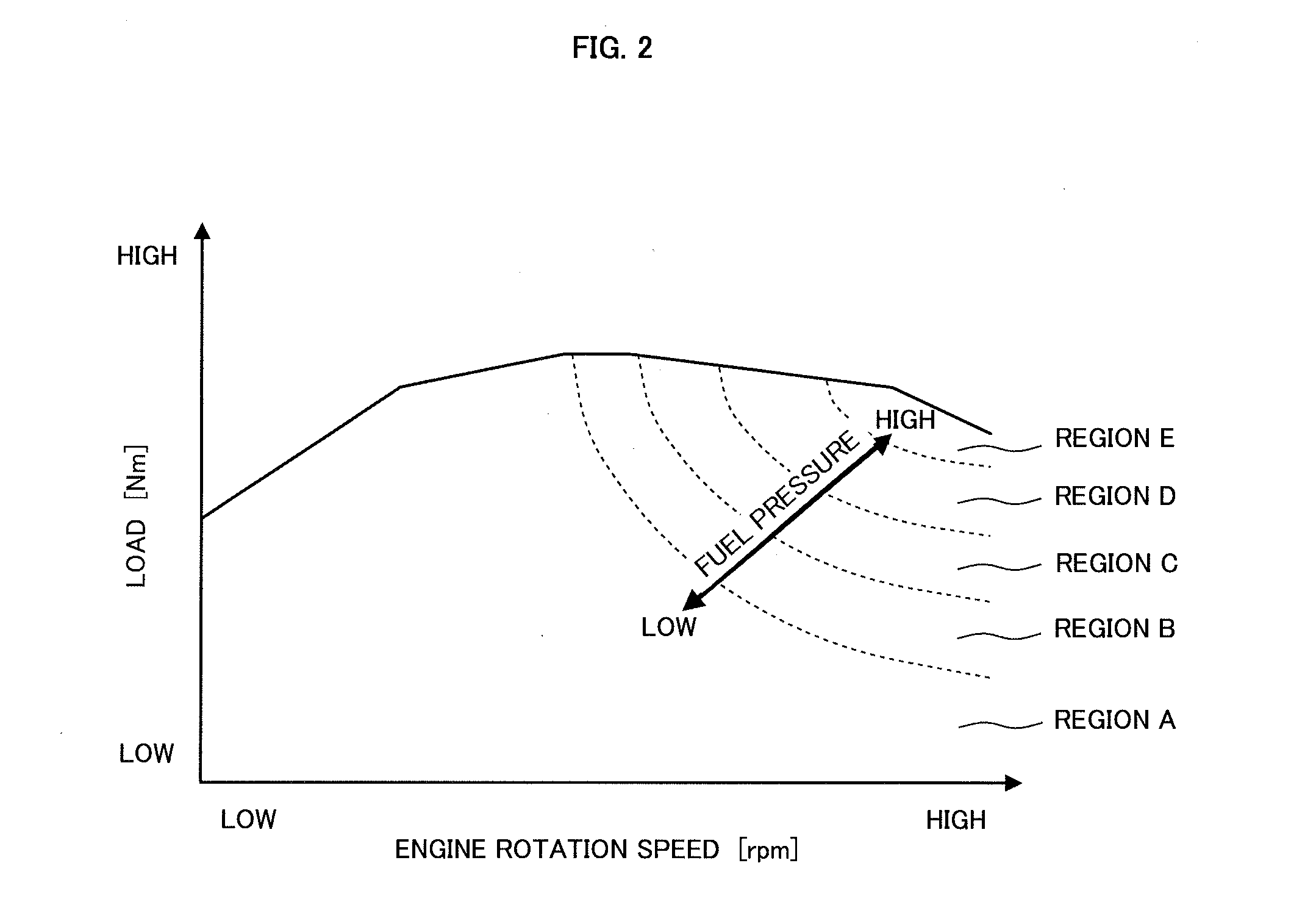

Fuel injection control device of engine and fuel injection control method of engine

ActiveUS20160215725A1Good fuel injectionEasy injectionElectrical controlInternal combustion piston enginesDifferential pressureCorrection request

A fuel injection control device of an engine is disclosed, that is provided with a fuel injection valve configured to inject a fuel according to a target pulse width into an intake passage, an intake flow rate detection unit arranged to detect a flow rate of an intake air supplied to the engine, an intake pressure detection unit arranged to detect an intake pressure in the intake passage, a fuel pressure detection unit arranged to detect a pressure of a fuel supplied to the fuel injection valve, and a pressure control unit configured to control the fuel pressure according to an engine operation state. The device is further provided with a request pulse width calculation unit configured to calculate a request pulse width on the basis of an intake flow rate detected by the intake flow rate detection unit, a fuel pressure detected by the fuel pressure detection unit, and a differential pressure between the fuel pressure and an intake pressure detected by the intake pressure detection unit, a post-correction request pulse width calculation unit configured to calculate a post-correction request pulse width through correcting the request pulse width according to the differential pressure, when injecting a fuel of which flow rate is lower than a predetermined flow rate; and a target pulse width setting unit configured to set the target pulse width on the basis of the post-correction request pulse width.

Owner:NISSAN MOTOR CO LTD

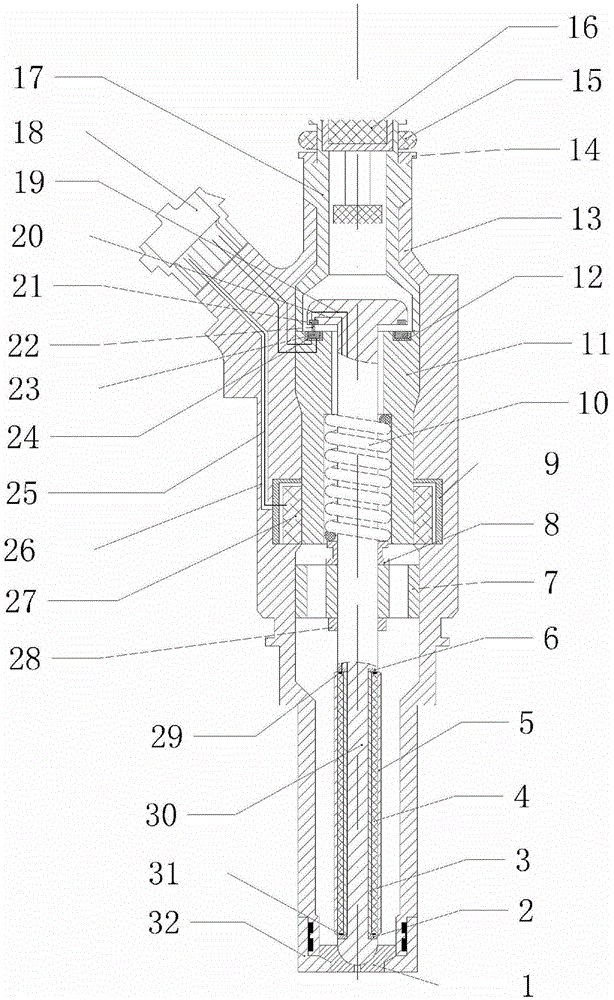

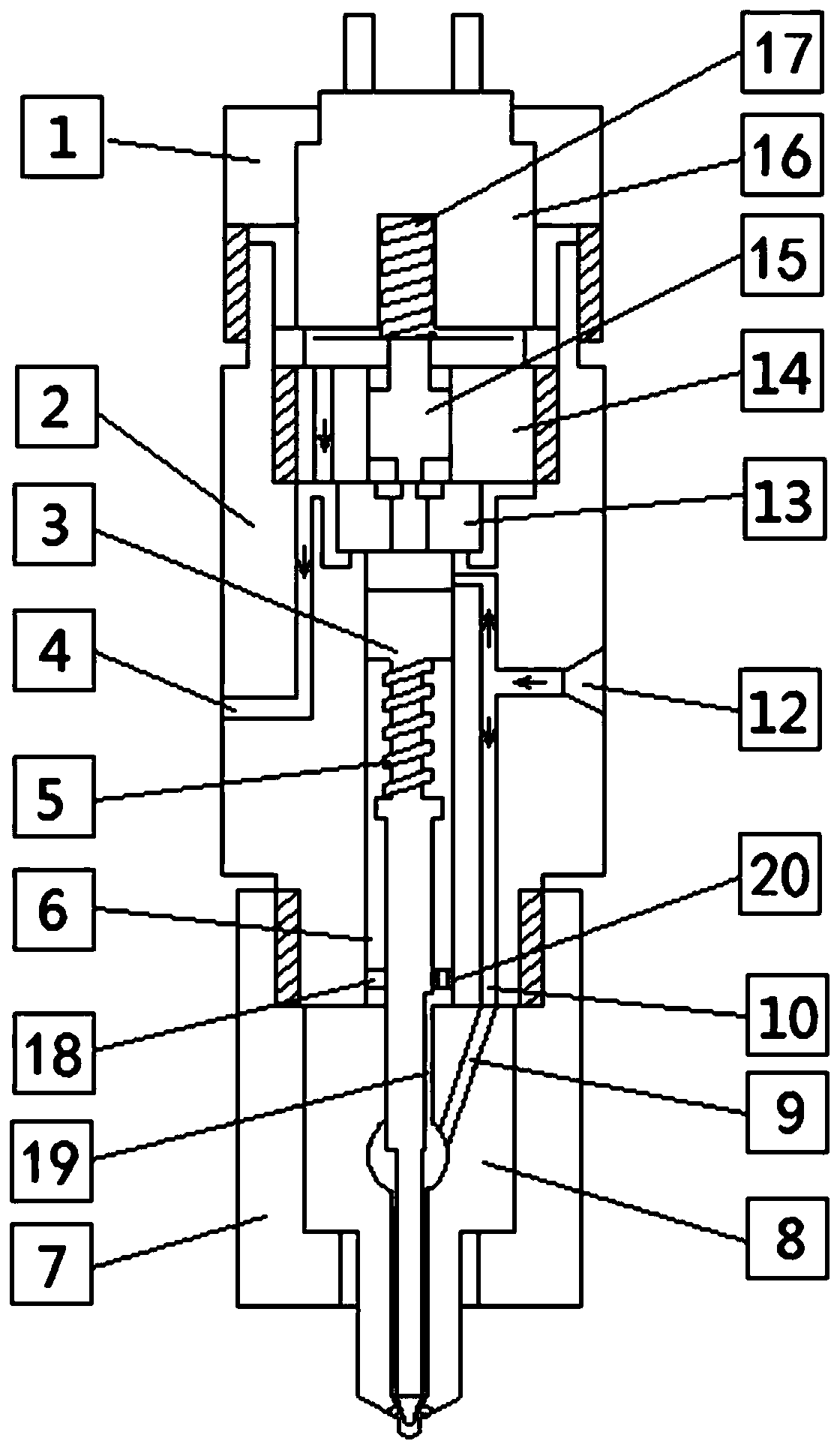

Electrically-controlled pressure-storage oil injector

ActiveCN110848060AImprove opening powerOpen resistance is smallFuel injection apparatusMachines/enginesInjector nozzleSolenoid valve

The invention provides an electrically-controlled pressure-storage oil injector. The oil injector comprises an oil injector body and a control plunger rod; a control valve, an armature assembly, a solenoid valve spring, a solenoid valve and first compacting mechanism are sequentially arranged above the oil injector body from bottom to top, the control valve is in pressing connection with the oil injector body through a second pressing mechanism, the control plunger rod is mounted in the oil injector body, and the exterior of the control plunger rod is sleeved with a needle valve spring; and the lower end of the oil injector body is provided with an oil nozzle matching part, an oil inlet channel is arranged in the oil nozzle matching part, the control plunger rod and the valve needle of theoil nozzle matching part are of an integral structure, the needle valve spring presses the valve needle of the oil nozzle matching part on the valve body, the large head of the control plunger rod and the oil nozzle matching part form a control plunger cavity in the oil injector body, and the control plunger cavity communicates with the high-pressure oil inlet channel. According to the electrically-controlled pressure-storage oil injector, the pressure of the control plunger cavity is controlled through throttling holes, so that the effect of improving the opening power of the needle valve and reducing the opening resistance of the needle valve is realized, and therefore the oil injection performance is optimized.

Owner:CHINA NORTH ENGINE INST TIANJIN

Oil spraying device of special coating machine for metallized film

InactiveCN106086780APrevent oil spillsShort injection efficiencyVacuum evaporation coatingSputtering coatingBottleAtmospheric pressure

The invention relates to an oil spraying device of a special coating machine for a metallized film. The oil spraying device comprises an oil bottle, an oil outlet tube, a horizontally-arranged oil control tube and a spray head; the top of the oil control tube is provided with a conical chamber, the tail end of the oil control tube is provided with a first cover plate, and the oil control tube is internally provided with a bead, a first spring, a first piston and a second spring; and the outer part of the first cover plate is provided with a first air inlet tube on which a first air valve is arranged. According to the oil spraying device of the special coating machine for the metallized film, the opening between the bead and the oil control tube is controlled by virtue of air pressure so that oil leakage of the oil spraying device is avoided; and then, the motion of a second piston is controlled by virtue of air pressure to carry out pressurization treatment on coating oil entering the spray head, so that the coating oil sprayed from the head part of the spray head has enough spraying speed and pressure, the oil spraying time is shortened, and the oil spraying efficiency and quality are improved. The oil spraying device is simple in structure, convenient to use, stable in operation, short in oil spraying time, high in oil spraying efficiency and good in oil spraying effect.

