An anti-rust fuel injection device for steel bundles in a prestressed channel and an fuel injection method thereof

A fuel injection device and prestressing technology, which is used in the erection/assembly of bridges, construction material processing, construction, etc., can solve the problem of inability to inject fuel into steel beams in the tunnel, and achieve good fuel injection effect, wide application range, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

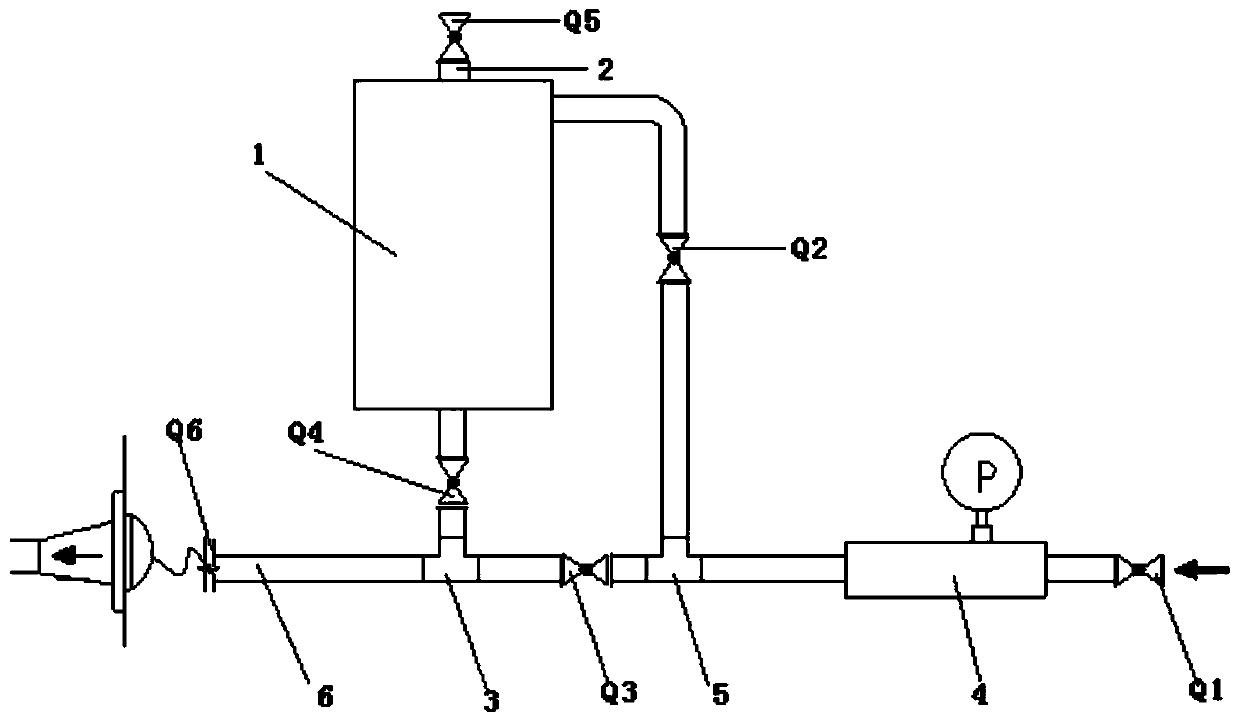

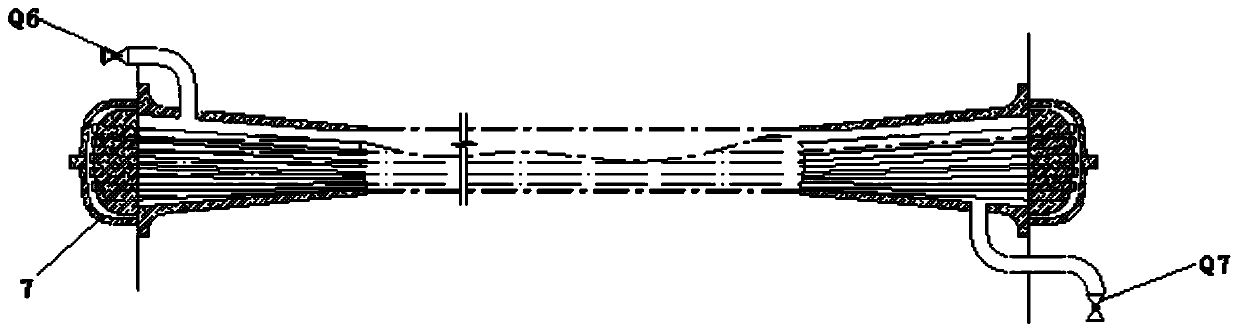

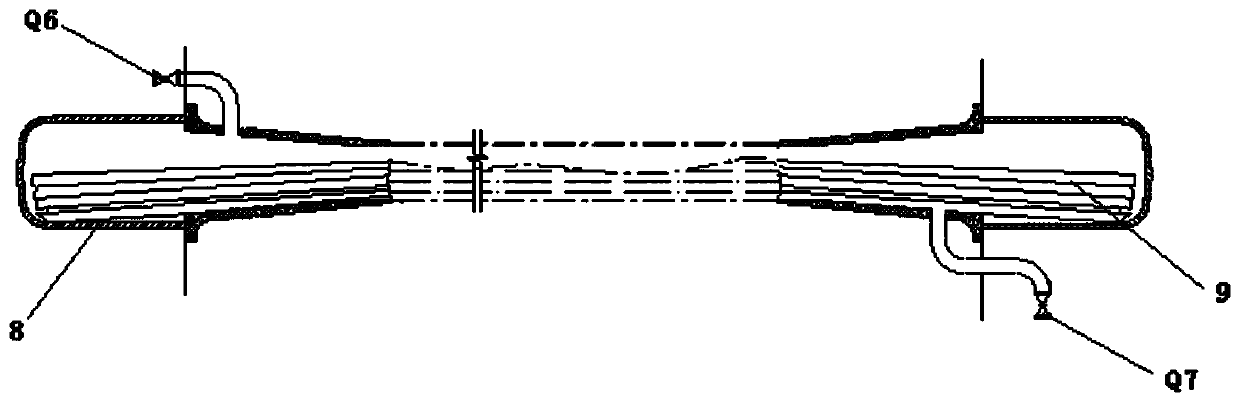

[0031] The structure of this embodiment is as Figure 1-Figure 3 As shown in the figure, a steel bundle anti-rust fuel injection device in a prestressed tunnel is provided with a grouting hole and a fuel injection outlet as the fuel injection inlet on the prestressed tunnel. The oil filling port of channel 2 is provided with an oil delivery port connected to the oil delivery channel at the bottom, and the oil supply pipe of the oil delivery channel is connected to the intake pipe and the output pipe through the first tee 3. The air end is connected to the air compressor, the inlet pipe and the oil supply tank 1 are connected to the oil return pipe through the second tee 5, the output pipe is connected to the grouting hole at one end of the hole through the hose, and the oil injection inlet 6 is provided with a valve Q6 and an oil injection outlet. There is a valve Q7 on the top, a valve Q5 on the refueling channel, a valve Q4 on the oil supply pipe, a valve Q1 and a valve Q3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com