Cashmere fiber fuel injection process and its device

A cashmere fiber and oil injection device technology, applied in the field of cashmere production, can solve the problems of quality deviation of oiling, poor oiling effect, uneven shape, etc., and achieve the effect of improving uniformity, good oiling effect, saving and crude oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment: cashmere fiber oil spraying process, the cashmere output from the cashmere machine is shaped by a pair of shaping rollers at an ambient temperature of 5°C, and the cashmere passed through the shaping rollers is arranged into a circular strip-shaped structure. The cashmere is sprayed with crude oil by several uniformly arranged oil nozzles at an ambient temperature of 5°C.

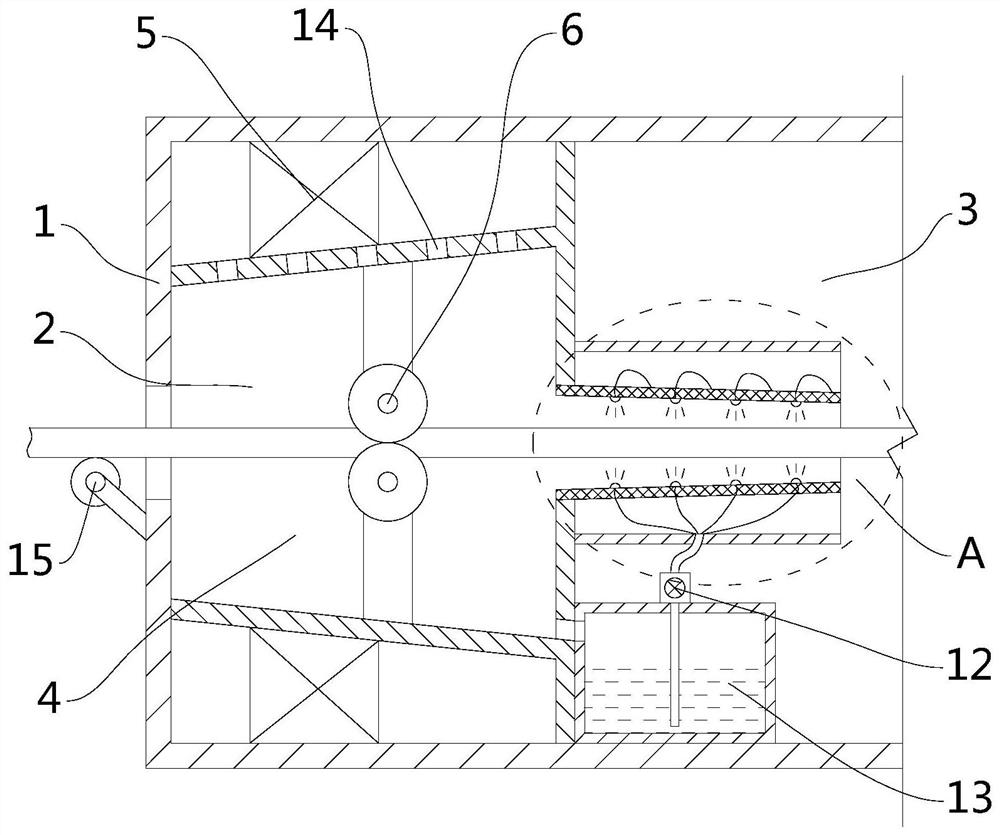

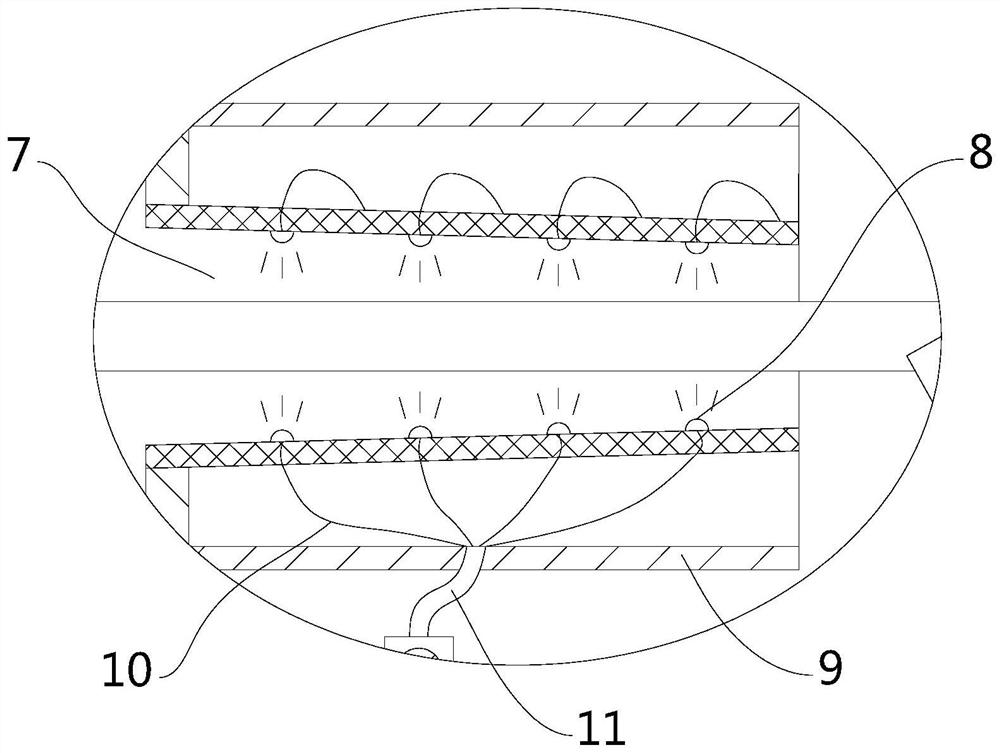

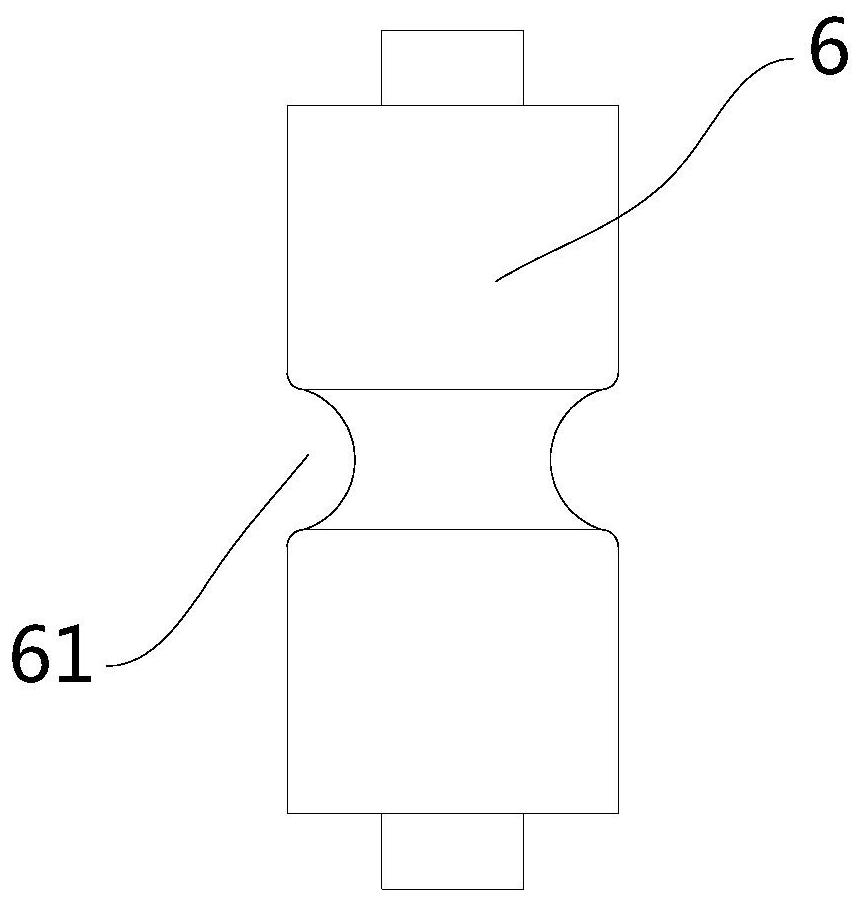

[0020] Cashmere fiber injection device, the structure is as follows Figure 1 to Figure 3 As shown, the fuel injection box 1 is included, and the fuel injection box 1 is provided with a shaping area 2 and a fuel injection area 3. The shaping area 2 is provided with a tapered first cashmere channel 4, and the outer side of the first cashmere channel 4 is A cooling fan 5 is fixed, and a pair of shaping rollers 6 arranged up and down next to each other are arranged inside the first cashmere channel 4, and a circular shaping channel is formed between the pair of shaping rollers 6, for the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com