Chain lubrication device for curing furnace

A technology for lubricating devices and curing furnaces, applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve problems such as poor effect and high fuel consumption, and achieve the effect of improving operation stability and efficient and precise spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

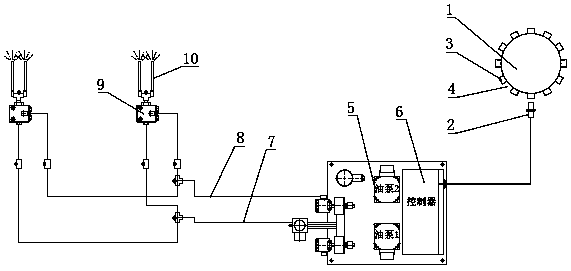

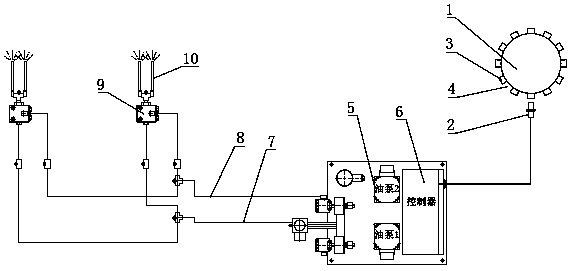

[0017] Such as figure 1 As shown, a chain lubricating device for a curing furnace described in this embodiment includes a disc 1, an induction element 2, an oil pump 5, an air pipe body 7 connected to the air pump, an oil-gas mixing distribution block 9, an oil outlet spray Pipe 10, controller 6; said oil-gas mixing distribution block 9 has an air passage chamber and an oil passage chamber, and correspondingly has an air passage inlet and an oil passage inlet. The air passage chamber and the oil passage chamber are connected, and the connection is provided with The mixture outlet is connected to the oil outlet nozzle 10; the oil pump 5 is connected to the oil passage inlet on the oil-gas mixing distribution block 9 through the oil pipe 8; the other end of the air pipe body 7 connected to the air pump is connected to the The gas path inlet on the oil-gas mixing distribution block 9 is connected; the oil-gas mixing distribution block 9 is at least one pair, and each pair is two,...

Embodiment 2

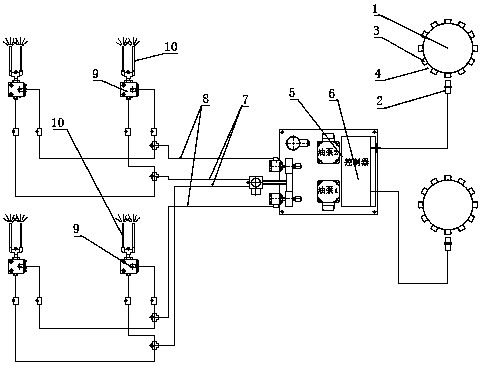

[0020] Such as figure 2 As shown, a chain lubricating device for a curing furnace described in this embodiment includes a disc 1, an induction element 2, an oil pump 5, an air pipe body 7 connected to the air pump, an oil-gas mixing distribution block 9, an oil outlet spray Pipe 10, controller 6; said oil-gas mixing distribution block 9 has an air passage chamber and an oil passage chamber, and correspondingly has an air passage inlet and an oil passage inlet. The air passage chamber and the oil passage chamber are connected, and the connection is provided with The mixture outlet is connected to the oil outlet nozzle 10; the oil pump 5 is connected to the oil passage inlet on the oil-gas mixing distribution block 9 through the oil pipe 8; the other end of the air pipe body 7 connected to the air pump is connected to the The gas path inlet on the oil-gas mixing distribution block 9 is connected; the oil-gas mixing distribution block 9 is at least one pair, and each pair is two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com