A multifunctional integrated dryer and its realization method

A realization method and technology of drying machine, which are applied in the directions of pretreatment equipment, pressure impregnation, wood processing appliances, etc., can solve the problems of poor use effect, easy deformation of wood, uneven heating, etc., and achieve easy heat control and wide application range. , good effect of fuel injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

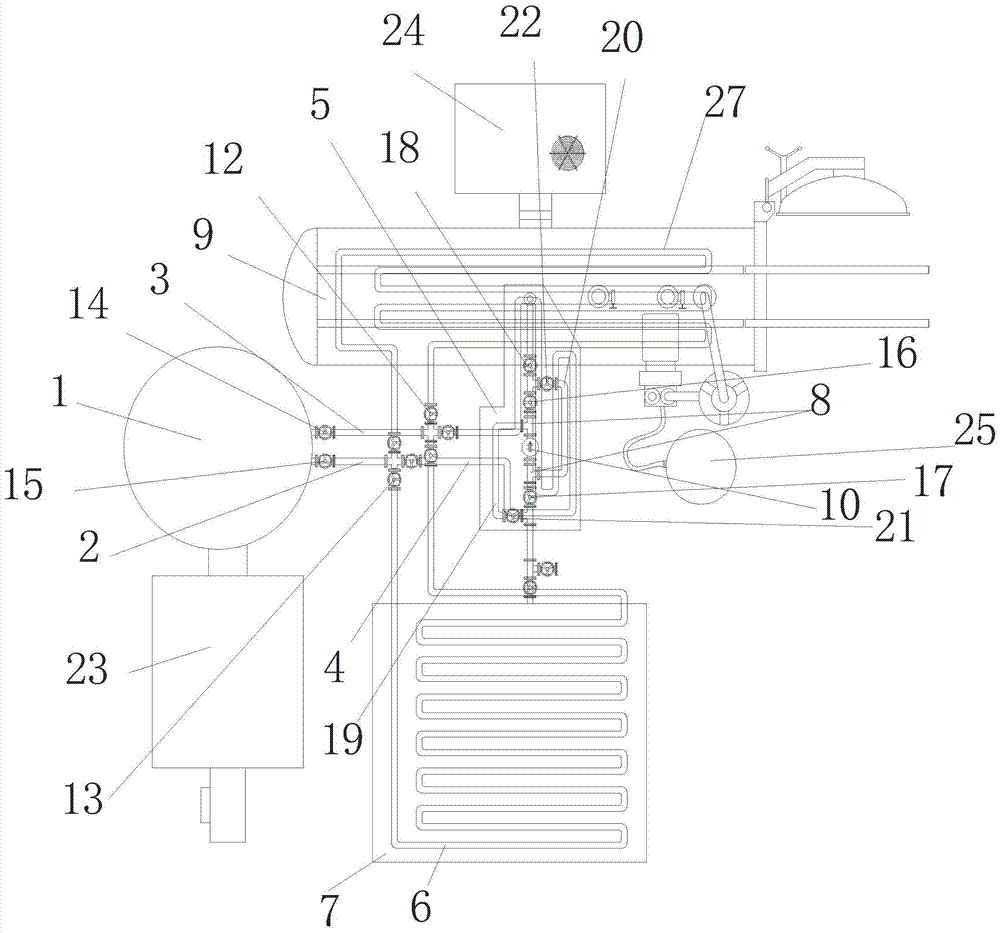

Embodiment 1

[0042] Such as figure 1 As shown, a multi-functional integrated dryer includes a heat transfer oil furnace. The heat transfer oil furnace is connected with a heat transfer oil circulation pipe outlet pipe and a heat transfer oil circulation pipe return pipe. The heat transfer oil circulation pipe outlet pipe is connected to one end of the first heating pipe. The other end of a heating pipe is connected to the return pipe of the heat transfer oil circulation pipe, and the first heating pipe enters the oil tank; the outlet pipe of the heat transfer oil circulation pipe is connected to one end of the second heating pipe, and the other end of the second heating pipe is connected to the return pipe of the heat transfer oil circulation pipe, The heating pipe enters into the oil storage tank; the oil storage tank is connected to the box body through the outlet pipe of the oil pipe, the oil pump is arranged on the outlet pipe of the oil pipe, and the outlet pipe of the oil pipe is arra...

