Method of starting a gas turbine helicopter engine, a fuel feed circuit for such an engine, and an engine having such a circuit

A technology of gas turbines and engines, applied in the direction of machines/engines, gas turbine devices, combustion methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

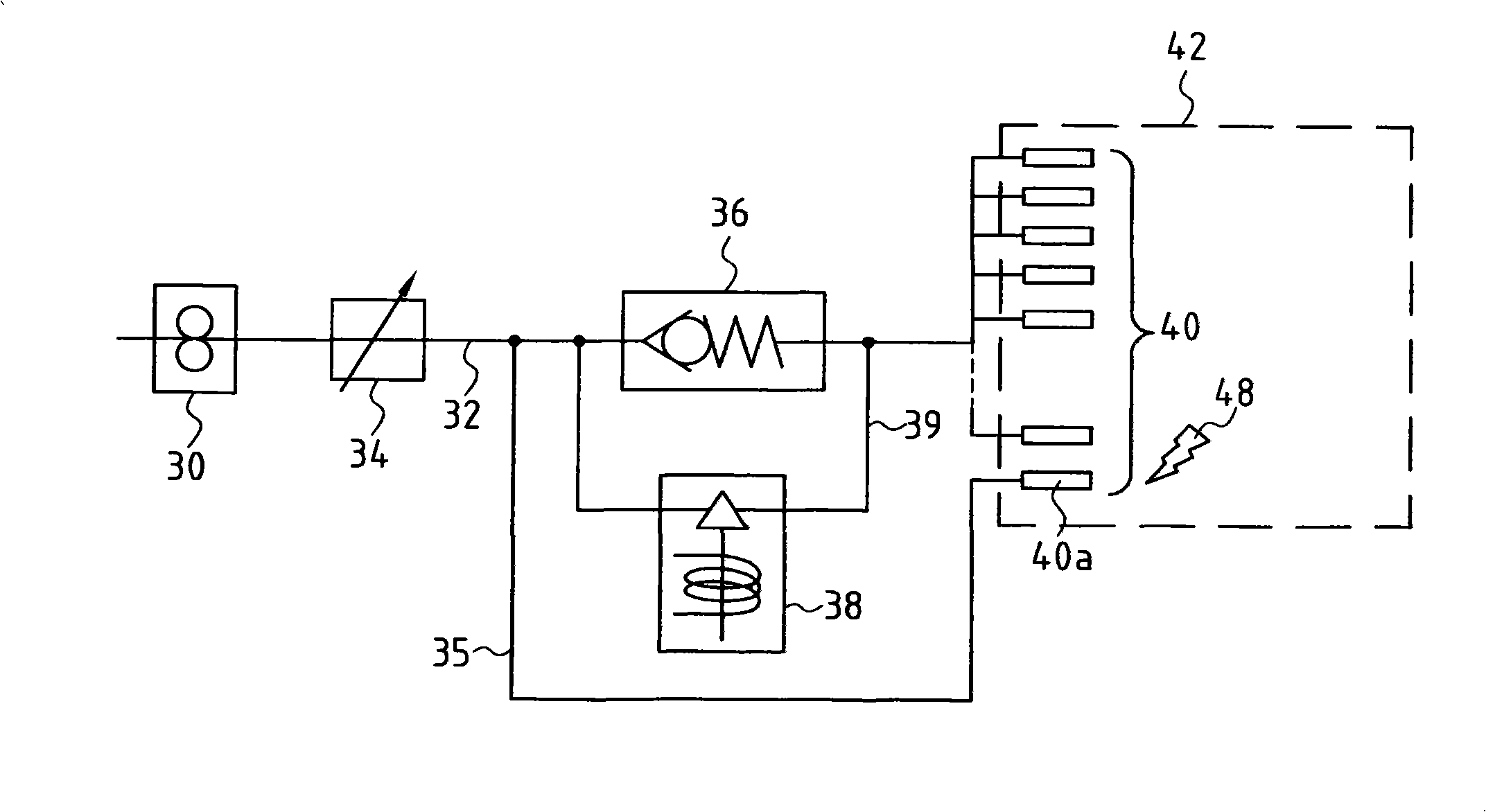

[0022] exist figure 2 In the fuel supply circuit shown, such as figure 1 The circuit shown is the same, and it can be seen that a fuel pump 30 draws fuel from a tank (not shown) and delivers it under pressure through a fuel line 32, which is equipped with a metering valve 34 for regulating fuel oil. flow.

