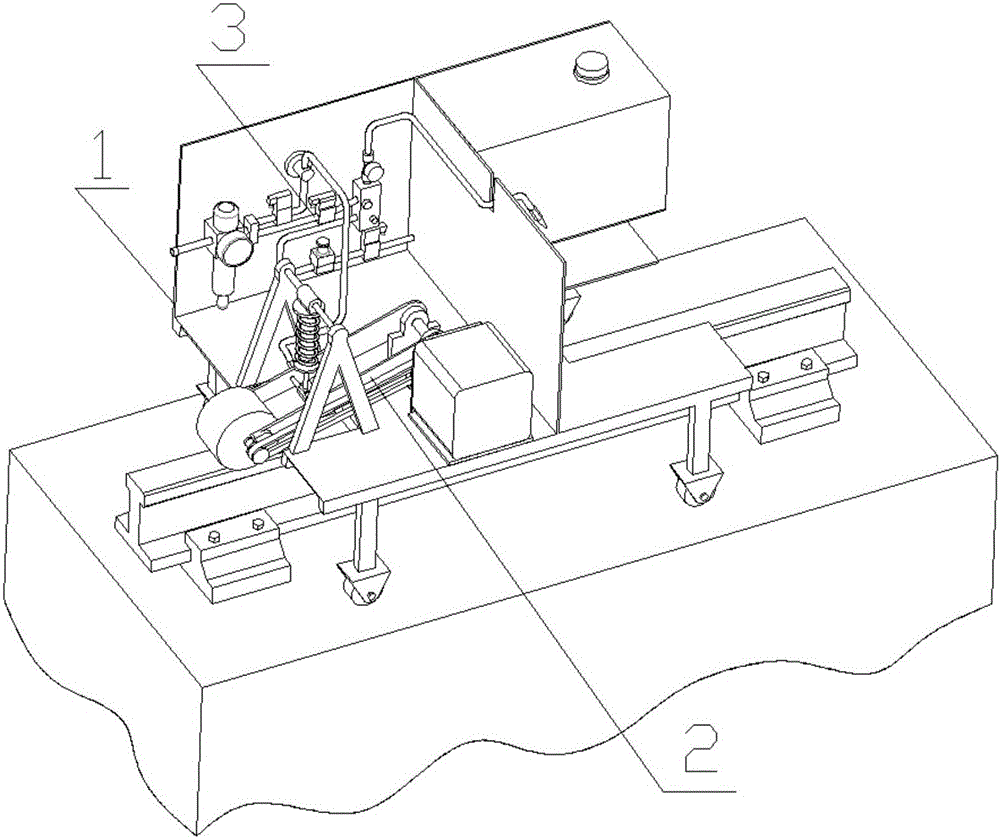

Oil spraying device for towing basin track cleaning

A technology of a fuel injection device and a towing tank, applied in the field of ships, can solve the problems of operation dependence, complex mechanism, inability to accurately control the amount of oil applied, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

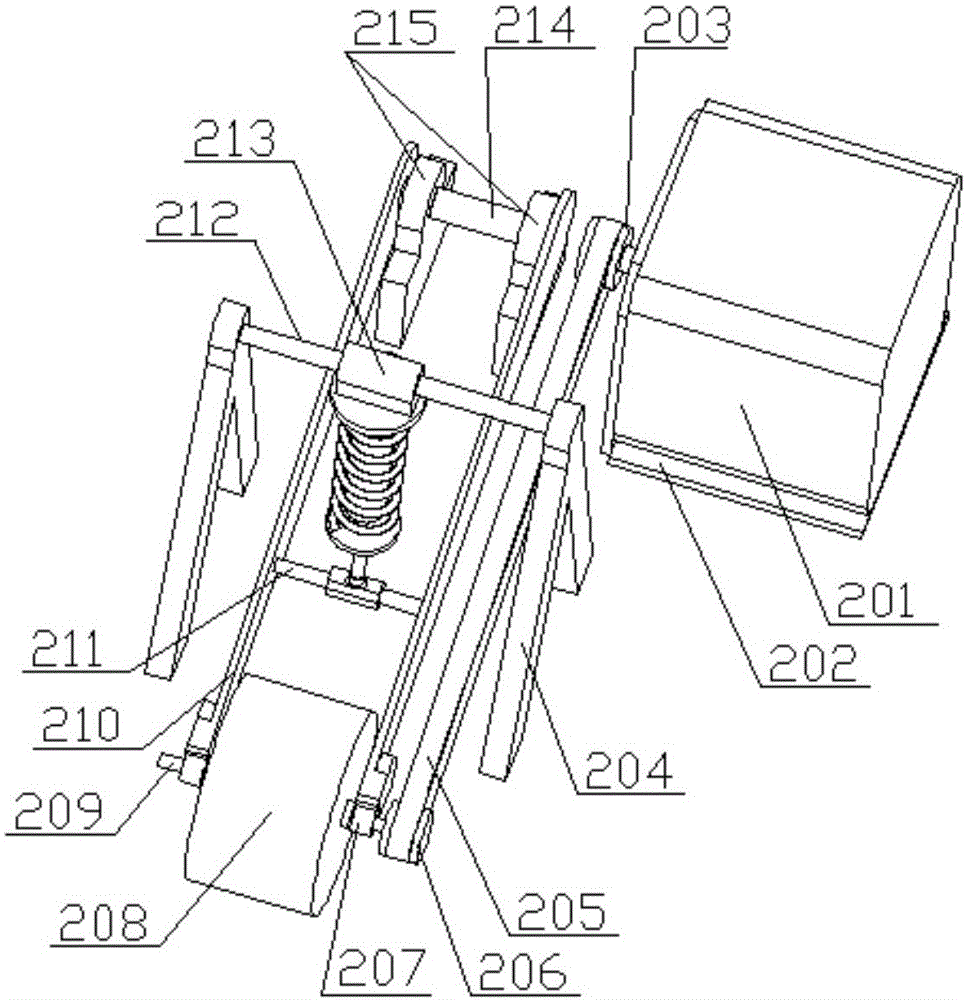

[0023] An implementation example of the present invention: the device is installed in front of the trailer, with the rolling brush 208 in front and the fuel tank 201 in the rear. The air source interface 305 is connected with the air pump on the trailer, and supplies air to the device through the air pump. Adjust the nut at the bottom of the spring shock absorber 213 to make the rolling brush 208 and the track pressure suitable. The roller brush cleaning device and the micro-spray device are controlled by the controller on the trailer. After the trailer is started, first open the motor 201 of the roller brush cleaning device and then start the electromagnetic valve on the micro injection device to carry out the fuel injection operation. After the motor 201 starts, the torque is transmitted to the roller brush shaft 209 by the belt 205 to drive the roller brush 208 to rotate on the track surface, and the track surface dirt is brushed up. When the rolling brush 208 encounters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com