GDI fuel injector utilizing PTC thermal sensitive ceramic for heating

A technology of heat-sensitive ceramics and fuel injectors, applied in fuel injection devices, machines/engines, charging systems, etc., can solve the problems of poor fuel atomization quality and high pollutant emissions, and achieve good fuel injection effects and high heating Efficiency, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

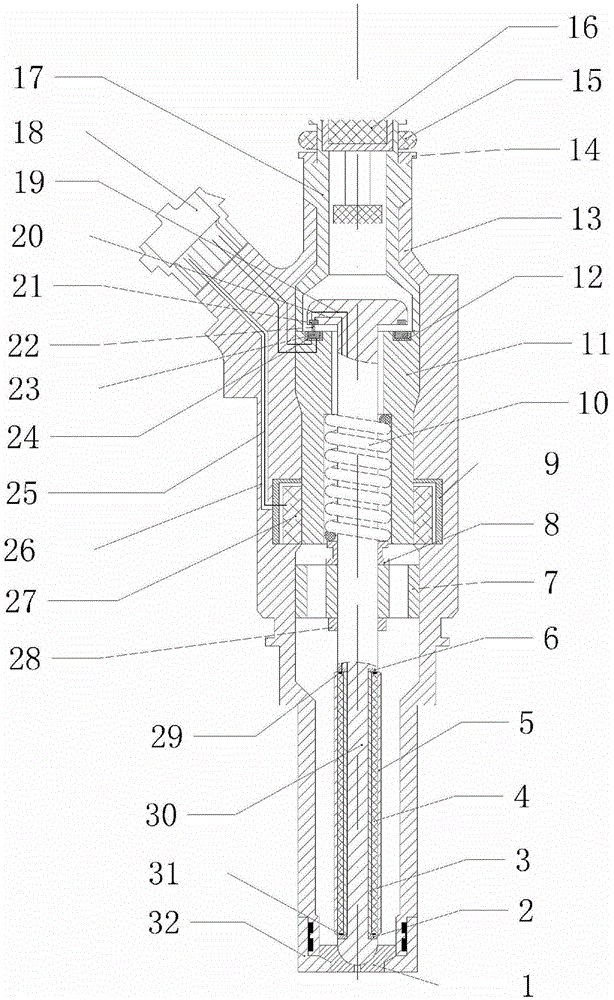

[0019] figure 1 Shown is the specific embodiment of the GDI fuel injector heated by PTC thermosensitive ceramics according to the present invention.

[0020] The present invention consists of a bottom plate 1, an insulating collar I2, an insulating sheath 3, a PTC heat-sensitive ceramic tube 4, a heat-conducting round tube 5, an insulating collar II6, an armature 7, a limiting collar I8, a coil support 9, and a return spring 10 , Sleeve 11, insulation groove 12, housing 13, sealing ring limit ring 14, sealing ring 15, filter screen 16, connecting sleeve 17, wiring harness plug 18, heating electrode negative wire 19, heating electrode positive wire 20, conductive Carbon ring I21, conductive spring 22, conductive carbon ring II23, insulating ring groove 24, electromagnetic coil wire 25, bushing 26, electromagnetic coil 27, limit collar II28, heating electrode positive pole 29, needle valve 30, heating electrode negative pole 31 , limit sleeve 32, wherein the connection sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com