A spraying device before necking of cans

A technology of spraying device and cans, applied in the direction of spraying device, etc., can solve the problems of excessive fuel injection and uneven fuel injection, and achieve the effect of reliable fuel injection process, good fuel injection effect and easy fixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

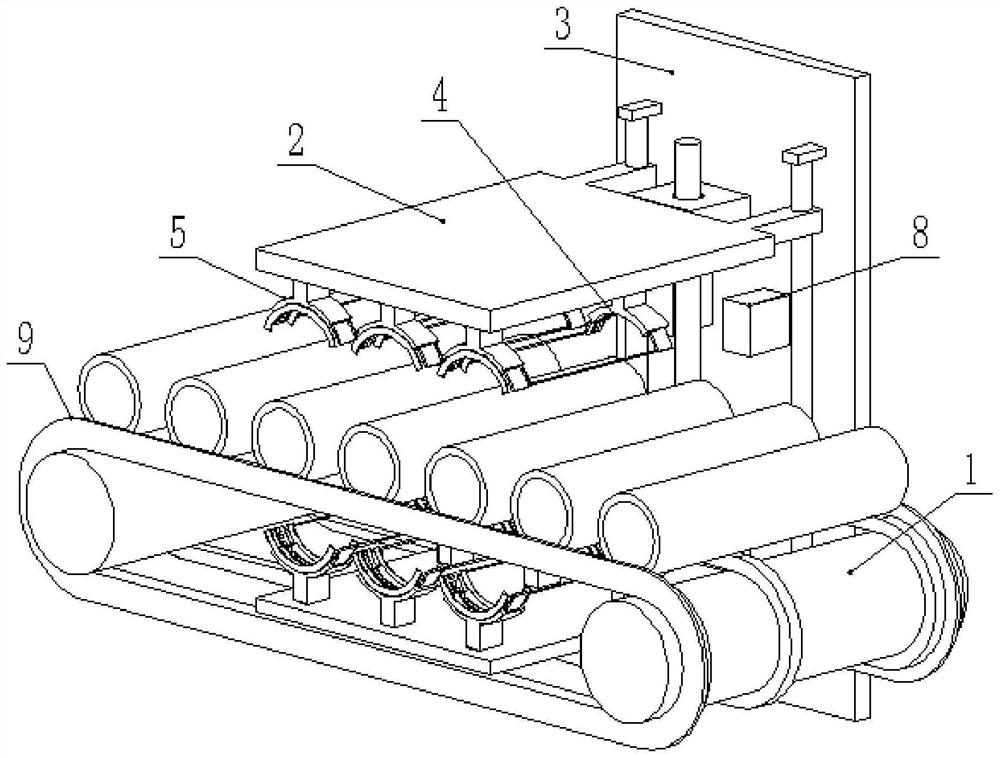

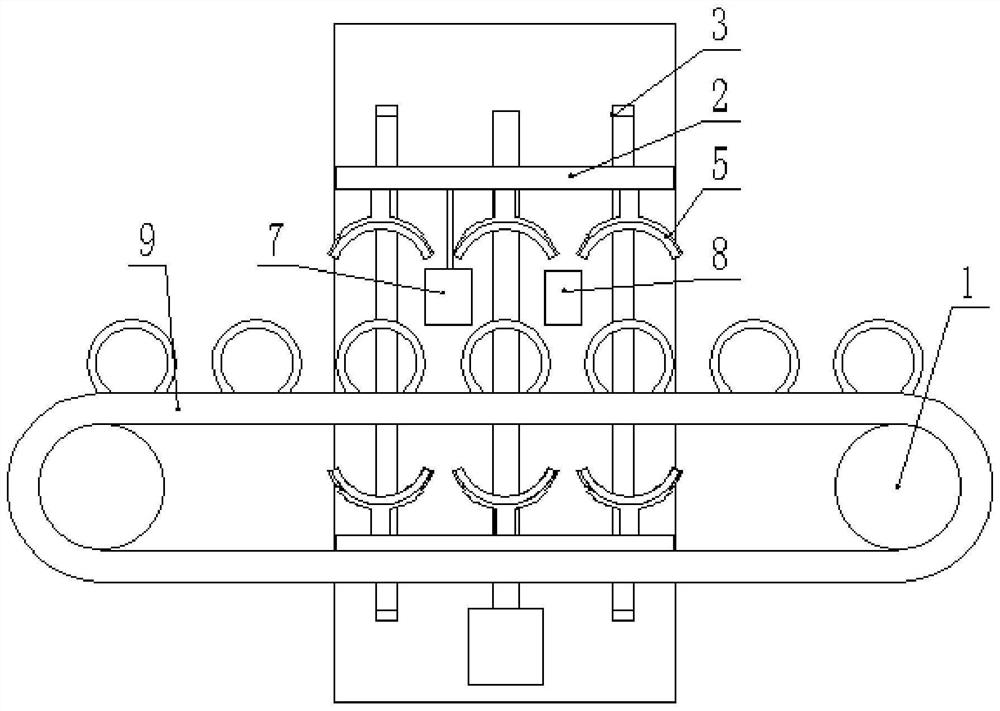

[0031] A spraying device before necking of pop cans, such as figure 1 and image 3 As shown, it includes a transmission mechanism 1 for transporting pop cans. The transmission mechanism 1 includes driving wheels, driven wheels and segmented conveyor belts. The segmented conveyor belts facilitate the contact of the fixing assembly 4 and the oil spray assembly 5 with the pop cans. The conveyor belt is provided with a rubber layer, which can increase the friction between the pop cans and the conveyor belt to prevent the pop cans from moving randomly.

