Patents

Literature

48results about How to "Spray oil evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

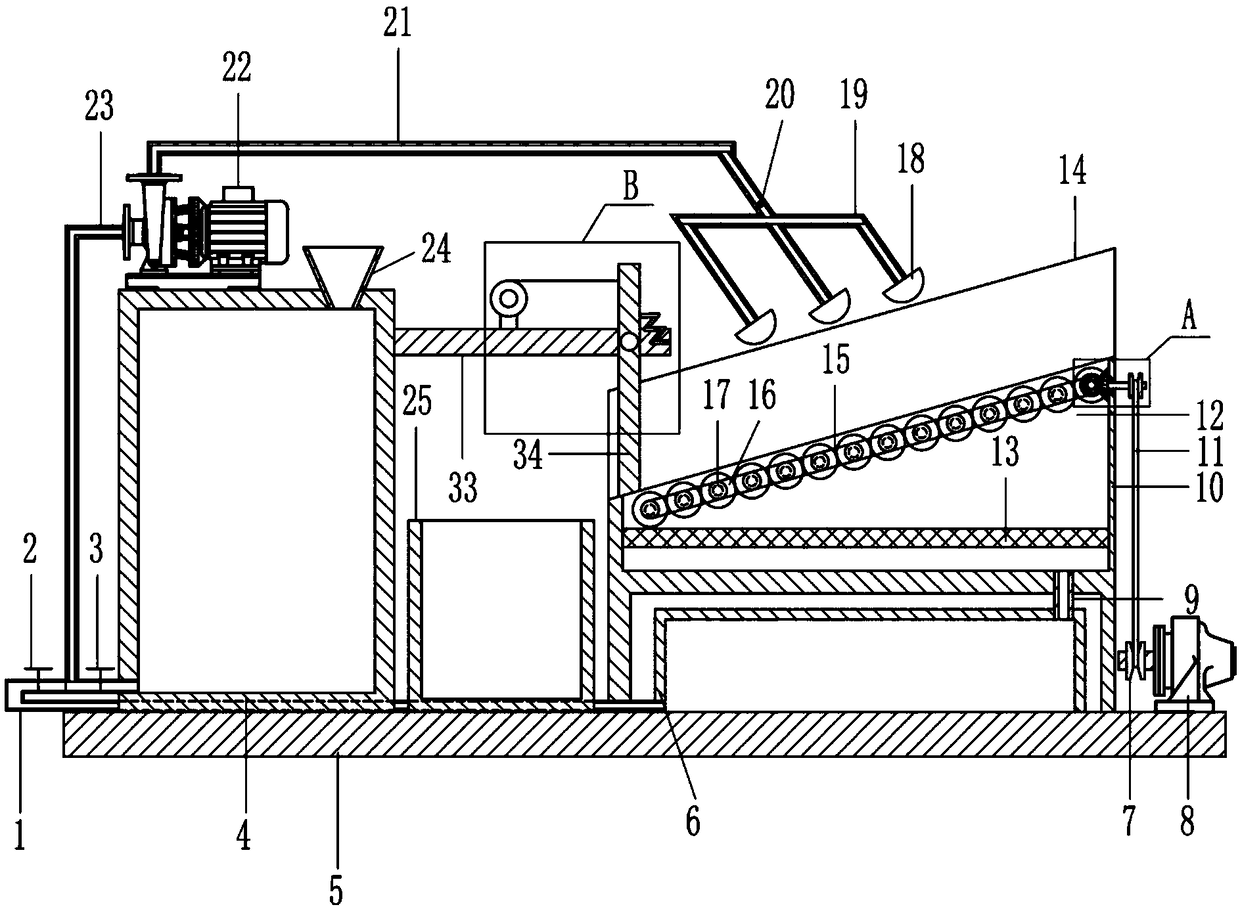

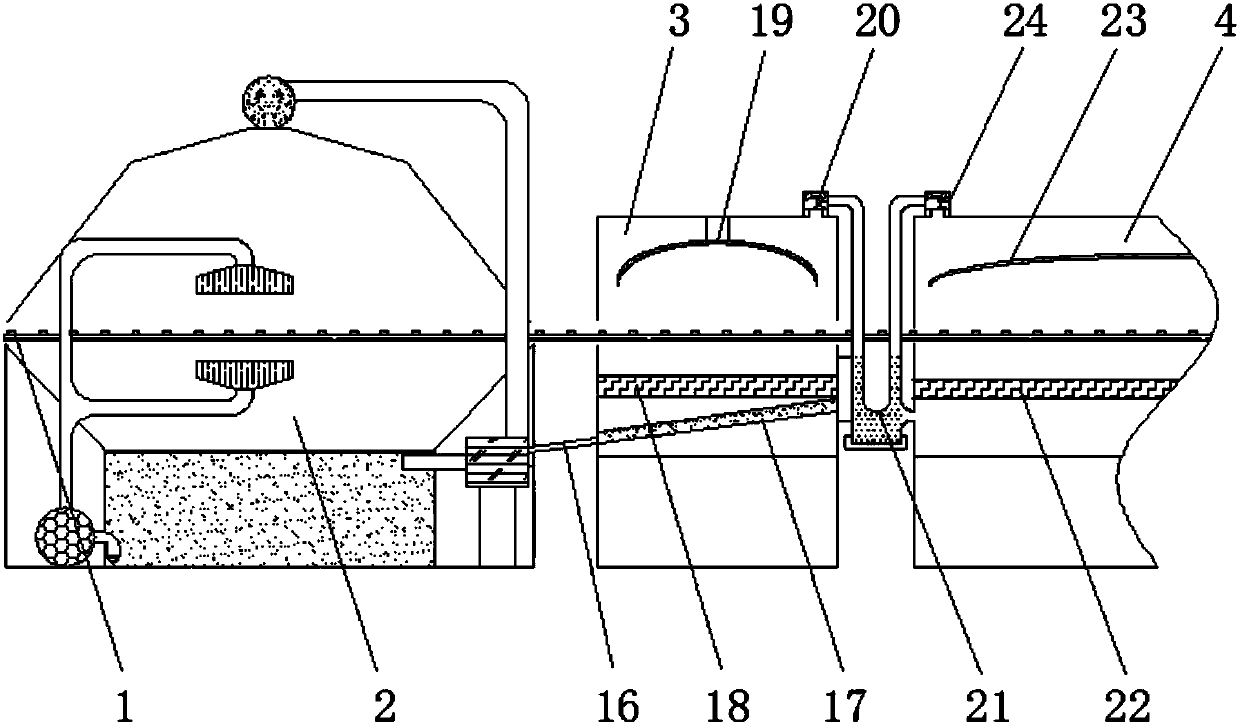

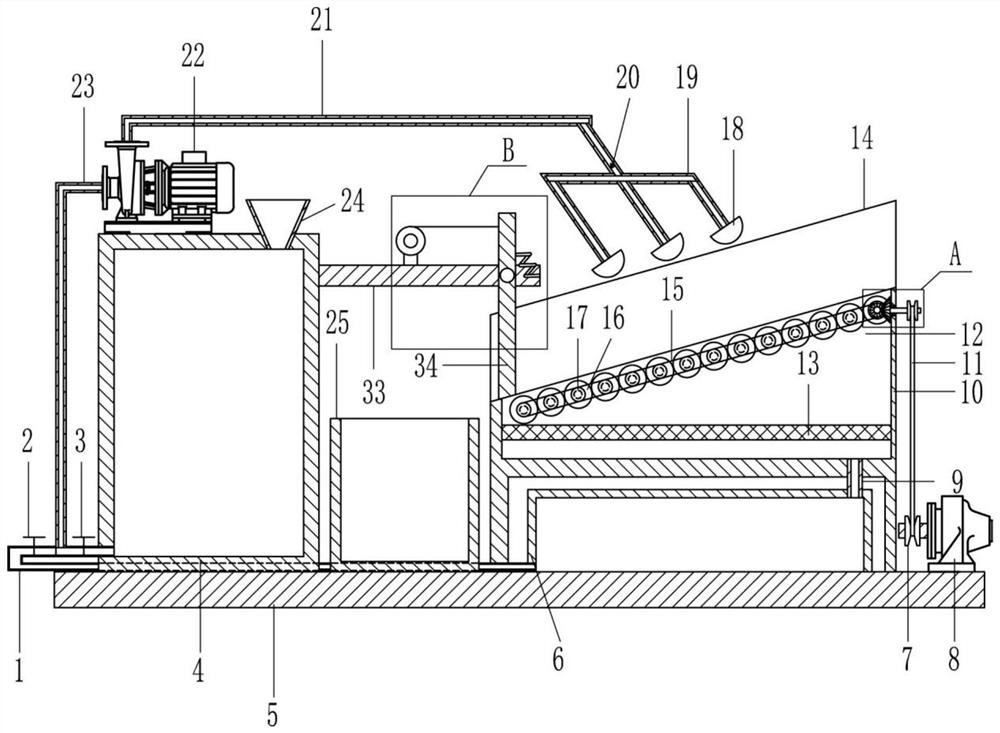

Flour mixing device of deep-fried dough stick machine

ActiveCN109006896AWell mixedImprove the mixing effectMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsDeep fryingAgricultural engineering