Owner:铜陵市铜创电子科技有限公司

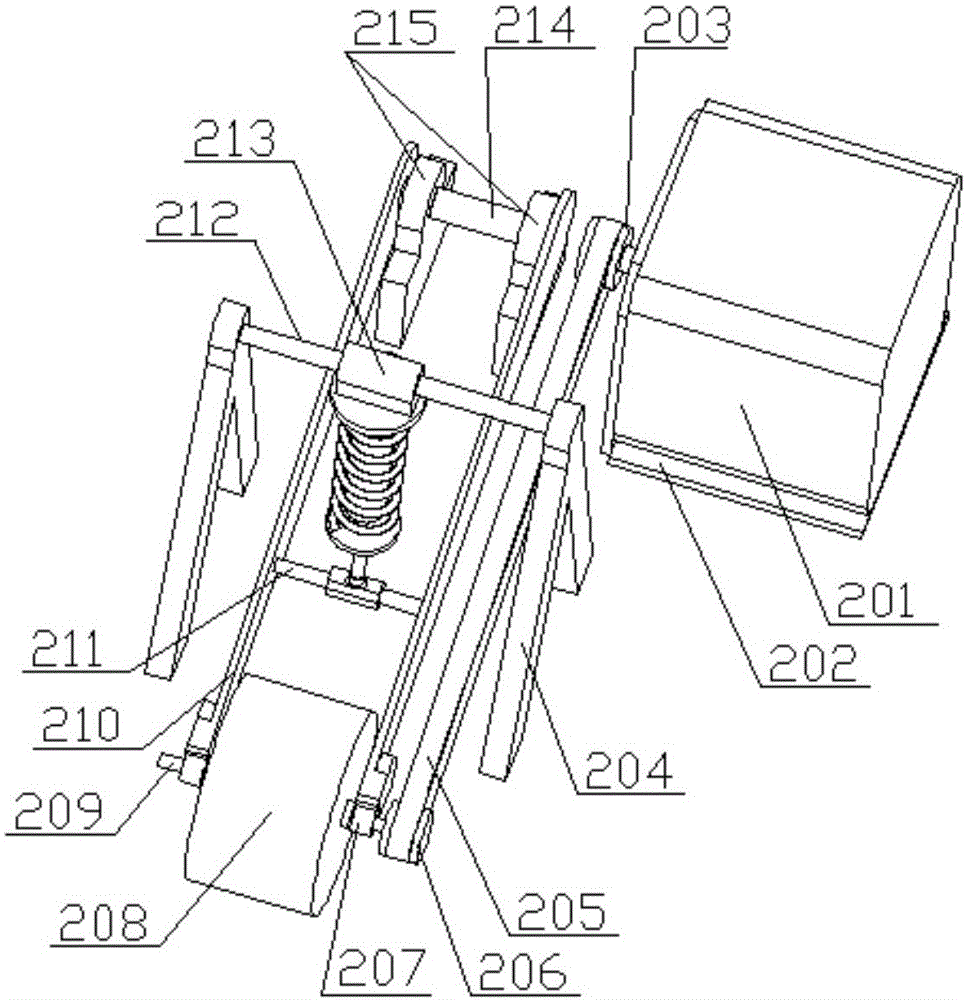

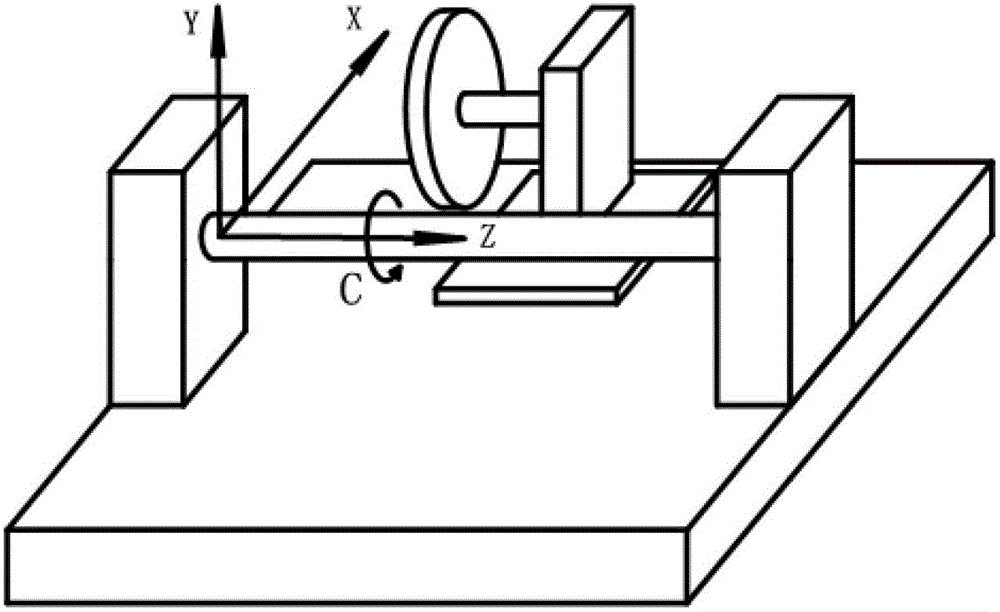

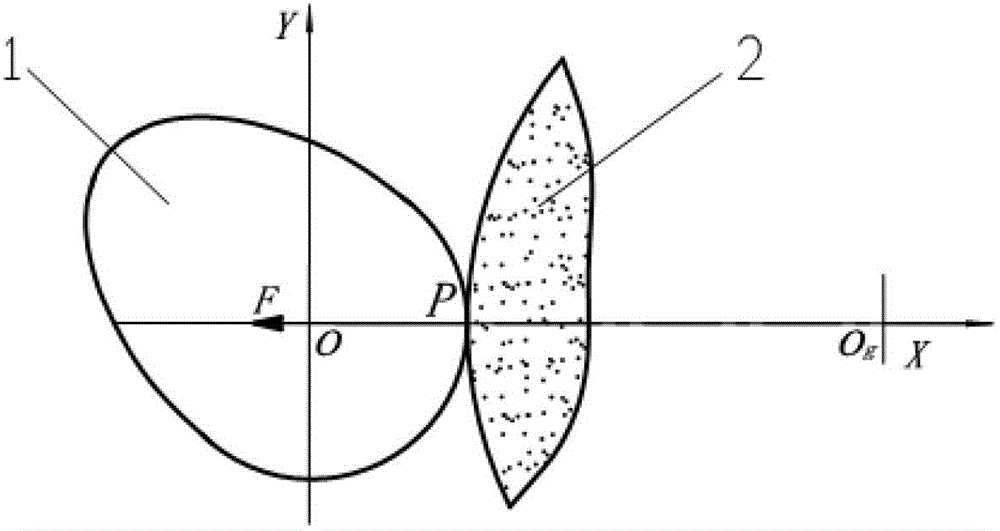

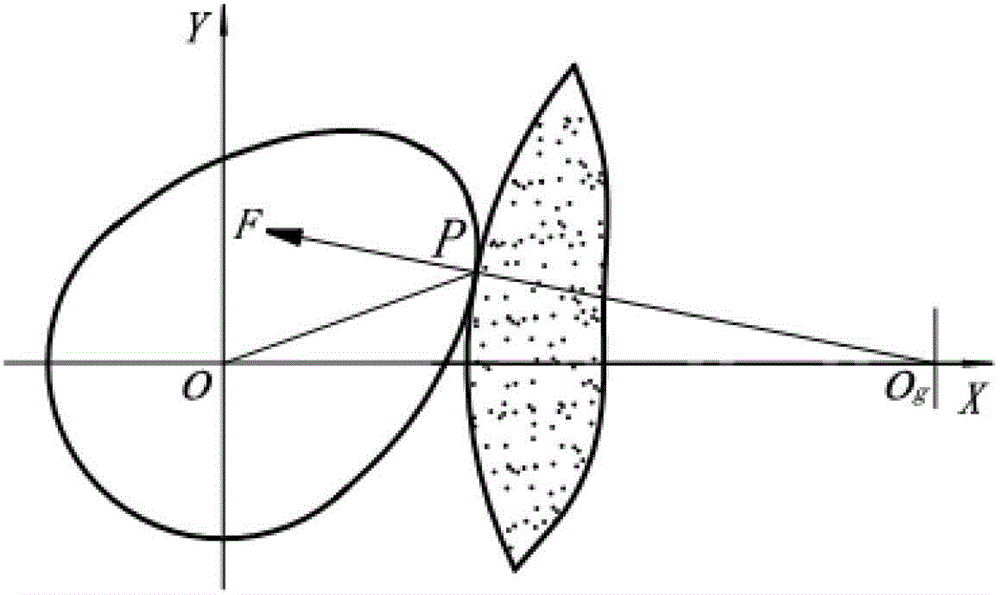

Compensation device and method of numerical control cam shaft grinding machine grinding deformation

ActiveCN103121184BAvoid deformationImprove machining accuracyBelt grinding machinesGrinding feed controlNumerical controlControl system

The invention provides a compensation device and a method of numerical control cam shaft grinding machine grinding deformation. Two compensation device bases are arranged in the direction paralleled with the axial line direction of a cam shaft main shaft on one side of a cam shaft grinding machine, the bases are arranged on two guide rails, and capable of moving along the guide rails and being fastened on the guide rails through locking screws. The compensation device is arranged on the bases and composed of a servo motor, a lead screw, a nut, a connection rod, a sliding block, a roller, a control system and the like. After a cam shaft blank is clamped on a main shaft, the compensation device bases are adjusted to the position where the cam shaft is provided with a bearing and locked tightly, the diameter of the position where the cam shaft is provided with the bearing is input into the control system of the compensation device, a starting button is pressed, and then the motor of the compensation device drives the sliding block to clamp the cam shaft tightly. The compensation device and the method of numerical control cam shaft grinding machine grinding deformation have the advantages that deformation of the cam shaft because of grinding force can be compensated conveniently and machining accuracy of the cam shaft can be improved under the precondition that normal functions of the numerical control cam shaft grinding machine are not affected.

