Variable spray hole type electric control oil sprayer

An electronically controlled fuel injection and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problem of inaccurate control of small fuel injection volume, poor diesel engine effect, high control accuracy and response speed, etc. problem, to achieve the effect of improving fuel injection effect, improving power and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings:

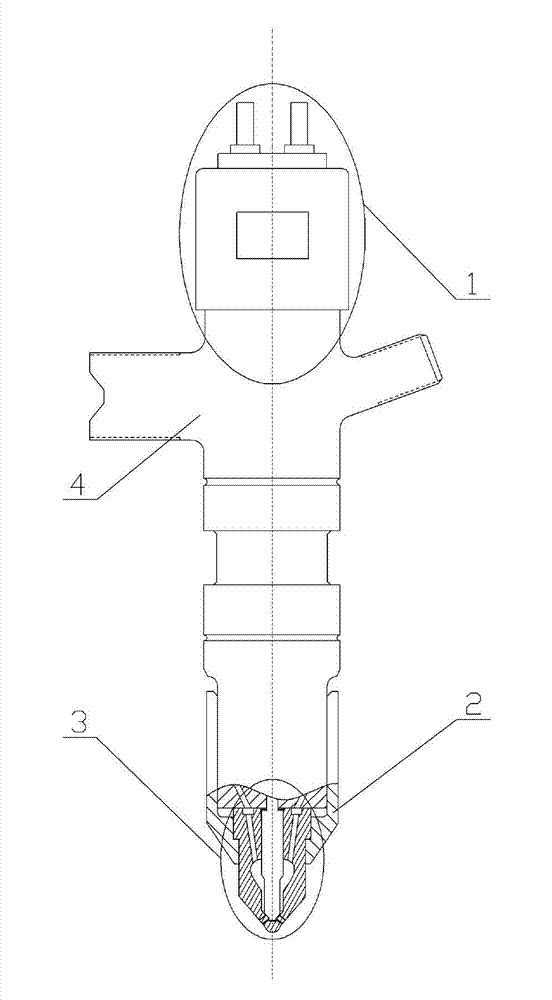

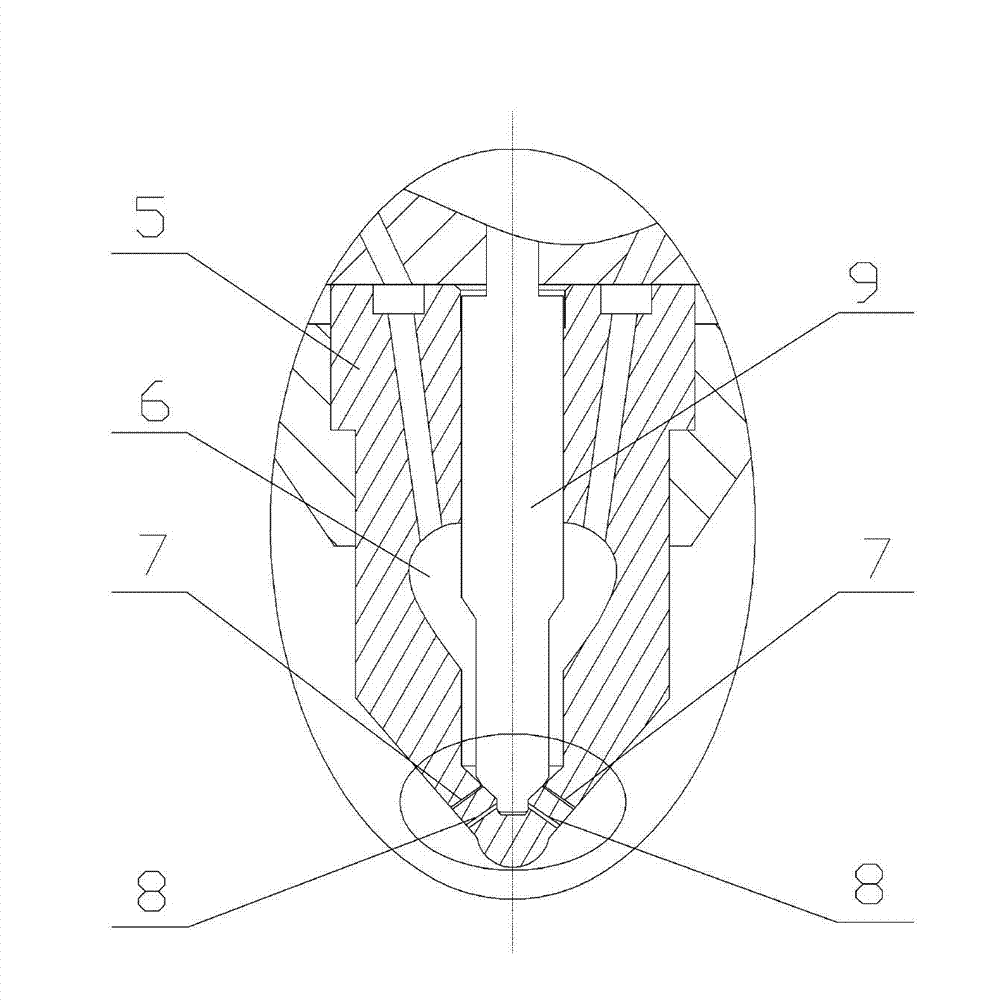

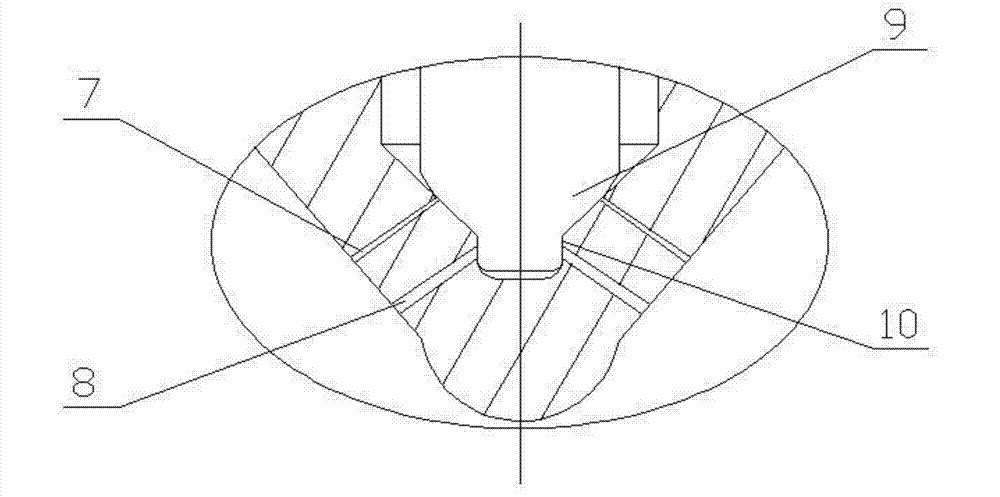

[0014] combine figure 1 ~3, the variable nozzle type electronically controlled fuel injector of the present invention is composed of an electronically controlled actuator part 1 , a fuel injector body 4 and a fuel injection nozzle 3 . The electronically controlled actuator part 1 is located above the fuel injector body 4, and controls the fuel injection timing and fuel injection quantity of the fuel injector by receiving control signals. The fuel injector 3 is located under the fuel injector body 4 and is connected to the fuel injector body 4 through the tight cap 2 . The fuel injection nozzle 3 includes a needle valve 9 and a fuel injection nozzle needle valve base 5, and an oil holding groove 6 is formed between the two, which is respectively communicated with the oil inlet oil passage and the oil injection hole. There are two rows of fuel injection holes at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com