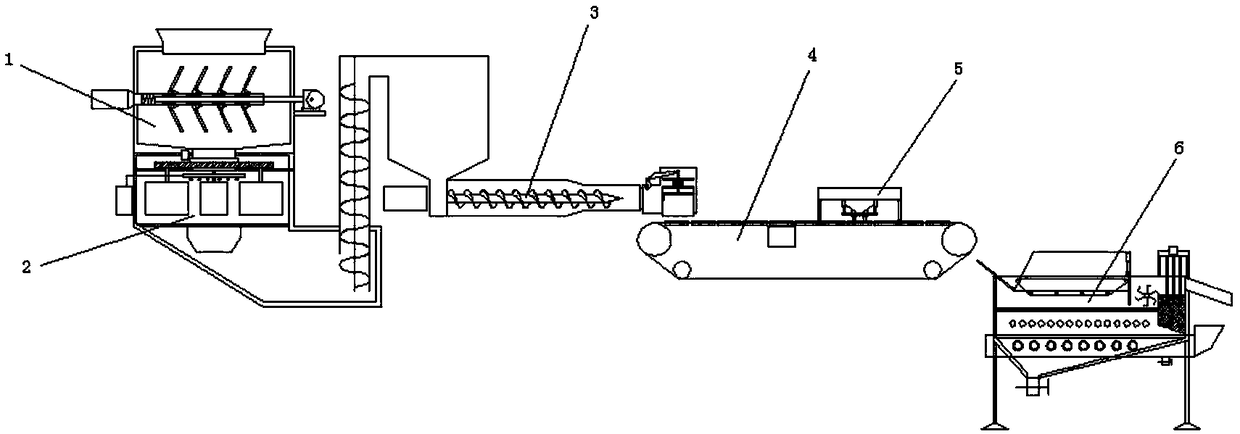

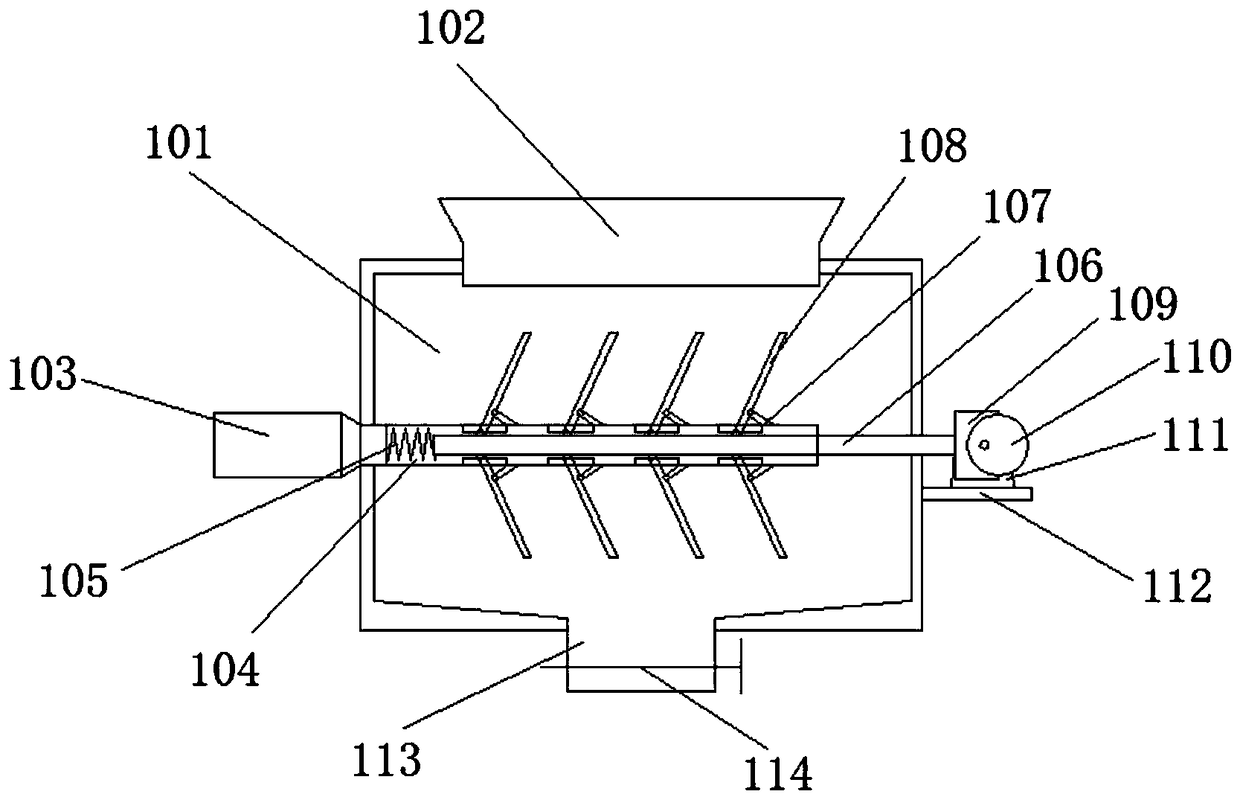

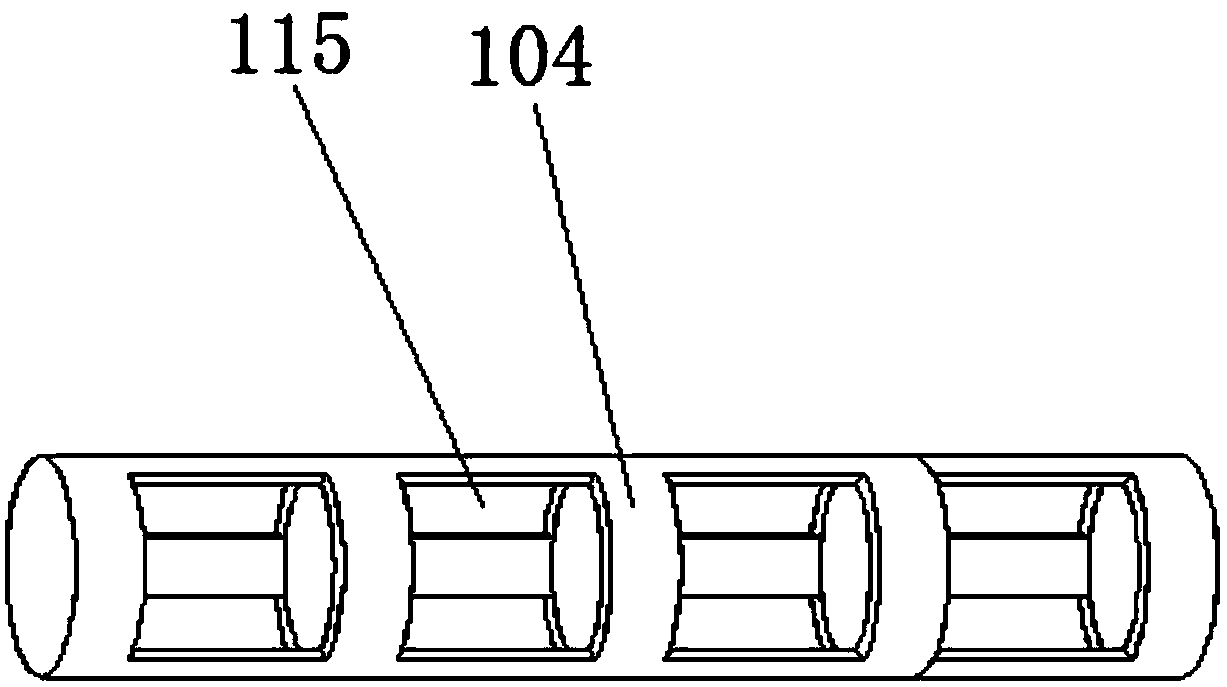

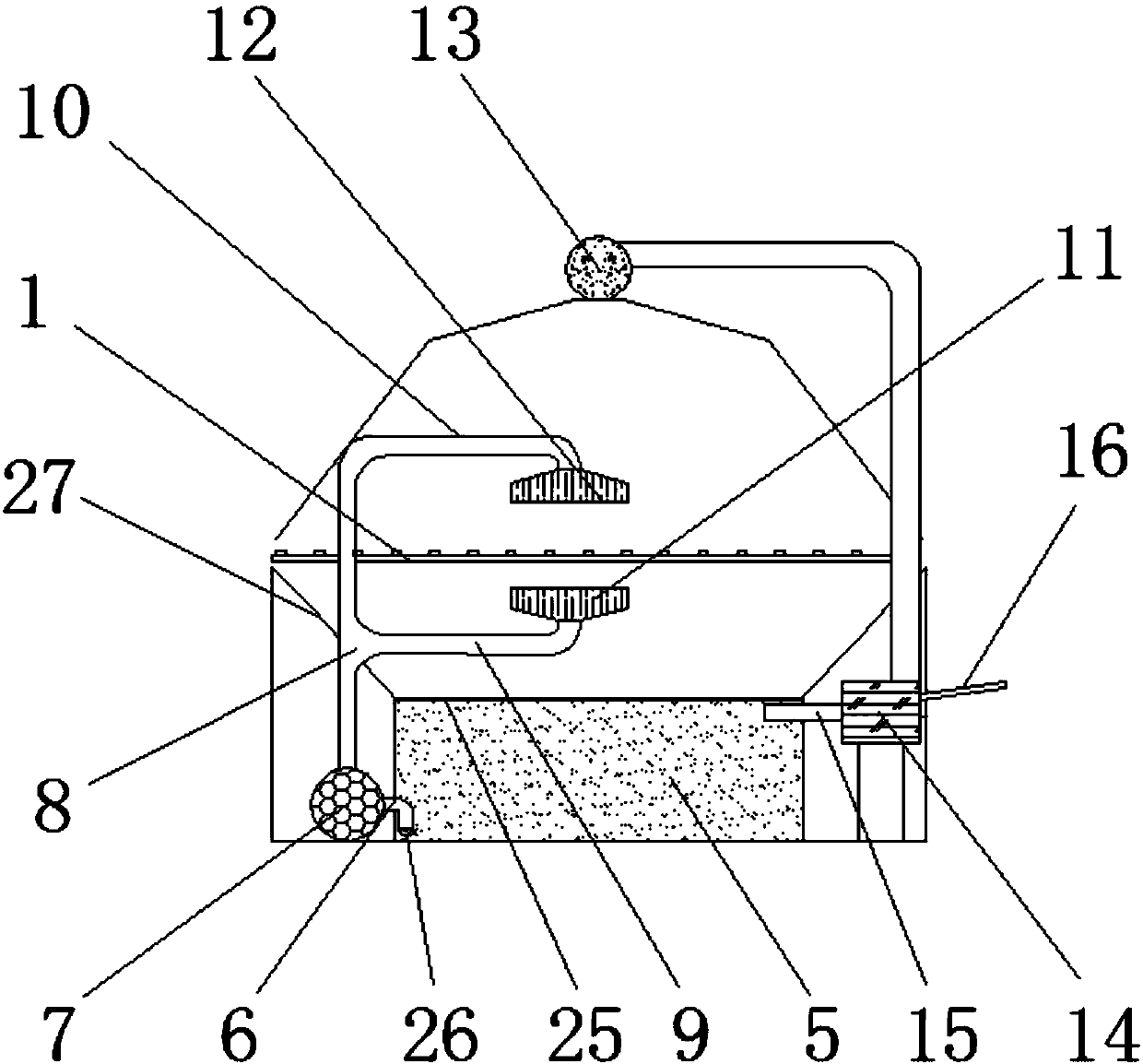

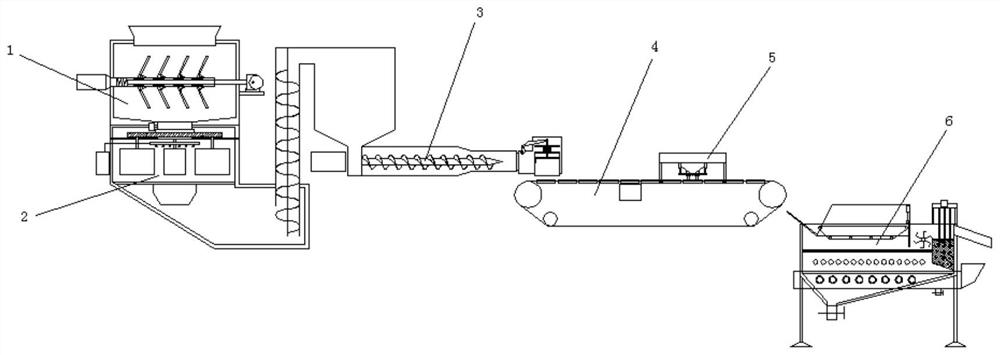

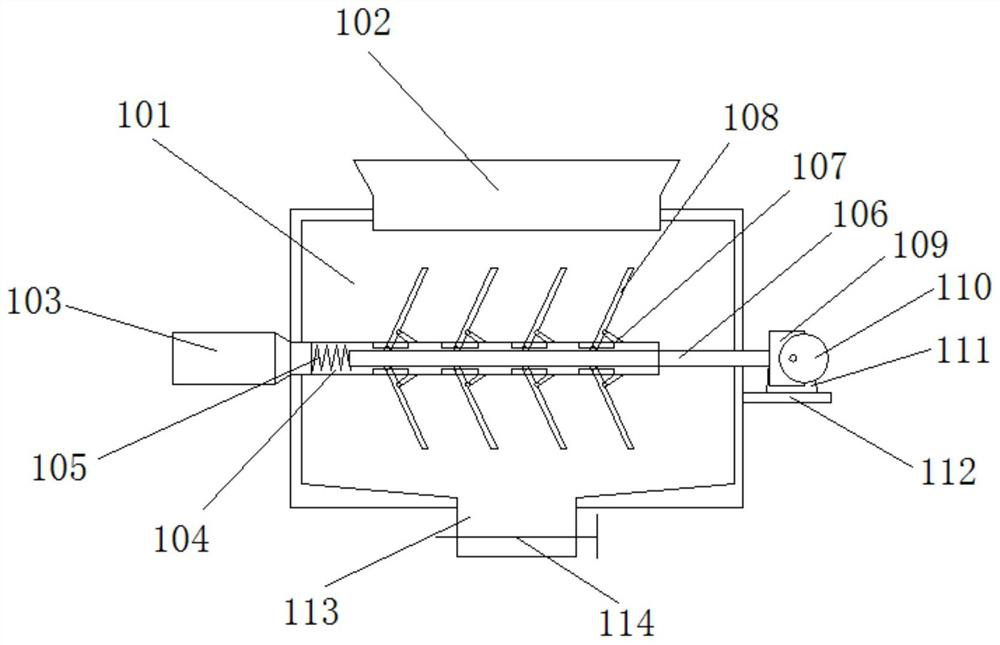

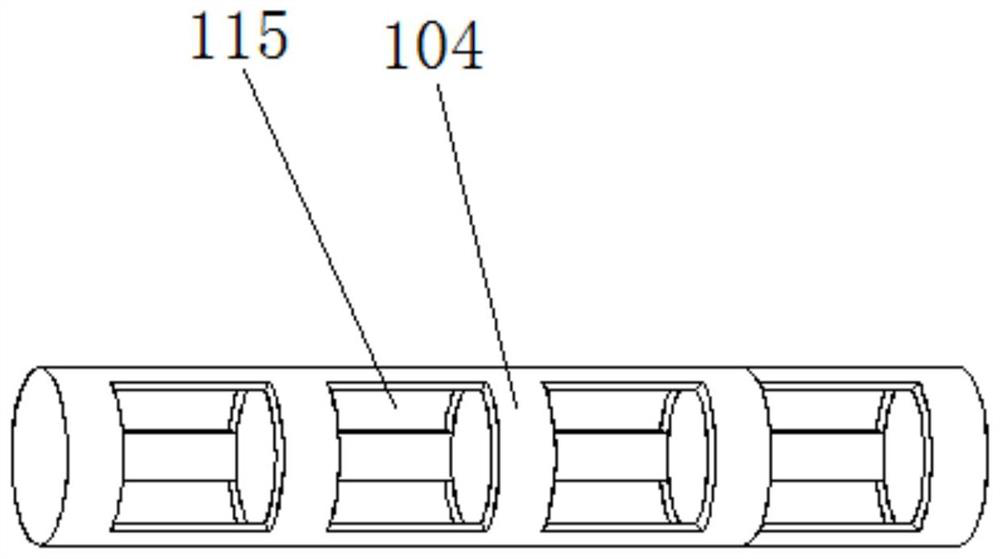

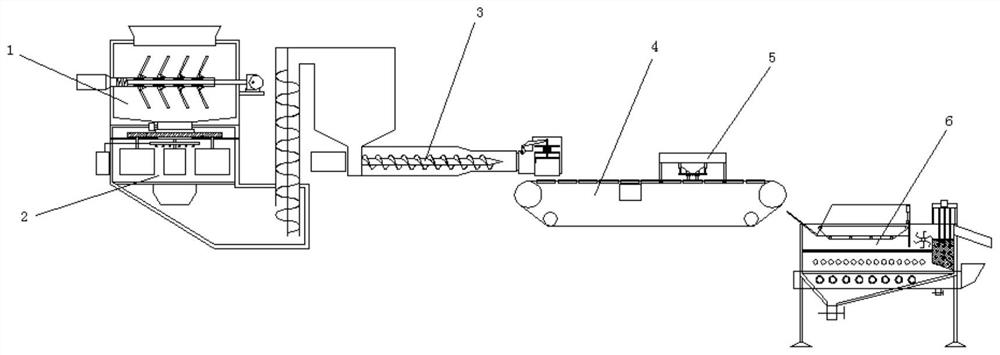

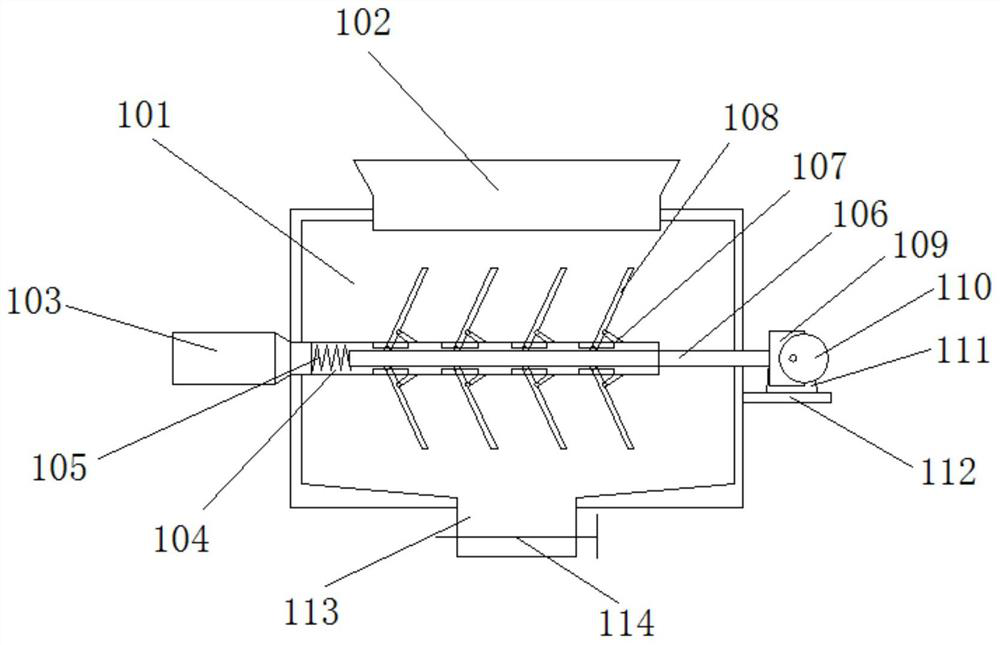

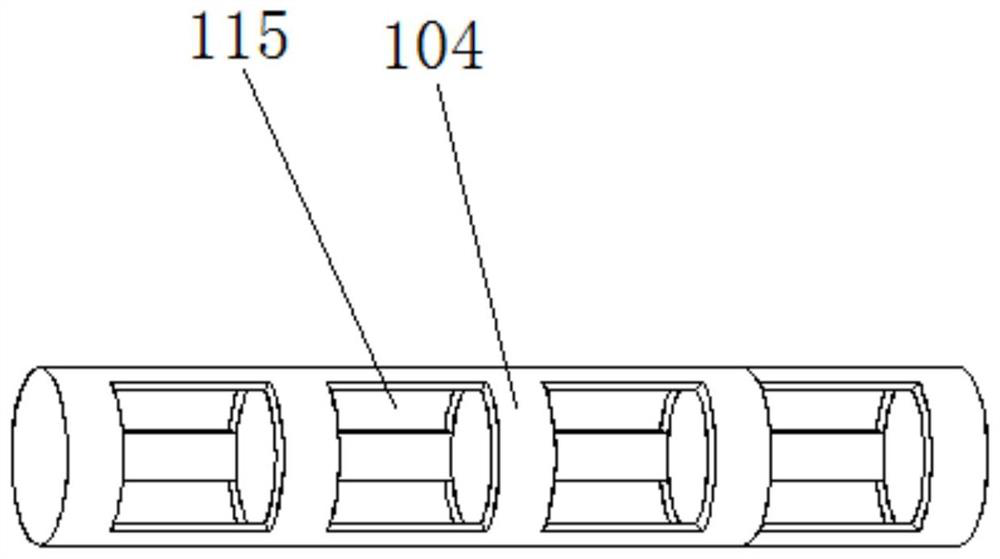

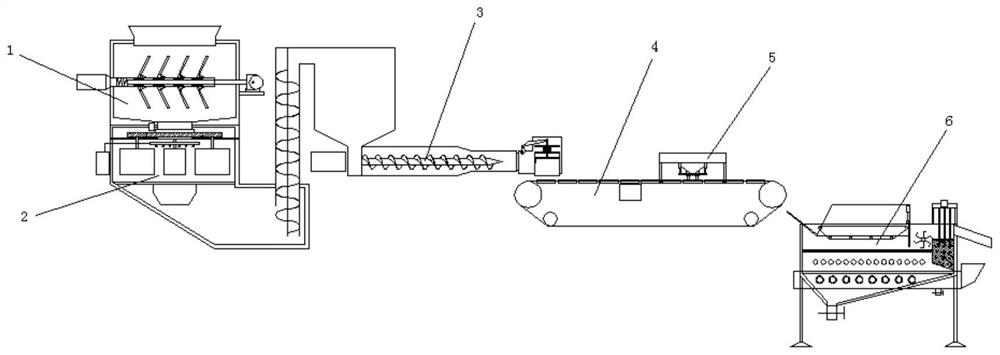

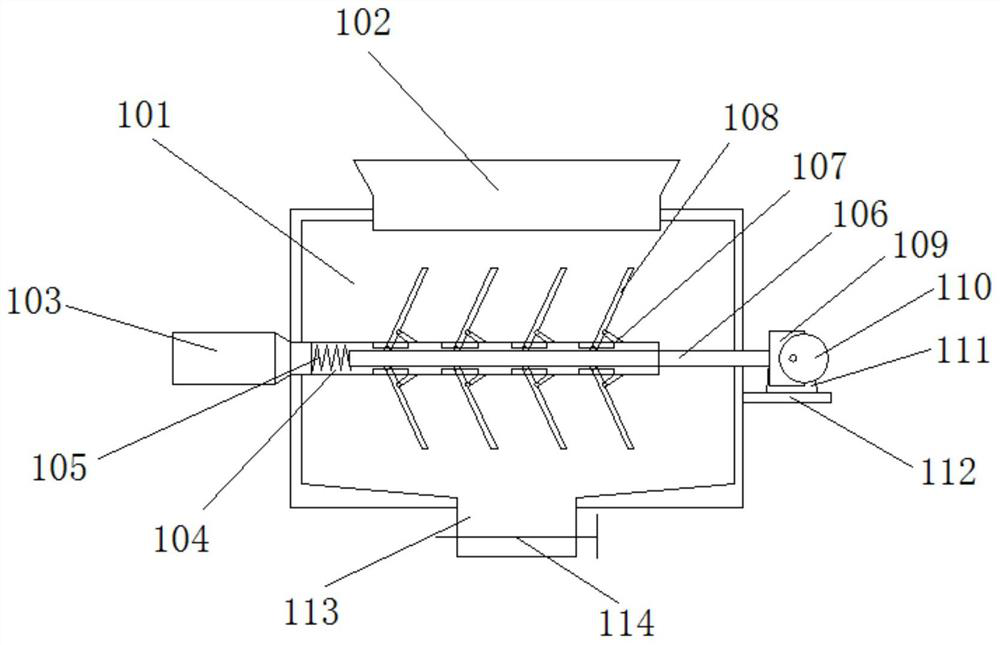

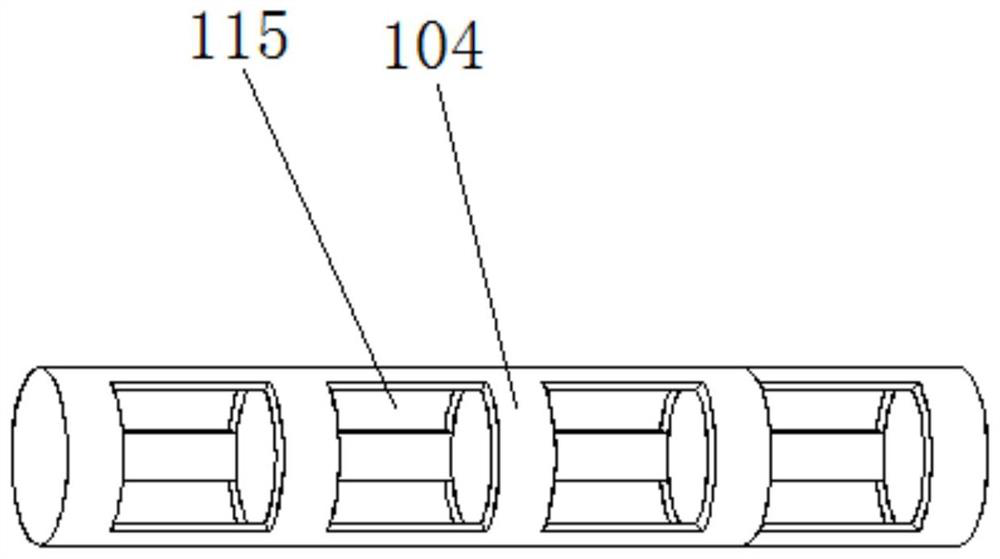

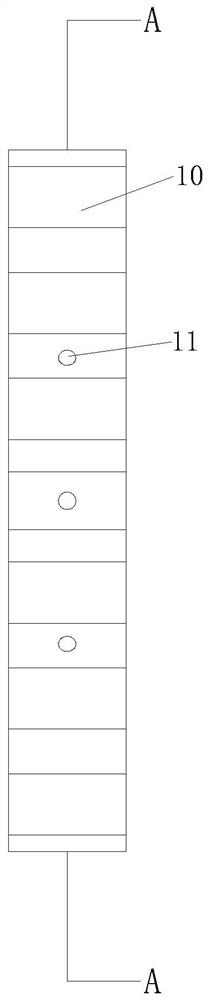

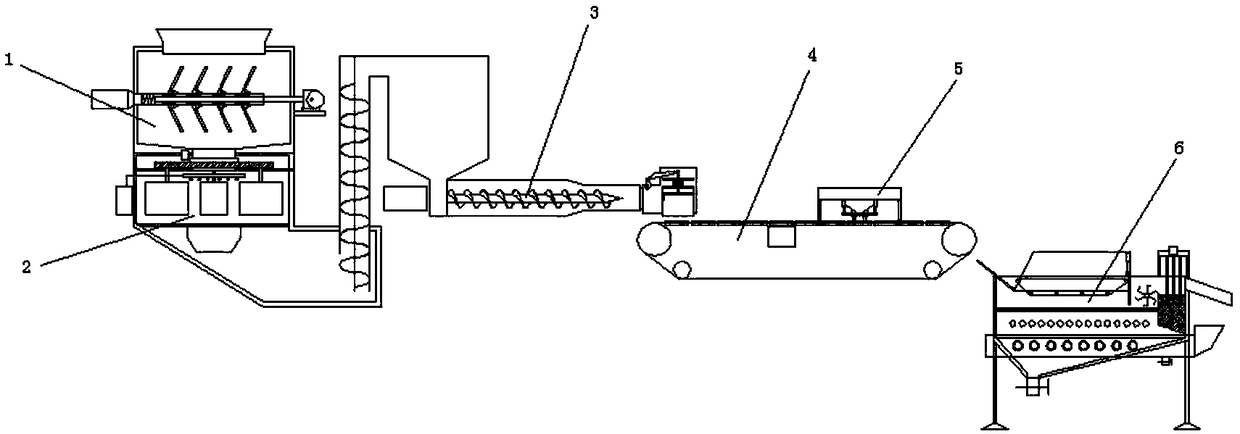

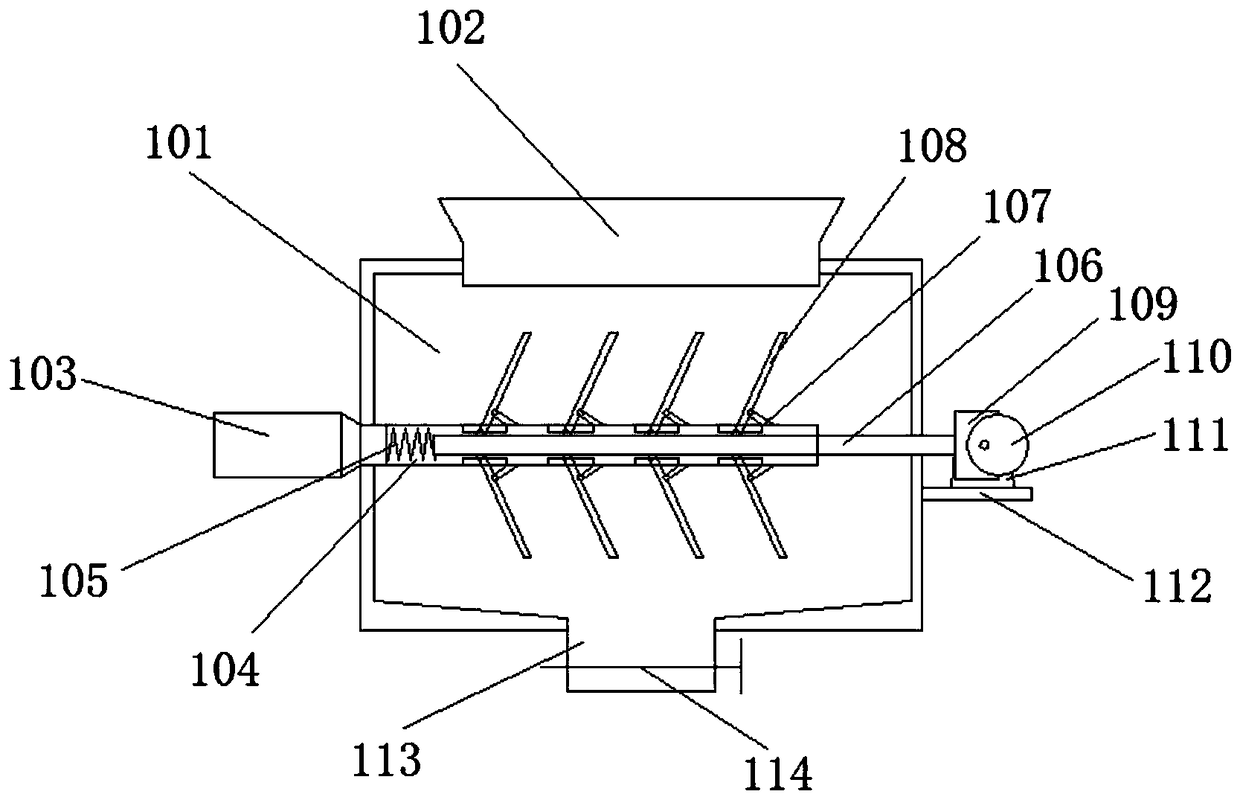

The invention discloses a flour mixing device of a deep-fried dough stick machine, and relates to the field of food processing. The flour mixing device includes a mixing mechanism, a dough kneading mechanism is arranged at the bottom of the mixing mechanism, a leavening cabin is connected to the right side of the dough kneading mechanism through a lifting machine, an extrusion machine is fixed tothe bottom of the leavening cabin, a discharging mechanism is arranged at the right end of the extrusion machine, a conveying machine is arranged below the discharging mechanism, a composite shaping mechanism is arranged at the middle of the conveying machine, a stretching detachment mechanism is arranged on the right portion of the conveying machine, and a deep-frying device is arranged at the bottom of the right end of the conveying machine. By adopting the flour mixing device of the deep-fried dough stick machine, a manual deep-fried dough stick making process can be stimulated, after wateris automatically added into flour and is mixed with the flour to make dough, the dough is kneaded, leavened, pressed, shaped and then stretched, finally, the dough is deeply fried, manual labor is greatly reduced, the mouthfeel of deep-fried dough sticks is ensured, the deep-fried dough sticks are efficiently and rapidly made, and the flour mixing device is suitable for being used in breakfast stores.

Owner:张乐

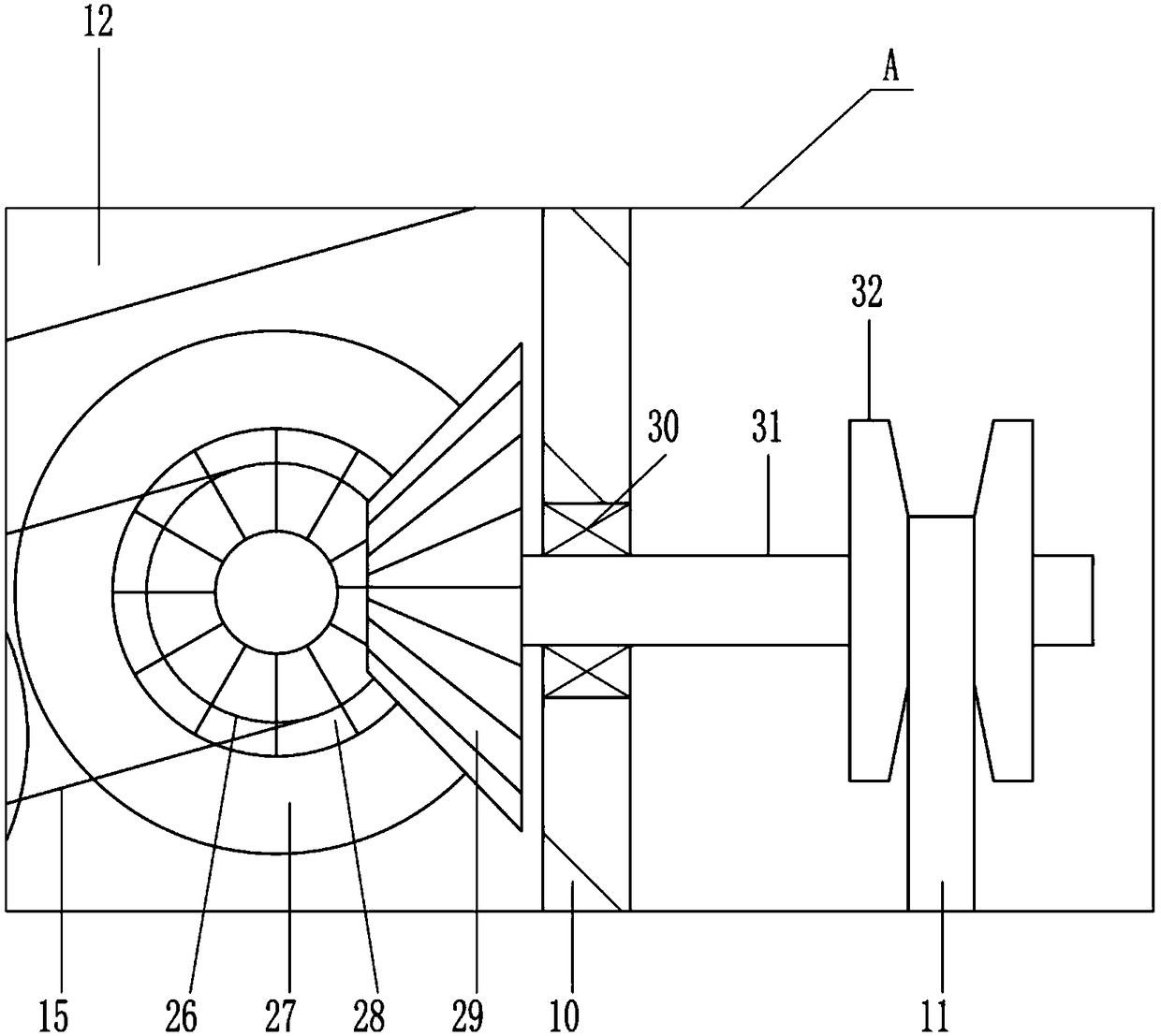

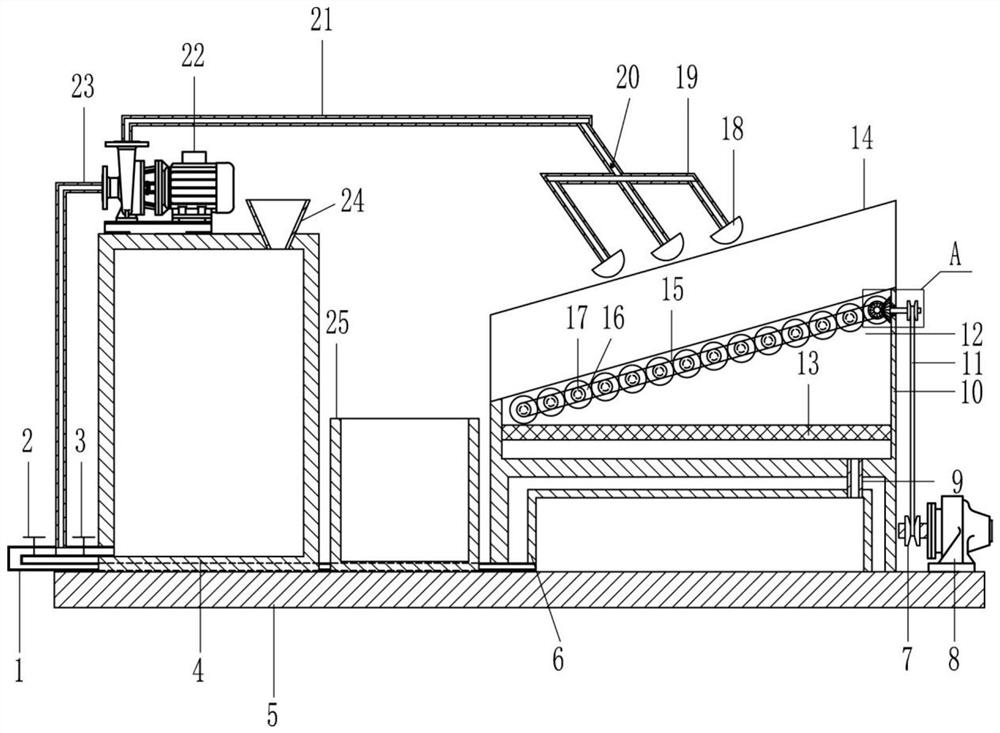

Oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing

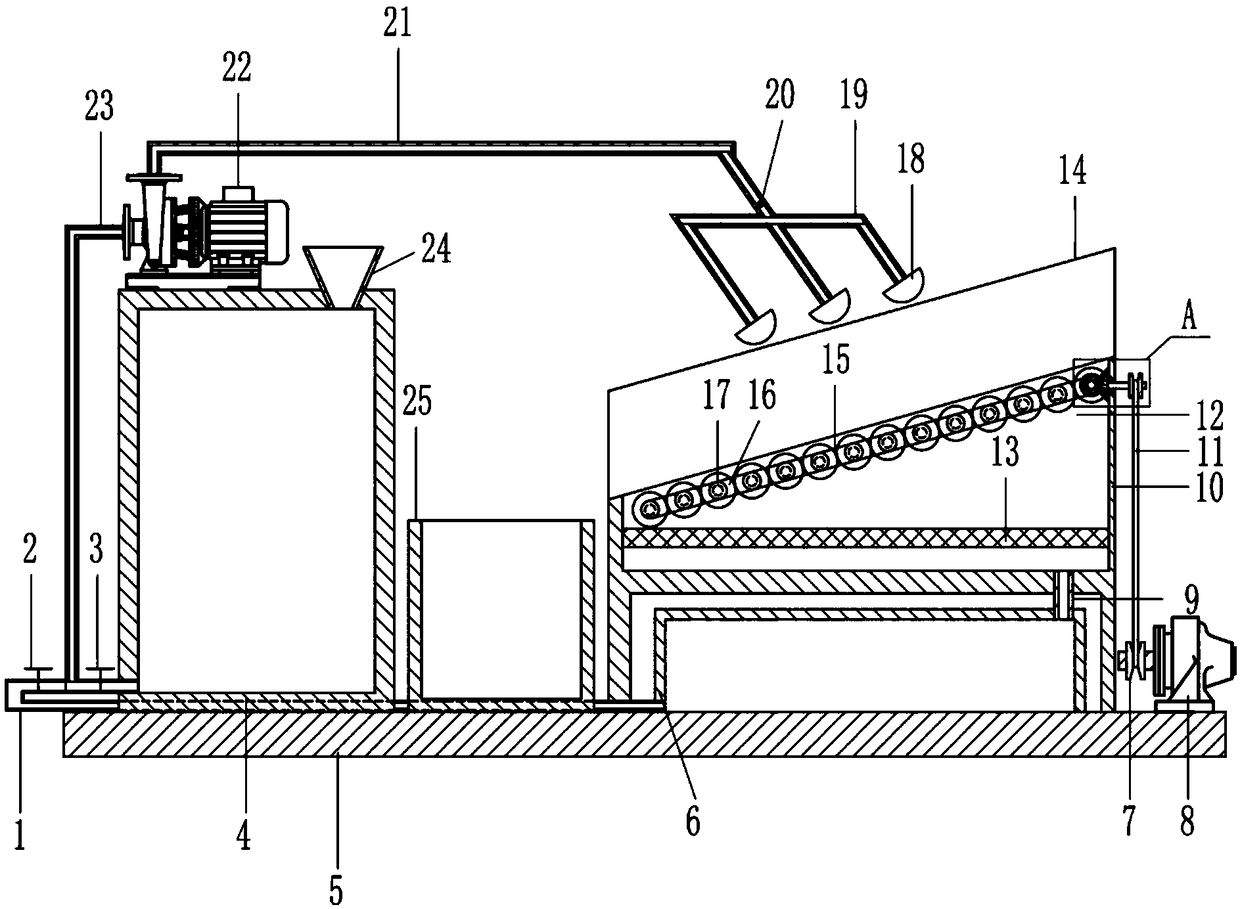

The invention relates to the field of loudspeaker box manufacturing, in particular to an oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing. The oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing is capable of saving energy, even in oil jetting treatment, capable of saving time and labor and convenient to operate. The oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing comprises an oil outlet pipe, a first valve, a second valve, an oil storage barrel, a fixed seat, an oil collecting hood, a first transmissionwheel, a motor, an oil discharging pipe, a mounting seat, a first transmission belt, a first baffle, a second transmission belt, a first conveying roller, a second transmission wheel, an oil jettingpipe, a flow dividing pipe, a one-way valve pipe, an oil delivering pipe, an oil pump, an oil pumping pipe, an oil inlet bucket, a collecting frame, a third transmission wheel, a second conveying roller, a first bevel gear and the like. The oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing achieves the effects of being capable of saving the energy, even in oil jettingtreatment, capable of saving time and labor and convenient to operate.