Owner:BEIJING UNIV OF TECH

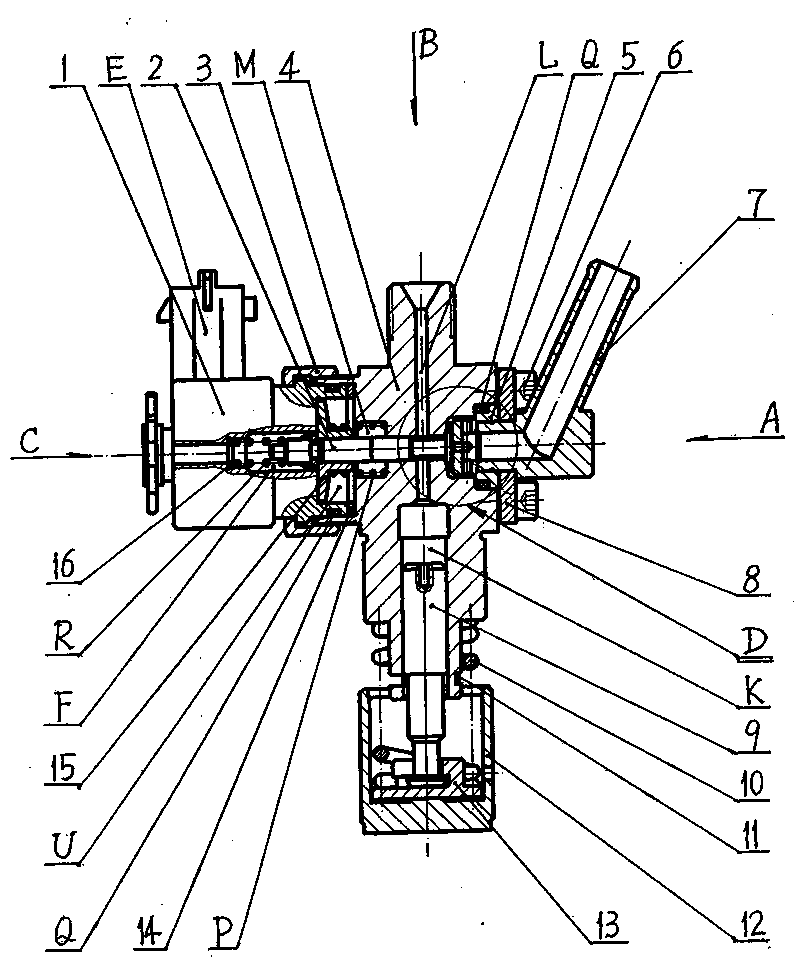

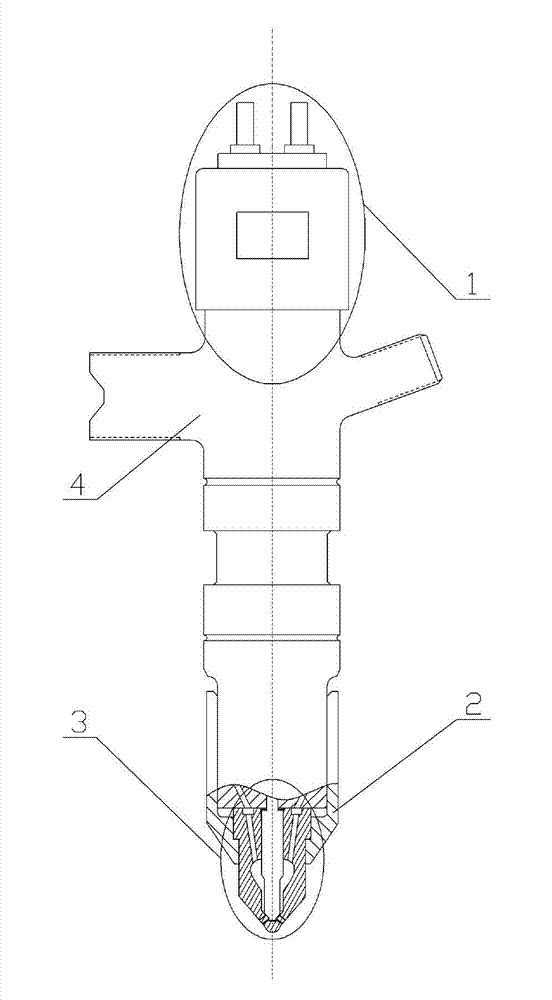

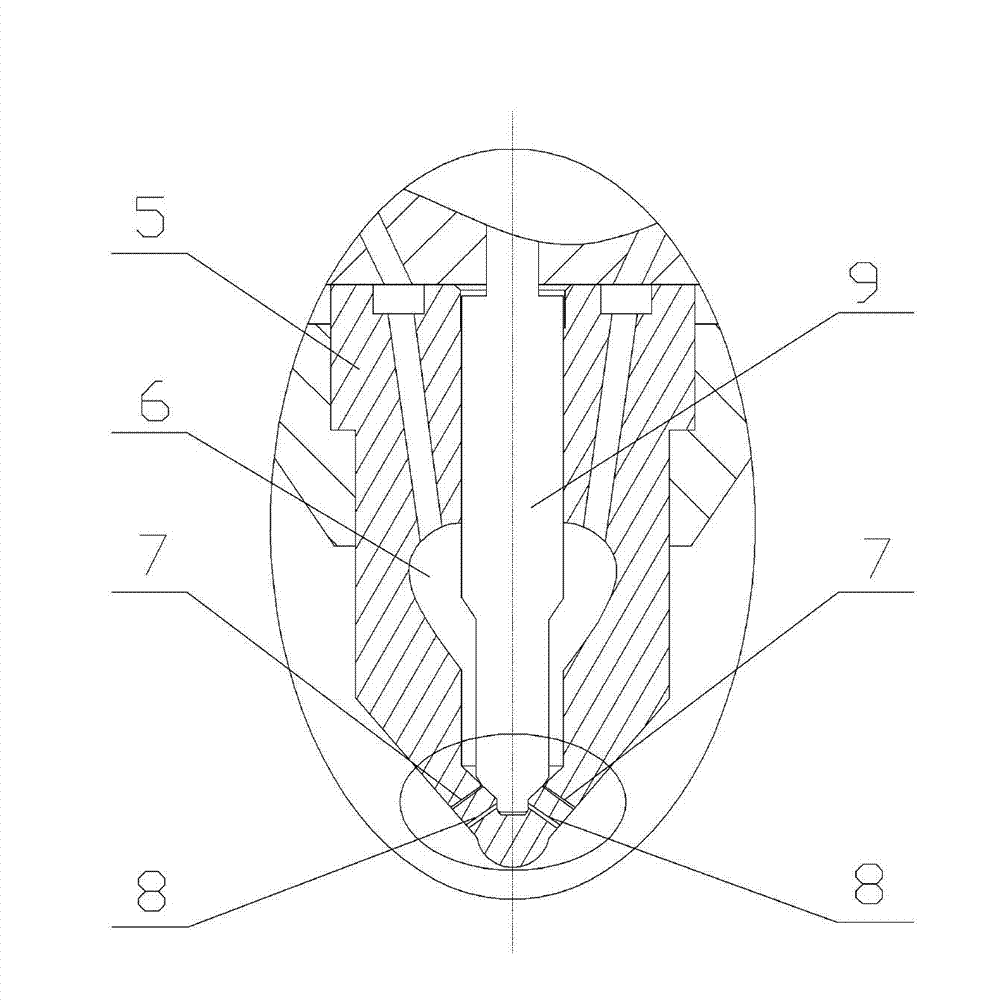

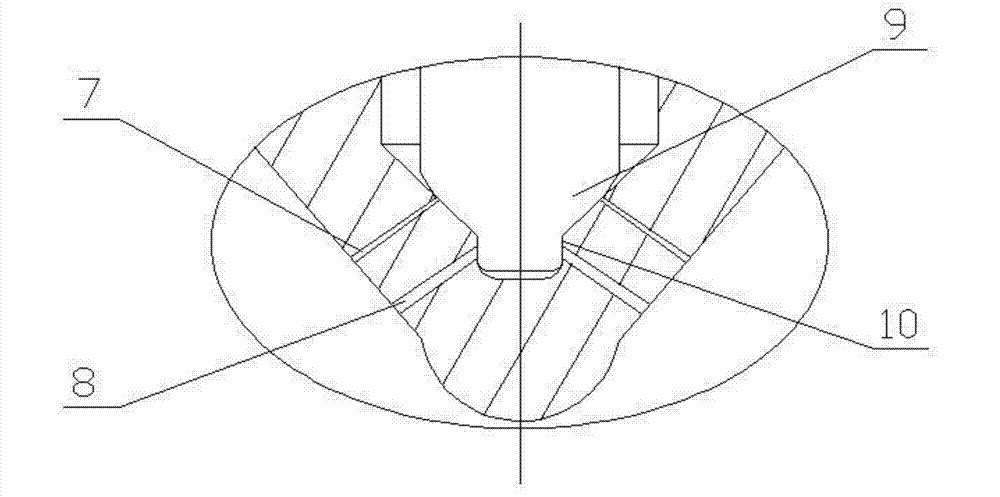

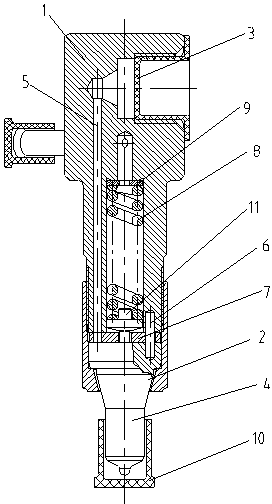

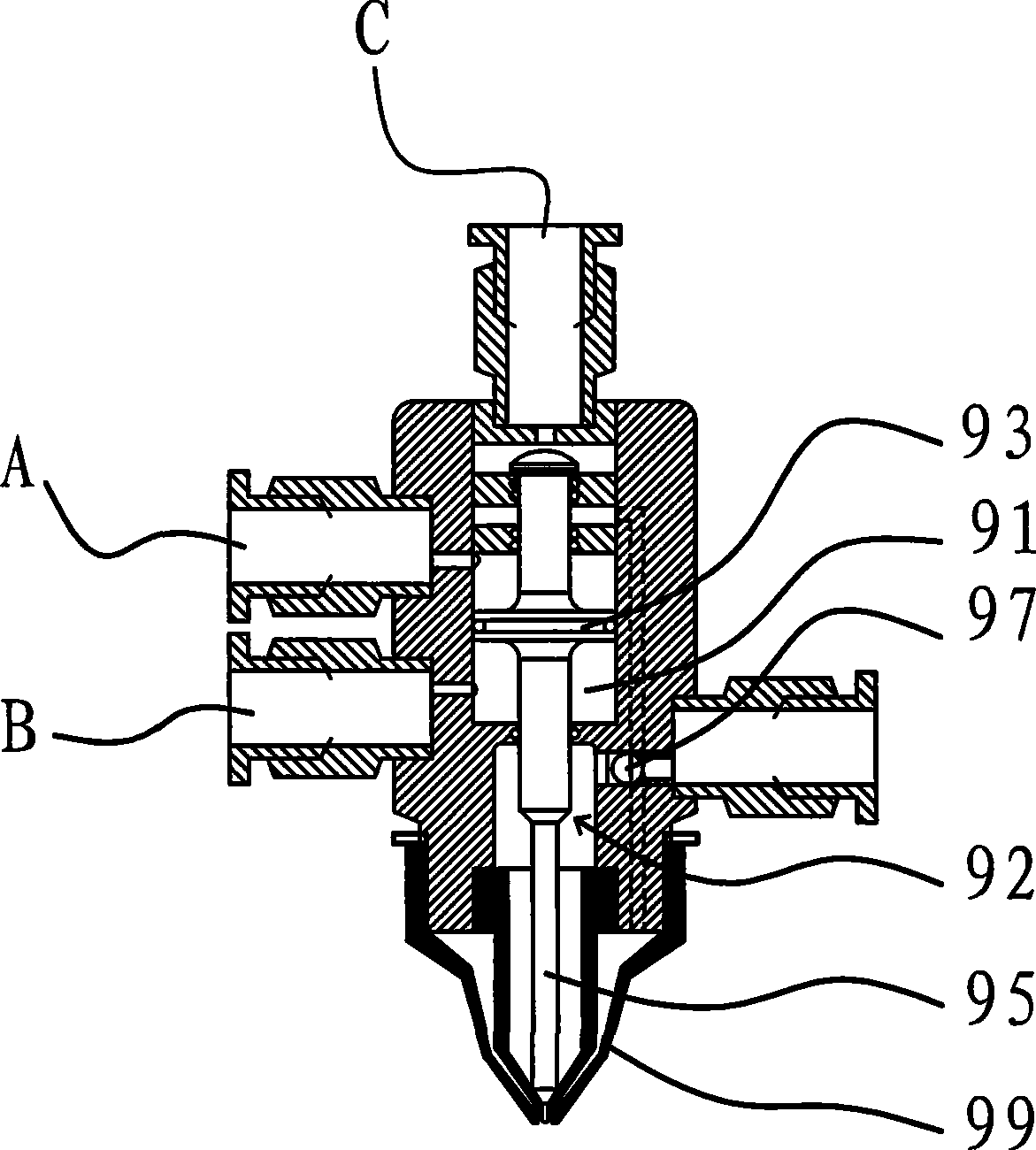

Oil atomizer with short nozzle

InactiveCN103452729AShorten the lengthGood fuel injectionFuel injection apparatusMachines/enginesBearing surfaceNeedle valve

The invention discloses an oil atomizer with a short nozzle, comprising an oil injection body and a needle valve body, wherein an oil inlet is formed in the upper part of the oil injection body, and is communicated with the bearing surface of the needle valve body through an oil duct; a filter element is assembled on the oil inlet; a pressure adjustment device which is arranged on the needle valve body in a pressing way is also arranged in the oil injection body; a needle valve is assembled in the needle valve body; the oil injection nozzle is arranged on the needle valve; the length of the oil injection nozzle is less than 17mm. By using such a mode, the length of the nozzle can be shortened, and is well matched with a diesel with a corresponding model, the oil injection effect can reach perfect, the oil injection performance is good, and the adjustment and control are easy.

Owner:WUXI TIANHONG MACHINERY MFG

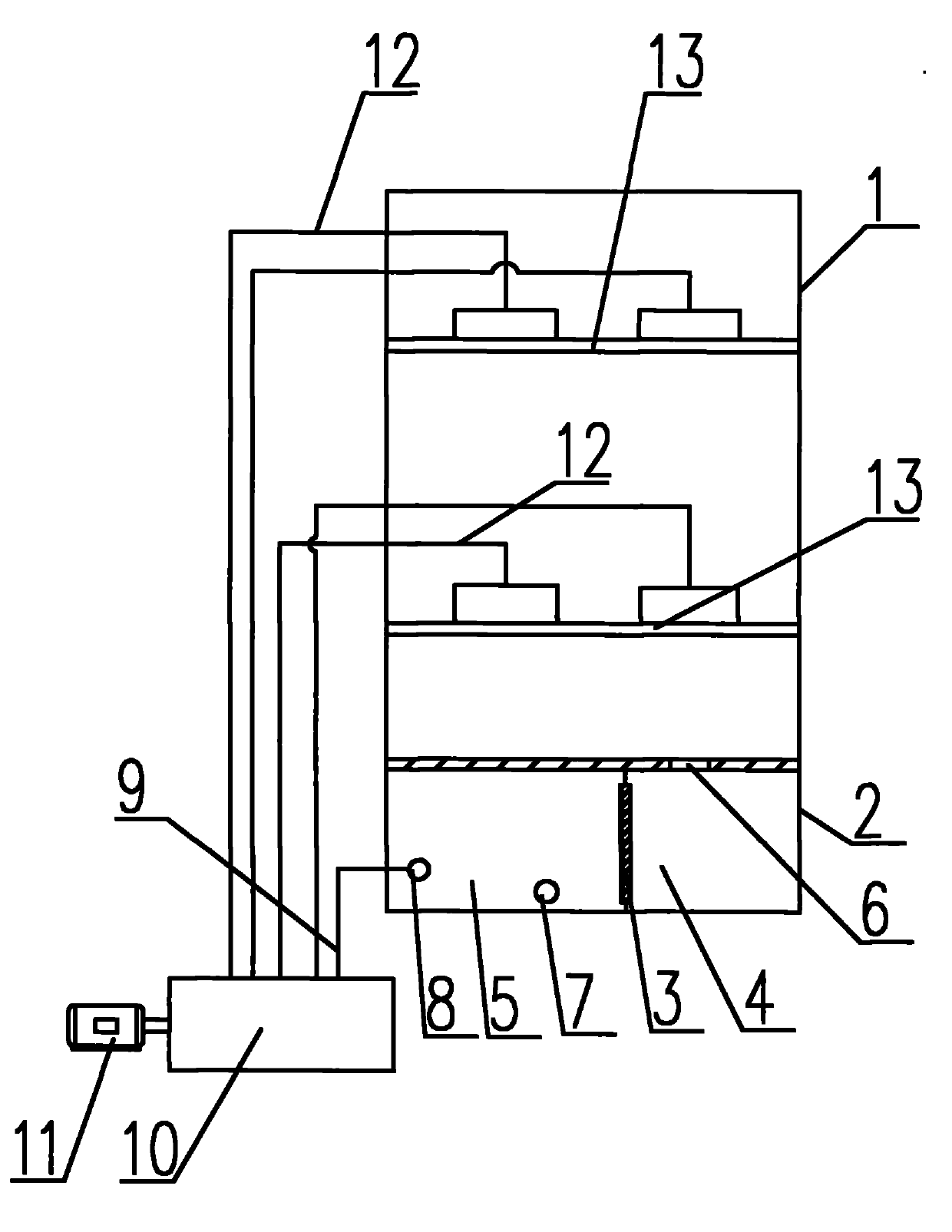

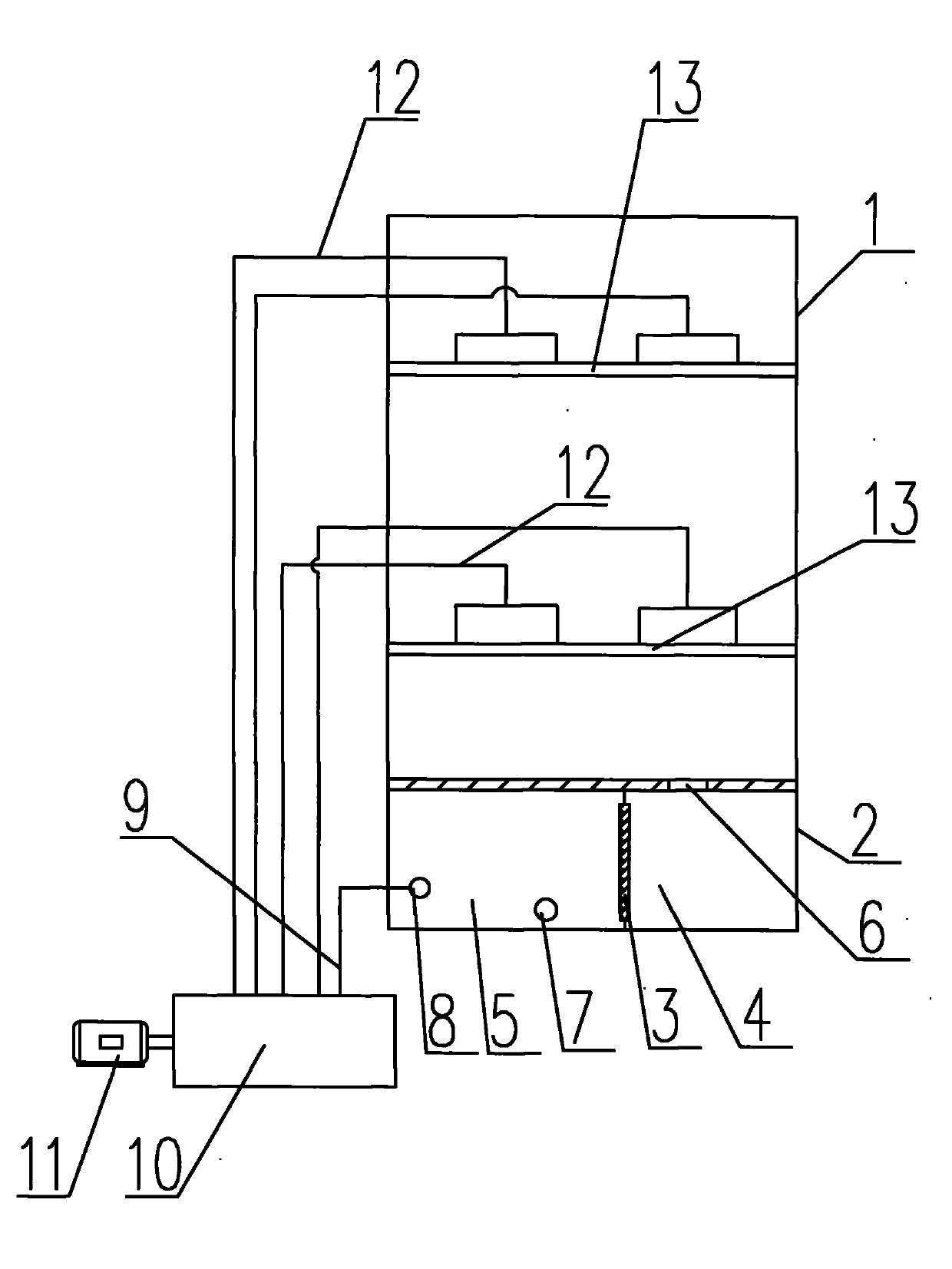

Multi-functional integral drier and implementation method thereof

ActiveCN105459235AImprove stabilityEasy to usePretreatment apparatusPressure impregnationHeat conductingFuel tank

