A fuel injection control method for a vehicle equipped with a direct injection engine

A control method and engine technology, applied in the direction of engine control, machine/engine, fuel injection control, etc., can solve the problem of not considering air pressure, etc., and achieve the effect of great promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with embodiment.

[0032] In this embodiment, the fuel injection control of the engine is divided into three types according to the operation conditions of the fuel rail pressure sensor, the high pressure oil pump and the low pressure oil pump.

[0033] The first type, when the fuel rail pressure sensor, high-pressure fuel pump, and low-pressure fuel pump do not have any failures, the fuel injection activation conditions must be met before fuel injection is allowed. The fuel injection activation conditions include activation conditions based on fuel rail fuel pressure and engine operating cycles The number of activation conditions, fuel injection is allowed only when the two activation conditions are met at the same time, otherwise fuel injection is not allowed.

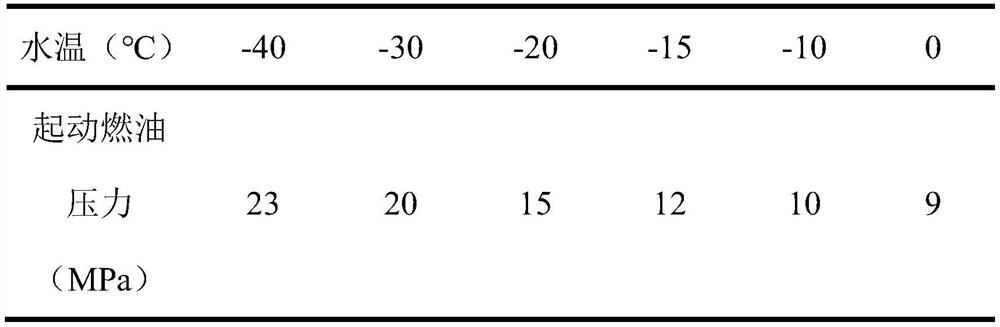

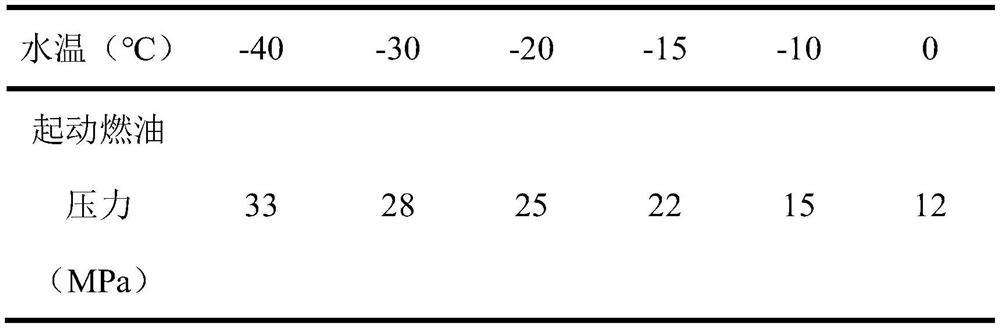

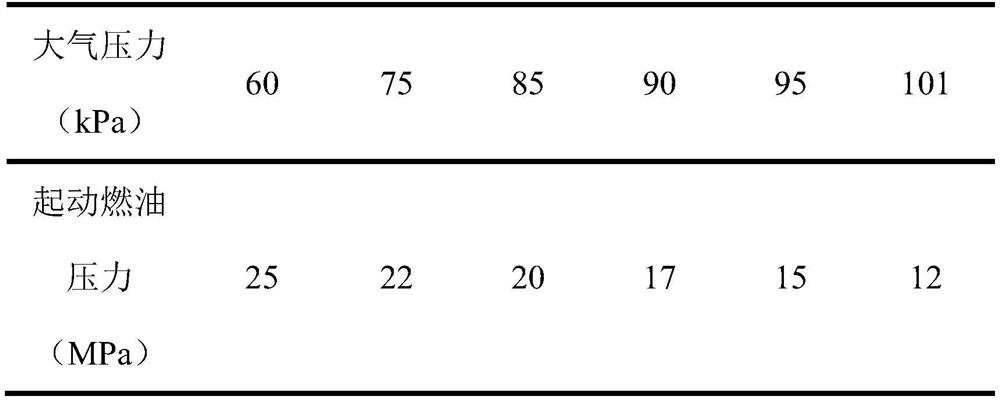

[0034] The activation condition based on fuel rail fuel pressure refers to the situation that the current fuel rail pressure value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com