Owner:灵璧县浩翔信息科技有限公司

High-pressure gas oil injection device

InactiveCN104175388AEasy to sprayIncrease flow rateCeramic shaping apparatusProduct gasHigh pressure

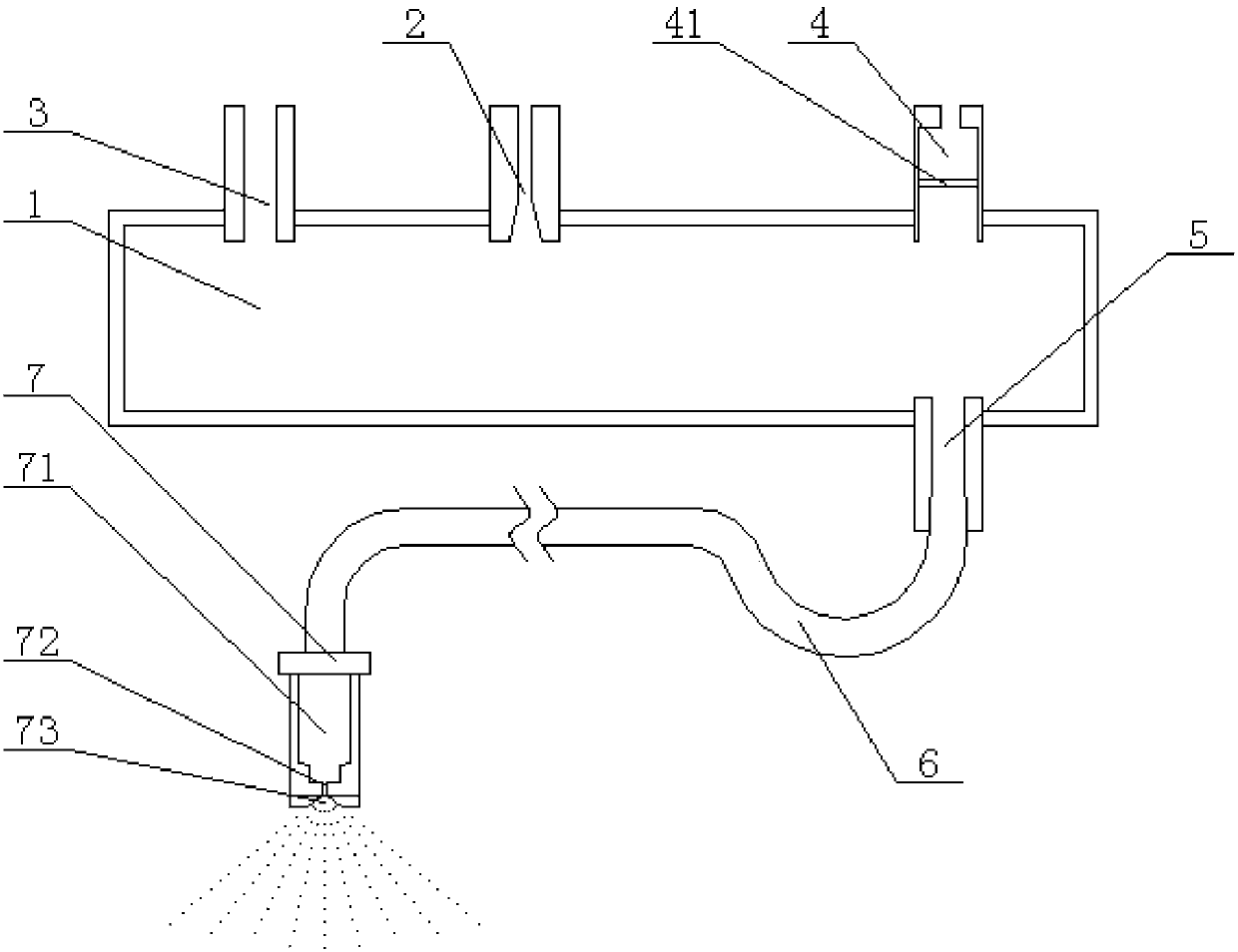

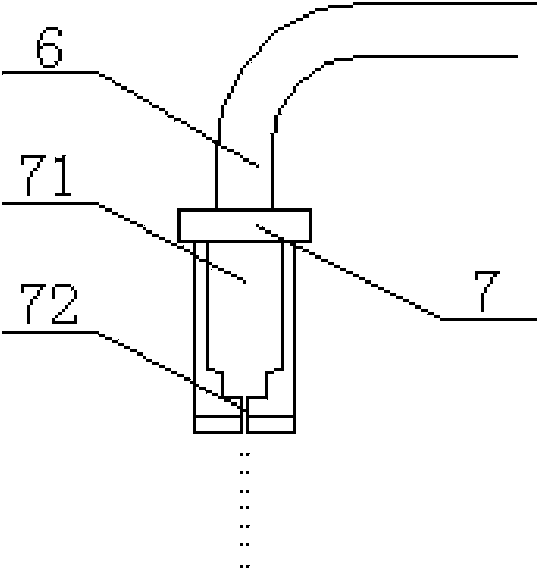

The invention discloses a high-pressure gas oil injection device. The high-pressure gas oil injection device comprises a mixing cylinder, a connecting hose and a nozzle, wherein a gas inlet is formed in the top wall at one end of the mixing cylinder; a gas outlet is formed in the top wall at the other end of the mixing cylinder; an oil-resistant breathable film is arranged in the gas outlet; an oil inlet is further formed in the top wall of the mixing cylinder, and is positioned between the gas inlet and the gas outlet; an oil outlet is formed in the bottom of the mixing cylinder; the oil outlet and the gas outlet are positioned at the same end of mixing cylinder; one end of the connecting hose is connected with the oil outlet, and the other end of the connecting hose is connected with the nozzle; a connecting cavity, an atomizing injecting opening and a fan-shaped injecting groove are formed in the nozzle; one end of the connecting cavity is connected with the connecting hose, and the other end of the connecting cavity is connected with the atomizing injecting opening; the fan-shaped injecting groove is formed in the spraying end of the nozzle; the atomizing injecting opening is positioned in the fan-shaped injecting groove.

Owner:合肥大来新型建材有限公司

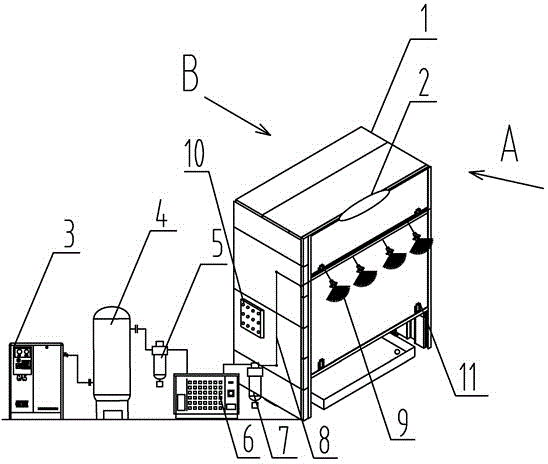

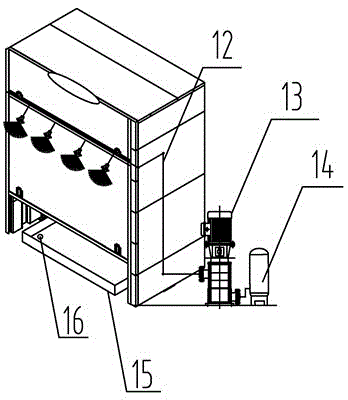

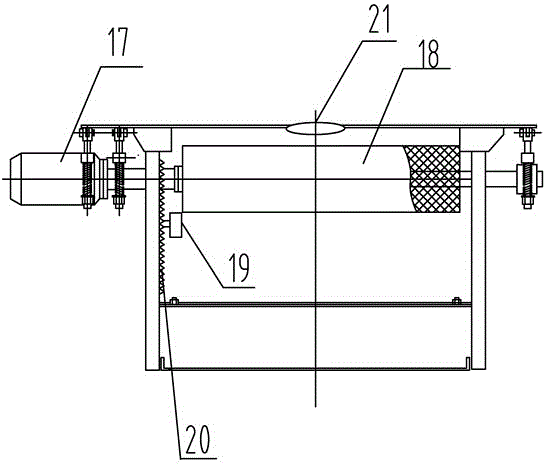

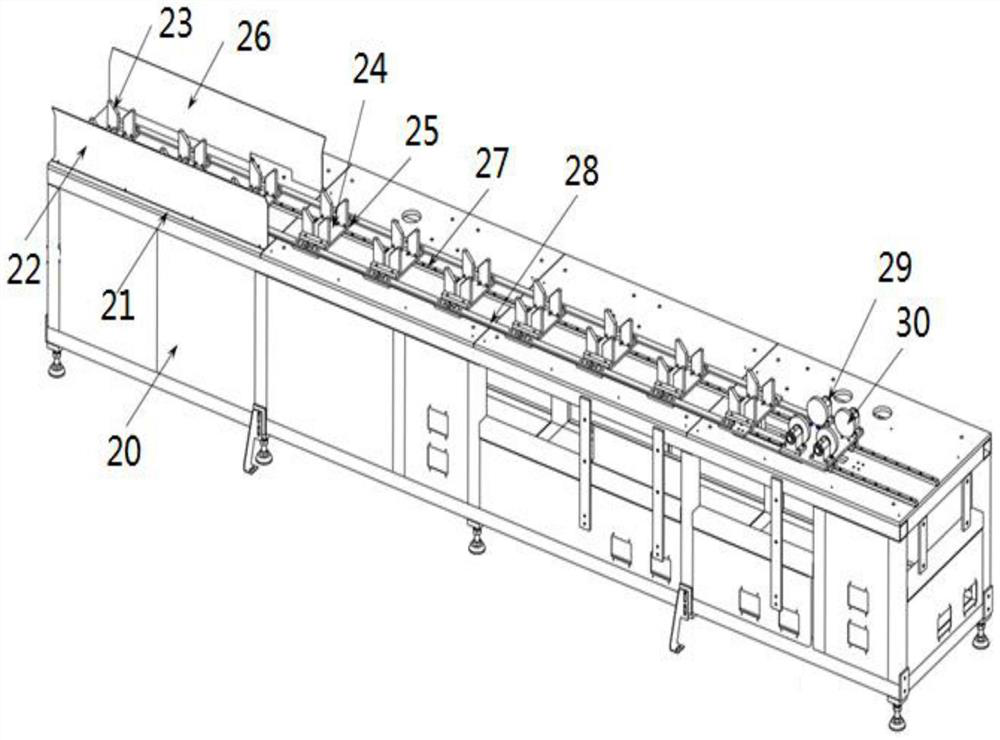

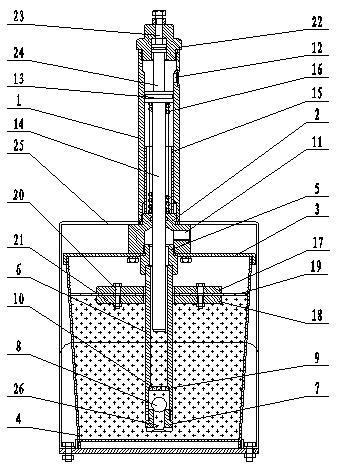

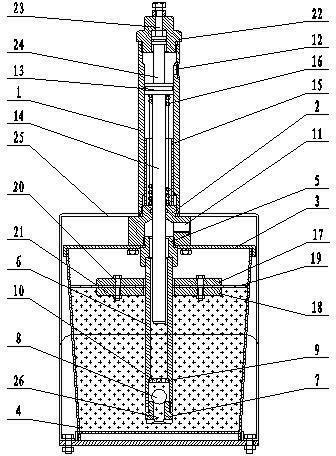

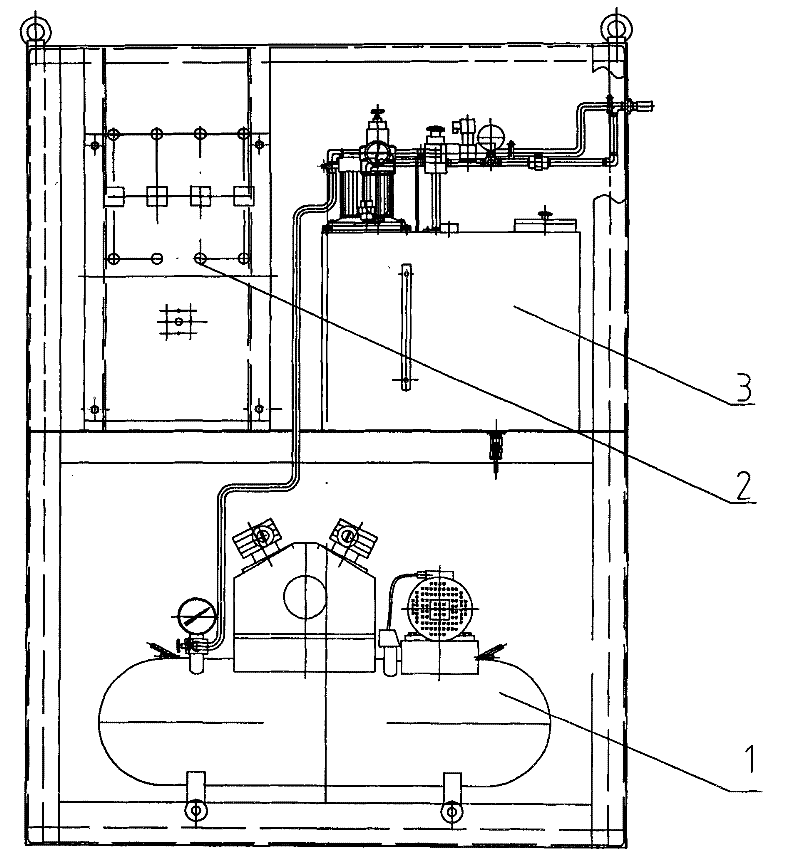

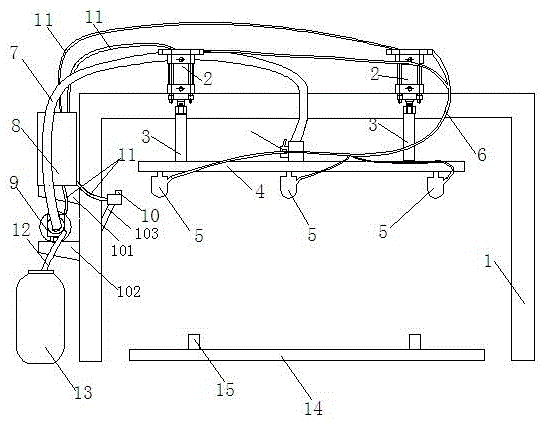

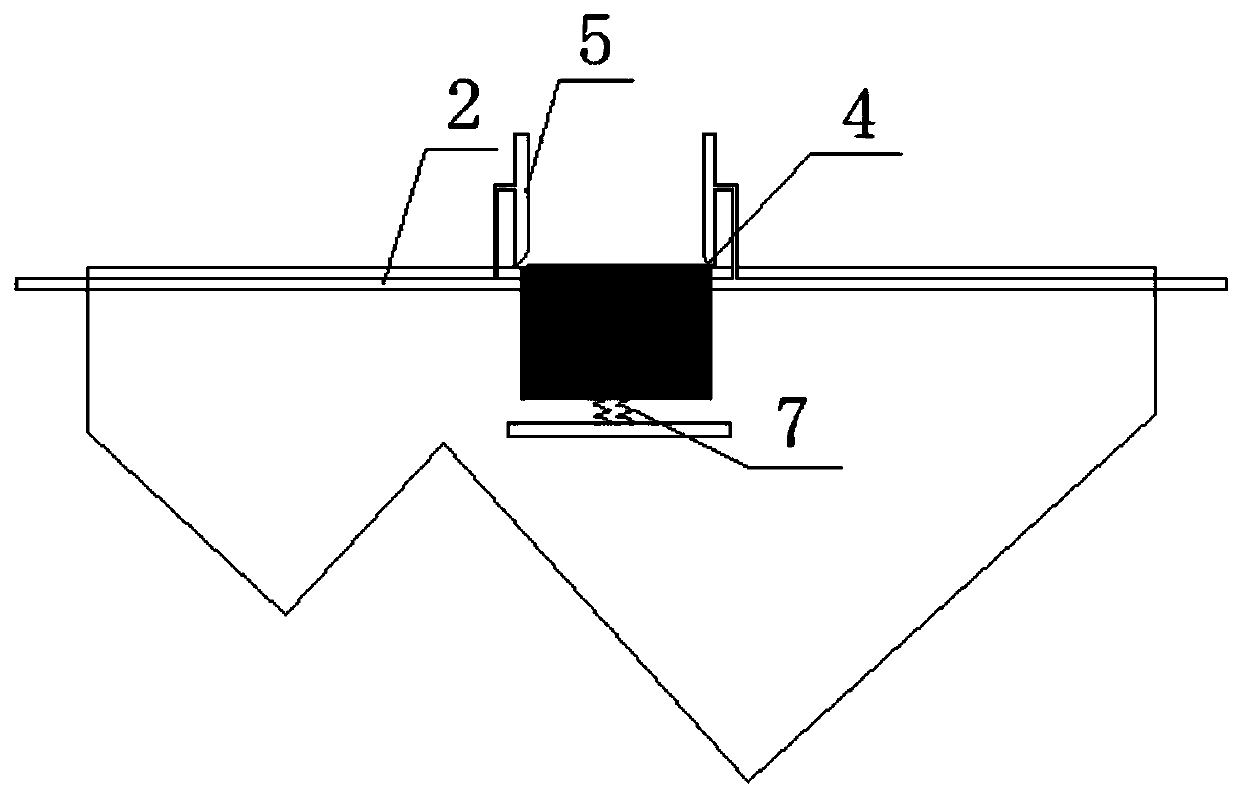

Prefabricated part sweeping and oil spraying machine

InactiveCN104476664ASpray oil evenlyEasy to useLiquid surface applicatorsSpray nozzlesSteel columnsOil supply

The invention discloses a prefabricated part sweeping and oil spraying machine applied to the technical field of precast concrete parts. The machine comprises a portal, a tray inlet sensor, an air compressor, a gas storage tank, a refrigerated air dryer, a primary effect filter, a medium effect filter, an oil storage tank, an oil leakage residue disk, a sweeping device motor, a lifting device, a tray outlet sensor and the like. An air compression system used for providing compressed air for the machine is arranged opposite to the left side of a spray assembly, the air compressor, the gas storage tank, the primary effect filter, the refrigerated air dryer and the medium effect filter are arranged in sequence and are connected through compressed air pipelines, and an operation table is arranged on the left side wall of the portal. An oil supply system for providing oil for the machine is arranged opposite to the right side of the spray assembly, and an oil pump and the oil storage tank are arranged in sequence and connected through an oil pipe. The prefabricated part sweeping and oil spraying machine integrates a sweeping system and an oil spraying system, fan-shaped film oil spraying is even, two steel column sweepers can achieve non-dead-corner sweeping, the machine is very easy to operate, low in cost, convenient to install, stable in work, safe, reliable and easy and convenient to maintain, and working is easy.

Owner:NORTHERN HEAVY IND GRP CO LTD

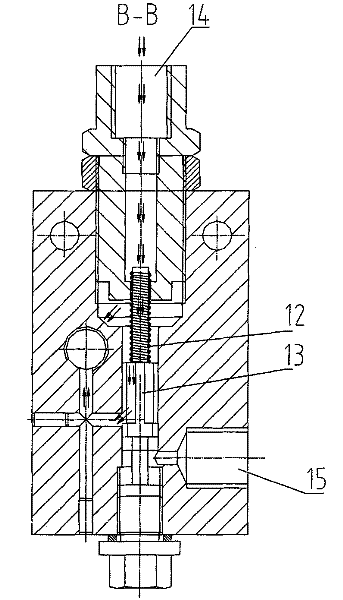

Oil nozzle of diesel engine

InactiveCN102392772AReduce volumePowerful fuel injectionFuel injection apparatusMachines/enginesFrustumDiesel engine

The invention belongs to the field of diesel engines, and particularly relates to an oil nozzle of a diesel engine. The oil nozzle comprises a needle valve body and a needle valve arranged in the needle valve body, wherein the needle valve body comprises a pressure chamber; the pressure chamber has an elliptical shape; a partition plate is arranged in the pressure chamber on the front side of theneedle valve; the pressure chamber is divided into a lower pressure chamber and a pressure chamber cavity by the partition plate; the section of the head part of the needle valve has a frustum shape;the frustum is provided with a spherical bulge; and the lower pressure chamber is communicated with an oil outlet channel of the needle valve body. The oil nozzle of the diesel engine, provided by the invention, has the advantages that: as the pressure chamber is changed into an elliptical shape, the volume of the pressure chamber is reduced; the pressure chamber is separated by the partition plate, so that the space of the pressure chamber is further compressed, and the oil injection of the oil nozzle is more powerful; and moreover, due to the pits on the partition plate, the formed oil mistis more uniform, and the burning efficiency of diesel oil is improved.