The invention discloses a multi-functional integral drier. The multi-functional integral drier comprises a heat conducting oil furnace, wherein a heat conduction oil circulating exhaust pipe and a heat conducting oil circulating return pipe are connected to the heat conducting oil furnace, the heat conducting oil circulating exhaust pipe is connected with one end of a first heating pipe, the other end of the first heating pipe is connected with the heat conducting oil circulating return pipe, and the first heating pipe enters an oil groove; the heat conducting oil circulating exhaust pipe is connected with one end of a second heating pipe, the other end of the second heating pipe is connected with the heat conducting oil circulating return pipe, and the second heating pipe enters an oil storage tank; the oil storage tank is connected to a tank body through oil exhaust pipes, and an oil pump is arranged on the oil exhaust pipes which are arranged in the oil groove; the tank body is connected with a high frequency generator. The invention further discloses an implementation method of the multi-functional integral drier. The multi-functional integral drier disclosed by the invention has the characteristics of being simple in structure, low in building cost, high in production efficiency, broad in application scope, good in timber stability, good in use effects and the like.

Owner:东阳市尚德电器机械有限公司

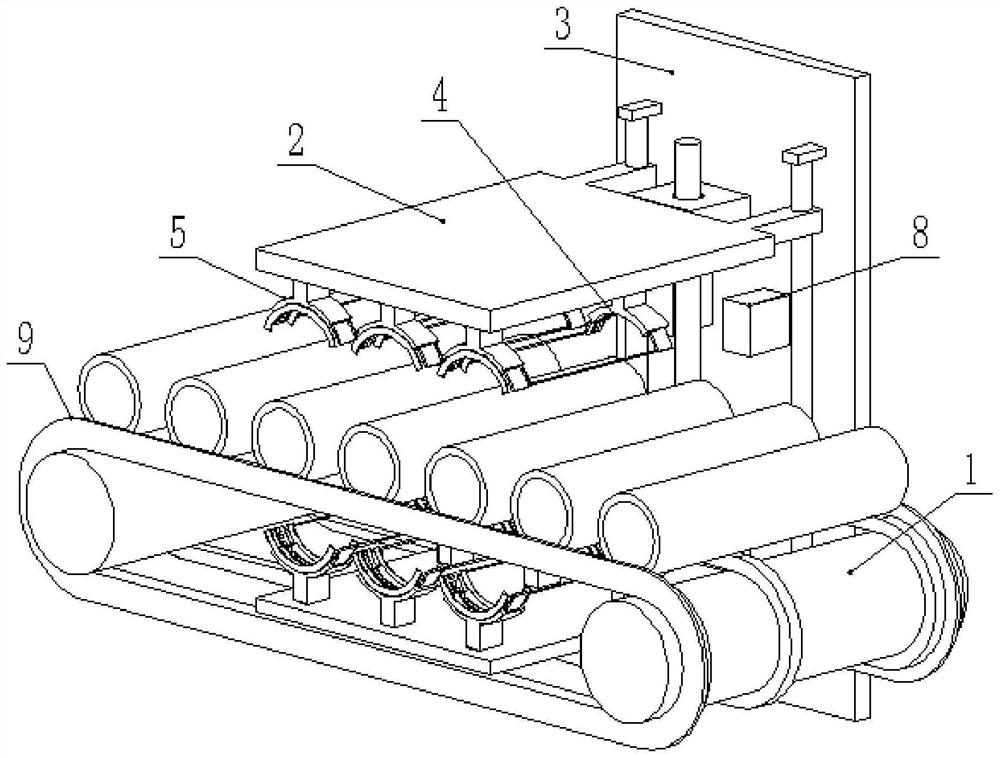

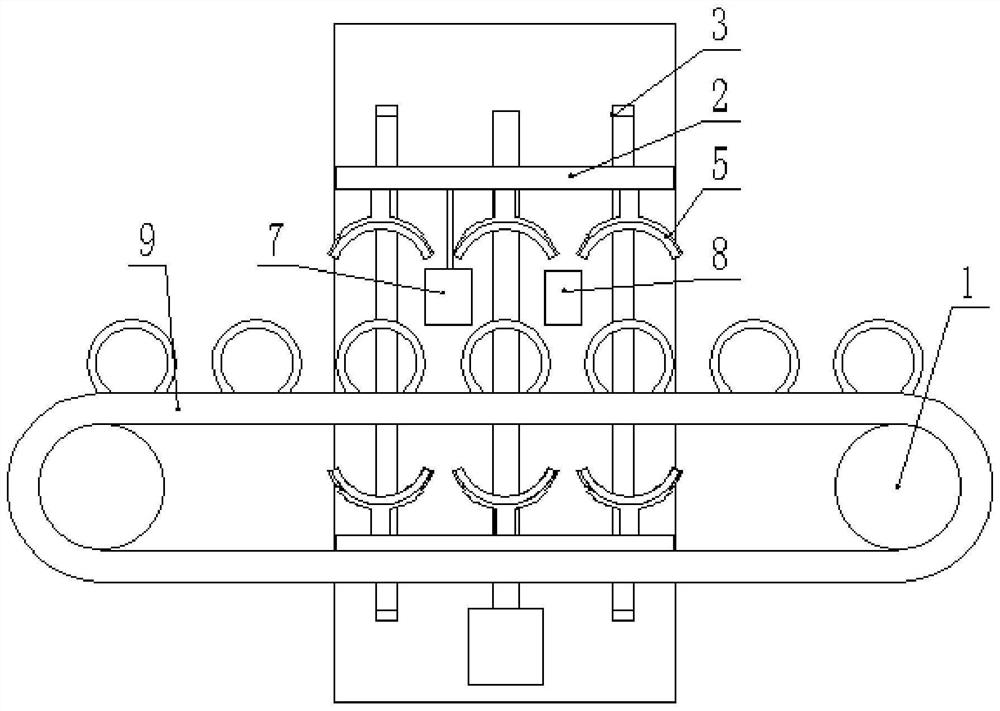

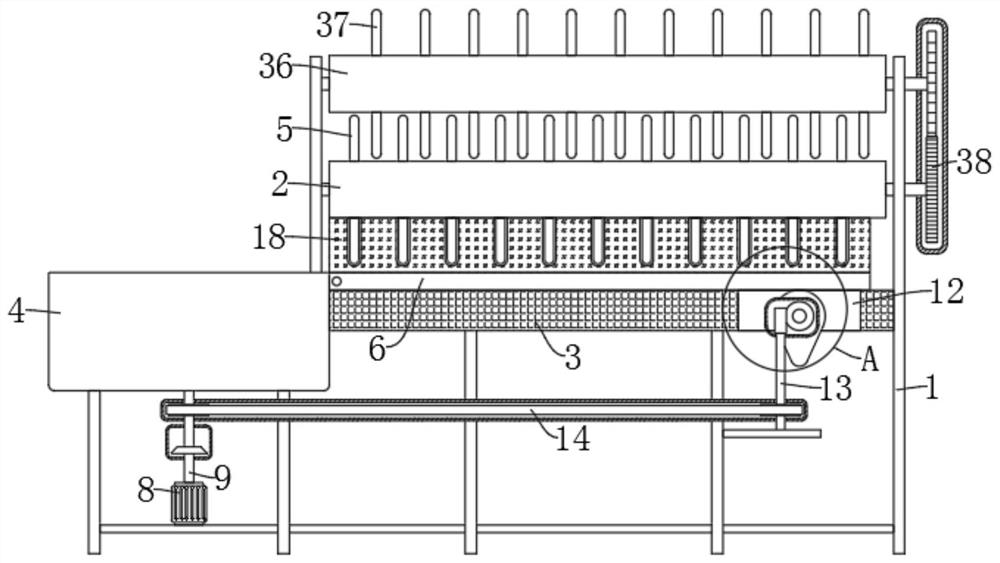

Antistatic hydraulic oil spraying and wetting machine for polyester short fiber

InactiveCN101949085AGood fuel injectionReduce fuel consumptionTextile treatment by spraying/projectingPolyesterFiber

The invention discloses an antistatic hydraulic oil spraying and wetting machine for polyester short fiber, which comprises an oil spraying tank and a movable oil tank, wherein the movable oil tank is movably arranged at the lower end of the oil spraying tank; a filtering screen is arranged at the middle part of the movable oil tank; the movable oil tank is divided into an oil return tank and an oil tank by the filtering screen; an oil return hole which is mutually communicated with the bottom of the oil spraying tank is arranged at the upper end of the oil return tank; an oil inlet and an oil outlet are respectively arranged on the oil tank; the oil outlet is connected with a multi-stage gear pump through an oil outflow pipe; the multi-stage gear pump is connected with a driving motor; the multi-stage gear pump is connected with an oil spraying pipe arranged in the oil spraying tank through a connecting pipe; and a plurality of oil spraying holes are uniformly arranged on the oil spraying pipe. The invention has the advantages that the oil spraying holes can not be clogged easily, the oil is sprayed uniformly, the oil spraying effect is good, the oil consumption is saved, the oil spraying quantity can be effectively controlled, and the use cost is reduced.

Owner:张家港保税区炬德化纤有限公司

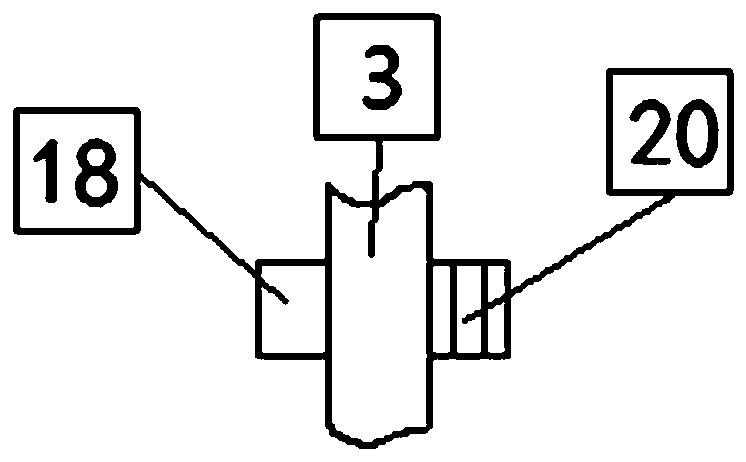

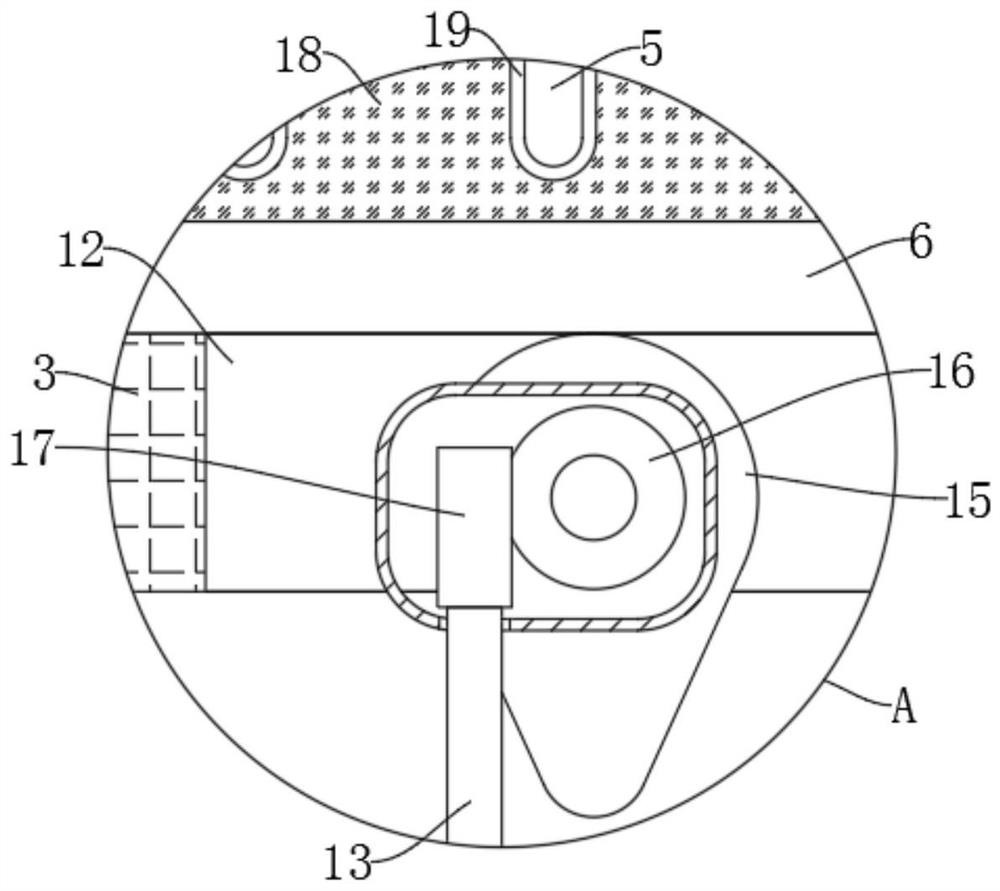

A spraying device before necking of cans

ActiveCN112317174BPrevent affecting subsequent necking operationsGood fuel injectionSpraying apparatusAir pumpEngineering

The invention provides a spraying device before necking of pop cans, which includes a transmission mechanism for transporting pop cans. One side of the transmission mechanism is provided with a relatively moving connecting plate and a driving mechanism for moving the connecting plate. The connecting plates are respectively located on the upper and lower sides of the conveying mechanism. On both sides, one side of the transmission mechanism is provided with a guide frame that restricts the moving direction of the connecting plate; the inner end of the connecting plate is installed with a fixed assembly for fixing the can One side of the components and the two are connected, and a contact sensor is provided on the fixed component at the lower side; an air pump and an oil tank are installed on the guide frame, and the air pump and the oil tank are connected with the fuel injection component. When the present invention is used, the order of first fixing the pop can and then spraying is adopted.

