Silicone-oil coater for injector assembler

A technology of assembling machine and applying silicone oil, applied in the field of machinery, can solve the problems of fixed spraying effect of the fuel injection mechanism, easy spraying of silicone oil outside the cylinder, but not spraying into the cylinder, etc., to achieve good fuel injection effect, avoid pollution, The effect of sufficient injection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

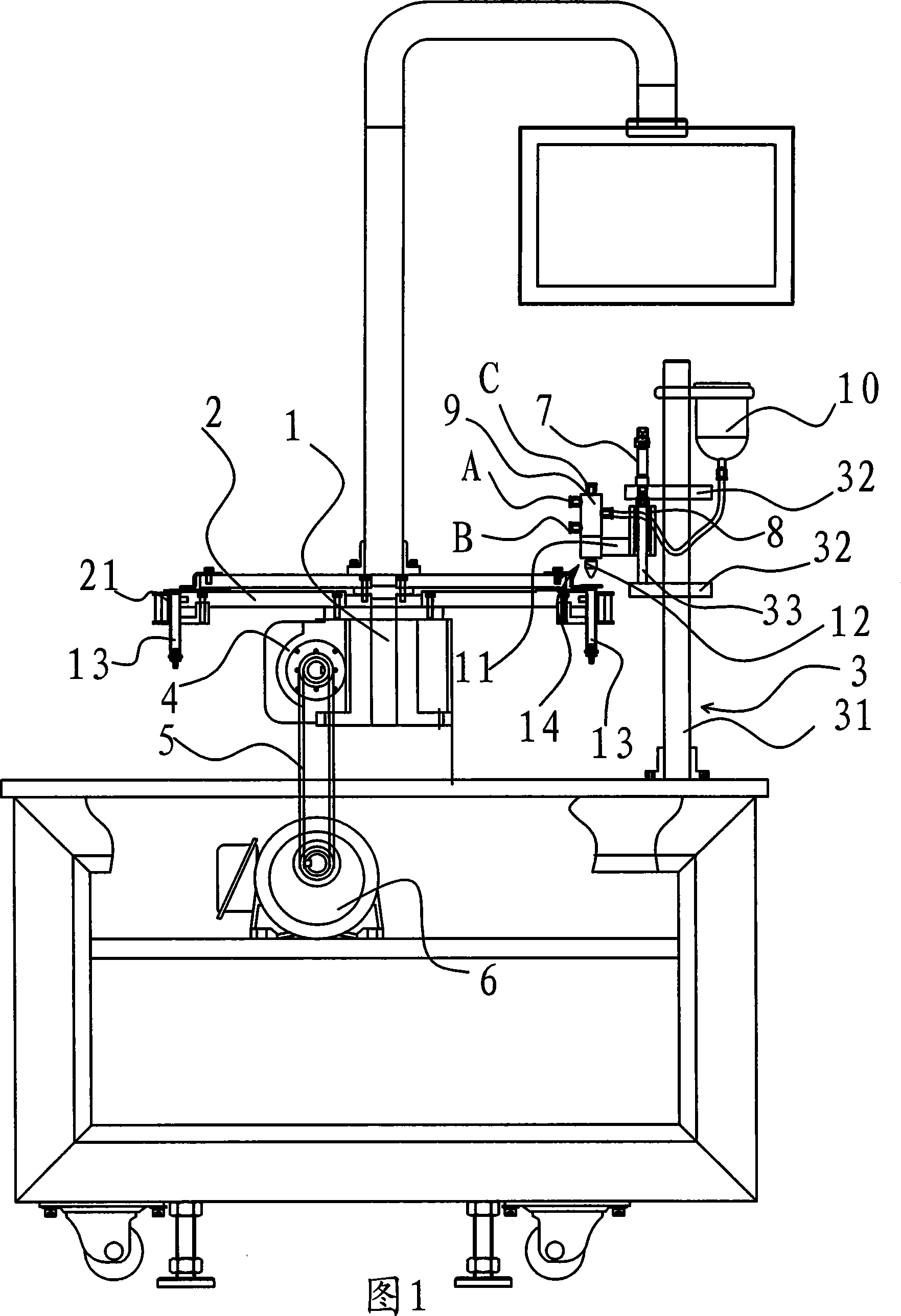

[0021] As shown in Figures 1 and 2, the silicone oil coating device of the syringe assembly machine includes a rotating shaft 1, a turntable 2, an oil spray frame 3 and an oil injection mechanism.