Owner:CHANGZHOU SHENGFA BULB FACTORY

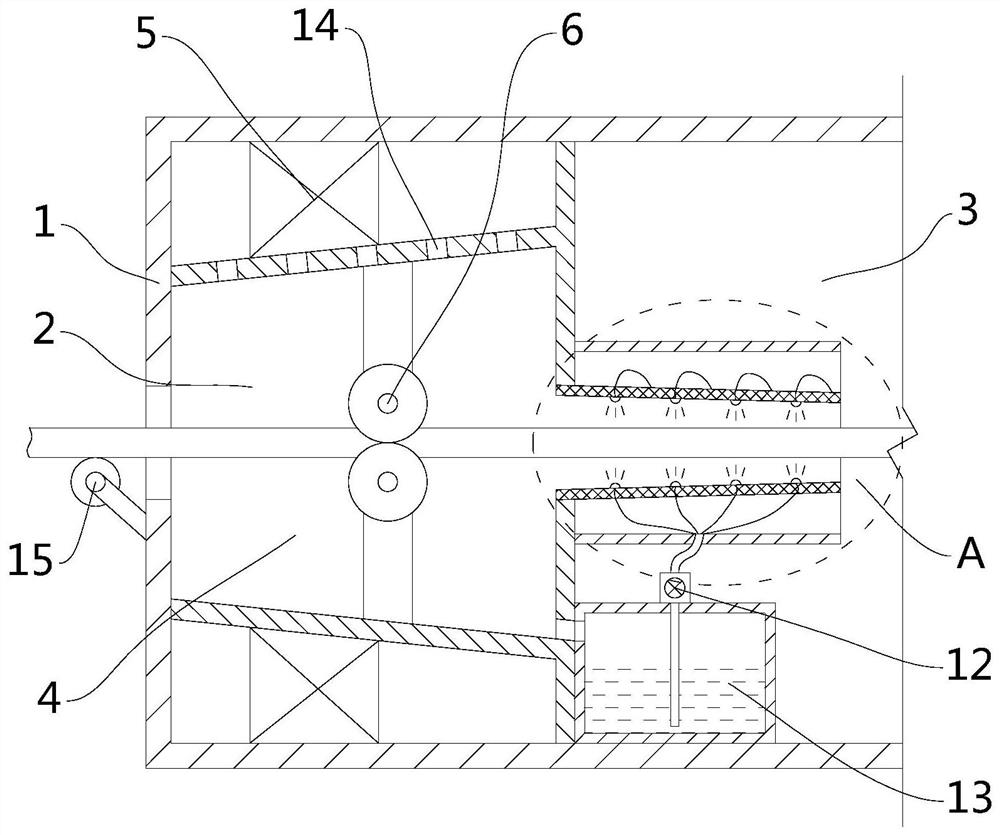

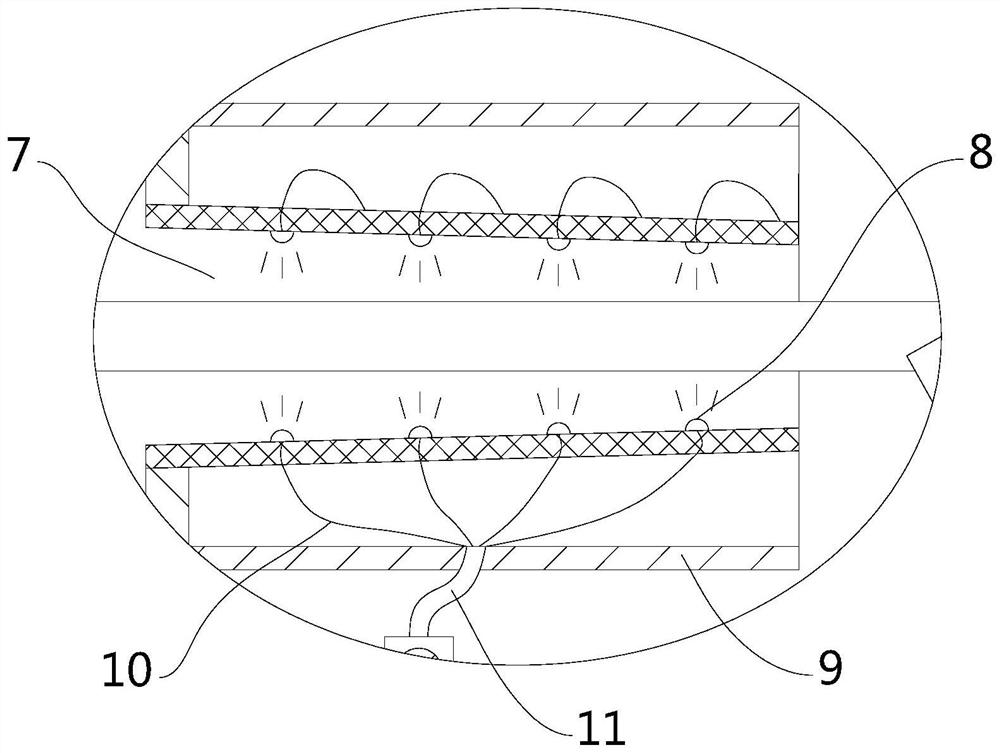

Novel oil injection baking device used for biscuit processing

InactiveCN107927038ASpray oil evenlyEnable recyclingOven air-treatment devicesDough processingCooking & bakingWater vapor

The invention discloses a novel oil injection baking device used for biscuit processing. The baking device comprises a conveying belt and is characterized in that the conveying belt sequentially penetrates through an oil injection chamber, a low temperature baking chamber and a high temperature baking chamber from left to right; an oil chamber is arranged at the bottom of the oil injection chamber. According to the novel oil injection baking device used for biscuit processing, oil can be uniformly injected on the upper surfaces and the lower surfaces of biscuits by an oil spray nozzle; by arranging a first air suction pump, a first oil collecting plate, a condenser and an oil collecting groove, adhered oil in air can be recycled, so that waste and oil contamination can be avoided; the biscuits are shaped at low temperature by the low temperature baking chamber firstly, so that cracking or deformation of the biscuits when the biscuits are directly heated by high temperature is avoided;by arranging a first heating wire, a first heat reflection plate, a second heating wire and a second heat reflection plate, the heat can be fully utilized; after water vapor is filtered by a filteringdevice, hot gas can be discharged into the high temperature baking chamber, so that the waste of energy can be avoided.

Owner:ANHUI JINMAILE FLOUR IND

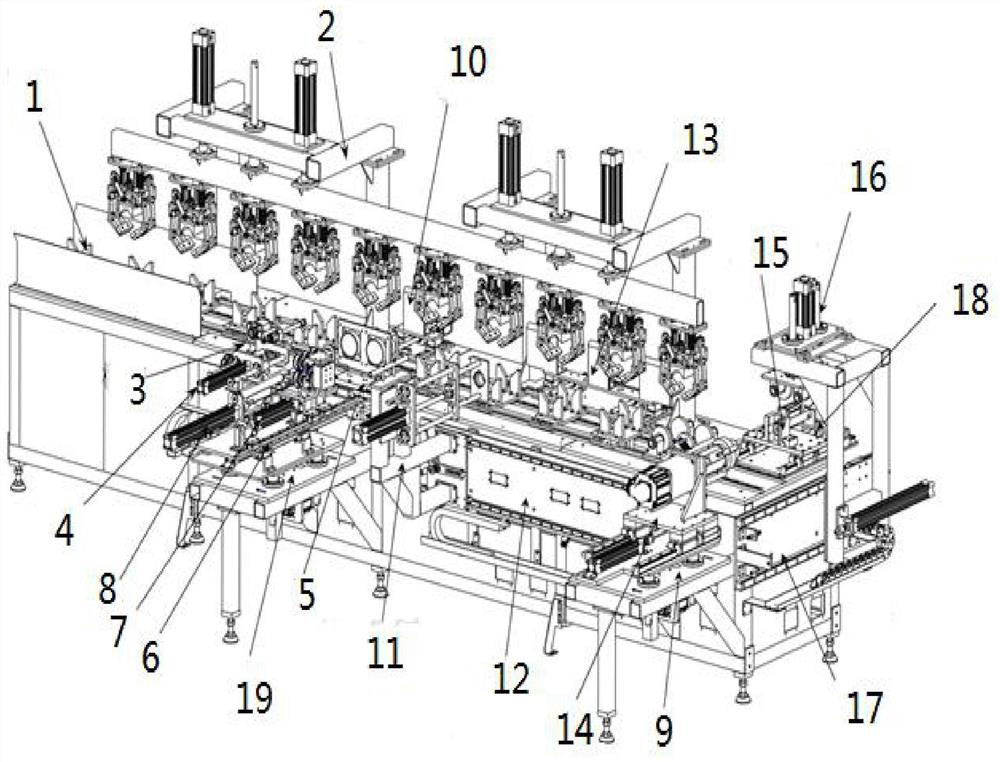

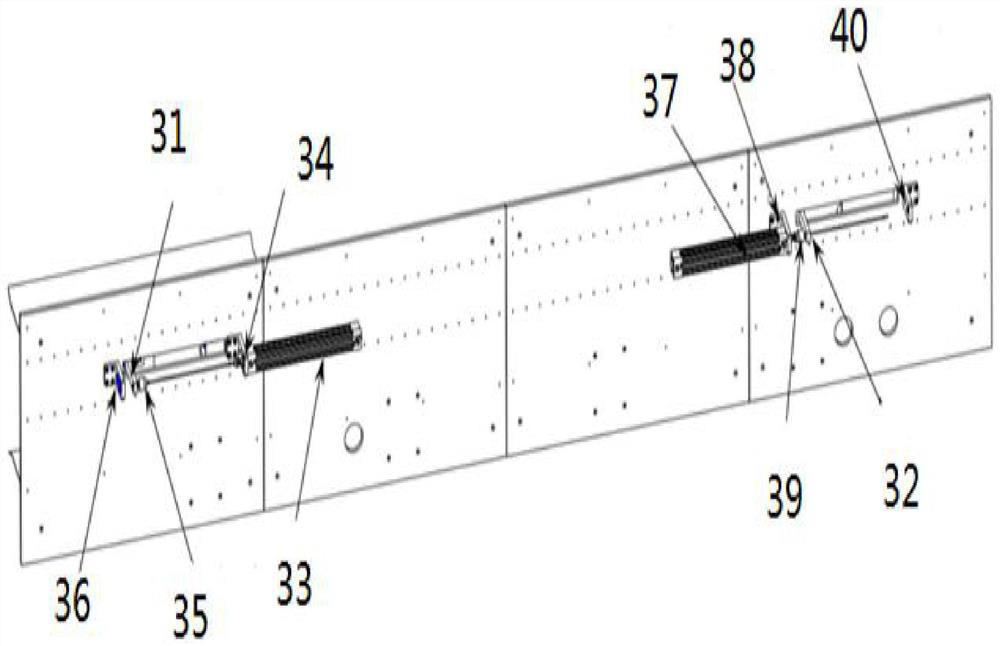

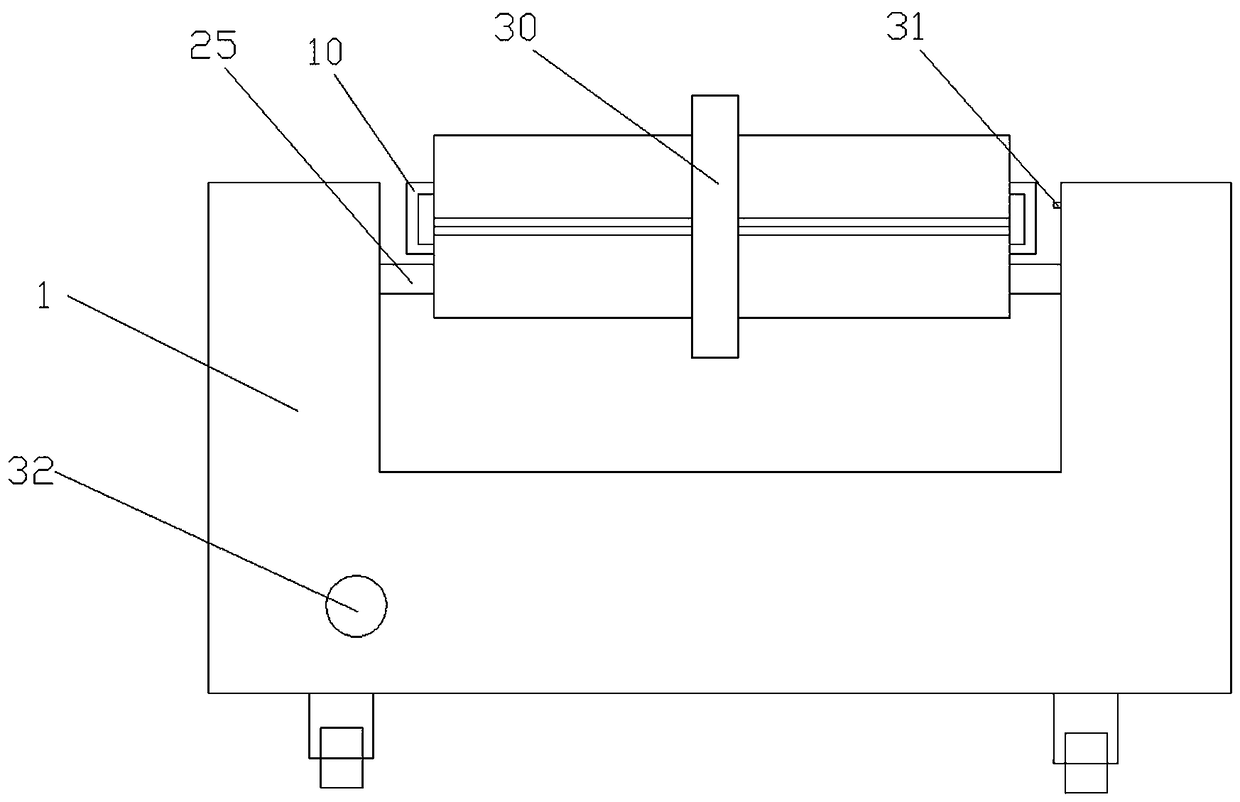

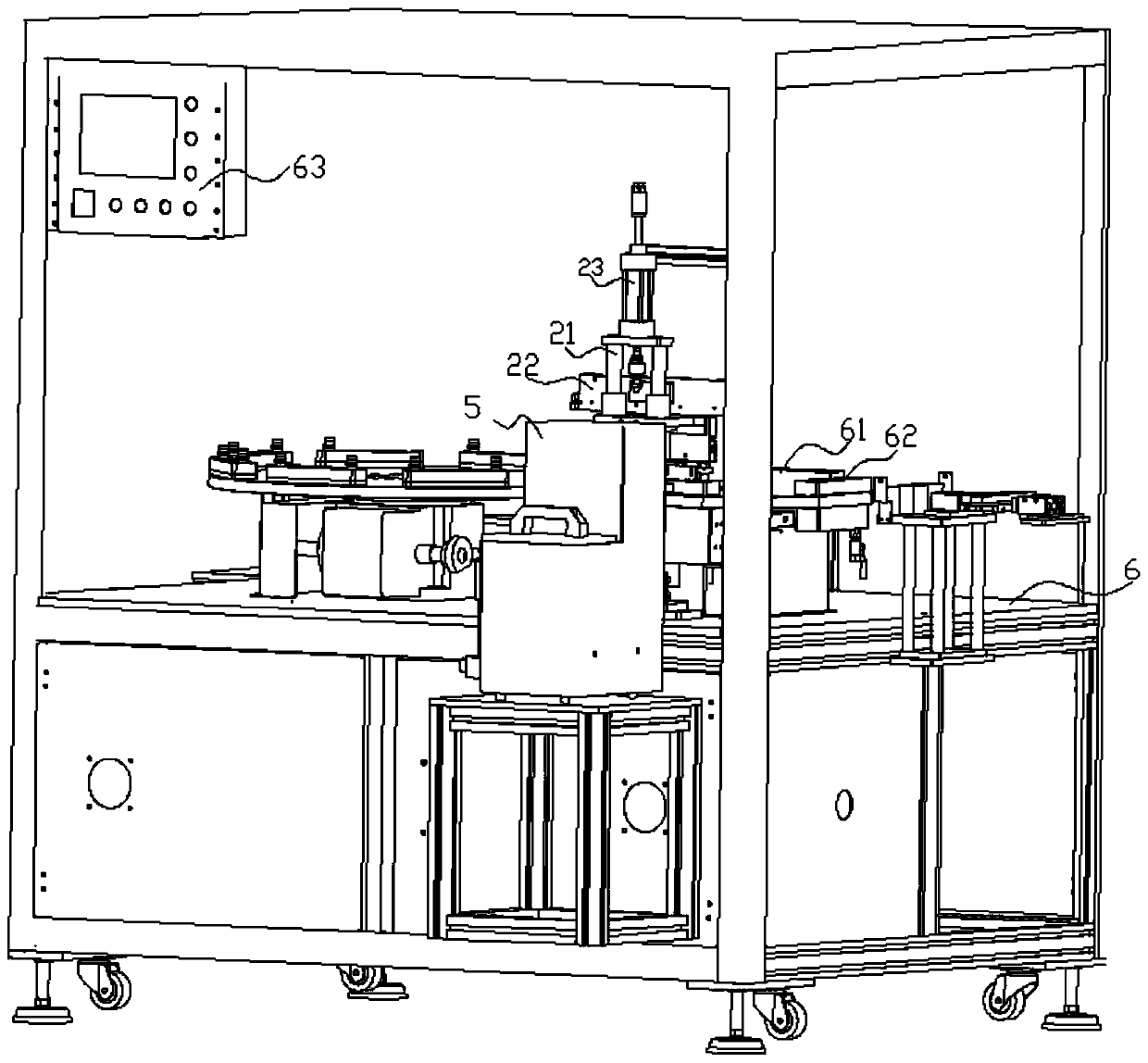

Flexible automatic assembly production line for oil cylinders

ActiveCN112222818AHigh degree of automationStable cleanlinessSpraying apparatusAssembly machinesProduction lineEngineering

The invention discloses a flexible automatic assembly production line for oil cylinders. The flexible automatic assembly production line for oil cylinders comprises a transfer mechanism, a lifting mechanism, an oil injection mechanism, a push rod mechanism, a guide mechanism, a sleeve feeding mechanism, a sleeve replacing mechanism, a first servo jacking mechanism, a first limiting mechanism, an auxiliary power assisting mechanism, a first moving mechanism, a second limiting mechanism, a guide sleeve screwing mechanism, a second servo jacking mechanism, a rotation stopping mechanism, a pressing mechanism, a rotation stopping adjusting mechanism and a second moving mechanism. The transfer mechanism enables a cylinder body to enter from the left end of the production line, the cylinder bodysequentially passes through various structures and then is output from the right end, the transfer mechanism transfers the cylinder body to the lifting mechanism, the lifting mechanism lifts the cylinder body, the transfer mechanism automatically withdraws, and the lifting mechanism transfers the cylinder body to a next positioning tool. The flexible automatic assembly production line for the oilcylinders is reasonable in design; and the production line is high in automation degree, stable in assembly process, standard in operation, reliable in assembly quality, high in production efficiencyand low in labor intensity, and workpieces are continuously and automatically transferred and assembled.

Owner:SHANDONG ATAW IND ROBOT TECH

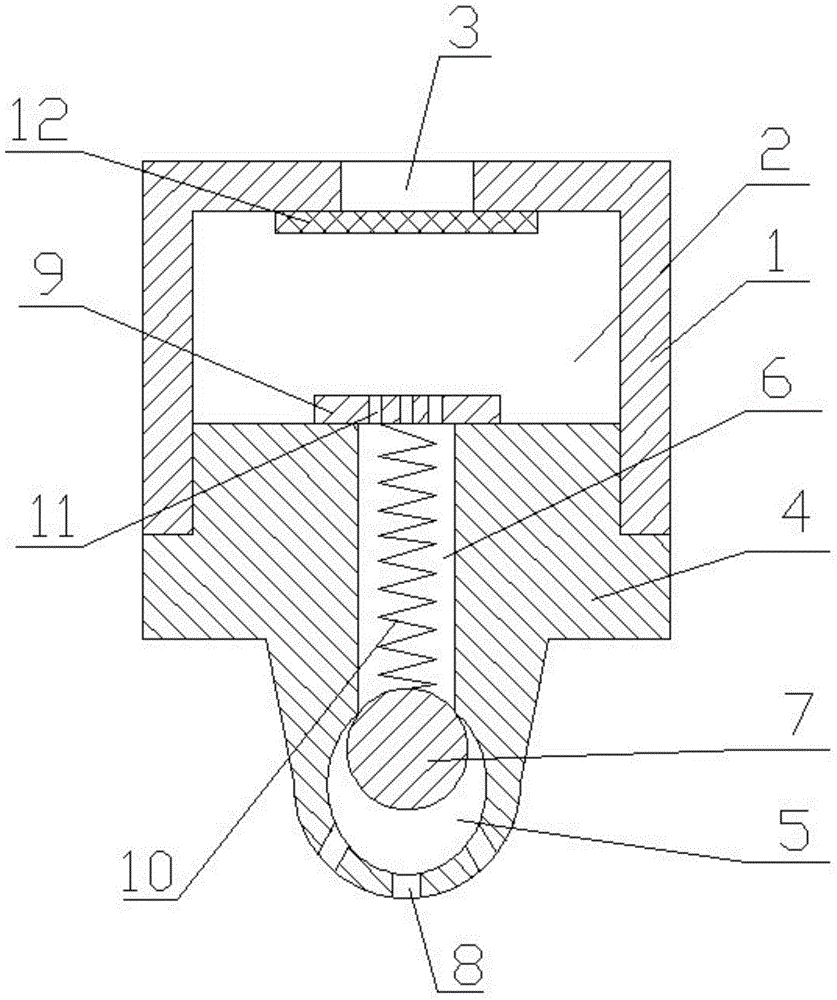

Automatic screw thread-added oil engine

InactiveCN102679126AEasy to useFuel injection fastLubricating pumpsLubrication containersUpper jointSteel ball

The invention discloses an automatic screw thread-added oil engine, which includes an upper cylinder barrel, wherein the lower end of the upper cylinder barrel is connected with a tank cover through an upper joint; the tank cover is arranged on an oil tank; the upper joint is connected with the lower end of a lower cylinder barrel through a lower connecting rod; a lower joint is arranged at the lower end of the lower cylinder barrel; a steel ball is arranged at the upper end of the lower joint in the lower cylinder barrel; a stop block is arranged in the lower cylinder barrel above the steel ball; a through hole is formed in the stop block; a screw thread oil outlet is arranged on one side of the upper joint; a hydraulic oil opening is arranged at the upper end of the upper cylinder barrel; a piston is arranged in the upper cylinder barrel; a piston rod is connected with the lower end of the piston; a spring seat is arranged at the lower end in the upper cylinder barrel; and a spring is sleeved on the piston rod between the spring seat and the piston. The invention has the advantages that the automatic screw thread-added oil engine is convenient to use, quickly and uniformly sprays oil, saves time, improves the working efficiency, and reduces the cost.

Owner:JIANGSU GOODENG ENG MACHINERY ASSEMBLING

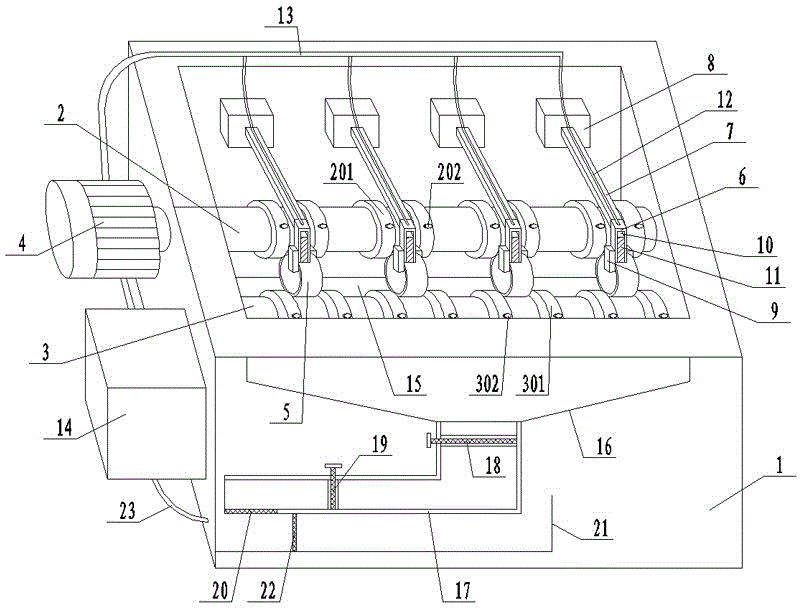

Cleaning device for speed reducer bearing inner rings

InactiveCN106391532ASimple structureEasy to installCleaning using toolsEngine lubricationEngineeringReducer

The invention discloses a cleaning device for speed reducer bearing inner rings. The cleaning device comprises a rack. A rotating shaft and a supporting shaft are arranged in the rack. One end of the rotating shaft stretches out of the rack and is connected with a drive device. The multiple bearing inner rings are evenly arranged between the rotating shaft and the supporting shaft. Cotton brush installing blocks are arranged at the upper ends of the bearing inner rings and connected with cotton brush installing block adjusting devices through adjusting supports. The cotton brush installing block adjusting devices are arranged on the rack. Bearing inner ring limiting blocks are symmetrically arranged on the two sides of each cotton brush installing block. Each bearing inner ring is clamped between the corresponding two bearing inner ring limiting blocks. Cotton brush installing grooves are formed in the cotton brush installing blocks. Cotton brushes matched with the bearing inner rings are arranged in the cotton brush installing grooves. Oil spraying branch pipes are arranged at the upper ends of the cotton brush installing blocks, and one ends of the oil spraying branch pipes communicate with the cotton brush installing grooves.