Owner:济南联合制罐有限公司

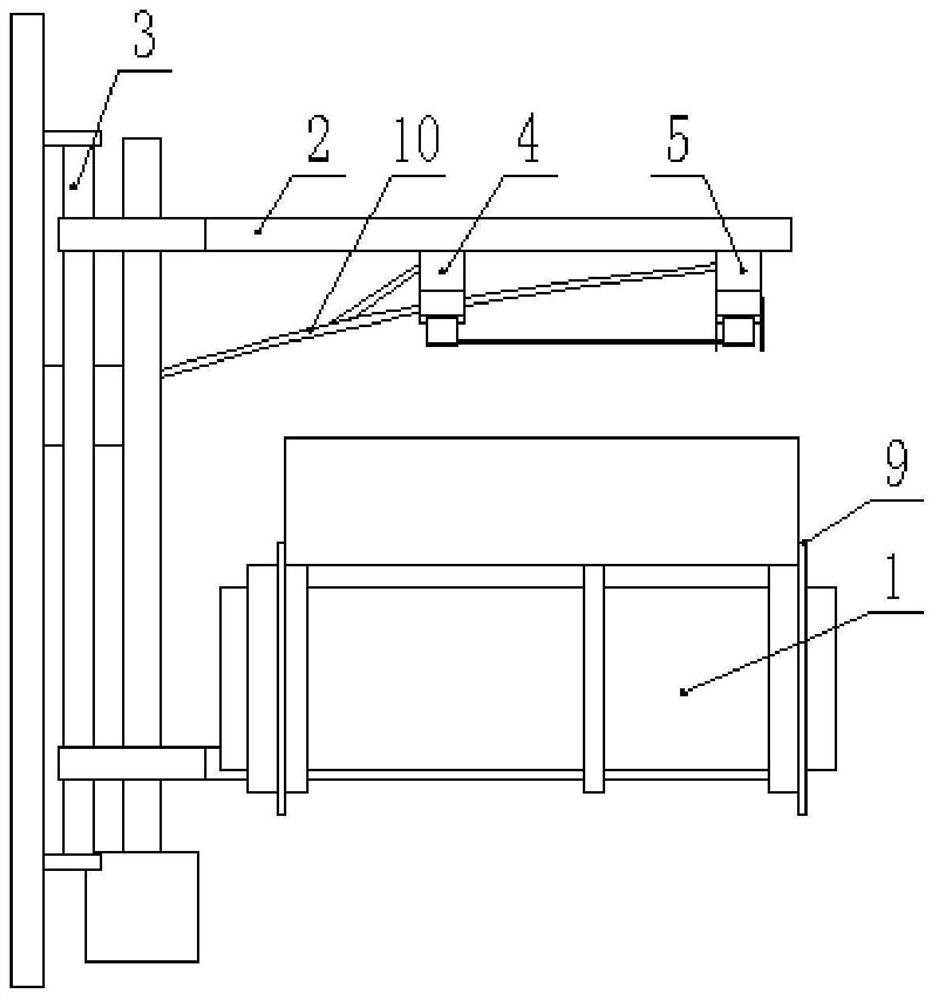

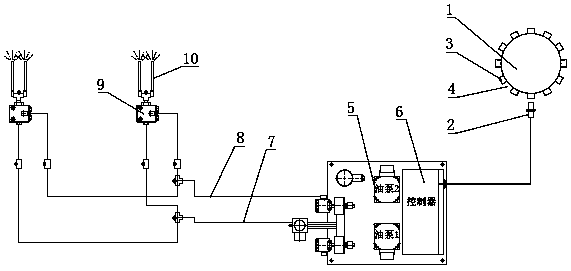

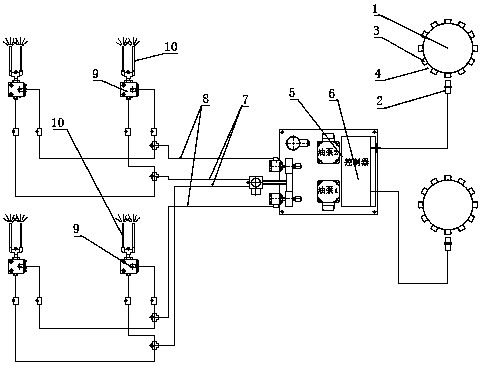

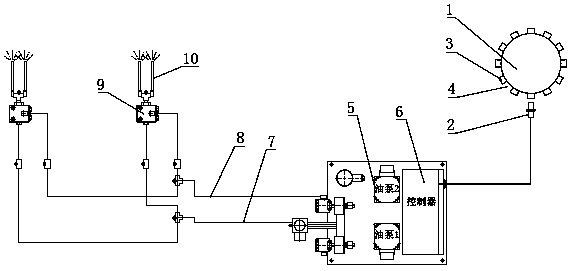

Chain lubrication device for curing furnace

The invention relates to a lubrication mechanism, in particular to a mechanism for lubricating chains in a curing furnace. The mechanism comprises a disc, an induction element, an oil pump, a gas pathpipe body connected with a gas pump, oil-gas mixing distribution blocks, oil outlet spraying pipes and a controller. At least one pair of oil-gas mixing distribution blocks are arranged, each pair comprises two oil-gas mixing distribution blocks, in other words, the corresponding oil outlet spraying pipe of one oil-gas mixing distribution block corresponds to a joint at one position of the chainon one side, and each joint of the chain on the other side corresponds to the corresponding oil outlet spraying pipe of the other oil-gas mixing distribution block. Protrusions are arranged on the circumference edge of the disc at equal intervals, grooves are formed between the protrusions, and the induction element is connected with the controller through a wire. An obtained chain lubrication device for the curing furnace has the characteristics of being good in oil spraying effect, accurate in point fixing, little in waste, high in efficiency, convenient to use and the like.

Owner:桐乡双玛机械有限公司

Oil injection device of special coating machine for metallized thin film

InactiveCN106086780BPrevent oil spillsShort injection efficiencyVacuum evaporation coatingSputtering coatingBottleAtmospheric pressure

The invention relates to an oil spraying device of a special coating machine for a metallized film. The oil spraying device comprises an oil bottle, an oil outlet tube, a horizontally-arranged oil control tube and a spray head; the top of the oil control tube is provided with a conical chamber, the tail end of the oil control tube is provided with a first cover plate, and the oil control tube is internally provided with a bead, a first spring, a first piston and a second spring; and the outer part of the first cover plate is provided with a first air inlet tube on which a first air valve is arranged. According to the oil spraying device of the special coating machine for the metallized film, the opening between the bead and the oil control tube is controlled by virtue of air pressure so that oil leakage of the oil spraying device is avoided; and then, the motion of a second piston is controlled by virtue of air pressure to carry out pressurization treatment on coating oil entering the spray head, so that the coating oil sprayed from the head part of the spray head has enough spraying speed and pressure, the oil spraying time is shortened, and the oil spraying efficiency and quality are improved. The oil spraying device is simple in structure, convenient to use, stable in operation, short in oil spraying time, high in oil spraying efficiency and good in oil spraying effect.

Owner:铜陵市铜创电子科技有限公司

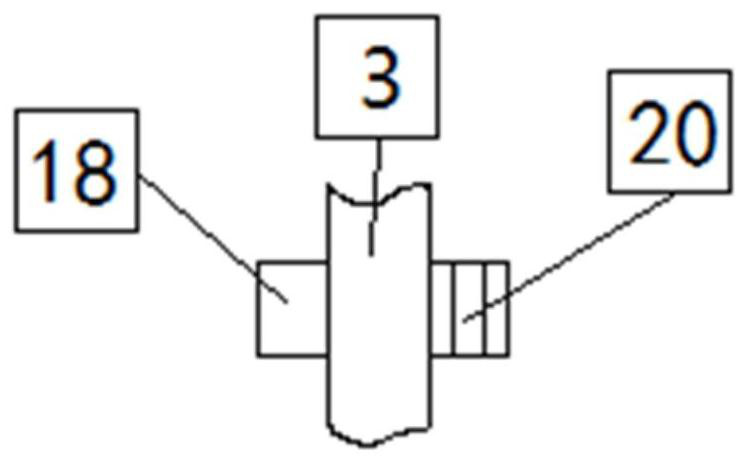

Lubricating mechanism oil nozzle structure

InactiveCN106352225AGood fuel injectionProtect the construction site environmentConduits/junctionsEngineeringMetal

The invention provides a lubricating mechanism oil nozzle structure, and relates to improvement of the lubricating mechanism oil nozzle structure. The invention provides a lubricating mechanism oil nozzle structure with simple structure, convenient use and good leakproofness. The lubricating mechanism oil nozzle structure comprises a inner oil tube, a metal sleeve, a ceramic tube, a junction plate, a nozzle, an outer shell, a junction surface, a connection block, a contact surface, a sealing surface, a ring groove, a connecting groove, an arc surface and a soft oil sealing sleeve. The lubricating mechanism oil nozzle structure is characterized in that the inner oil tube comprises the ceramic tube, the metal sleeve is arranged outside the ceramic tube, the connection block is arranged above the metal sleeve through the arc surface, and the connection block is arranged inside the connecting groove which has the nozzle; the sealing surface is arranged between the connection block and the connecting groove; the junction plate is arranged outside the metal sleeve, the soft oil sealing sleeve is arranged between the junction plate and the connection block.

Owner:张桂春

An electronically controlled accumulator fuel injector

ActiveCN110848060BImprove opening powerOpen resistance is smallFuel injection apparatusMachines/enginesInjector nozzleSolenoid valve

The invention provides an electronically controlled accumulator fuel injector, which includes a fuel injector body and a control plunger rod. A control valve, an armature assembly, a solenoid valve spring, a solenoid valve and a first A pressing mechanism, the control valve is tightly connected with the injector body through the second pressing mechanism, the control plunger rod is installed inside the injector body, and the needle valve spring is socketed outside the control plunger rod, and the lower end of the injector body Install the fuel injection nozzle assembly, which is provided with an oil inlet passage inside, the control plunger rod and the valve needle of the fuel injection nozzle assembly are integrated, and the needle valve spring presses the valve needle of the fuel injection nozzle assembly against the valve. On the body, the big head of the control plunger rod and the nozzle assembly form a control plunger chamber inside the injector body, and the control plunger chamber communicates with the high-pressure oil inlet passage. The electronically controlled accumulator fuel injector of the present invention controls the pressure of the plunger cavity through the orifice, so as to increase the opening power of the needle valve and reduce the opening resistance of the needle valve, thereby optimizing the fuel injection performance.

Owner:CHINA NORTH ENGINE INST TIANJIN

A water conservancy decontamination machine based on computer control

ActiveCN112431178BNo accumulationAutomatic feedingWater cleaningFiltration separationElectric machineryHydraulic engineering

The invention discloses a water conservancy decontamination machine based on computer control, which belongs to the field of water conservancy engineering. A water conservancy decontamination machine based on computer control, including a support frame, the upper end of the support frame is fixedly equipped with a hollow conveyor belt arranged obliquely, the outer wall of the hollow conveyor belt is fixedly equipped with a plurality of uniformly distributed conveyor rods, and the side wall of the support frame The incineration cylinder is fixedly installed, the side wall of the incineration cylinder is fixedly equipped with a lower hollow plate, the upper end of the lower hollow plate is provided with an upper hollow plate that is rotatably connected with the side wall of the incineration cylinder, and the lower end of the incineration cylinder is fixedly installed with a motor. The rotating shaft of the motor extends to the incineration cylinder and is fixedly connected with a cross bar. The lower end of the cross bar is fixedly connected with a plurality of stirring paddles. The side wall of the cylinder is provided with a combustion-supporting mechanism; the invention can recover river waste and incinerate the waste at the same time, has complete functions and does not need to be loaded and checked, and is more convenient to use.

