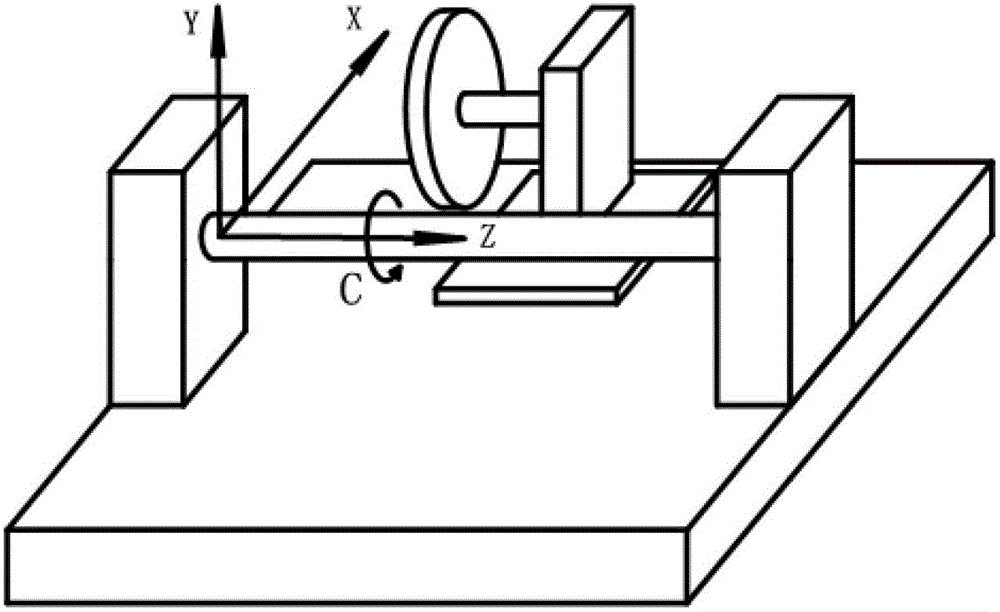

Compensation device and method of numerical control cam shaft grinding machine grinding deformation

A technology of deformation compensation device and camshaft, which is applied in the direction of abrasive belt grinders, grinding machine parts, grinding/polishing equipment, etc., can solve problems affecting work efficiency, improve machining accuracy, improve air intake and exhaust performance or Injection performance, deformation prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

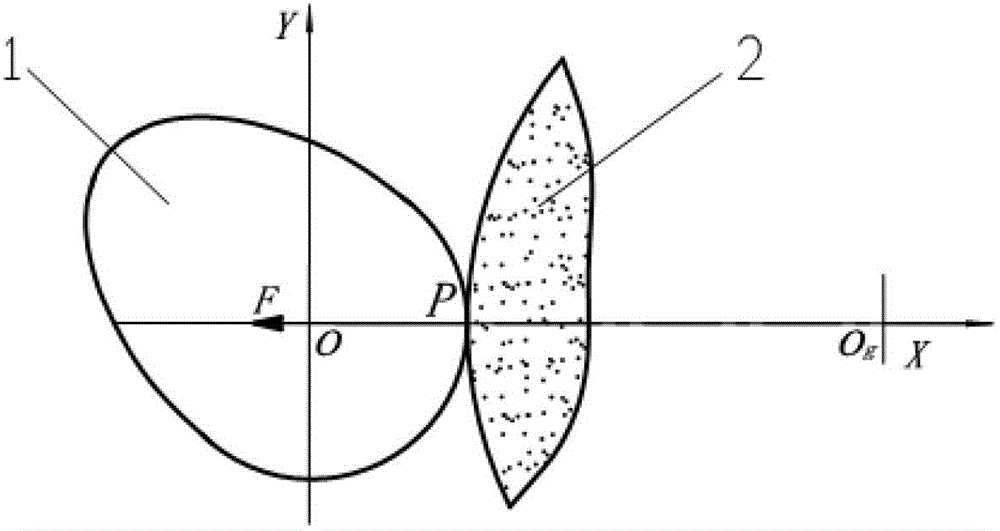

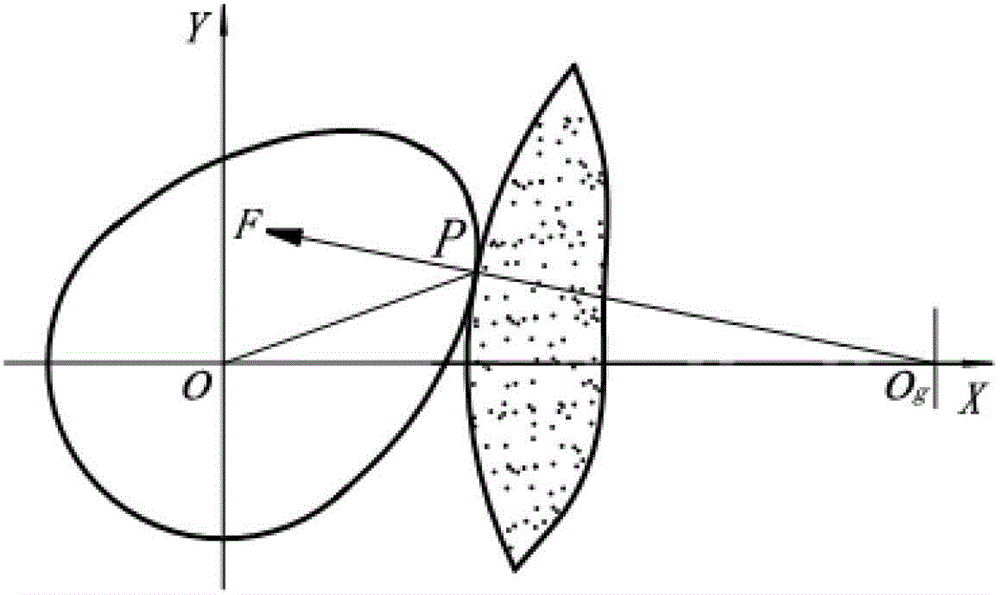

[0033] figure 2 It is the force analysis diagram of the grinding point at the base circle during CNC camshaft grinding. This figure mainly shows that when the grinding point is at the cam base circle, the camshaft will bend to the left; image 3 It is the force analysis diagram when the grinding point is on the upper half of the grinding wheel during CNC camshaft grinding. This figure mainly shows that when the grinding point is on the upper half of the grinding wheel, the camshaft will deform in the upper left direction; Figure 4It is the force analysis diagram when the grinding point is in the lower half of the grinding wheel during CNC camshaft grinding. This figure mainly shows that when the grinding point is in the lower half of the grinding wheel, the camshaft will be deformed in the downward direction to the left;

[0034] comprehensive figure 2 , image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com