Owner:PROFIT TRANSMISSION EQUIP YANCHENG CO LTD

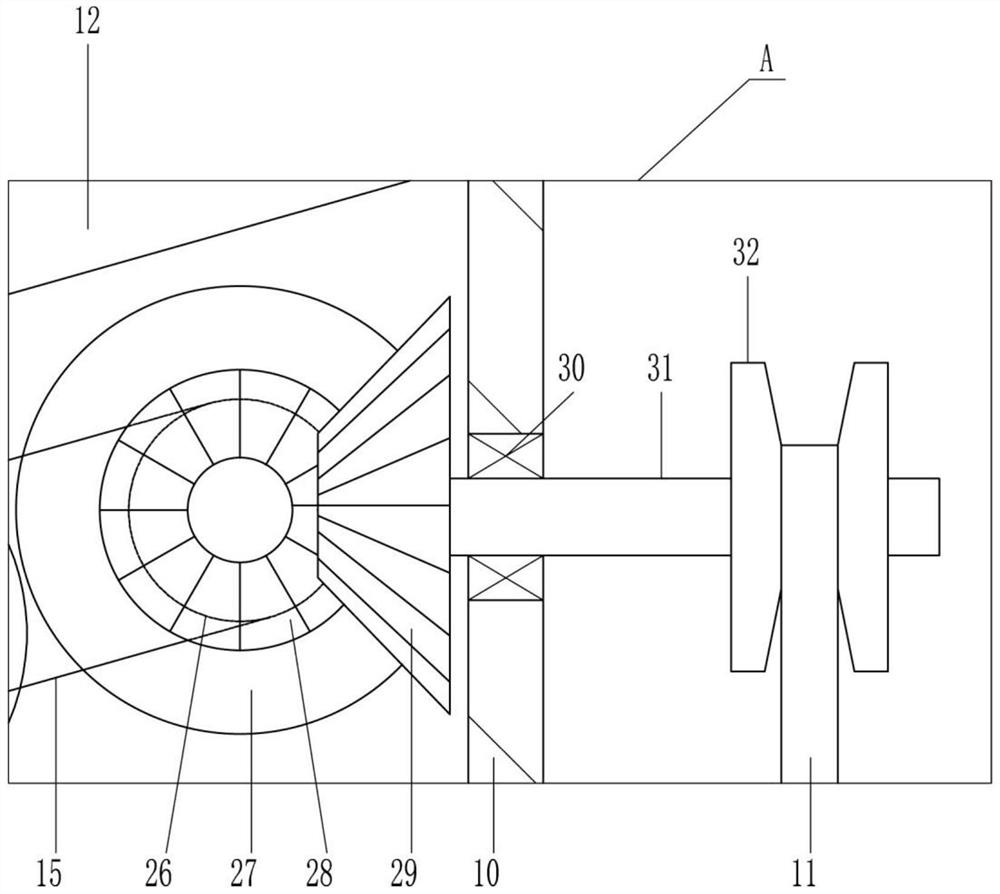

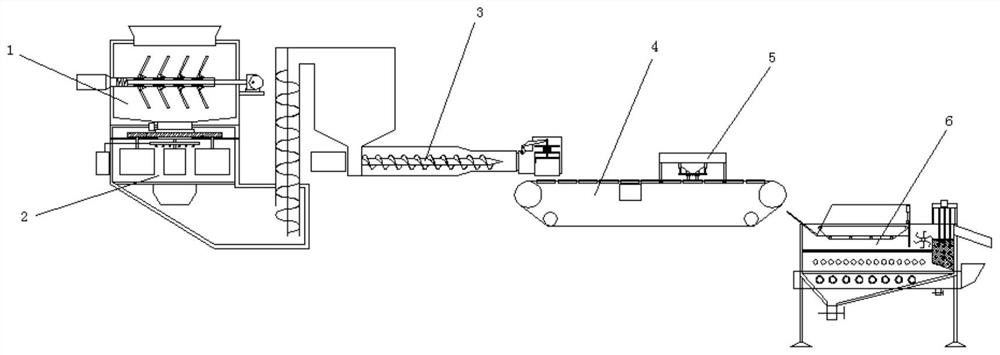

A kind of extruding and other material slitting device of deep-fried dough stick machine

ActiveCN109380458BWell mixedGreat tasteDough shaping and cutting apparatusDough extruding machinesEngineeringMechanical engineering

The invention discloses an extruding and other material slitting device for a deep-fried dough stick machine, which comprises a dough kneading mechanism. The bottom of the kneading dough kneading mechanism is provided with a kneading dough kneading mechanism. warehouse, the bottom of the wake-up noodle warehouse is fixedly equipped with an extruder, the right end of the extruder is provided with a feeding mechanism, the lower part of the feeding mechanism is provided with a conveyor, and the middle part of the conveyor is provided with a composite molding mechanism. The right part of the conveyor is provided with a stretching and disengaging mechanism, and the bottom of the right end of the conveyor is provided with a frying device, which relates to the field of food processing. The invention can automatically add water to the flour and mix it into dough by imitating the manual process of making deep-fried dough sticks. Kneading the dough, waking up the dough, stretching after pressing and forming, and finally frying, greatly reducing the manpower and ensuring the taste of the fried dough sticks, making fried dough sticks efficiently and quickly, suitable for use in breakfast shops.

Owner:张乐

Maintenance tool for hoisting rope of elevator

The invention discloses a maintenance tool for a hoisting rope of an elevator, and relates to the technical field of elevators. The maintenance tool comprises a maintenance device body and a connecting part arranged outside the maintenance device body, and further comprises a maintenance mechanism connected to the top of the maintenance device body and a transmission assembly rotatably connected to the inner wall of the maintenance device body and connected with a second gear in a meshed mode, and an output end of the transmission assembly is matched with a second maintenance device; a rotating shaft is connected to the middle of a driving disc, and the outer wall of the rotating shaft is connected with a telescopic device; and a cleaning assembly which is connected to the top of the rotating shaft, and a roller component and an oil supply component are connected into the maintenance device body. According to the maintenance tool for the hoisting rope of the elevator provided by the invention, the hoisting rope can be detected in all directions, damage to detection equipment due to the fact that friction force between a detection device and the hoisting rope is large is effectively avoided, meanwhile, the oil supply component can evenly spray oil to the hoisting rope through the roller component, and therefore the hoisting rope can be maintained.

Owner:宸宇电梯科技有限公司

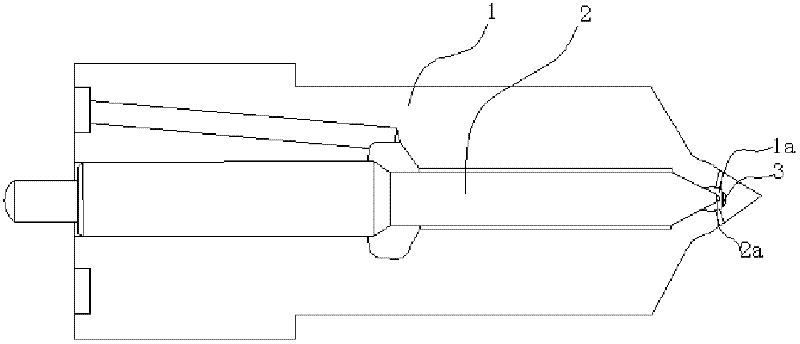

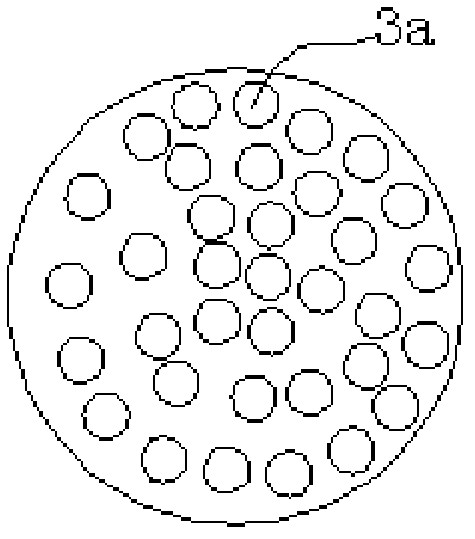

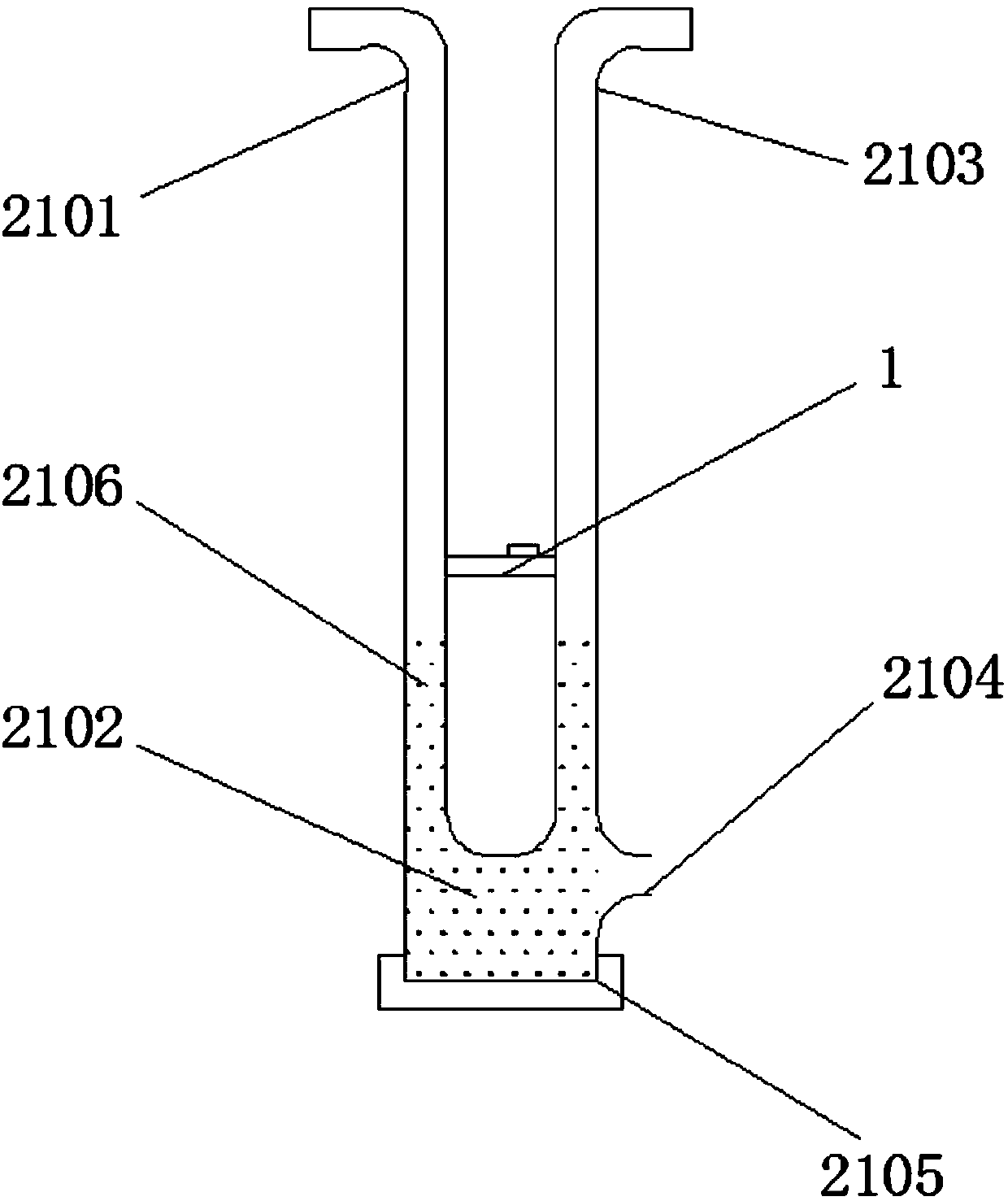

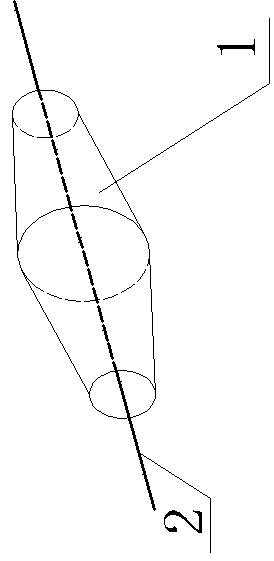

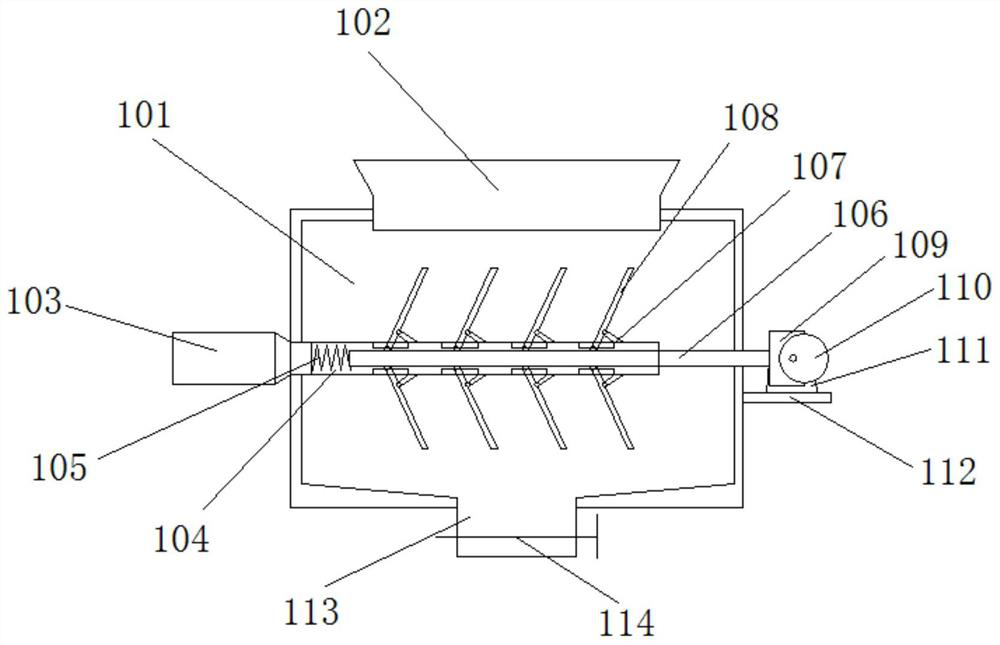

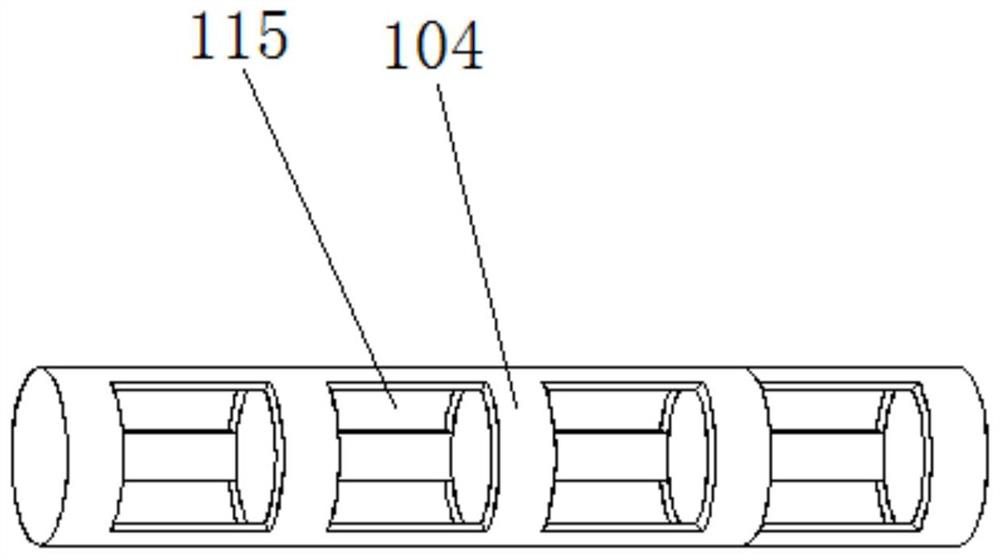

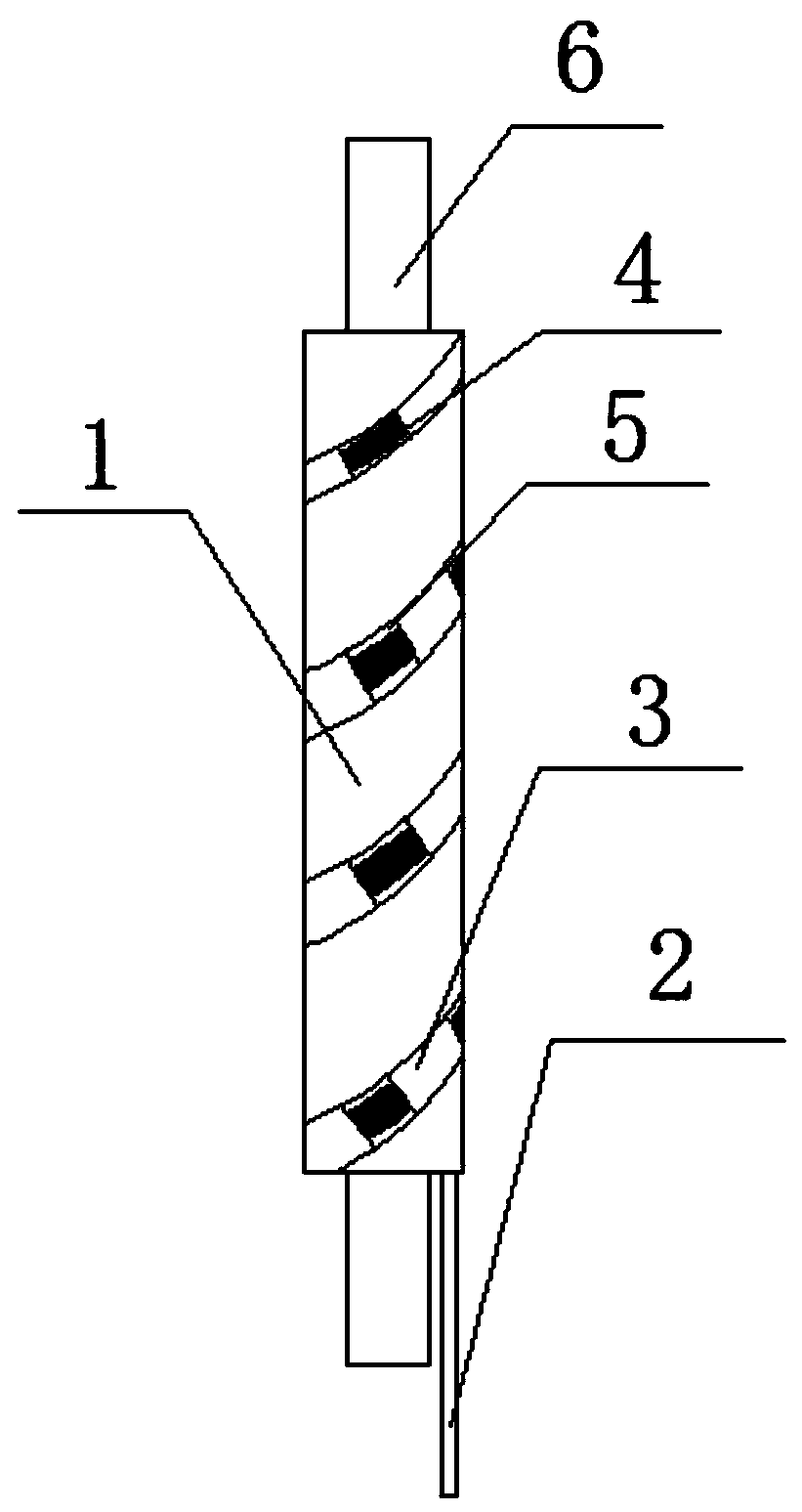

Cashmere fiber fuel injection process and its device

The invention discloses a cashmere fiber oil spraying process and its device. In the cashmere fiber oil spraying process, the cashmere output from the condensor is shaped by a pair of shaping rollers at an ambient temperature of 5°C. The cashmere is sorted into a circular strip structure, and the cashmere after shaping is sprayed with crude oil by several uniformly arranged oil nozzles at an ambient temperature of 5°C; the cashmere fiber oil injection device includes an oil injection box body, a shaping area and an oil injection area are arranged in the fuel injection box, a cone-shaped first cashmere channel is arranged in the said shaping area, and a pair of shaping rollers arranged up and down next to each other are arranged inside the first cashmere channel; The area includes a cone-shaped second cashmere channel. The inner side of the second cashmere channel is provided with several groups of oil nozzles arranged at equal intervals along the axial direction of the second cashmere channel. Arrange evenly. The invention has the advantages of high uniformity of oil spraying and good oiling effect.

