Lipstick inner tube oil injection mechanism

A lipstick and inner tube technology, used in mechanical equipment, engine components, lubricating oil containers, etc., can solve the problems of uneven application, difficult to control the amount of oil applied, and low efficiency of lubricating oil spraying, so as to ensure standardization and prevent backflow. , the effect of flexible painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

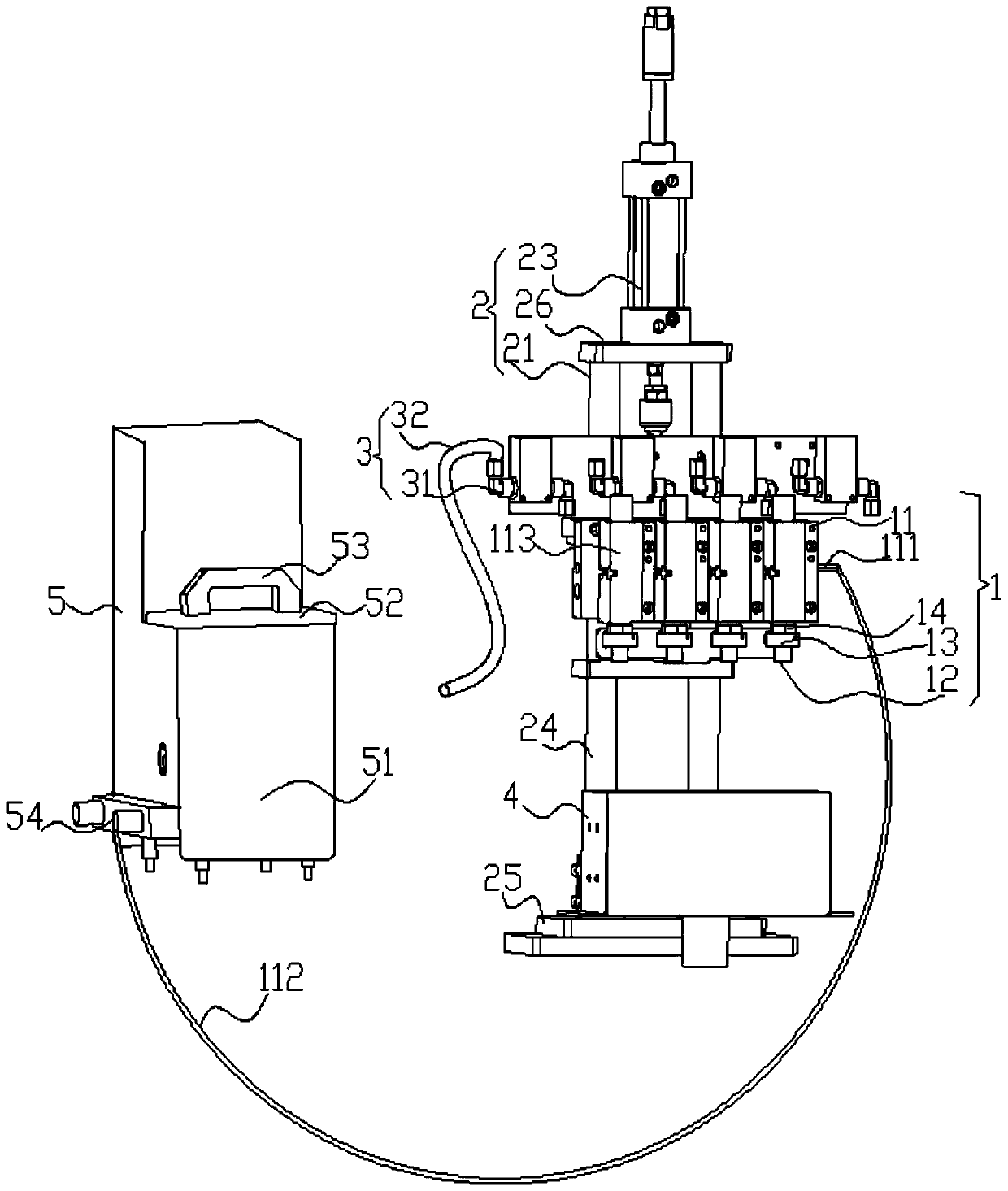

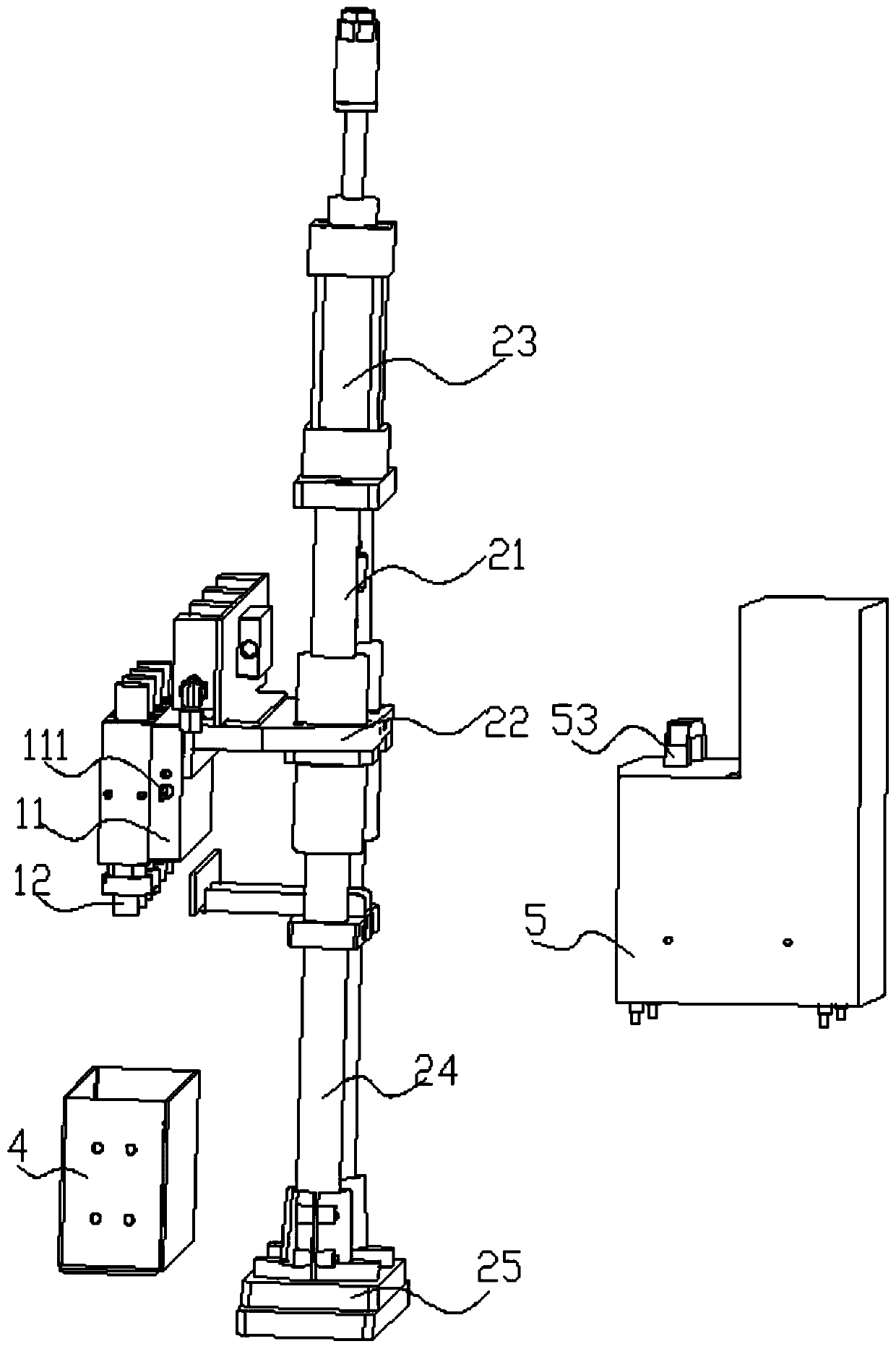

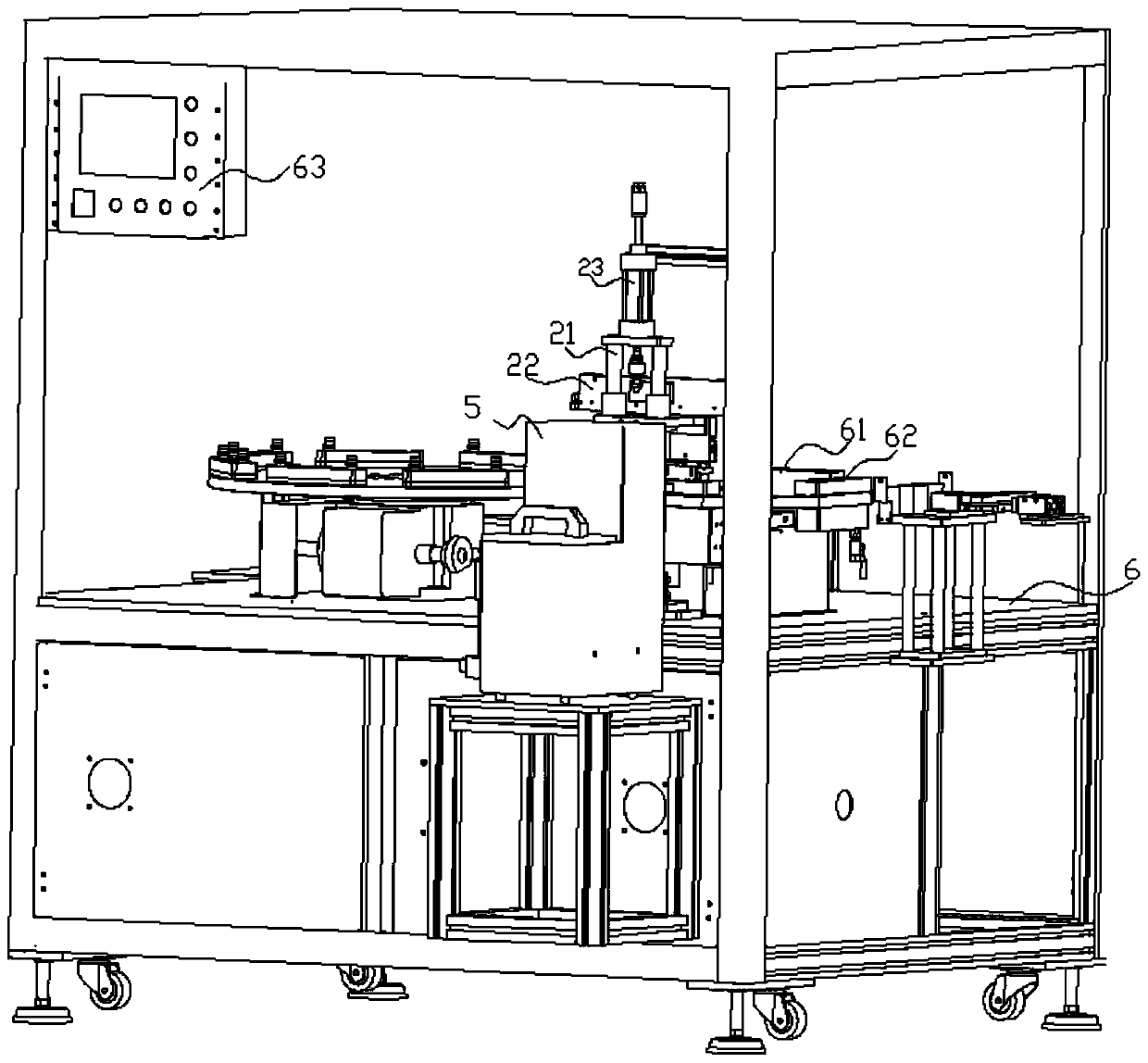

[0047] refer to figure 1 , the oil storage chamber 11 protrudes forward to form four rectangular oil storage compartments 113, the oil storage compartments 113 communicate with the oil storage chamber 