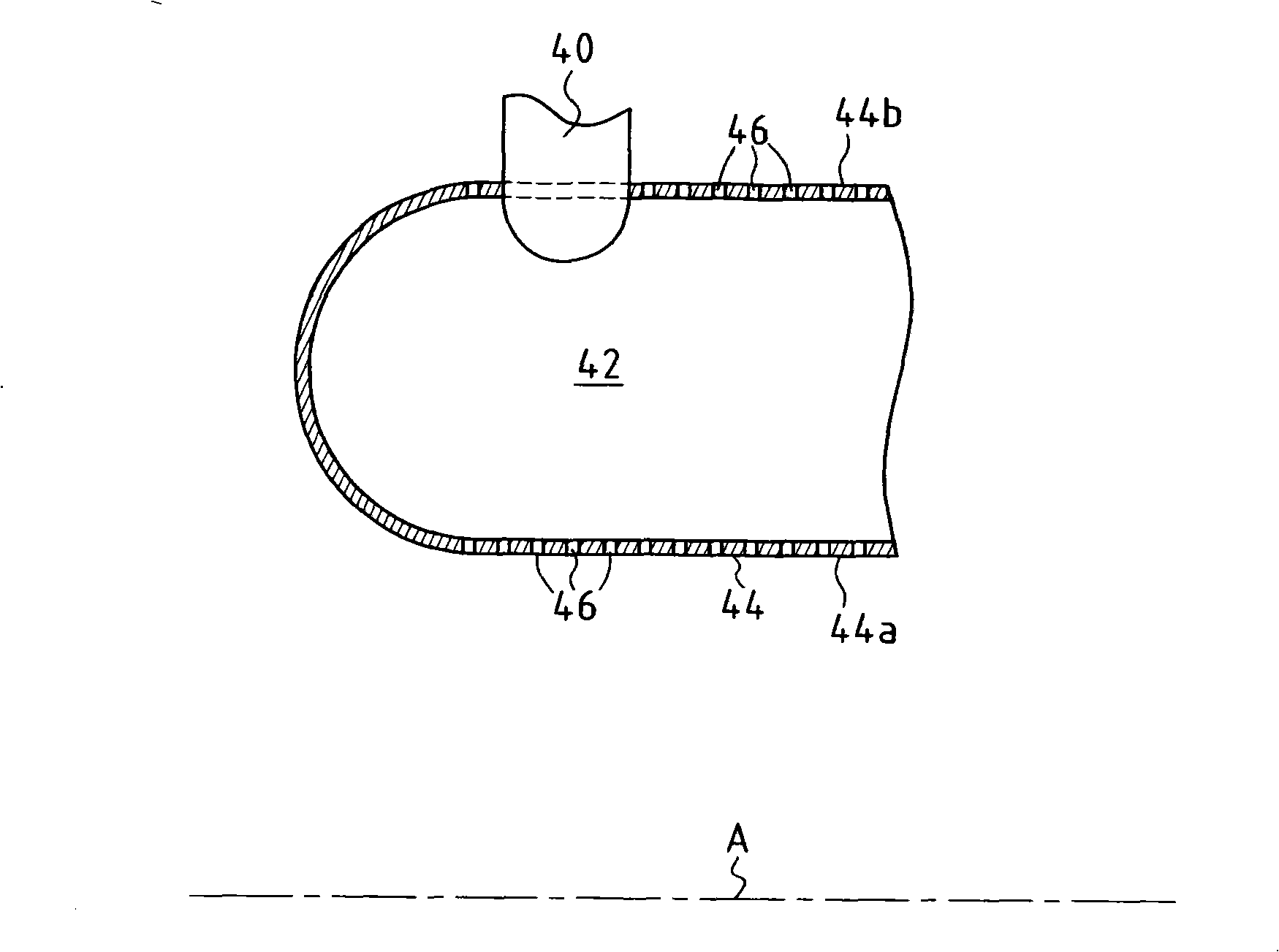

[0023] A plurality of main injectors 40 are mounted on the walls of the combustion chamber 42 to inject an air and fuel mixture into the combustion chamber. One of the main injectors 40 a is directly connected to the fuel line 32 through a line 35 . The other main injectors are connected to the fuel line 32 by a circuit comprising a rated flow holding valve or level valve 36 mounted in parallel, and an on / off valve 38 mounted on a line 39 from Passing beside the oil level valve 36 , the pipe 35 is connected to the fuel line 32 upstream of the oil level valve 36 . The oil level valve 36 applies a pre-regulated head loss - eg - 6 bar to 10 bar (0.6 MPa to 1 MPa) via a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com