[0022] The above-mentioned rotating shaft 1 is fixedly connected on the splitter 4 , the splitter 4 is connected with the motor 6 through the belt 5 , and the above-mentioned rotating disk 3 is fixedly connected on the rotating shaft 1 . After the motor 6 is started, the rotating shaft 1 rotates according to the steps set by the divider 4 . A number of bayonets 21 for fixing the barrel 13 are evenly distributed on the edge of the turntable 2 , and an oil spray frame 3 is arranged beside the turntable 2 , and the above-mentioned oil spray mechanism is arranged on the oil spray frame 3 .

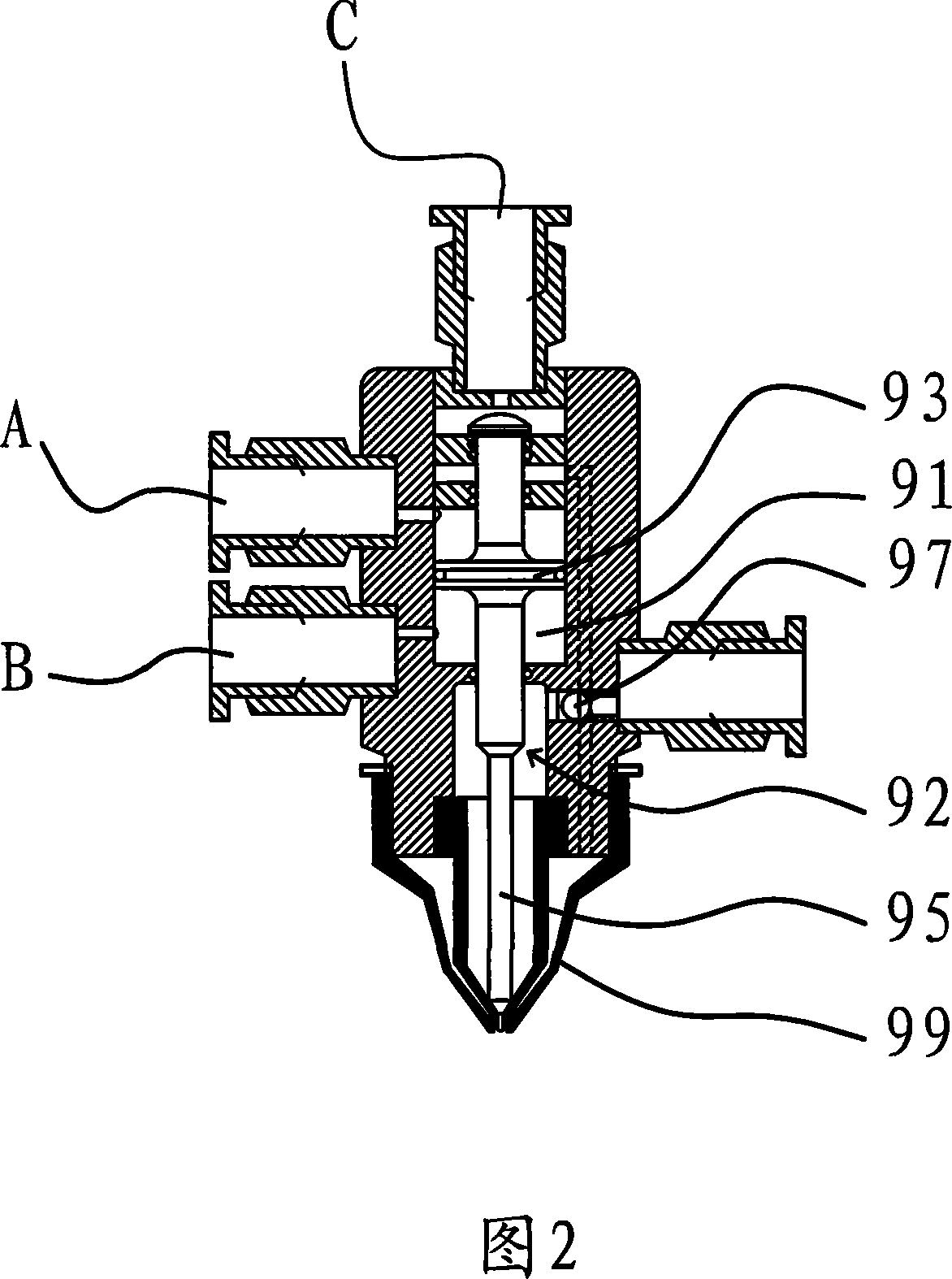

[0023] The oil injection mechanism includes an oil injection head 9 and an oil cup 10 connected with the oil injection head 9 . The fuel injector 9 has an air chamber 91 and a liquid chamber 92, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com