Electric control uniset fuel injection pump for diesel engine

A technology for diesel engines and fuel injection pumps, which is applied to fuel injection pumps, fuel injection pumps, engine control, etc., and can solve problems such as short service life, easy wear, and poor recovery accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

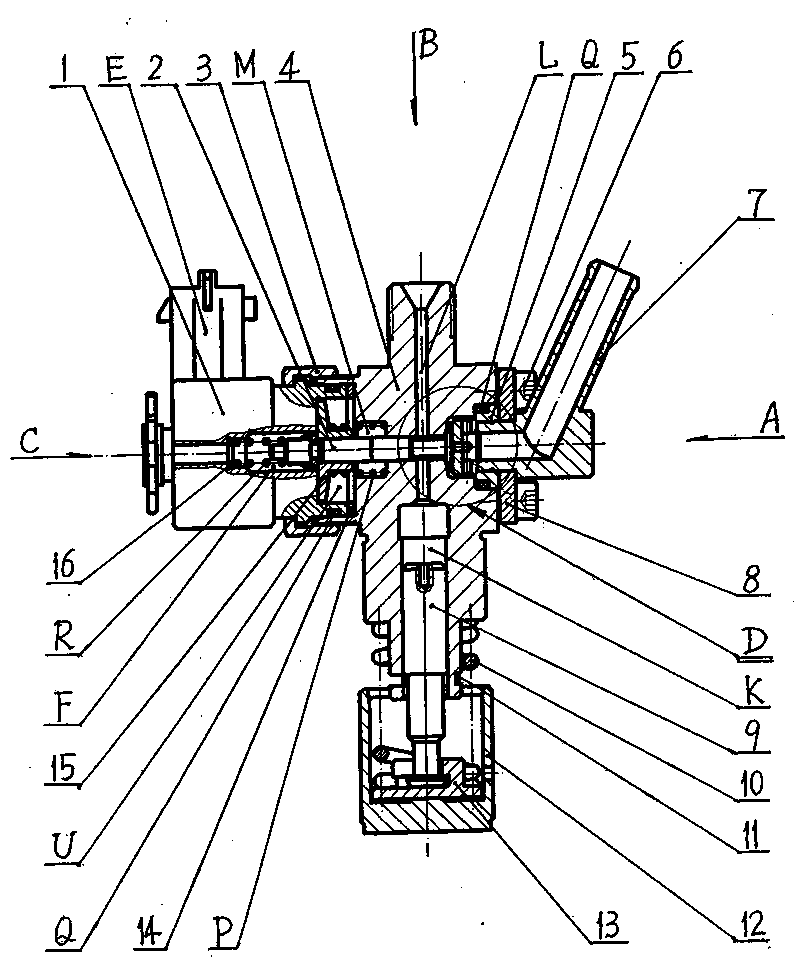

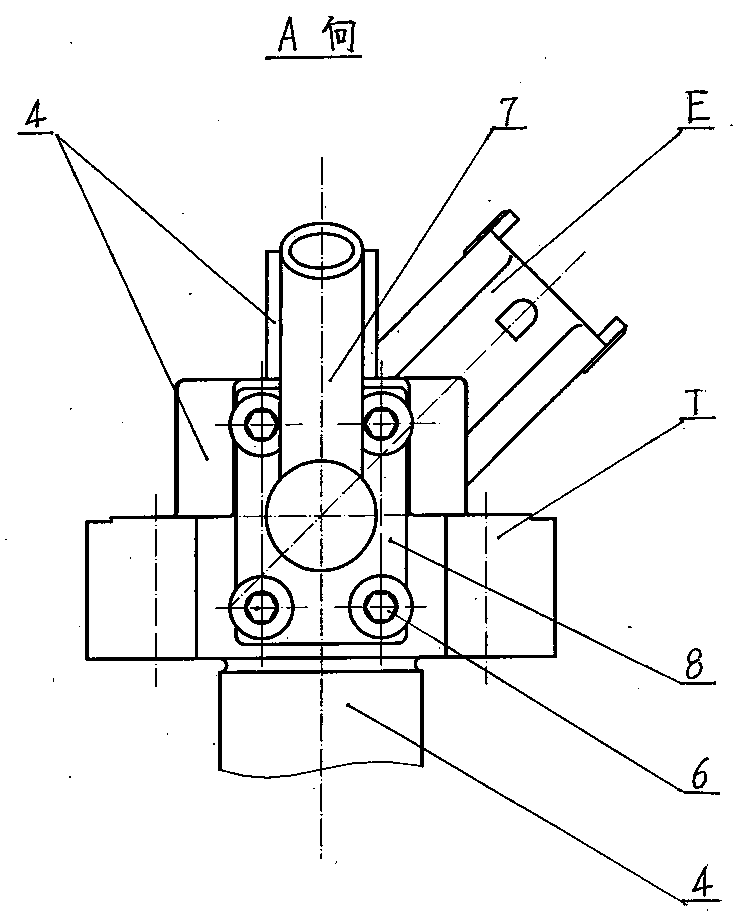

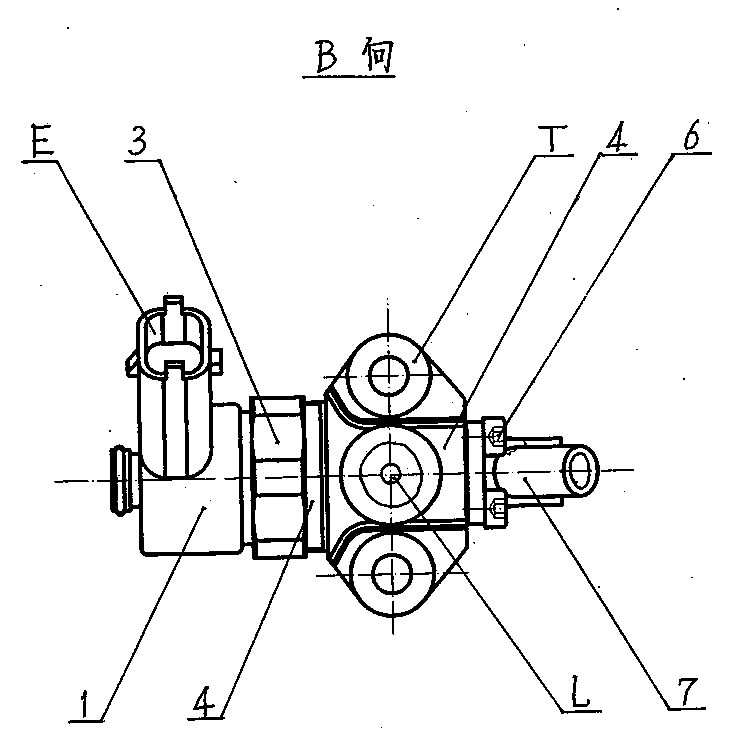

[0018] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0019] refer to figure 1 , figure 2 , image 3 , Figure 4, the present invention is composed of a plunger assembly, a solenoid valve assembly, and an oil supply assembly installed on the pump body 4, and the oil supply is controlled by an electric control system. L, with electromagnet installation hole M and low-pressure oil supply chamber N respectively opened on both sides, connected through connecting middle hole H, and vertically connected with high-pressure oil hole L; plunger assembly includes plunger 9, plunger spring 10, under spring Seat 13, push rod body 12, the front section of plunger 9 is fitted in the plunger cavity K of pump body 4, and the rear section sets plunger spring 10 to connect spring lower seat 13, and is embedded in push rod body 12; The valve assembly includes an electromagnet 1, an armature 15, a valve core 2, a return ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com