Owner:PALUOPO CASHMERE PROD CO LTD

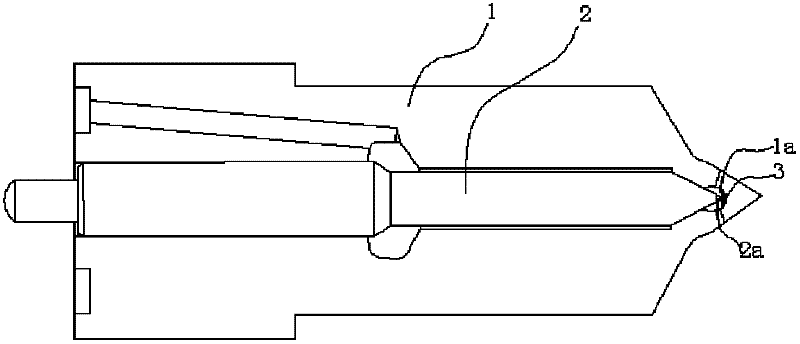

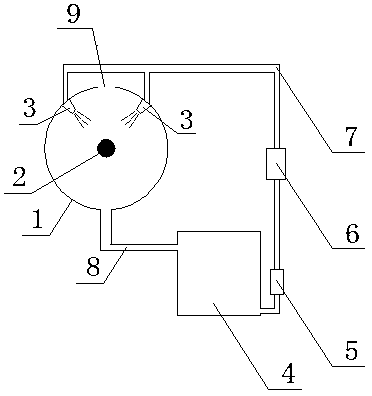

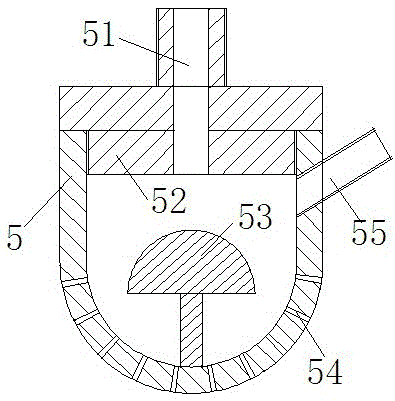

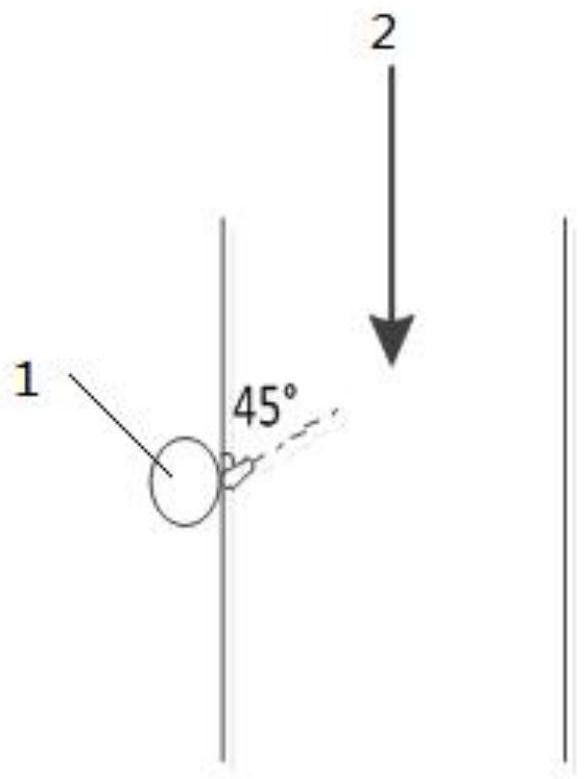

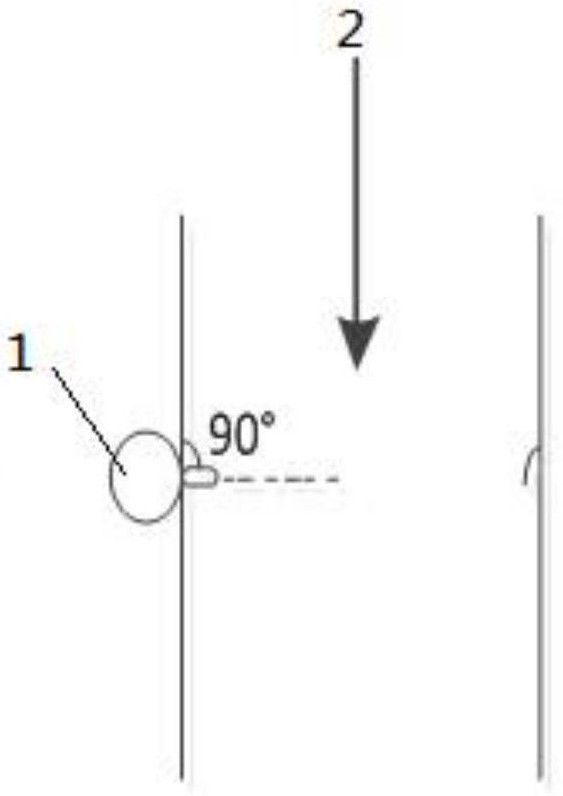

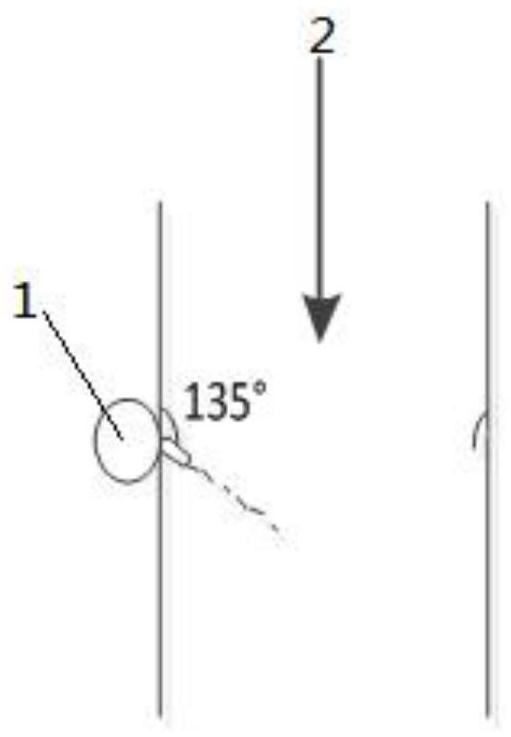

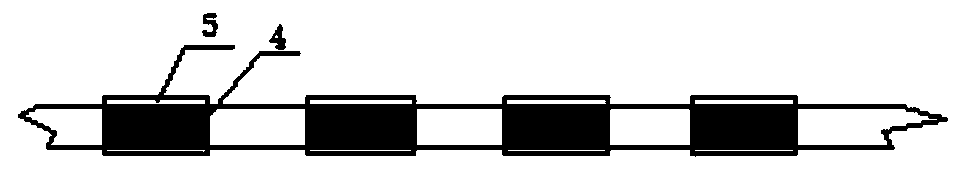

Oil injection device for coal mine winch steel wire rope

InactiveCN103588133ASpray oil evenlyLess oil drippingSpraying apparatusWinding mechanismsCoalWire rope

The invention relates to an oil injection device for a coal mine winch steel wire rope. The oil injection device is mainly composed of an oil injection cover (1), an oil tank (4) and an oil pump, wherein the oil injection cover (1) is in the shape of a spindle; a mounting groove (9) is formed in the upper side of the oil injection cover (1) to enable the oil injection cover (1) to be mounted in a required position; oil injection nozzles (3) are arranged on the inner wall of the upper side of the oil injection cover (1), an even number of oil injection nozzles (3) need to be arranged and evenly distributed on the two sides of the mounting groove (9) to ensure uniform oil injection, and when the number of the oil injection nozzles is two or four, the oil injection device is uniform in oil injection and little in oil dripping amount.

Owner:SHANDONG UNIV OF SCI & TECH

Gear lubricating device for ball mill

ActiveCN101585011BImprove the lubrication effectSimple designGrain treatmentsPressure systemGear wheel

The invention discloses a gear lubricating device for a ball mill. The gear lubricating device can spray high-octane lubricating oil fully atomized onto the surface of a gear through a specially designed nozzle to form a complete adhesive oil film; and the nozzle of the gear lubricating device for spraying the lubricating oil is isolated from the external by a gear cover, which not only avoids thedeficient protection on a gear meshing surface by the conventional lubricating method, but also saves a great quantity of manpower and materials. The structure of the gear lubricating device comprises a pressure system and a hydraulic system which are connected with an electric control system, and simultaneously connected with a sprinkler plate device respectively through pipelines; and the sprinkler plate device is arranged on a position of the gear cover matched with a gear meshing part.

Owner:JINAN HEAVY MACHINERY JOINT STOCK

Decontaminating device for surface grinding of speed reducer bearing inner rings

InactiveCN106475338ASimple structureEasy to installCleaning using toolsLubrication elementsReducerEngineering

The invention discloses a decontaminating device for surface grinding of speed reducer bearing inner rings. The device comprises a rack, wherein a rotating shaft and a supporting shaft are arranged in the rack, one end of the rotating shaft extends out of the rack and is connected with a drive device, the multiple bearing inner rings are evenly arranged between the rotating shaft and the supporting shaft, the positions, located on the two sides of the bearing inner rings, of the rotating shaft are symmetrically sleeved with upper plastic check rings, the upper plastic check rings are connected with the rotating shaft through upper adjusting screws, the positions, located on the two sides of the bearing inner rings, of the supporting shaft are sleeved with lower plastic check rings, the lower plastic check rings are connected with the supporting shaft through lower adjusting screws, cotton brush mounting blocks are arranged at the upper ends of bearing outer rings and are connected with cotton brush mounting block adjusting devices through adjusting supports, the cotton brush mounting block adjusting devices are arranged on the rack, and bearing inner ring limiting blocks are symmetrically arranged on the two sides of the cotton brush mounting blocks.

Owner:PROFIT TRANSMISSION EQUIP YANCHENG CO LTD

Lubricating device of drill rod

The invention relates to a lubricating device of a drill rod. The lubricating device of the drill rod is characterized by comprising an adjusting compass, a fixing ring, an adjusting core, a piston, a piston barrel, an upper cylinder barrel, an upper connecting ring, a thread dope outlet, a lower connecting ring, a lower cylinder barrel, a blocking plate, steel balls and oil channels, wherein the lubricating device comprises the upper cylinder barrel and the lower cylinder barrel; the lower end of the upper cylinder barrel is connected with the lower cylinder barrel through the upper connecting ring and the lower connecting ring; the thread dope outlet is formed in one side of the upper connecting ring; the piston barrel penetrates through the upper cylinder barrel and the lower cylinder barrel; the piston is arranged at the upper end of the piston barrel; the adjusting core is connected to the piston to be connected with the adjusting compass; the fixing ring is arranged between the upper cylinder barrel and the adjusting core; the blocking plate with a through hole is arranged in a position under the piston barrel in the lower cylinder barrel; a plurality of oil channels are formed in the lower end of the lower cylinder barrel; and each steel ball is arranged at the upper end of the corresponding oil channel. The lubricating device of the drill rod disclosed by the invention has the advantages of being convenient to use and quick and uniform in oil injection, the time is saved, the working efficiency is improved, and the cost is reduced.

Owner:吴鹏飞

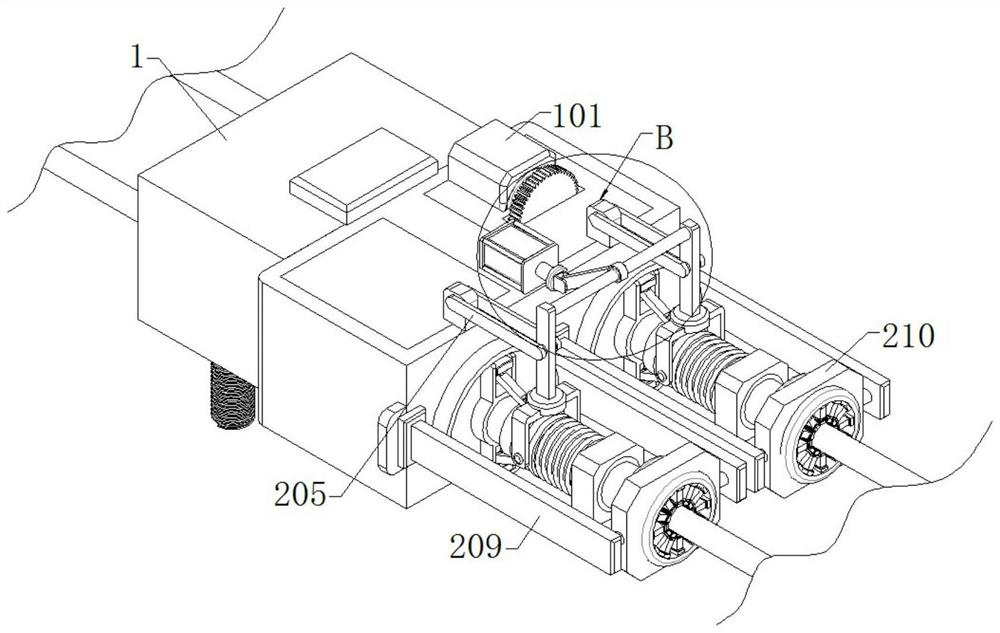

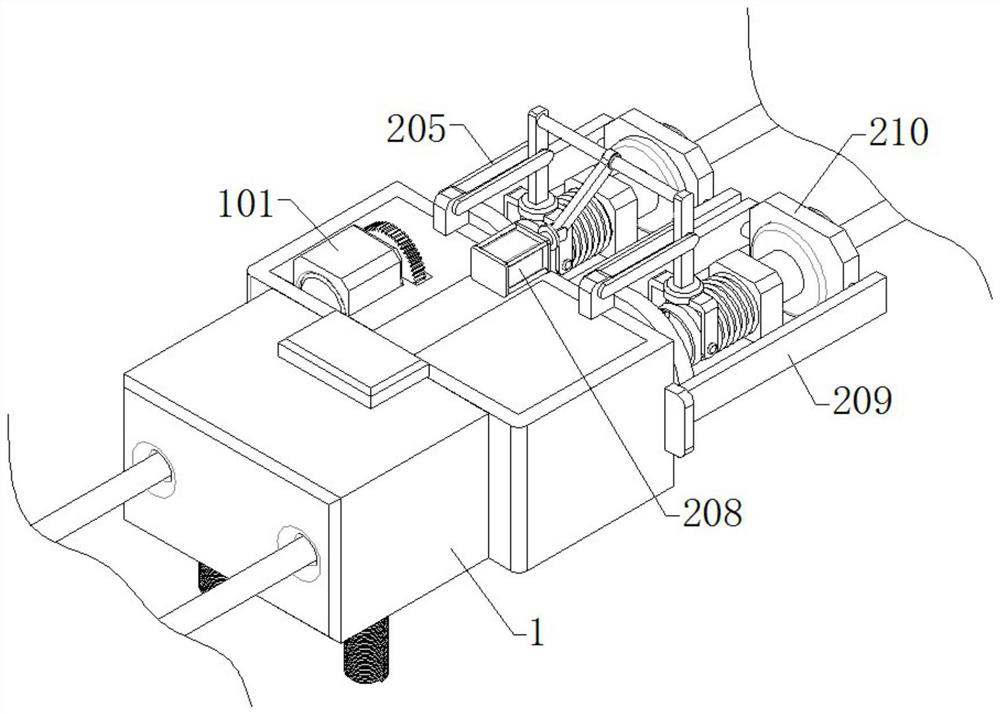

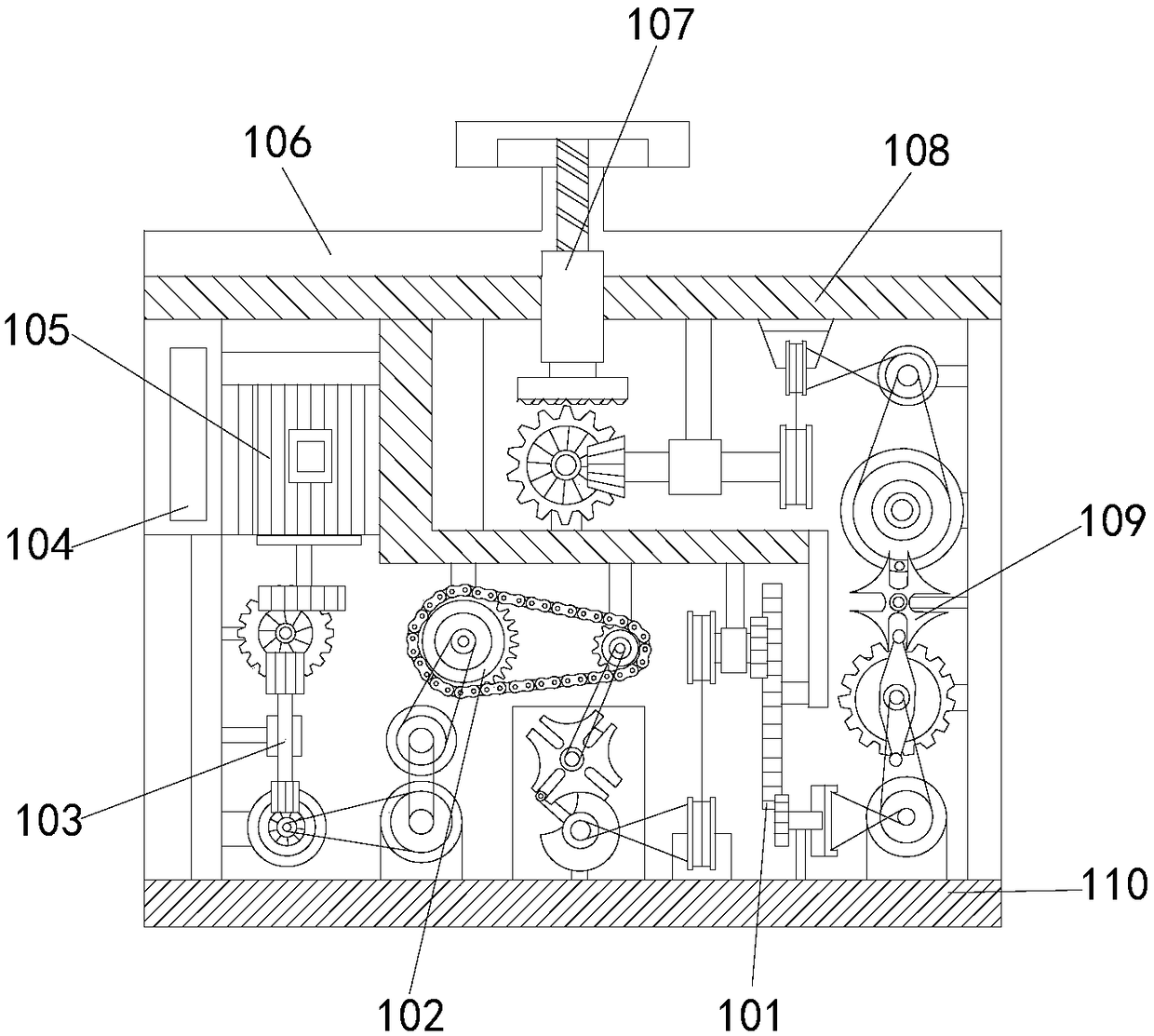

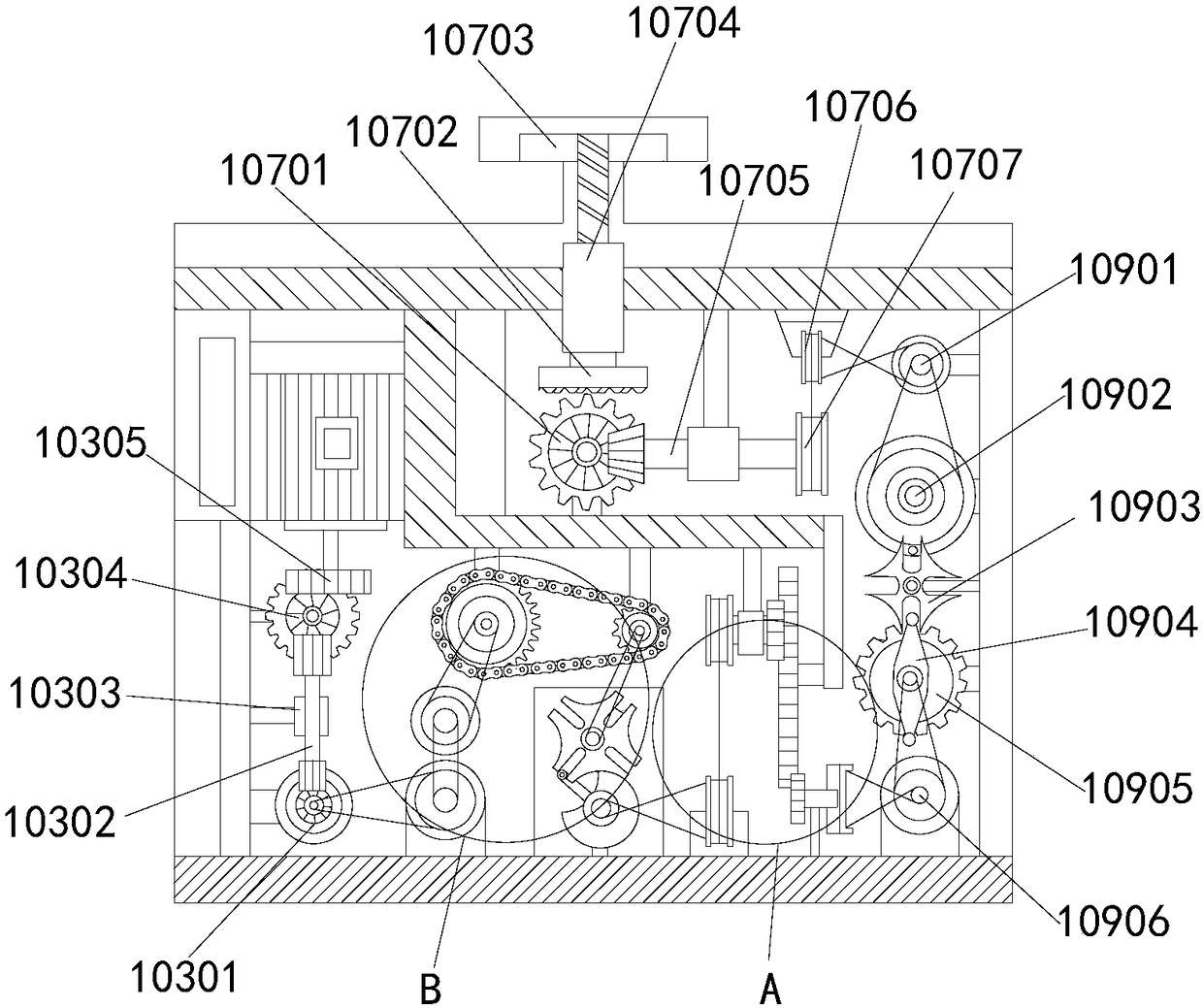

Composite forming conveying device for fried dough stick machine

ActiveCN109362820BWell mixedGreat tasteMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringMechanical engineering

The invention discloses a compound forming conveying device of a deep-fried dough stick machine, which comprises a dough kneading mechanism. The bottom of the dough kneading mechanism is provided with a dough kneading mechanism. An extruder is fixedly installed at the bottom of the noodle bin, the right end of the extruder is provided with a feeding mechanism, the lower part of the feeding mechanism is provided with a conveyor, and the middle part of the conveyor is provided with a composite molding mechanism. The right part of the conveyor is provided with a stretching and disengaging mechanism, and the bottom of the right end of the conveyor is provided with a frying device, which relates to the field of food processing. The present invention can imitate the process of manually making deep-fried dough sticks, automatically add water to the flour and mix it into dough, then knead the dough, Wake up the dough and stretch it after pressing and forming, and finally fry it, which greatly reduces the manpower and can ensure the taste of the fried dough sticks. It is efficient and quick to make fried dough sticks, which is suitable for use in breakfast shops.

Owner:张乐

A fuel injector that is easy to recycle and reuse for speaker manufacturing

The invention relates to the field of loudspeaker box manufacturing, in particular to an oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing. The oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing is capable of saving energy, even in oil jetting treatment, capable of saving time and labor and convenient to operate. The oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing comprises an oil outlet pipe, a first valve, a second valve, an oil storage barrel, a fixed seat, an oil collecting hood, a first transmissionwheel, a motor, an oil discharging pipe, a mounting seat, a first transmission belt, a first baffle, a second transmission belt, a first conveying roller, a second transmission wheel, an oil jettingpipe, a flow dividing pipe, a one-way valve pipe, an oil delivering pipe, an oil pump, an oil pumping pipe, an oil inlet bucket, a collecting frame, a third transmission wheel, a second conveying roller, a first bevel gear and the like. The oil jetting machine easy to recycle and reuse for loudspeaker box manufacturing achieves the effects of being capable of saving the energy, even in oil jettingtreatment, capable of saving time and labor and convenient to operate.

