Decontaminating device for surface grinding of speed reducer bearing inner rings

A technology of bearing inner ring and decontamination device, which is used in mechanical equipment, engine components, engine lubrication, etc., can solve the problem that the grinding and decontamination work cannot be carried out normally, the inner ring of the bearing is prone to scratches, and the inner ring of the bearing is prone to deviation and other problems, to achieve the effect of simple structure, good positioning effect and uniform fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

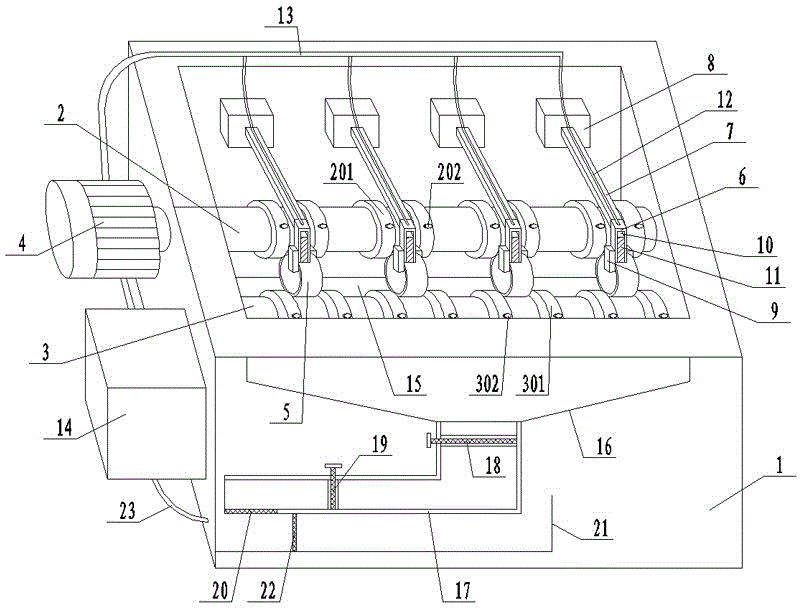

[0010] Such as figure 1 As shown, the surface grinding and decontamination device of the bearing inner ring of the reducer includes: a frame 1, a rotating shaft 2 and a supporting shaft 3 are arranged inside the frame 1, and one end of the rotating shaft 2 protrudes from the frame 1 and the driving device 4 phase connection, a number of bearing inner rings 5 are evenly arranged between the rotating shaft 2 and the supporting shaft 3, and upper plastic retaining rings 201 are symmetrically sleeved on the rotating shaft 2 on both sides of the bearing inner ring 5, and the upper The plastic retaining ring 201 is connected with the rotating shaft 2 through the upper adjusting screw 202, and the lower plastic retaining ring 301 is sleeved on the support shaft 3 on both sides of the bearing inner ring 5, and the lower plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com