[0032] Such as figure 2 and image 3 As shown, one side of the transmission mechanism 1 is provided with a relatively moving connecting plate 2 and a driving mechanism for moving the connecting plate 2. The driving mechanism is a two-way cylinder or a lead screw or nut with opposite threads. The connecting plate 2 can be relatively close to the pop can or away from the pop can. The connecting plates 2 are respectively located ...

Embodiment 2

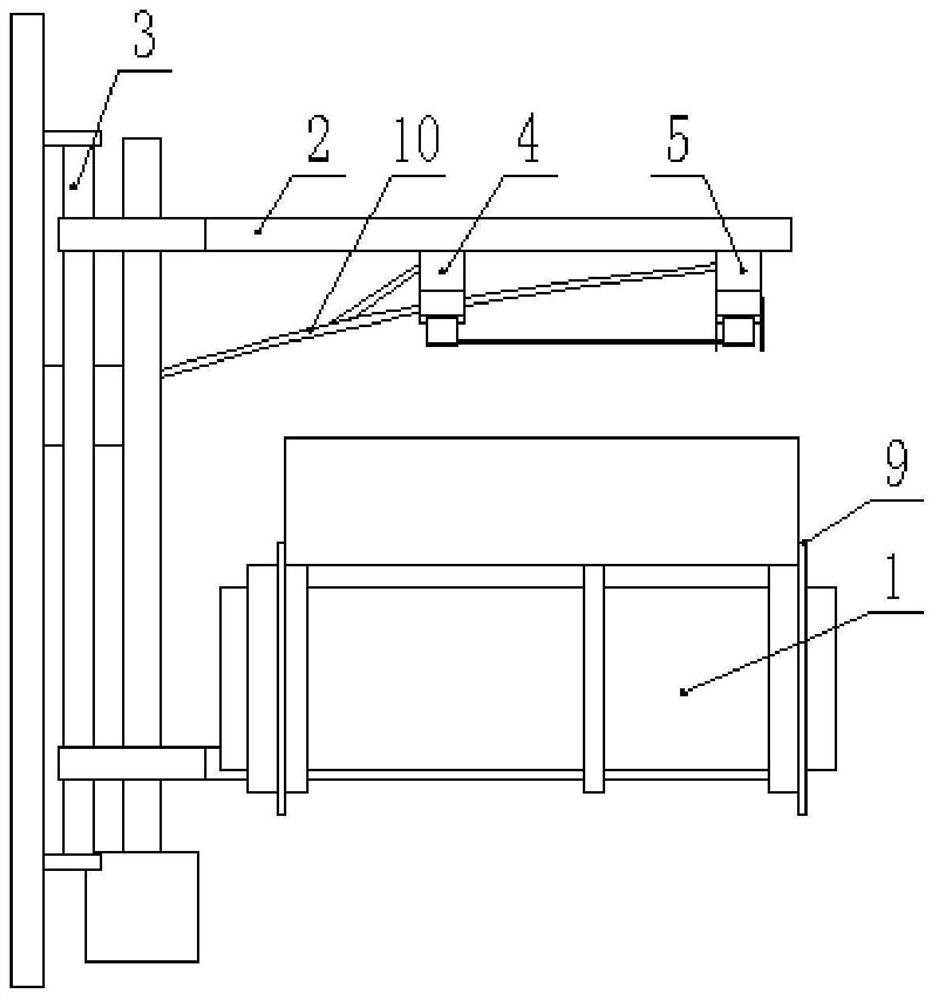

[0041] On the basis of Example 1, such as image 3 As shown, the two sides of the conveyor belt are respectively provided with positioning plates 9, the positioning plate 9 near the mouth of the tank is fixedly connected with the conveyor belt, and the positioning plate 9 near the bottom of the tank is movably connected with the conveyor belt. The installation position of the positioning plate 9 on one side and the conveyor belt can be adjusted, so as to change the distance between the positioning plates 9, thereby restricting tanks of different lengths, and avoiding the offset of the tank during transmission and affecting the positioning of the fuel injection.

[0042] Such as figure 1 and Figure 5 As shown, the connecting sleeve 51 and the sliding sleeve 52 are provided with segmented telescopic baffles 55 , and the oil nozzle 54 is located between the telescopic baffles 55 . The telescopic baffle 55 prevents the oil from being sprayed to other positions. It is used in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com