Owner:灵璧县浩翔信息科技有限公司

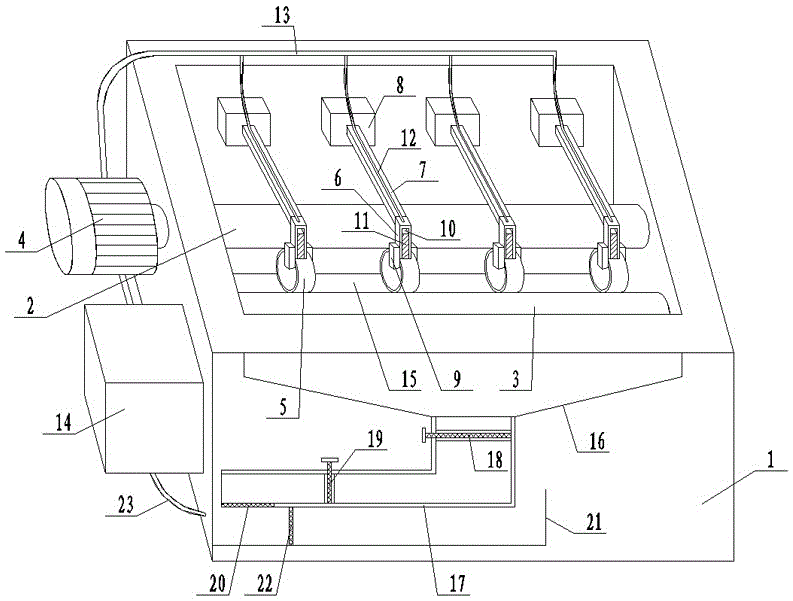

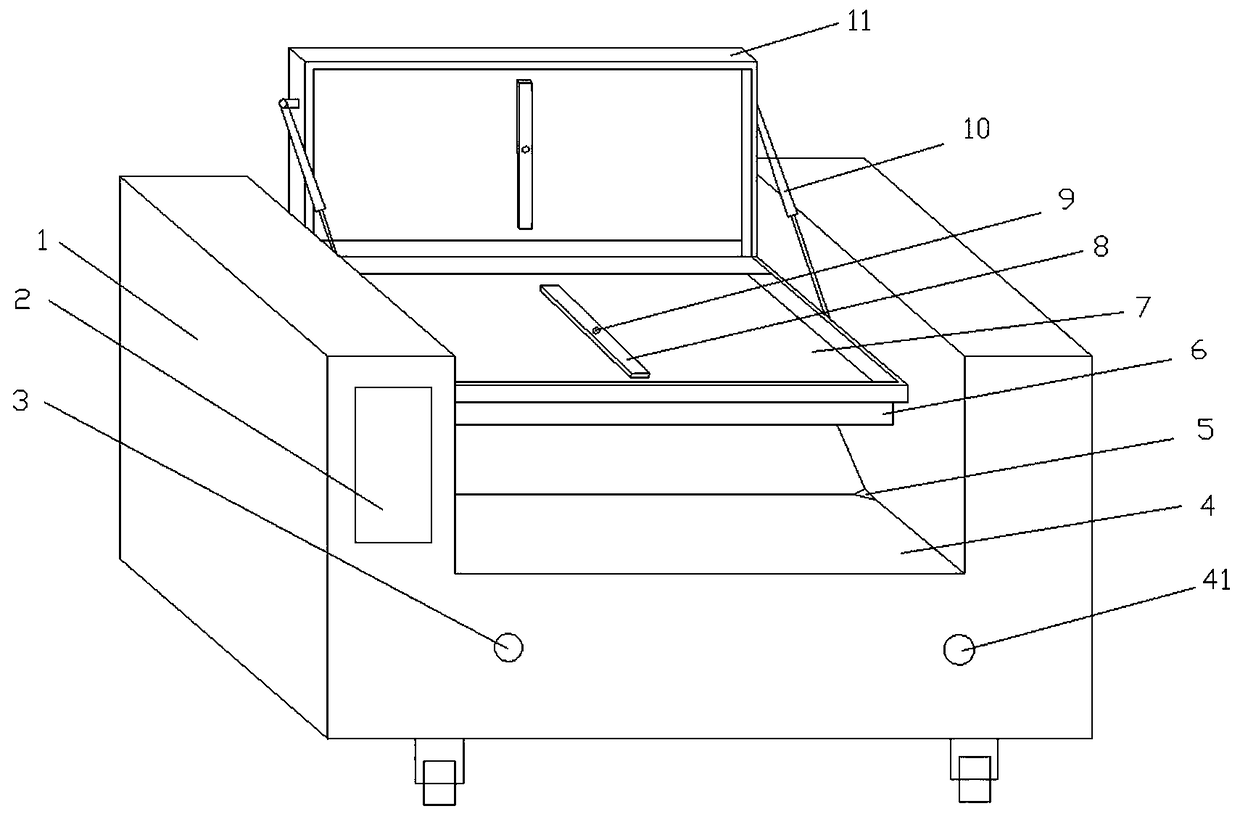

Automatic electric pancake machine

PendingCN108497004ASolve flipFree laborBaking surface cleaning/greasingHollow article bakingFood processingElectrical and Electronics engineering

The invention relates to the field of food processing, and especially relates to an automatic electric pancake machine. The automatic electric pancake machine comprises a machine frame; a turning chamber is formed in the machine frame; a turning oven is connected with the interior of the turning chamber; a transmission mechanism is arranged, at one side, in the machine frame; a tension adjusting mechanism is further arranged for the transmission mechanism; a power supply circuit and an oil supply pipeline are arranged, at the other side, in the machine frame; an alarm is arranged, at a lower part, of a front part of the machine frame; an induction protection device is arranged, close to the machine frame, at an opening of the oven; and a control panel is arranged on a surface of the machine frame. The automatic electric pancake machine is simple in structure, convenient to use, improved in work efficiency, and capable of improving food quality.

Owner:平顶山市迈思达机械设备制造有限公司

A special automatic oil injection device for aerated concrete block mold

InactiveCN103878870BAvoid undersprayRealize multi-directional sprayingCeramic shaping apparatusHigh pressurePetroleum engineering

The invention discloses a special automatic oil spraying device for an aerated concrete block mold. The device comprises a machine frame, wherein the top of the machine frame is provided with two cylinders, the bottoms of the two cylinders are vertically connected with supporting arms, an oil duct is horizontally connected between the supporting arms, the bottom of the oil duct is provided with three spherical spraying heads which are respectively provided with a gas filling nozzle, the gas filling nozzles are connected with the two cylinders through air filling pipes, the middle of the top of the oil duct is provided with an oil conveying pipe, the oil conveying pipe is provided with a one-way valve, the outside of the one side of the machine frame is provided with two trapezoid platforms, each platform is provided with a PLC controller and a high-pressure oil pump, the inner side of one side of the machine frame is provided with a supporting frame, the supporting is provided with a sensor, the sensor is connected with the PLC controllers through wires, the PLC controllers are connected with the cylinders and the high-pressure oil pumps through wires, the high-pressure oil pumps are connected with the oil conveying pipe and are connected with an oil barrel through oil inlet pipes, manual oil coating is avoided, work efficiency is improved, labor cost is reduced, product quality is guaranteed, and safety hidden risks and health hidden risks of workers are reduced.

Owner:江苏中技新型建材有限公司

Self-lubricating gear with oil guide grooves

ActiveCN112762159APrevent backflowEasy to remove and replaceGear lubrication/coolingPortable liftingOil canGear wheel

The invention discloses a self-lubricating gear with oil guide grooves, and belongs to the field of mechanical transmission. The self-lubricating gear with the oil guide grooves comprises a gear body, partition plates, an oil storage cavity, an oil inlet and a plurality of lubricating devices. One-way valves are arranged at the communication positions of the second oil guide grooves and the oil storage cavity, so that lubricating oil can be prevented from flowing back when the gear works. Conical pressing blocks are detachably connected with hydraulic cavities, so that detachment can be conveniently performed to replace pistons. The number of the lubricating devices is equal to that of gear teeth, so that the root of each gear tooth is provided with one oil injection assembly, and the lubricating quality can be guaranteed. The number of the first oil guide grooves is twice that of the gear teeth, and each oil injection assembly is communicated with two first oil guide grooves which are communicated with the left side and the right side of the oil injection assembly respectively, so that oil injection can be more uniform, and when the first oil guide groove on one side is blocked, the gear can continue to be lubricated.

Owner:温岭市腾力机械有限公司

A kind of preparation method of high-efficiency post-spraying process of poultry feed

ActiveCN109588566BImprove growth performanceIncrease daily weight gainWorking-up animal fodderOil and greaseEconomic benefits

Owner:TANGRENSHEN GRP CO LTD

Flour mixing device of a deep-fried dough stick machine

ActiveCN109006896BWell mixedGreat tasteMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsProcess engineeringMechanical engineering

The invention discloses a flour mixing device of a deep-fried dough stick machine, which comprises a dough kneading mechanism, a dough kneading mechanism is arranged at the bottom of the dough kneading mechanism, and a wake-up bin is connected to the right side of the dough kneading mechanism through a hoist. An extruder is fixedly installed at the bottom of the wake-up noodle bin, the right end of the extruder is provided with a feeding mechanism, the lower part of the feeding mechanism is provided with a conveyor, the middle part of the conveyor is provided with a composite molding mechanism, and the conveyor The right part is provided with a stretching and disengaging mechanism, and the bottom of the right end of the conveyor is provided with a frying device, which relates to the field of food processing. The invention can automatically add water to the flour and mix it into dough by imitating the process of artificially making deep-fried dough sticks. The noodles are stretched after being pressed and formed, and finally fried, which greatly reduces manpower and can ensure the taste of fried dough sticks. It is efficient and quick to make fried dough sticks, which is suitable for use in breakfast shops.

Owner:张乐

a fuel injector

ActiveCN104074656BAvoid wastingAvoid cloggingFuel injection apparatusMachines/enginesResidual oilFuel injection