Owner:天津万联高新科技有限公司

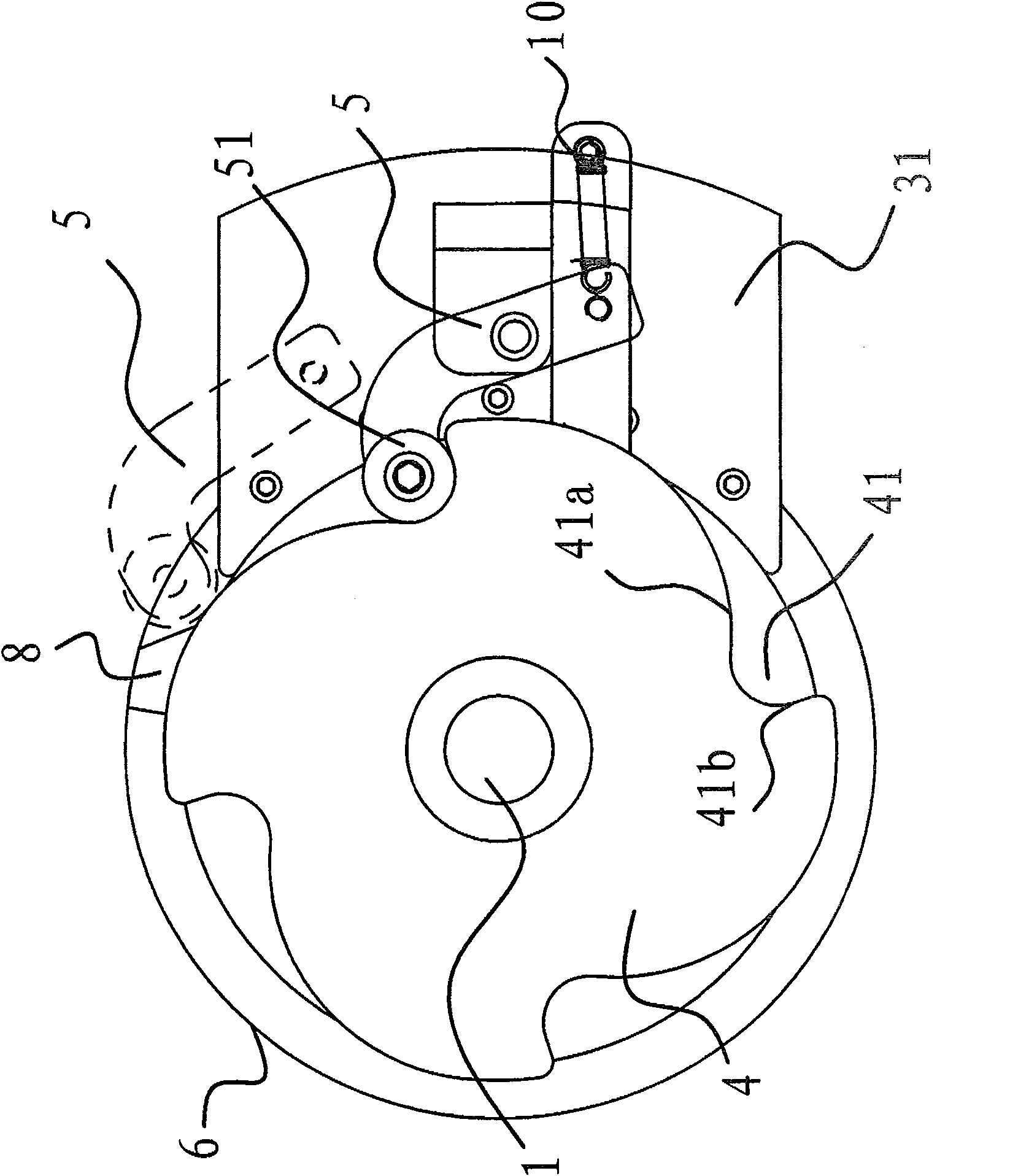

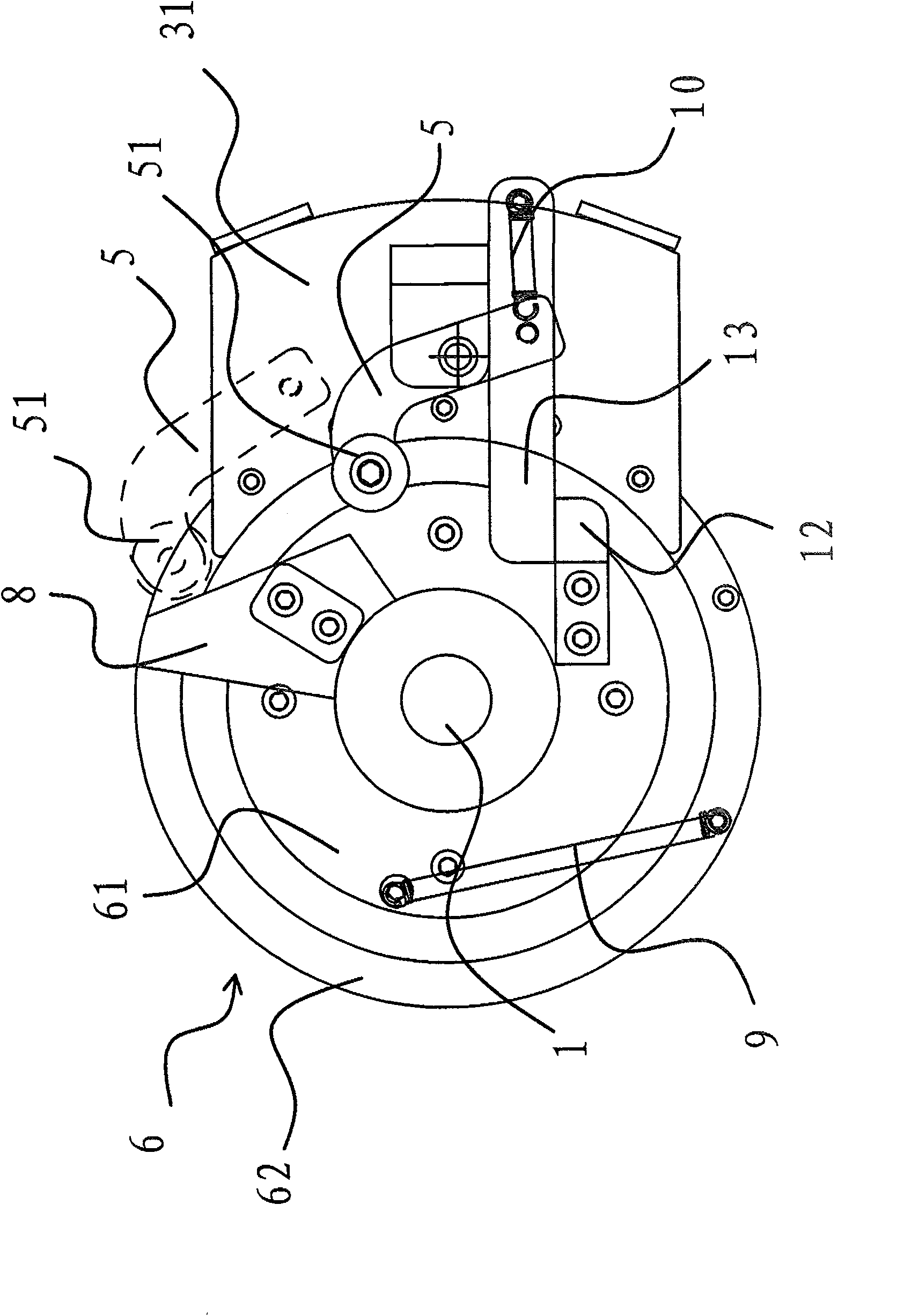

Tube tracking oil sprayer of injector assembling machine

InactiveCN100577304CImplement trackingFull fuel injectionLiquid surface applicatorsCoatingsSprayerEngineering

The present invention provides one kind of tube tracking oil sprayer of injector assembling machine and belongs to the field of mechanical technology. The tube tracking oil sprayer includes one rotation shaft, one material feeding pan with notch in the edge for fixing tube, one spray gun frame beside the material feeding pan, one synchronous driving mechanism, and one spray gun frame detaching and resetting mechanism. The tube tracking oil sprayer has the features of high compatibility, sufficient oil spraying time, no contamination on the injector, high safety and high reliability.

Owner:郏正秋

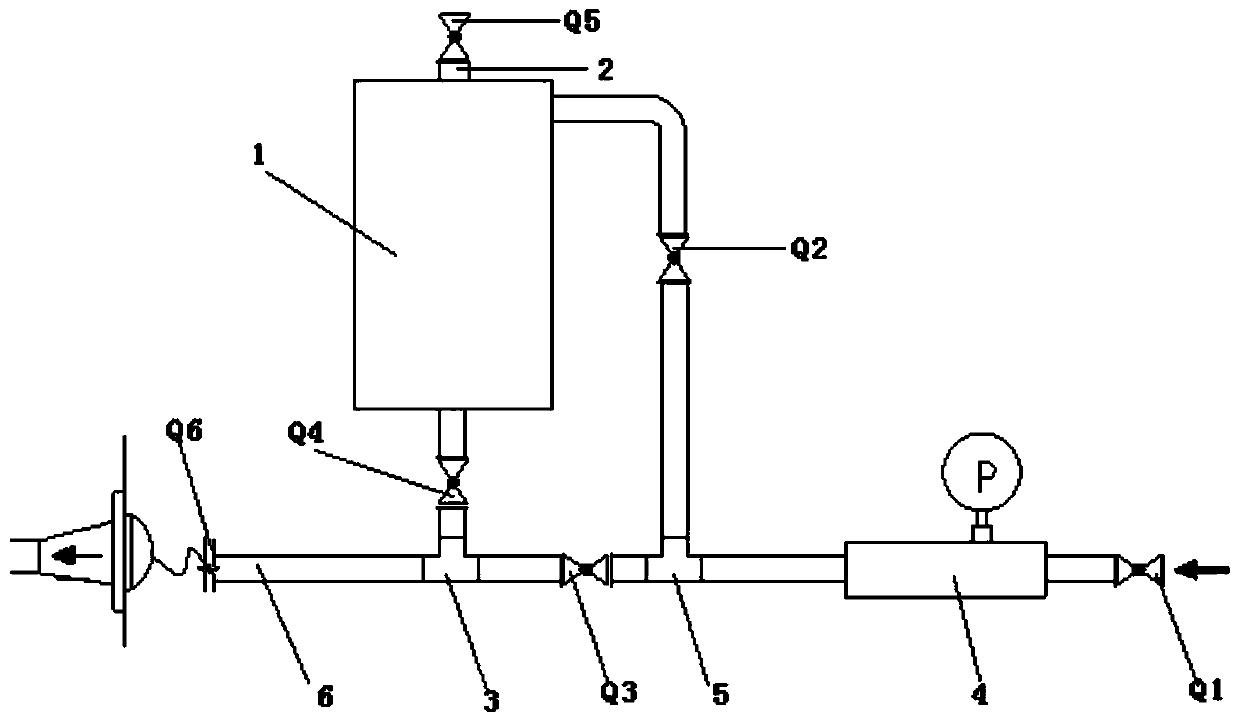

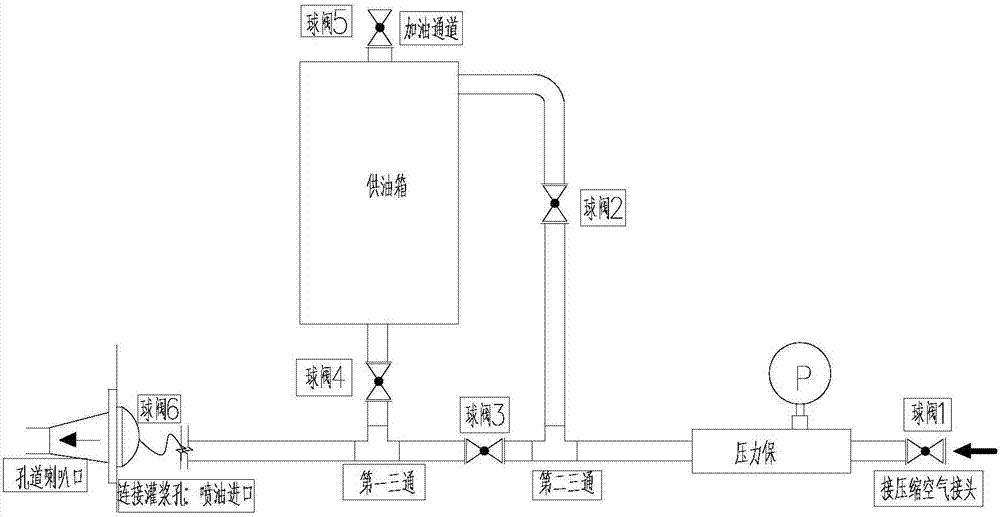

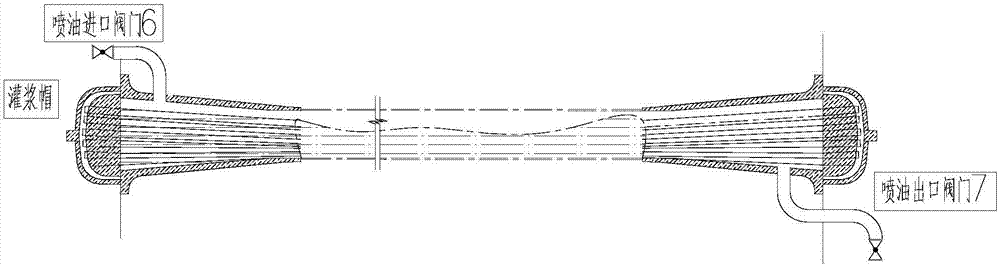

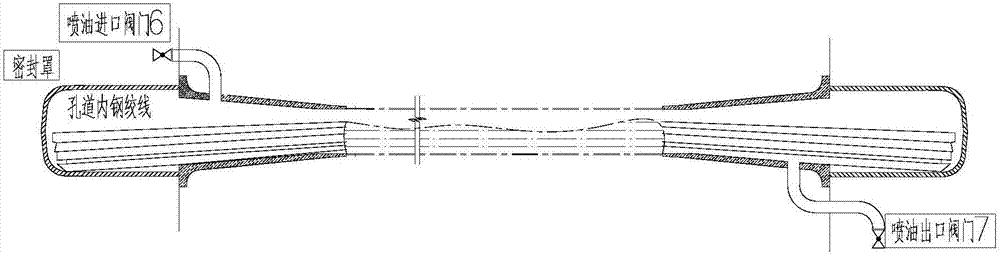

An anti-rust fuel injection device for steel bundles in a prestressed channel and an fuel injection method thereof

ActiveCN106988536BThe principle is simpleEasy to operateBridge erection/assemblyBuilding material handlingPre stressTime limit

The invention relates to a device and method for a prestressed duct, in particular to an antirust oil injection device for a steel cable in a prestressed duct and an oil injection method thereof, and belongs to the technical field of building engineering construction. The device and the method are designed for complex environments with large tonnage, super-long cables and anomalous events and are achieved through machining and manufacturing, simulation test and entity application practice. The device is simple in principle and convenient to operate; the profile occupied space is small, the weight is low, carrying is easy, the manufacturing cost is low, and the safety risk of high-altitude operation is low; the oil injection effect is good, cost is saved, efficiency is high, cost is low, and practicability is high; and at the same time, design requirements are met, the cost can also be lowered, the efficiency is improved, the time limit for a project is shortened, and the project quality is improved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

A gdi fuel injector heated by ptc thermosensitive ceramics

InactiveCN105484917BTemperature controlControl heating effectFuel injection apparatusMachines/enginesGasoline direct injectionHeat sensitive

The invention belongs to the technical field of fuel injection systems of gasoline engines, and relates to a GDI fuel injector utilizing PTC thermal sensitive ceramic for heating. An insulation sheath, a PTC thermal sensitive ceramic pipe and a heat conduction round pipe in the GDI fuel injector sequentially wrap the outer ring of the lower portion of a needle valve, and insulation gaskets are arranged between the upper end of the PTC thermal sensitive ceramic pipe and a boss of the needle valve of the fuel injector and between the lower end of the PTC thermal sensitive ceramic pipe and the boss of the needle valve of the fuel injector respectively. The upper end of a positive wire and the upper end of a negative wire are connected with a wiring harness plug through electric conduction carbon rings and an electric conduction spring, the lower end of the positive wire and the lower end of the negative wire are connected with the positive pole and the negative pole of a heating electrode respectively, and the electric conduction carbon ring I and the electric conduction carbon ring II are connected through the electric conduction spring. The GDI fuel injector belongs to internal heating, fuel in the fuel injector can be heated to high temperature within short time, the fuel injection effect is good, the spraying effect in an air cylinder of a gasoline direct injection engine is greatly improved, cold start combustion efficiency is improved, and cold start tail gas emission is reduced. The GDI fuel injector is simple in structure, and other systems of an internal combustion engine do not need to be greatly modified.