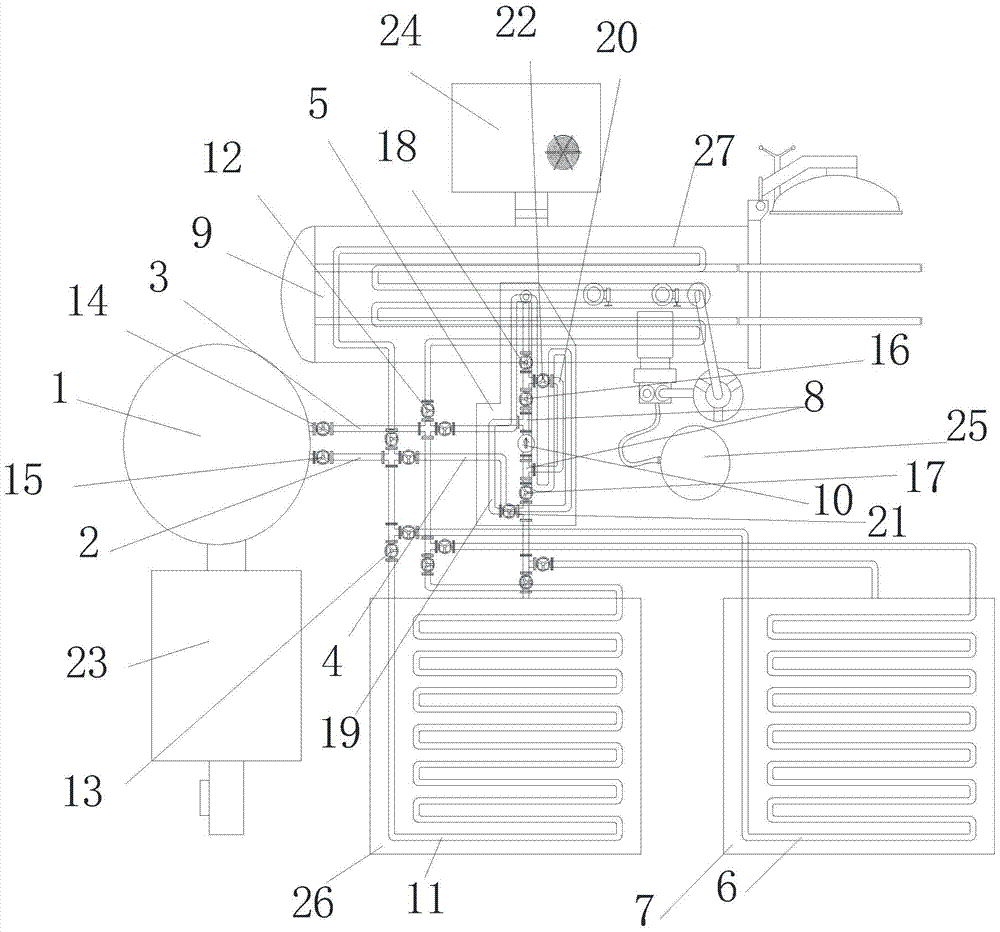

Embodiment 2

[0058] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the inlet end of the sixth valve in this embodiment is connected to one end of the first "U"-shaped pipe, and the other end of the first "U"-shaped pipe is connected to the fifth valve and Between the oil pumps, one end of the second "U"-shaped pipe is connected between the sixth valve and the oil pump, and the other end of the second "U"-shaped pipe is connected between the fifth valve and the oil outlet valve; the first "U"-shaped pipe There is a seventh valve on the top, and an eighth valve on the second "U"-shaped pipe; it also includes a third heating pipe, which leads into the box, and one end of the third heating pipe is connected to the outlet pipe of the heat transfer oil circulation pipe , the other end of the third heating pipe is connected to the return pipe of the heat transfer oil circulation pipe.

[0059] This embodiment also includes a wax tank, the fourth heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com