Owner:DONGFENG YUEDA KIA MOTORS CO LTD

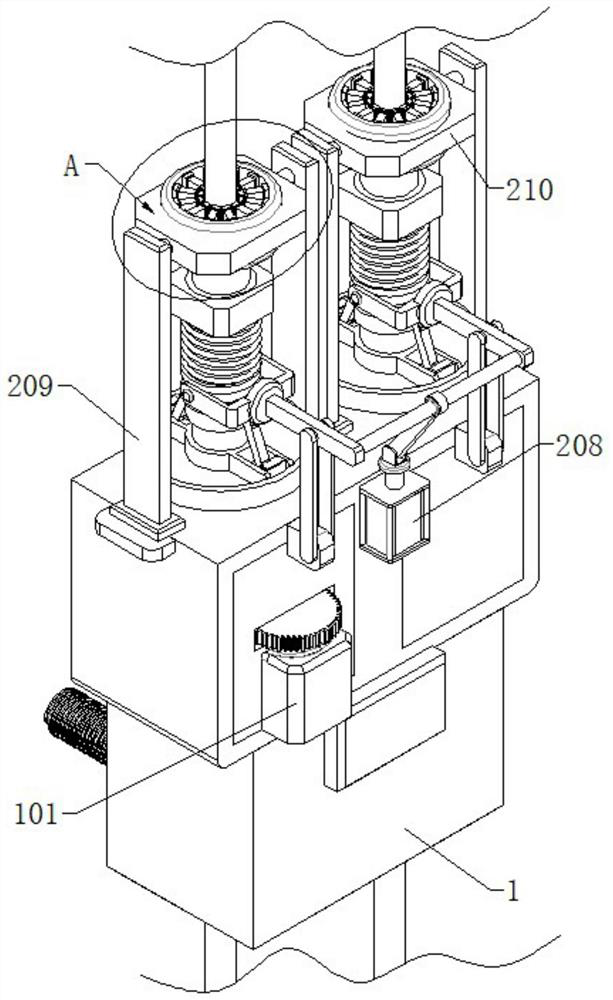

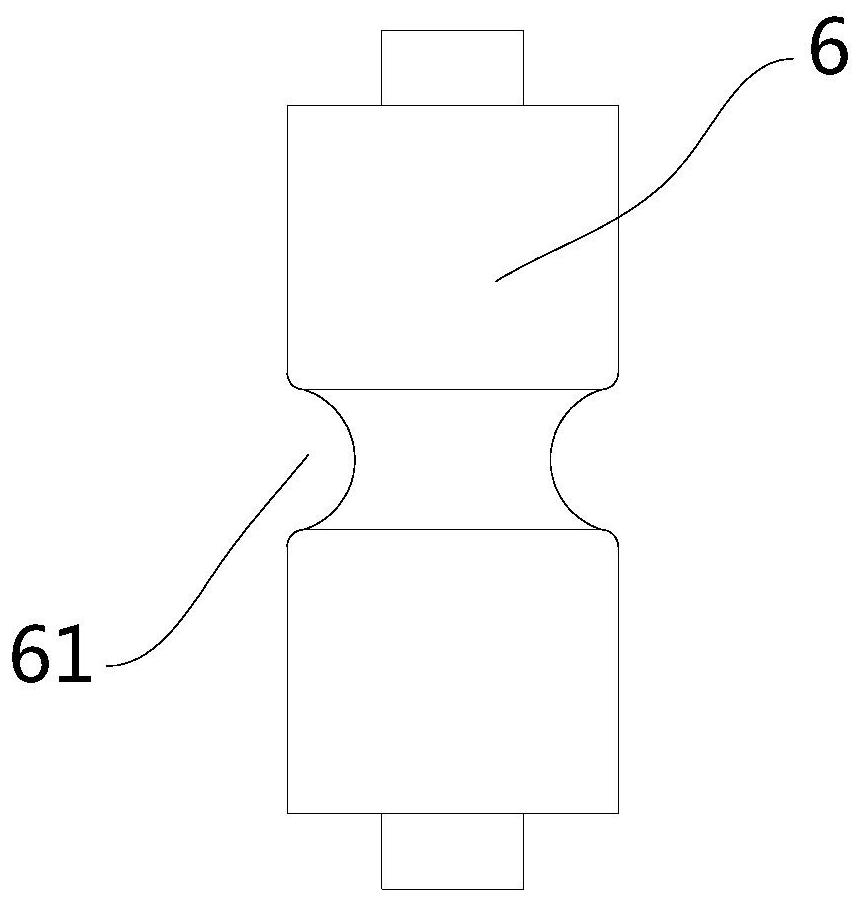

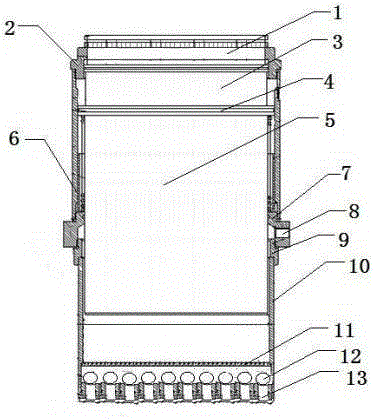

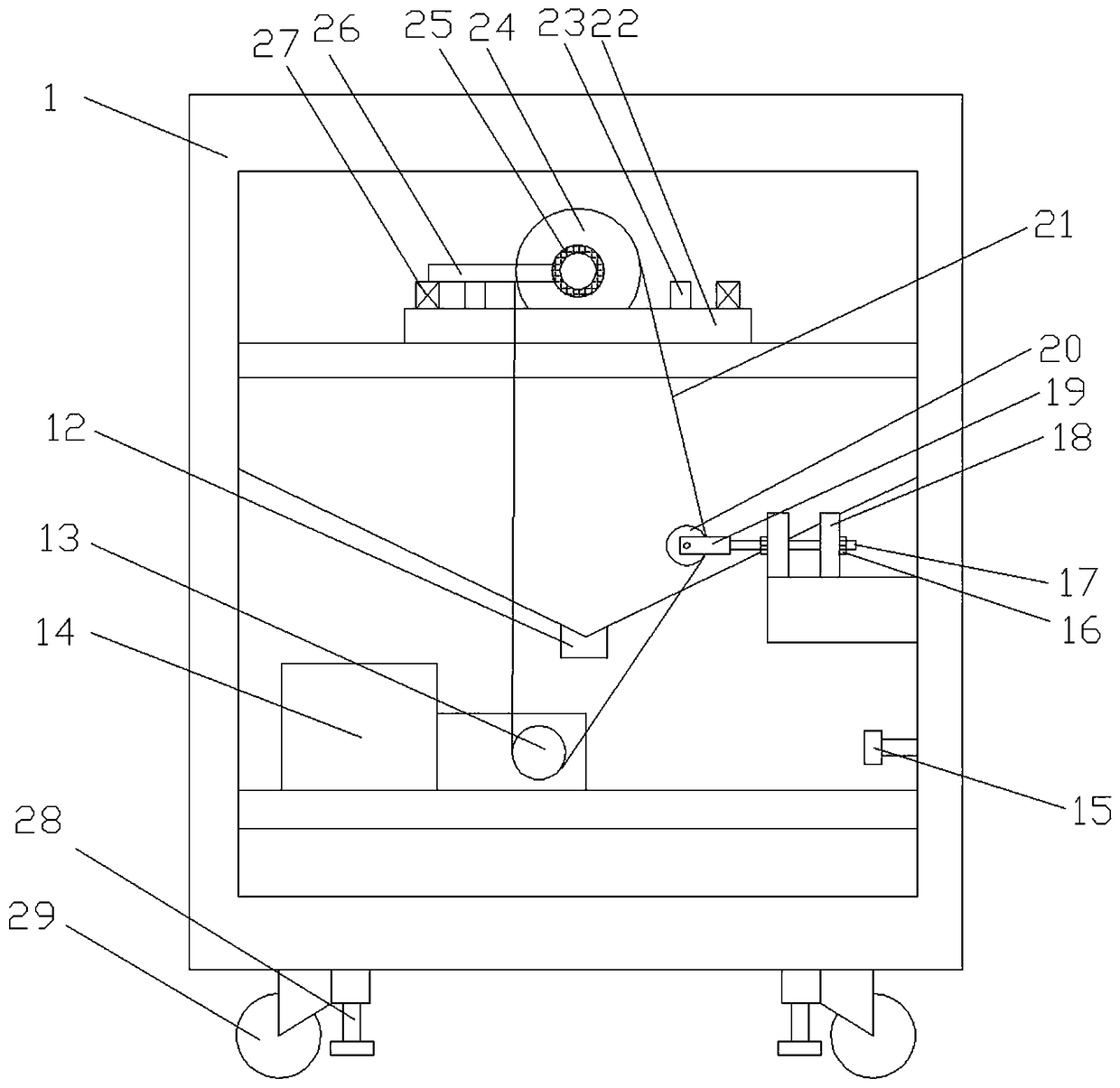

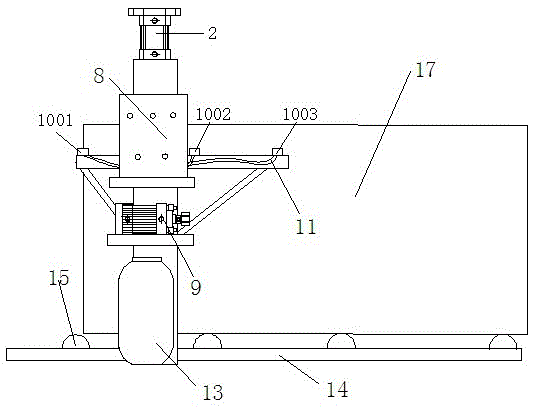

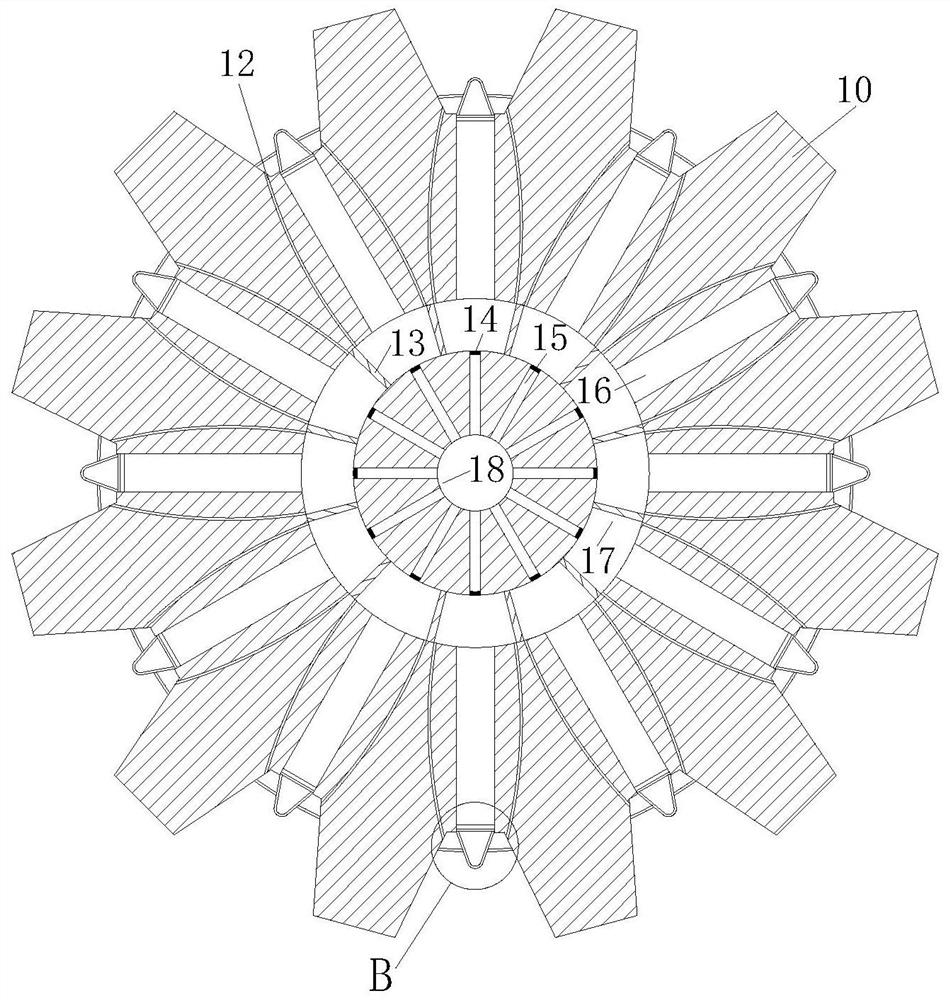

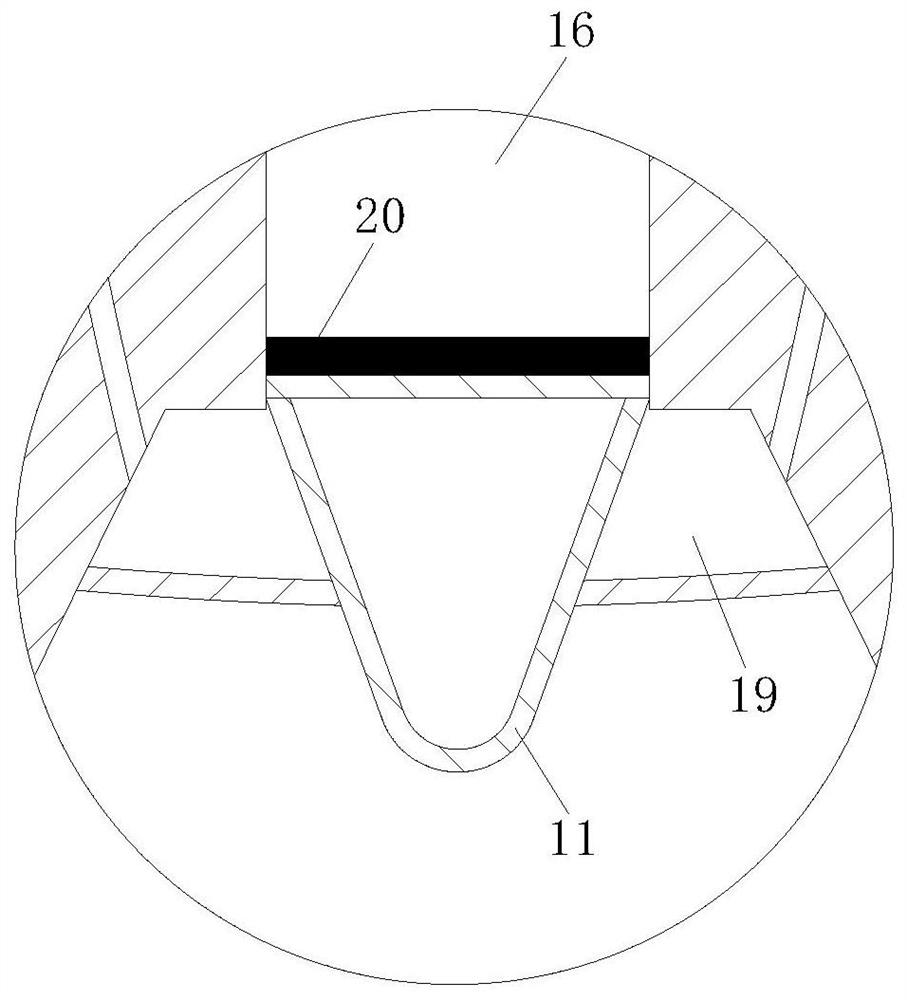

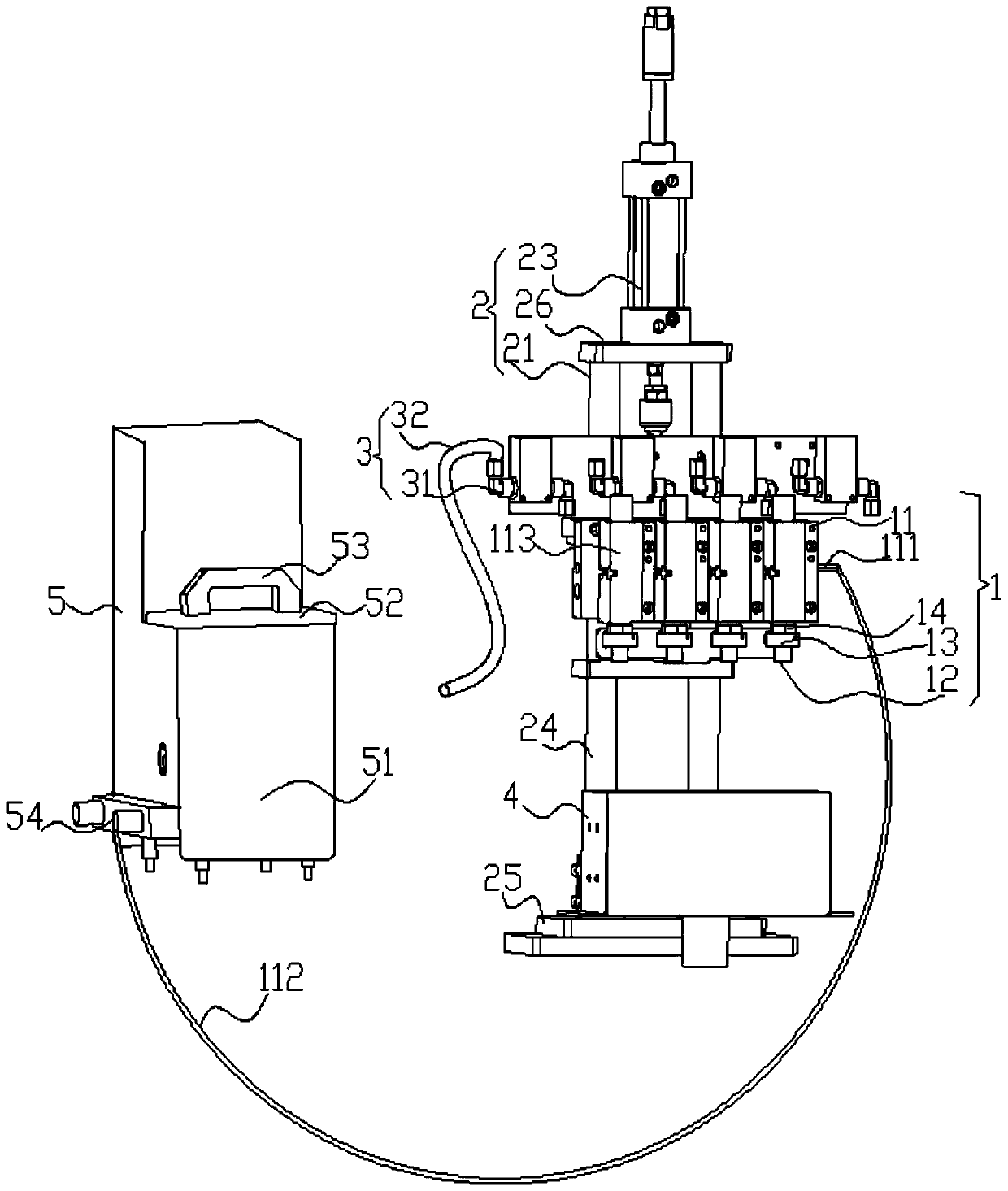

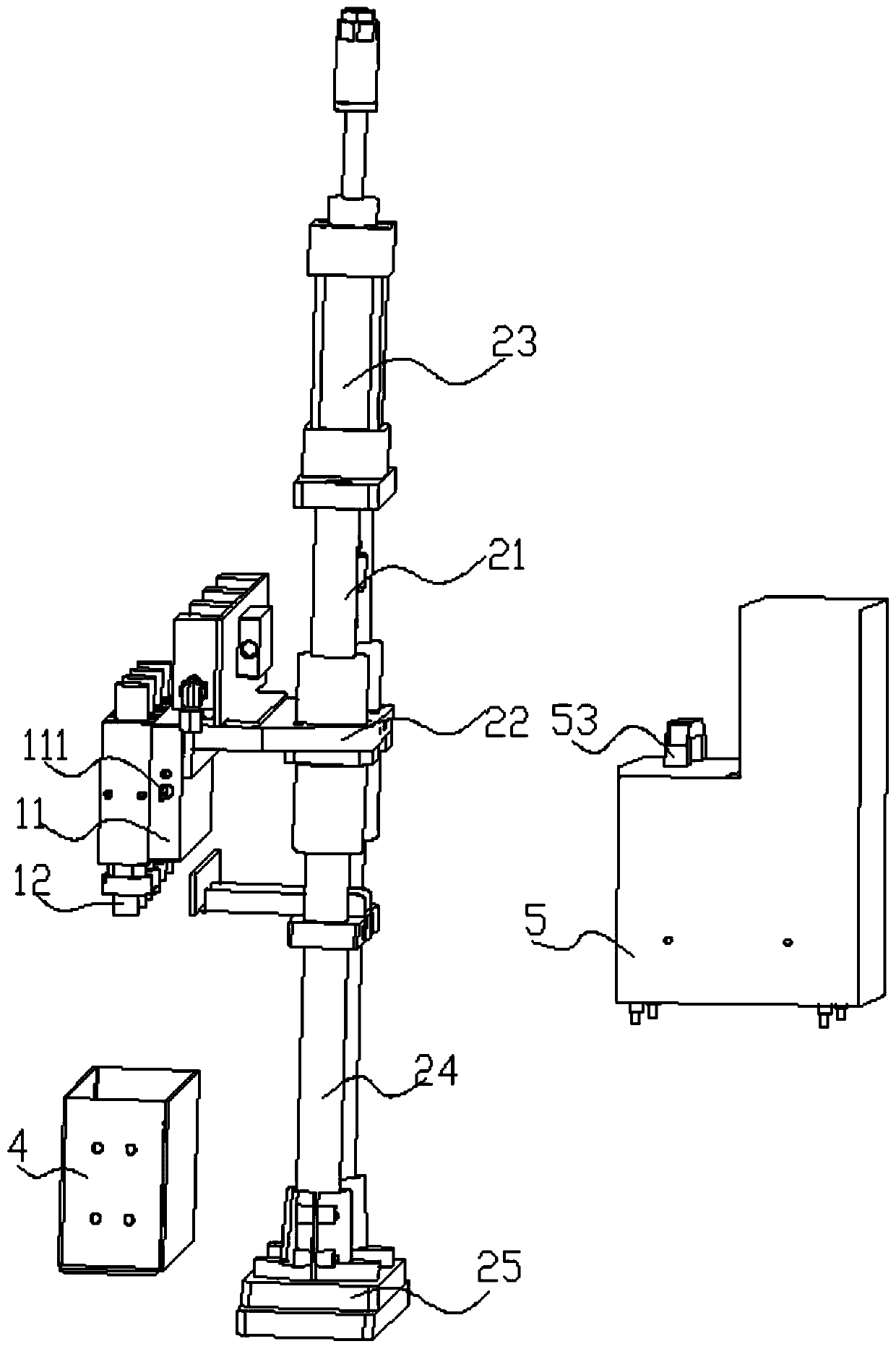

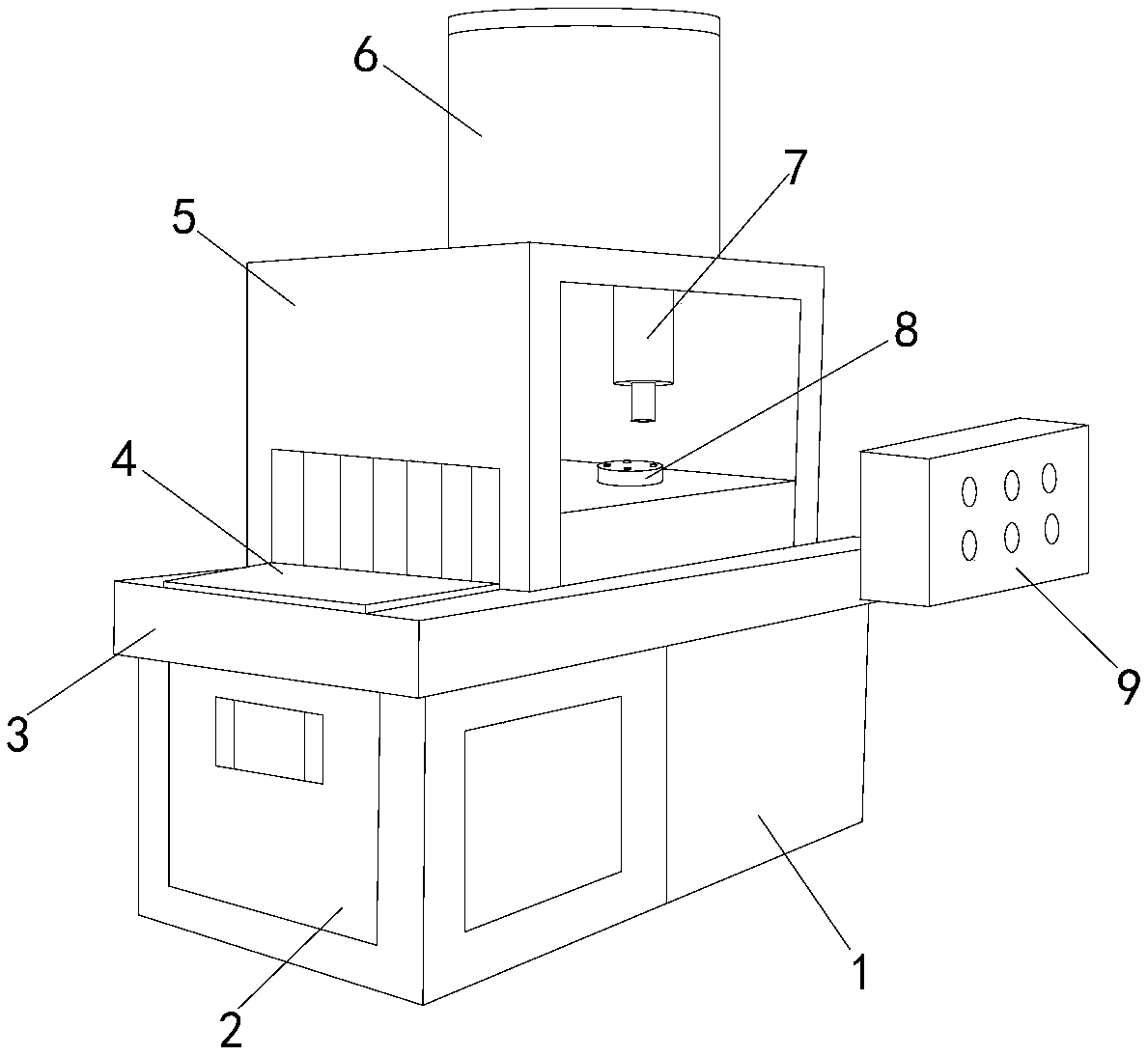

Lipstick inner tube oil injection mechanism

InactiveCN111140758ASpray oil evenlyEvenly lubricatedLubrication containersLubrication check valvesLipstickOil storage

The invention discloses a lipstick inner tube oil injection mechanism. The lipstick inner tube oil injection mechanism comprises an oil injection assembly and a lifting assembly used for controlling the oil injection assembly to rise and drop. The lifting assembly is located above the oil injection assembly and connected with the oil injection assembly. The oil injection assembly comprises an oilstorage accommodating chamber. The oil storage accommodating chamber is located on one side of the lifting assembly and connected with the lifting assembly. The lifting assembly rises and drops through the oil storage accommodating chamber to realize rising and dropping of the oil injection assembly. A control assembly used for controlling the oil injection speed and flow of the oil injection assembly is arranged above the oil storage accommodating chamber. The control assembly is connected with the oil injection assembly. The lipstick inner tube oil injection mechanism provided by the invention provided by the invention can inject oil uniformly, control the oil injection speed and the oil injection flow, can reduce the cost and improve the oil injection efficiency and is high in automation degree and capable of preventing residual lubricating oil on a spray head from dripping to a working platform or lipstick inner tubes and preventing the working platform from being contaminated.

Owner:GUANGZHOU JINHU AUTOMATION EQUIP CO LTD

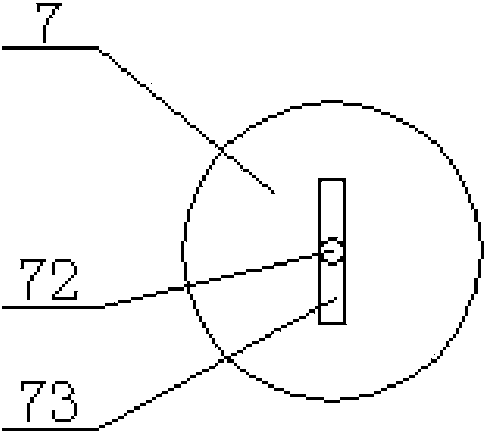

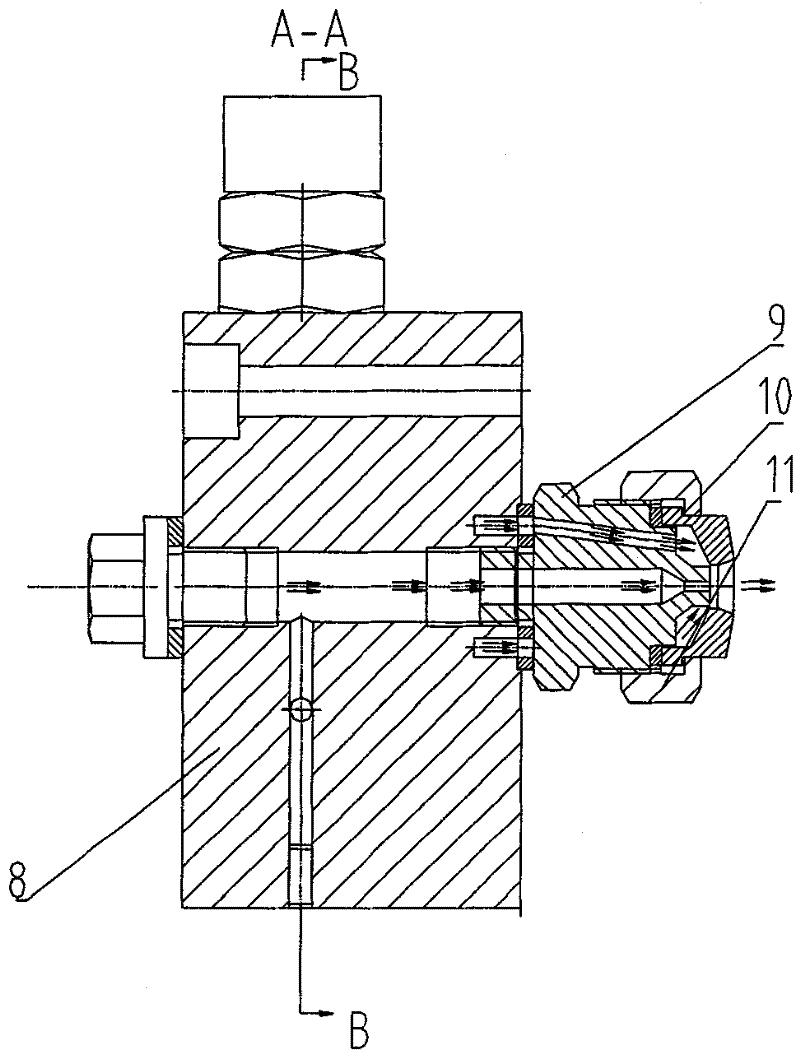

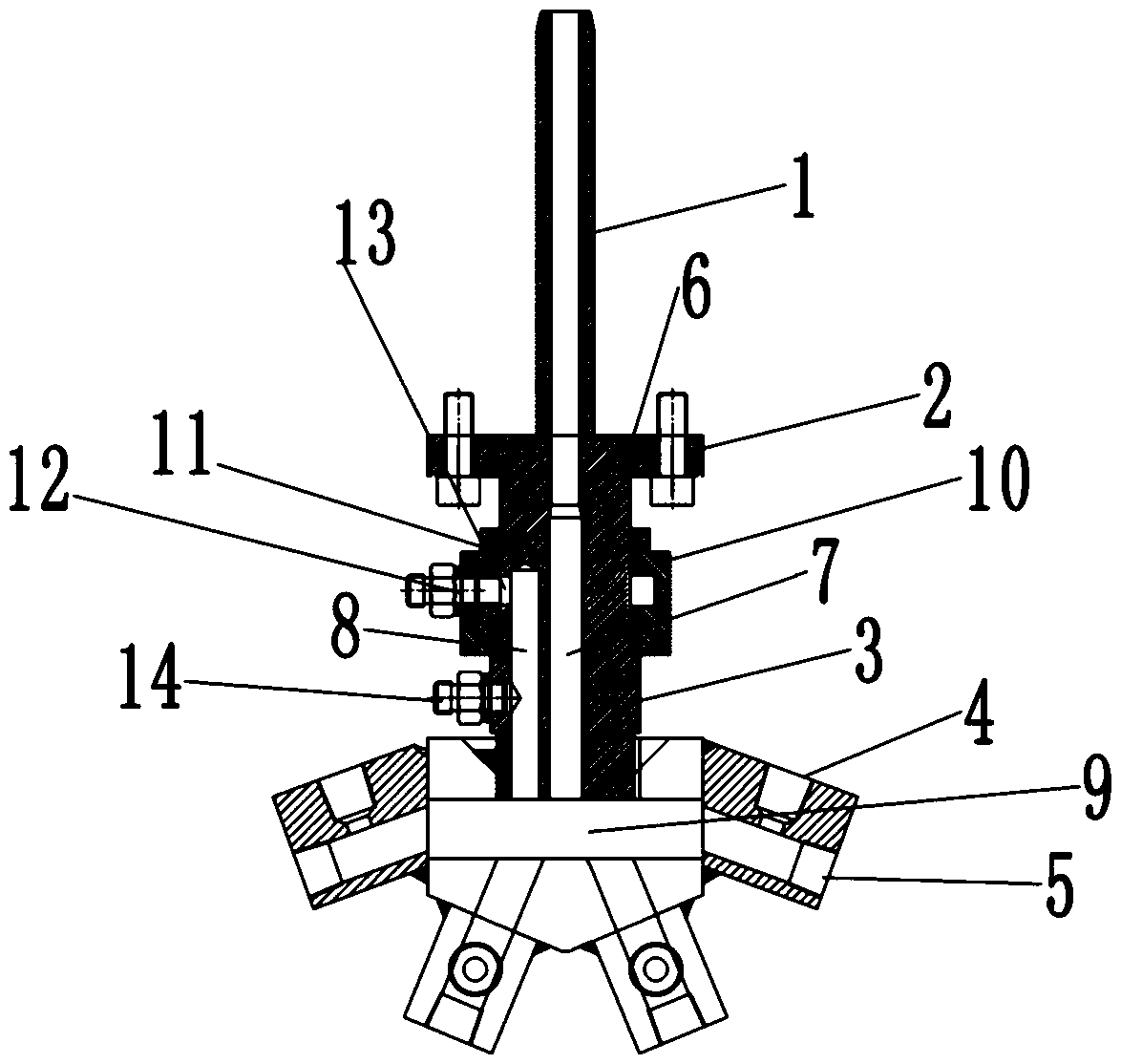

Oil spray machine rotary joint

The invention discloses an oil spray machine rotary joint which comprises a gas transmission guide pipe1, a flange plate 2, an oil-gas mixing part 3 and a joint assembly. The joint assembly comprisesan oil pipe connector 4 and a nozzle connector 5, the flange plate 2 is movably connected with the oil-gas mixing part 3 through a bearing 6, the oil-gas mixing part 3 is internally provided with a high pressure gas cavity 7, an oil cavity 8 and an oil-gas mixing cavity 9, and a pipe cavity of the gas transmission guide pipe 1 communicates with the high pressure gas cavity 7. The oil spray machinerotary joint has the beneficial effects that rotation and oil spraying can be carried out at the same time, oil and gas are supplied respectively, and therefore oil spraying is more uniform.

Owner:NANTONG HENGDA MACHINERY MFG

Hardware block oil spraying antirust device

The invention discloses a hardware block oil spraying antirust device. The hardware block oil spraying antirust device structurally comprises a rotation machine body, a distribution box, a bearing platform, a motion plate, an outer frame, an oil storage barrel, an oil spraying barrel, a loading fixing frame and a controller. The rotation machine body is arranged on the right side of the distribution box and electrically connected with the distribution box. The bearing platform is arranged above the rotation machine body and the distribution box and is in lock connection with the rotation machine body and the distribution box. The loading fixing frame is arranged above the rotation machine body and is in transition fit with the loading fixing frame. The loading fixing frame is arranged below the oil spraying barrel and is in interference fit with the oil spraying barrel. The oil spraying barrel is arranged above the inner side of the outer frame and is in lock connection to the outer frame. When the equipment is used, through an arranged rotation mechanism, the hardware block oil spraying antirust device can solve the problems that in the prior art, when oil spraying is conducted ona hardware block, for irregularity, oil spraying is uneven due to assembling plate fixing, and the optimal spraying antirust effect cannot be achieved, equipment spraying is more uniform, and the antirust effect is better.

Owner:浙江光和园林有限公司

Deep-frying device for deep-fried dough sticks, capable of maintaining quality of used oil

ActiveCN109197924AImprove the mixing effectImprove mixing efficiencyOil/fat bakingBaking plantsEngineeringFood processing

The invention discloses a deep-frying device for deep-fried dough sticks, capable of maintaining the quality of used oil. The deep-frying device comprises a dough mixing mechanism, wherein a dough kneading mechanism is arranged at the bottom of the dough mixing mechanism; a dough fermenting bin is connected to the right side of the dough kneading mechanism through a lifting machine; an extruding machine is fixedly mounted at the bottom of the dough fermenting bin; a discharging mechanism is arranged at the right end of the extruding machine; a conveyor is arranged below the discharging mechanism; a composite shaping mechanism is arranged at the middle part of the conveyor; a stretching and separating mechanism is arranged at the right part of the conveyor; and an deep-frying device is arranged at the bottom of the right end of the conveyor. The invention relates to the field of food processing. According to the deep-frying device disclosed by the invention, the course of manually making the deep-fried dough sticks can be imitated, water is automatically added to flour, mixing is performed to form dough, dough kneading, dough fermenting and compressing for shaping are performed, then stretching is performed, and finally deep-frying is performed, so that labor is greatly reduced, the mouth feel of the deep-fried dough sticks can be guaranteed, the deep-fried dough sticks are effectively and quickly made, and the deep-frying device is suitable for breakfast shops to use.

Owner:张乐

A screw air compressor fuel injection device

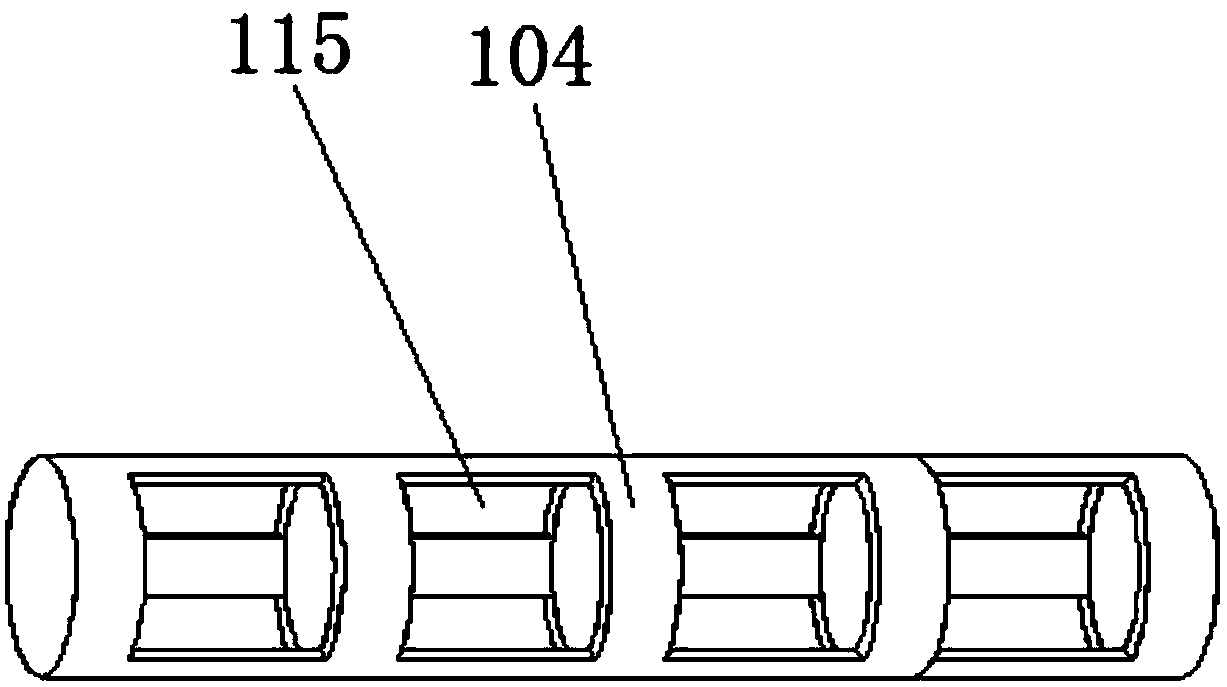

ActiveCN107906008BSpray oil evenlySolve the blockageRotary/oscillating piston pump componentsLiquid fuel engine componentsAir compressorInjection device

The invention discloses an oil injection device of a screw air compressor. The oil injection device comprises a male screw (8), and further comprises an oil injection rod (1) and an oil pipe (2); oneend of the oil pipe (2) extends into the oil injection rod (1); the other end of the oil injection rod (1) is connected to external oil liquid; a spiral groove (3) which meshes with the male screw (8)is formed in the outer wall of the oil injection rod (1); a plurality of oil blocking blocks (4) are arranged in the spiral groove (3); through holes allowing the oil blocking blocks (4) to vertically slide in the axial direction of the oil injection rod (1) are formed in the spiral groove (3); the oil blocking blocks (4) are connected with reset springs (7) penetrating through the through holes;oil injection plates (5) which are attached to the oil blocking blocks (4) are arranged on the spiral groove (3) and communicate with the oil pipe (2); and rotating shaft (6) are arranged at the twoends of the oil spraying rod (1) in an extending mode. The oil injection device has the beneficial effects that oil injection can be more uniform, and the blockage of the oil pipe can be avoided.

Owner:HAIYAN JINHAI HARDWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com