Owner:JILIN UNIV

Polyester staple fibre water-oil wet spraying machine

The invention discloses a polyester staple fibre water-oil wet spraying machine comprising an oil spray tank, a movable oil tank, a filter screen, an oil return tank, an oil tank, an oil return hole, an oil inlet, an oil outlet, an oil outlet pipe, a multistage gear pump, a drive motor, a connecting pipe, an oil spray pipe, a plurality of oil spray holes and a compressed air pipe, wherein the movable oil tank is movably arranged at the lower end of the oil spray tank; the filter screen is arranged in the middle of the movable oil tank and can divide the movable oil tank into the oil return tank and the oil tank; the upper end of the oil return tank is provided with the oil return hole mutually communicated to the bottom of the oil spray tank; the oil tank is respectively provided with theoil inlet and the oil outlet; the oil outlet is connected with the multistage gear pump through the oil outlet pipe; the multistage gear pump is connected with the drive motor and connected with the oil spray pipe arranged in the oil spray tank through the connecting pipe; and the oil spray pipe is uniformly provided with the plurality of oil spray holes and is connected with the compressed air pipe. The oil spray holes are difficult to block and connected with the compressed air pipe so that the oil spray amount can be regulated according to the magnitude of working speed; and the invention has the advantages of uniform oil spray, good oil spray effect, oil consumption saving and reduced using cost.

Owner:张家港保税区炬德化纤有限公司

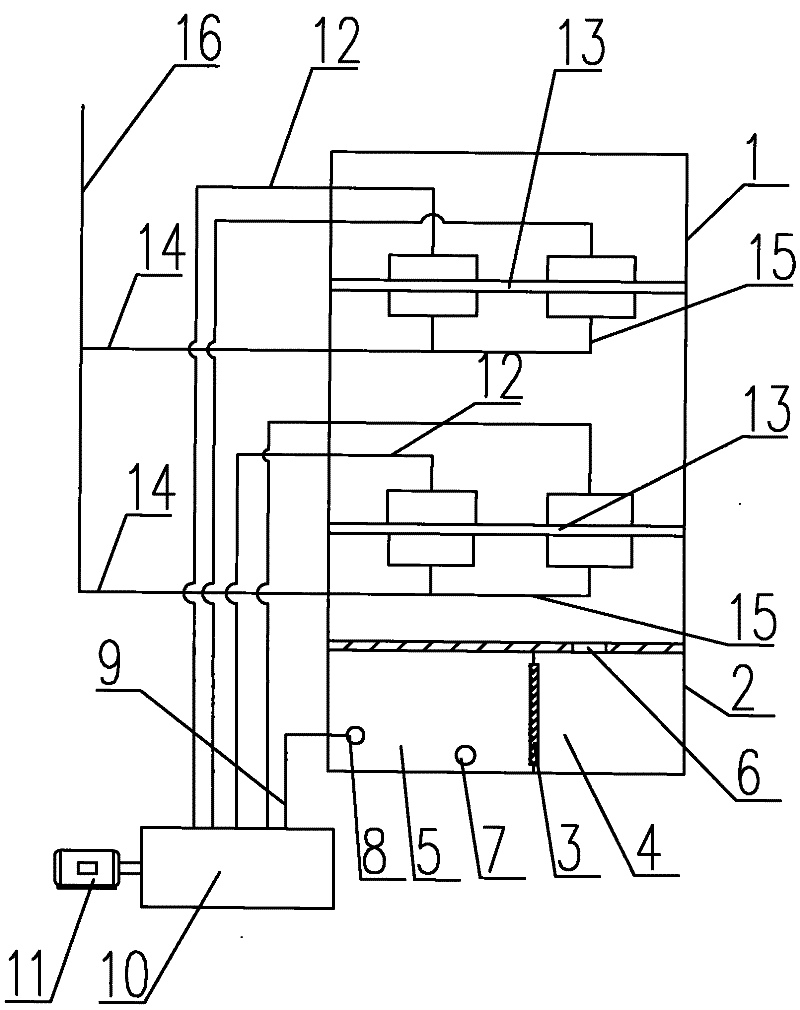

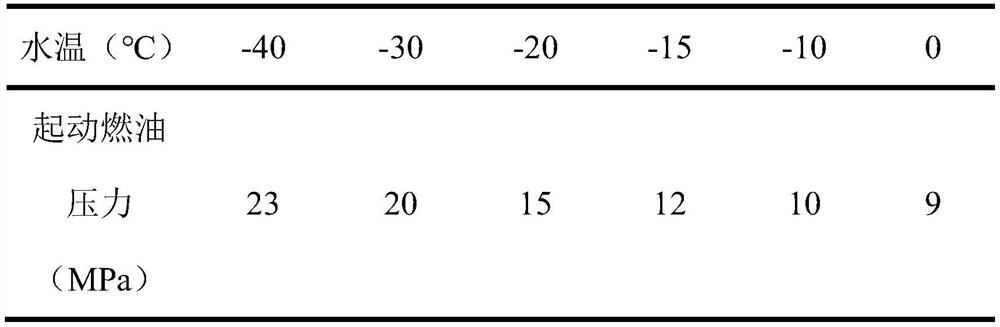

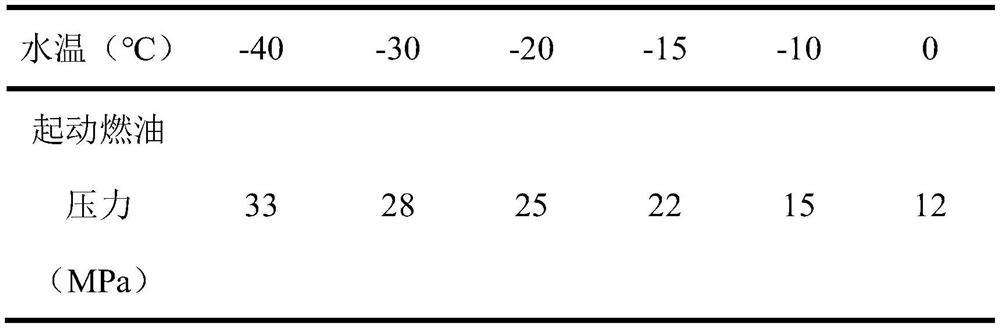

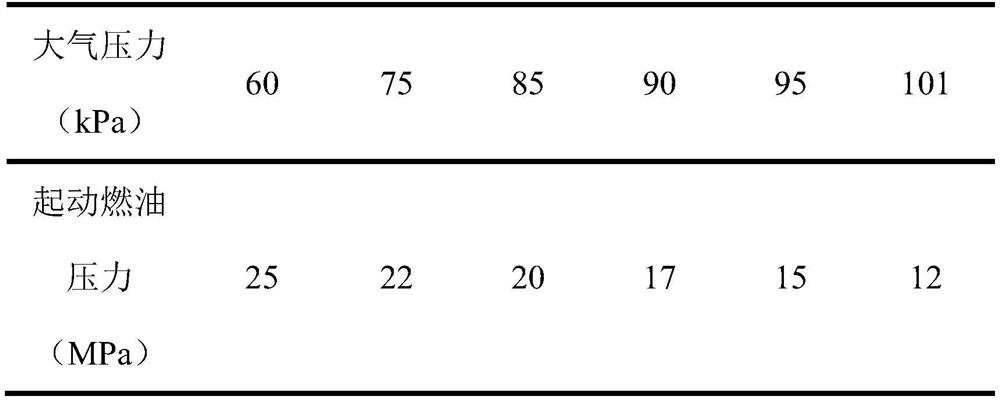

A fuel injection control method for a vehicle equipped with a direct injection engine

The invention relates to the technical field of automobile control, in particular to a fuel injection control method for a vehicle equipped with a direct injection engine. The fuel injection activation conditions include the activation conditions based on fuel rail fuel pressure and the activation conditions based on the number of engine operating cycles. Fuel injection is allowed only when the two activation conditions are met at the same time; the activation conditions based on fuel rail fuel pressure refer to the current fuel rail pressure value Greater than the minimum fuel rail fuel pressure determined based on the current engine water temperature and the ambient atmospheric pressure of the engine; the activation condition based on the number of engine operating cycles means that the actual number of engine operating cycles is greater than the minimum number of engine operating cycles determined based on the current engine water temperature. The present invention fully considers the control method of various factors affecting the fuel atomization effect, takes into account the influence of water temperature, atmospheric pressure and engine operation cycle times on the fuel atomization effect, and selects the most reasonable fuel injection control scheme to achieve Optimum spray effect.

