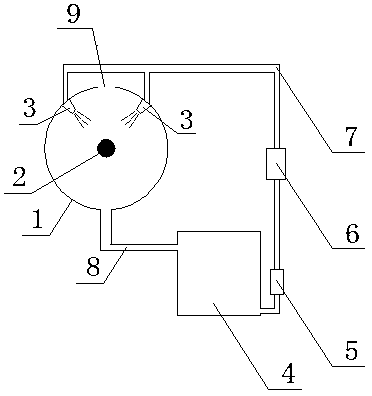

Oil injection device for coal mine winch steel wire rope

A technology of oil injection device and wire rope, which is applied in the direction of injection device, hoisting device, clockwork mechanism, etc., can solve the problems of wasting oil, unsafe, polluting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

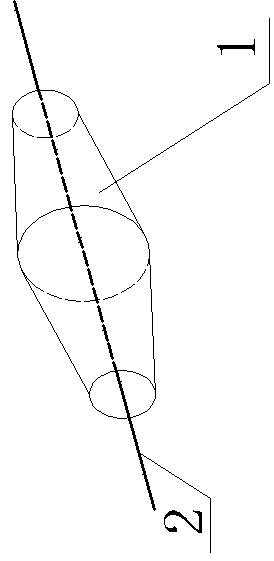

[0006] The fuel spray cover of the present invention is installed to the desired position, and the fuel spray cover wraps part of the steel wire rope. After the oil pump is turned on, the fuel in the fuel tank will be evenly sprayed onto the wire rope through the fuel nozzle, and some fuel will drip from the wire rope, and the dripping fuel will collect at the bottom of the fuel injection cover, and return to the fuel tank through the oil return pipe for circulation use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com