11, wherein four nozzles 12 are provided, and the turntable 13 is also provided with four, and driving rod 14 is also provided with four, and each nozzle 12 is all connected with a rotating disc 13, and each rotating disc 13 is all connected with a driving rod 14, and each nozzle 12 top is correspondingly installed with a The oil storage compartment 113 is distributed from the oil in the oil storage compartment 11 to the oil storage compartment 113, and the nozzle 12 sprays oil through the lubricating oil from the oil storage compartment 113 installed above it. One nozzle 12 can spray oil on the inner walls of multiple lipstick spiral tubes at the same time, which improves the work efficiency of oil injection and reduces the cost;

[0048] The oil storage chamber 11 is provided ...

Embodiment 2

[0050] The structure about the nozzle 12 assembly can be:

[0051] The outer end of the nozzle 12 can be surrounded by a cushion material, and the cushion material can be a sponge cushion. When the cushion material is absorbed by the surrounding cushion material, when the cushion material extends into the lipstick spiral tube along with the nozzle 12, the drive rod 14 drives the turntable 13 to drive the nozzle 12 to rotate, so that the cushion material is squeezed, so that the cushion material and the lipstick spiral The inner wall of the tube fits snugly, so that the upper lubricating oil seeps out of the cushion substance and spreads evenly on the inner wall of the lipstick spiral tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com