Owner:DONGFENG MOTOR CORP HUBEI

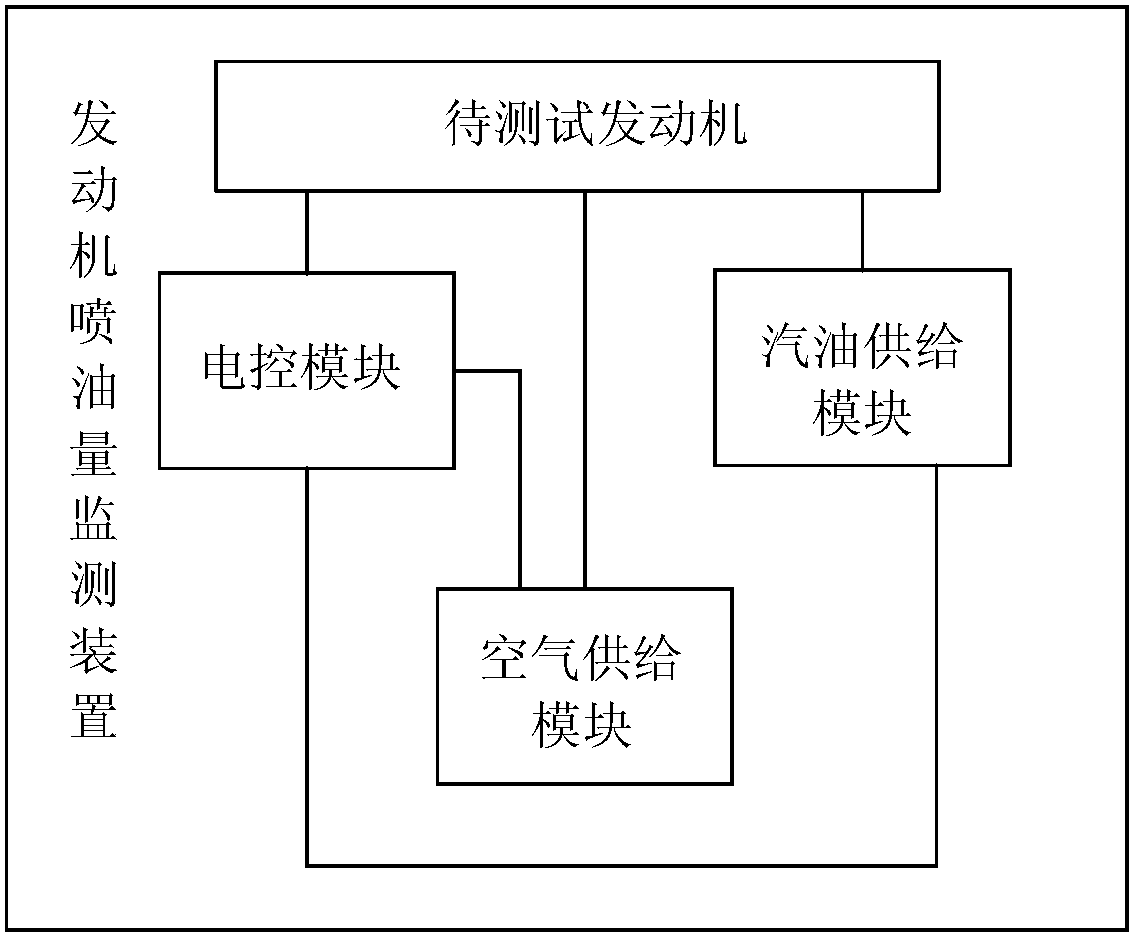

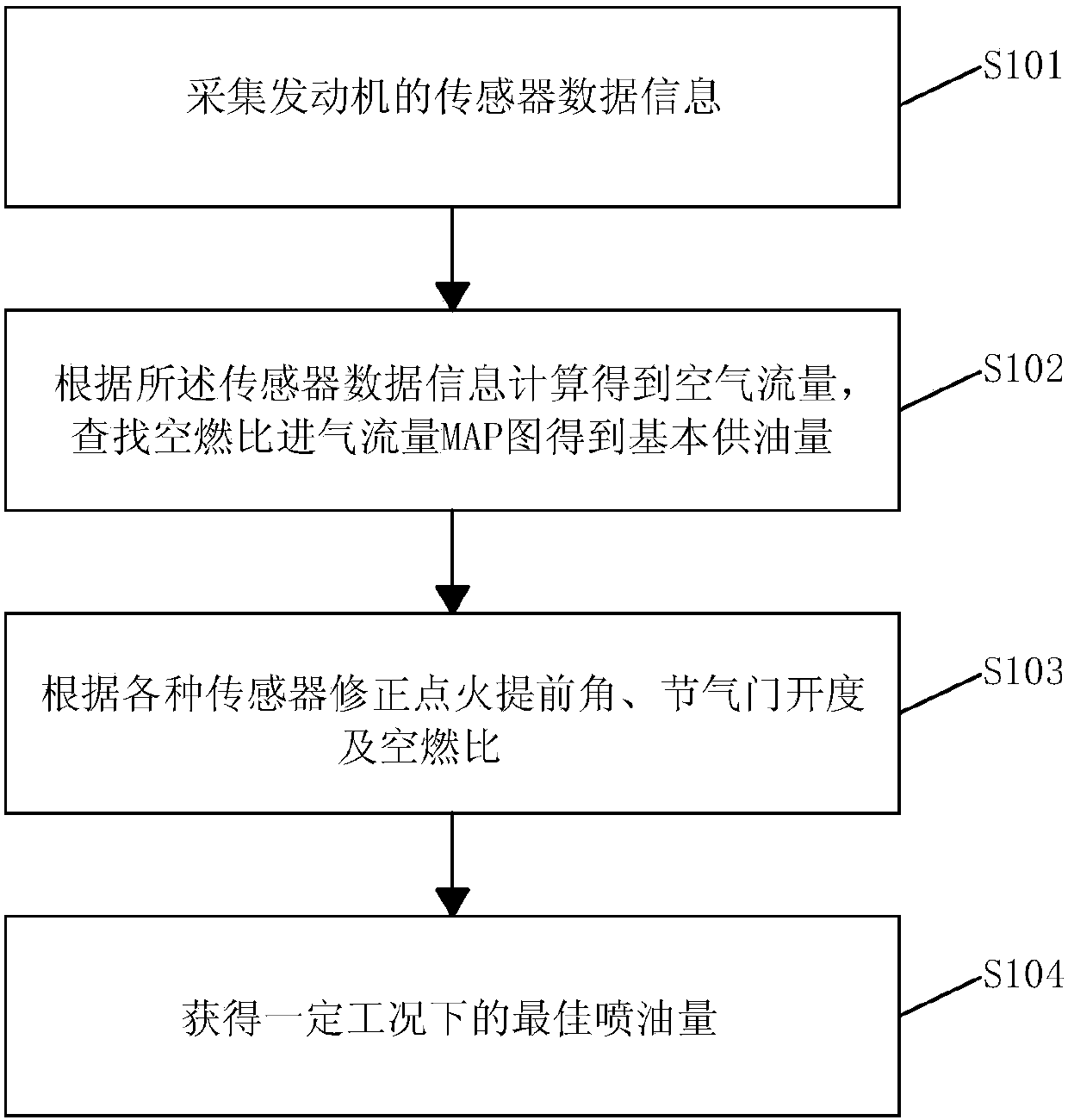

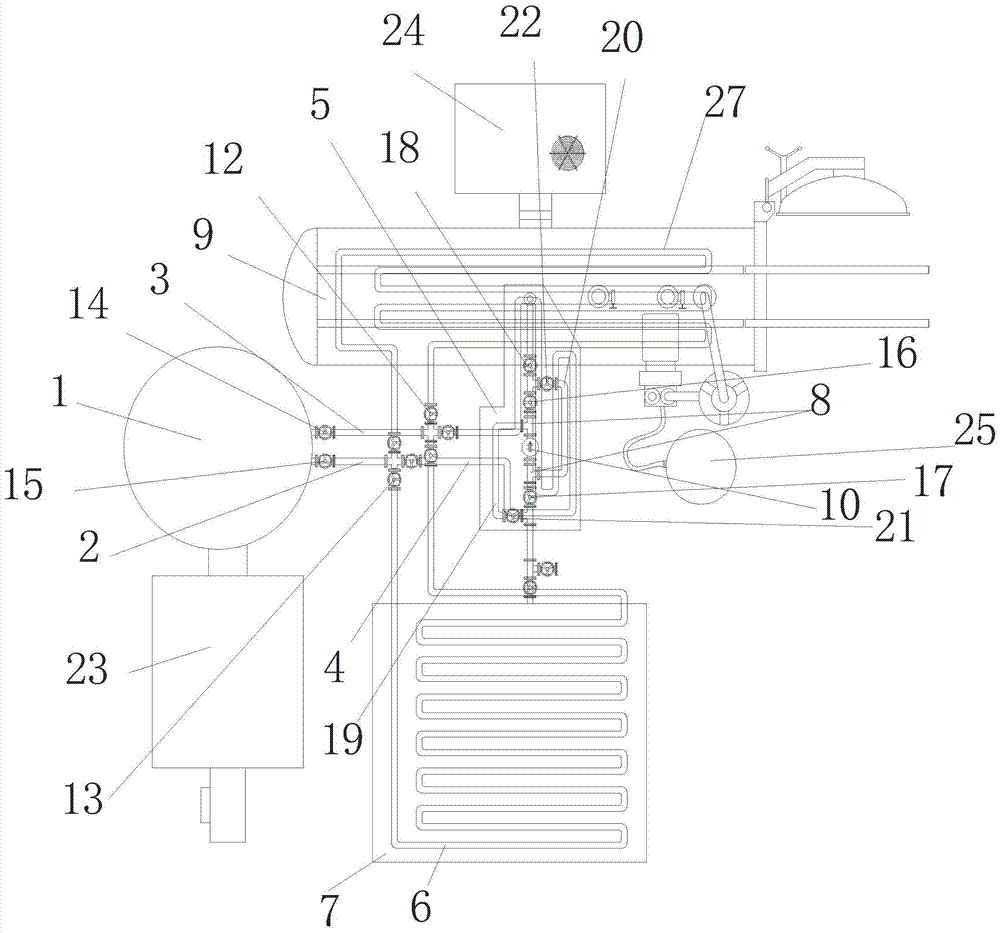

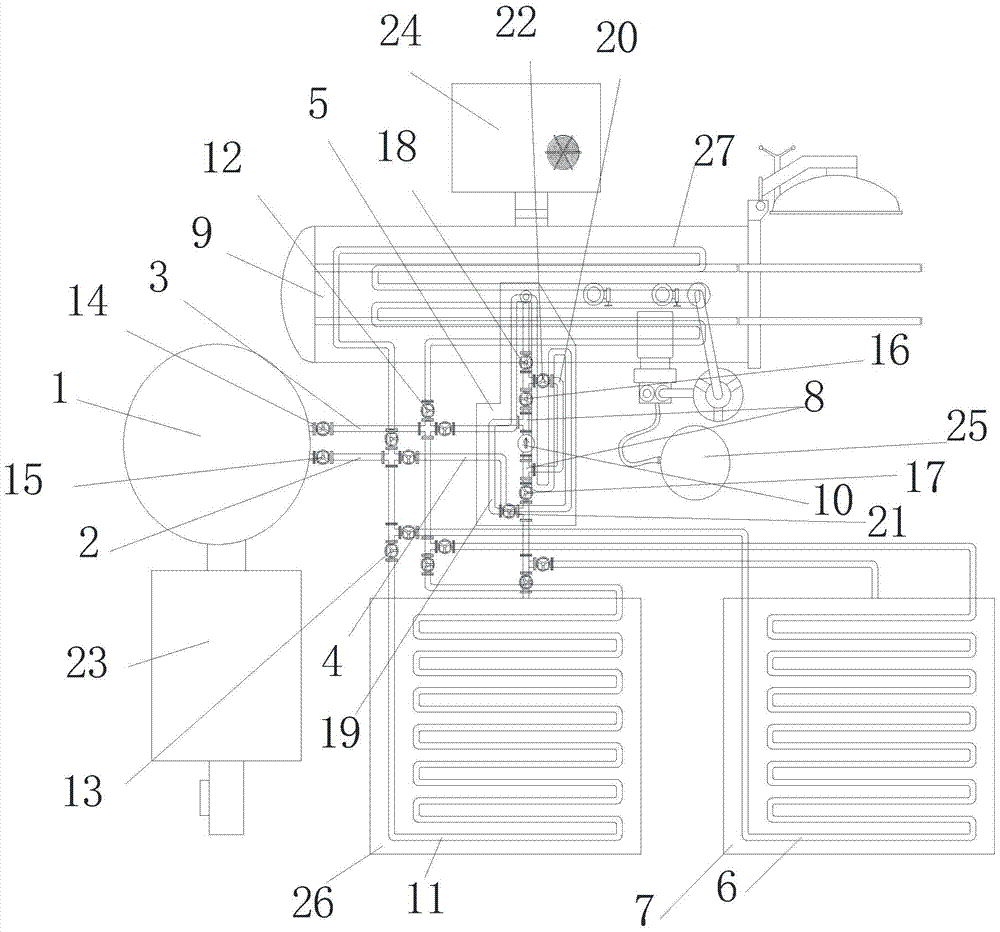

Engine fuel-injection capacity monitoring device and method

InactiveCN107559097AGood fuel injectionSimple structureElectrical controlMachines/enginesThrottle openingAir–fuel ratio

The invention discloses an engine fuel injection quantity monitoring device and method. The method includes the following steps: S101 , collecting sensor data information of the engine; S102 , calculating and obtaining air flow according to the sensor data information, and searching for an air-fuel ratio intake flow MAP The basic fuel supply amount is obtained from the figure; S103, the ignition advance angle, the throttle valve opening and the air-fuel ratio are corrected according to various sensors; S104, the optimal fuel injection amount under a certain working condition is obtained. The present invention can accurately and quickly obtain the optimum fuel injection quantity of the engine, and provides data execution for the related debugging of the engine in the later stage, and the present invention has a simple structure and is easy to operate.

Owner:邹科颖

A multifunctional integrated dryer and its realization method

ActiveCN105459235BImprove stabilityEasy to usePretreatment apparatusPressure impregnationHeat conductingFuel tank

The invention discloses a multi-functional integral drier. The multi-functional integral drier comprises a heat conducting oil furnace, wherein a heat conduction oil circulating exhaust pipe and a heat conducting oil circulating return pipe are connected to the heat conducting oil furnace, the heat conducting oil circulating exhaust pipe is connected with one end of a first heating pipe, the other end of the first heating pipe is connected with the heat conducting oil circulating return pipe, and the first heating pipe enters an oil groove; the heat conducting oil circulating exhaust pipe is connected with one end of a second heating pipe, the other end of the second heating pipe is connected with the heat conducting oil circulating return pipe, and the second heating pipe enters an oil storage tank; the oil storage tank is connected to a tank body through oil exhaust pipes, and an oil pump is arranged on the oil exhaust pipes which are arranged in the oil groove; the tank body is connected with a high frequency generator. The invention further discloses an implementation method of the multi-functional integral drier. The multi-functional integral drier disclosed by the invention has the characteristics of being simple in structure, low in building cost, high in production efficiency, broad in application scope, good in timber stability, good in use effects and the like.

Owner:东阳市尚德电器机械有限公司

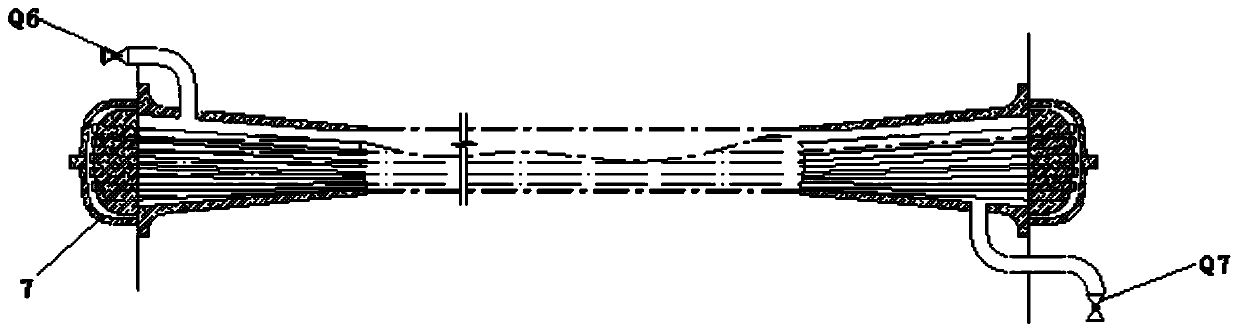

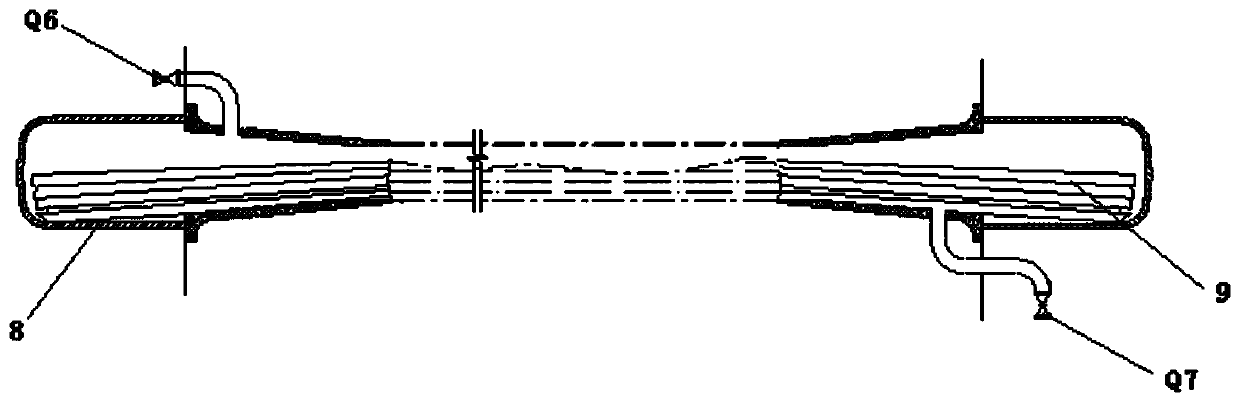

Antirust oil injection device for steel cable in prestressed duct and oil injection method thereof

ActiveCN106988536AThe principle is simpleEasy to operateBridge erection/assemblyBuilding material handlingMachiningInjection device

The invention relates to a device and method for a prestressed duct, in particular to an antirust oil injection device for a steel cable in a prestressed duct and an oil injection method thereof, and belongs to the technical field of building engineering construction. The device and the method are designed for complex environments with large tonnage, super-long cables and anomalous events and are achieved through machining and manufacturing, simulation test and entity application practice. The device is simple in principle and convenient to operate; the profile occupied space is small, the weight is low, carrying is easy, the manufacturing cost is low, and the safety risk of high-altitude operation is low; the oil injection effect is good, cost is saved, efficiency is high, cost is low, and practicability is high; and at the same time, design requirements are met, the cost can also be lowered, the efficiency is improved, the time limit for a project is shortened, and the project quality is improved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com