A kind of preparation method of high-efficiency post-spraying process of poultry feed

A post-injection fuel quantity and feed technology, which is applied in the molding or processing of animal feed, animal feed, and application, can solve the problems of easy agglomeration, too small fuel injection, uneven fuel injection, etc., so as to improve the growth performance. , The effect is good, the effect of avoiding the loss of feed nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Tangrenshen Group Xuzhou Xiangda Meat Duck Compound Feed 313T was used as the post-injection test object, and the total amount of feed for a single injection was M tons. In order to verify the test effect, the granulation efficiency of the granulator is set at a stable feeding rate of 9 tons to 10 tons per hour. The fan nozzle uses a 303 stainless steel nozzle with a connection size of 1 / 4 inch, model 1 / 4GSS6520; the conical nozzle uses a connection 303 stainless steel nozzle with a size of 1 / 4 inch, model 1 / 4GGSS6.5, the follow-up examples and comparative examples, except for the change of fuel injection volume and fuel injection temperature, other indicators remain unchanged, and the follow-up will not be repeated.

[0035] Specifically include the following steps:

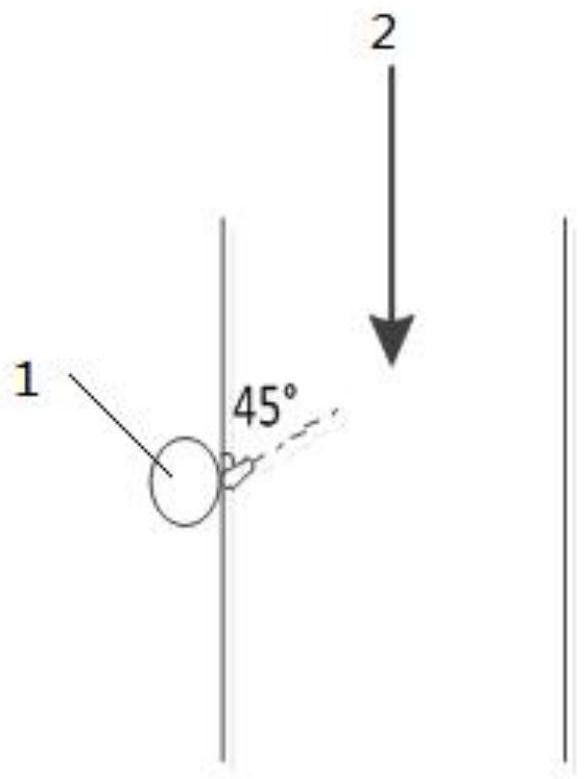

[0036] (1) After the meat and poultry pellets are granulated from the pellet mill, the feed is lifted to the silo by the elevator, and then the first post-injection is performed; the first injection is 5%...

Embodiment 2

[0047] Tangrenshen Group Xuzhou Xiangda Meat Duck Compound Feed 313T was used as the post-spray test object.

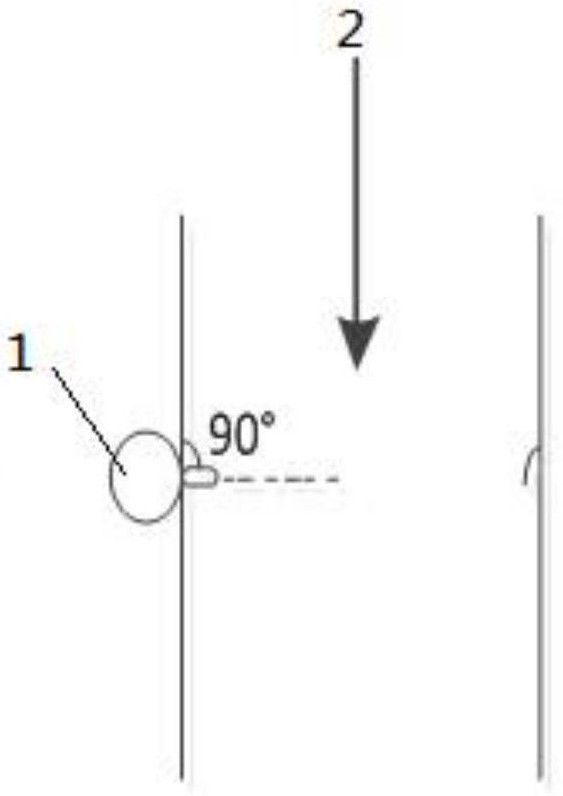

[0048] (1) After the granulation of the meat and poultry pellets is completed, the first oil injection is carried out; the first oil injection is 5% M, the oil injection temperature is 75°C, and the number of oil injection nozzles is 4 fan-shaped nozzles, and the nozzles and the feed are arranged at 90°.

[0049] (2) The feed after the first oil injection is put into the auger for stirring. The length of the auger is 5m, and the feed speed in the auger is controlled at 0.5m / s; the internal temperature of the auger is controlled at 75°C.

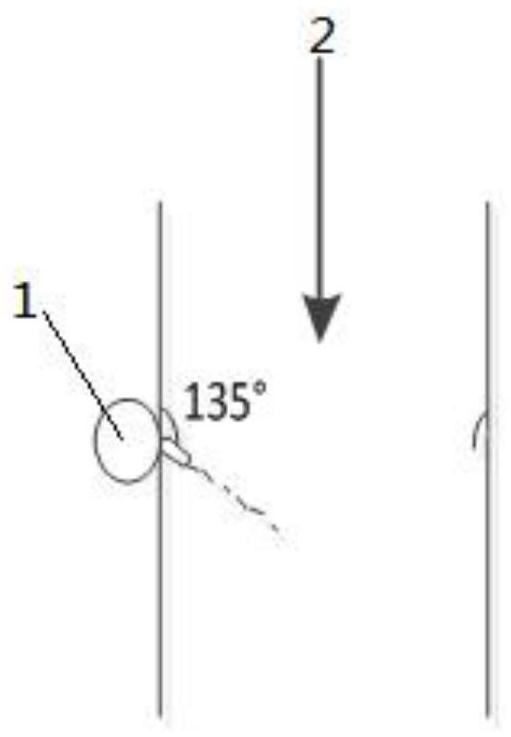

[0050] (3) After the feed flows out from the auger, the second injection is carried out; the amount of the second injection is 5% M, the number of nozzles is 4 conical nozzles, the nozzles and the feed are arranged at 135°, and the injection temperature is 75°C .

Embodiment 3

[0056] Tangrenshen Group Xuzhou Xiangda Meat Duck Compound Feed 313T was used as the post-spray test object.

[0057] (1) After the granulation of meat and poultry pellets is completed, the first post-injection is carried out; the first injection volume is 5% M, the injection temperature is 85°C, the number of nozzles is 4 fan-shaped nozzles, and the nozzles and feed are arranged at 90°.

[0058] (2) The feed after the first oil injection is put into the auger for stirring. The length of the auger is 5m, and the forward speed of the feed in the auger is controlled at 1.0m / s; the internal temperature of the auger is controlled at 70°C.

[0059] (3) After the feed flows out from the auger, the second oil injection is carried out; the amount of the second injection is 5% M, the number of nozzles is 4 fan-shaped nozzles, the nozzles and the feed are arranged at 90°, and the injection temperature is 85°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com