Tube tracking oil sprayer of injector assembling machine

A technology of fuel injection device and assembly machine, which is applied in the field of fuel injection device and barrel tracking fuel injection device, which can solve the problems of difficult coordination of feeding and working steps, increased workload of operators, hidden dangers of human body safety, etc., and achieve the effect of fuel injection Good, compact structure, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

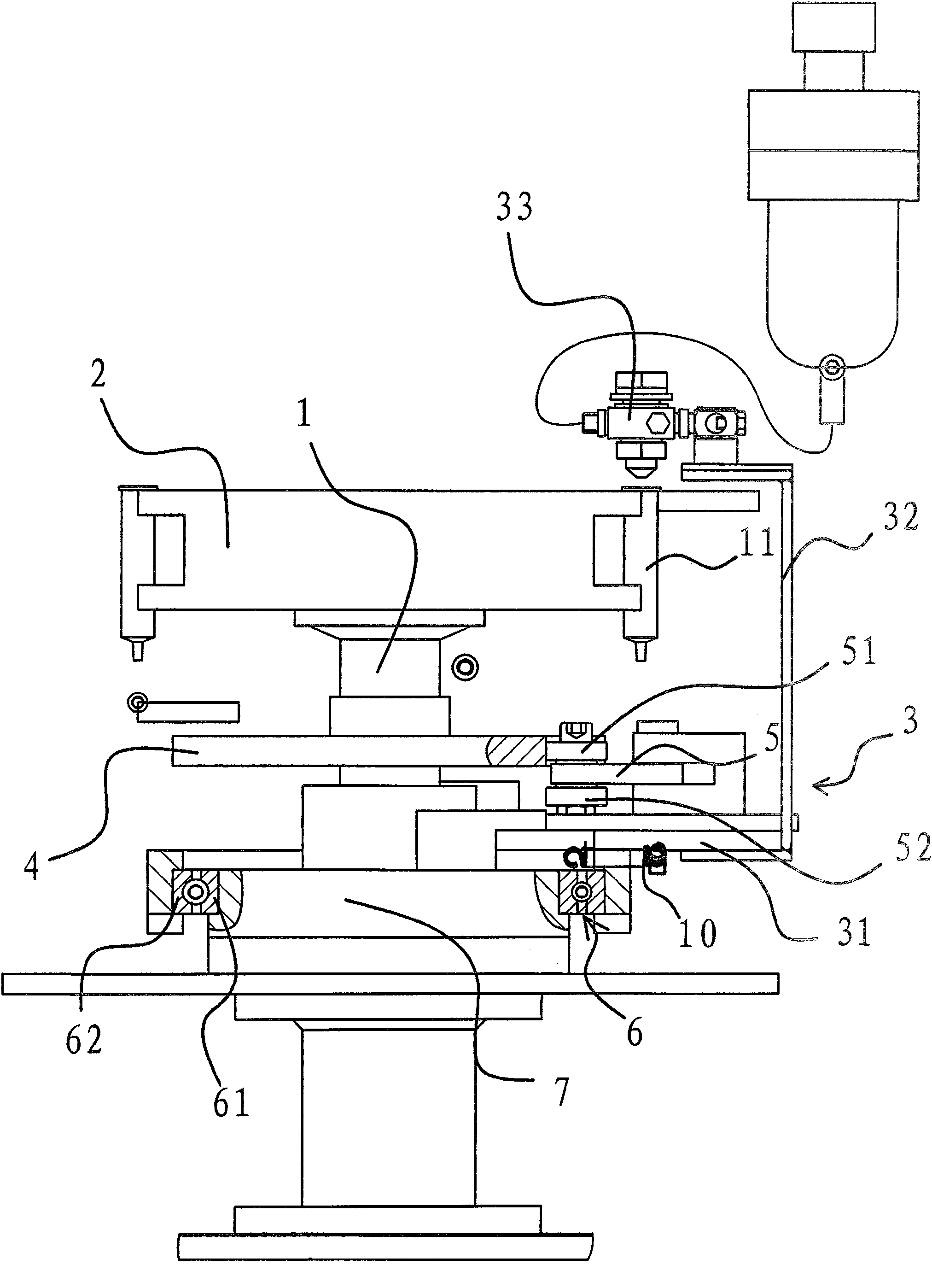

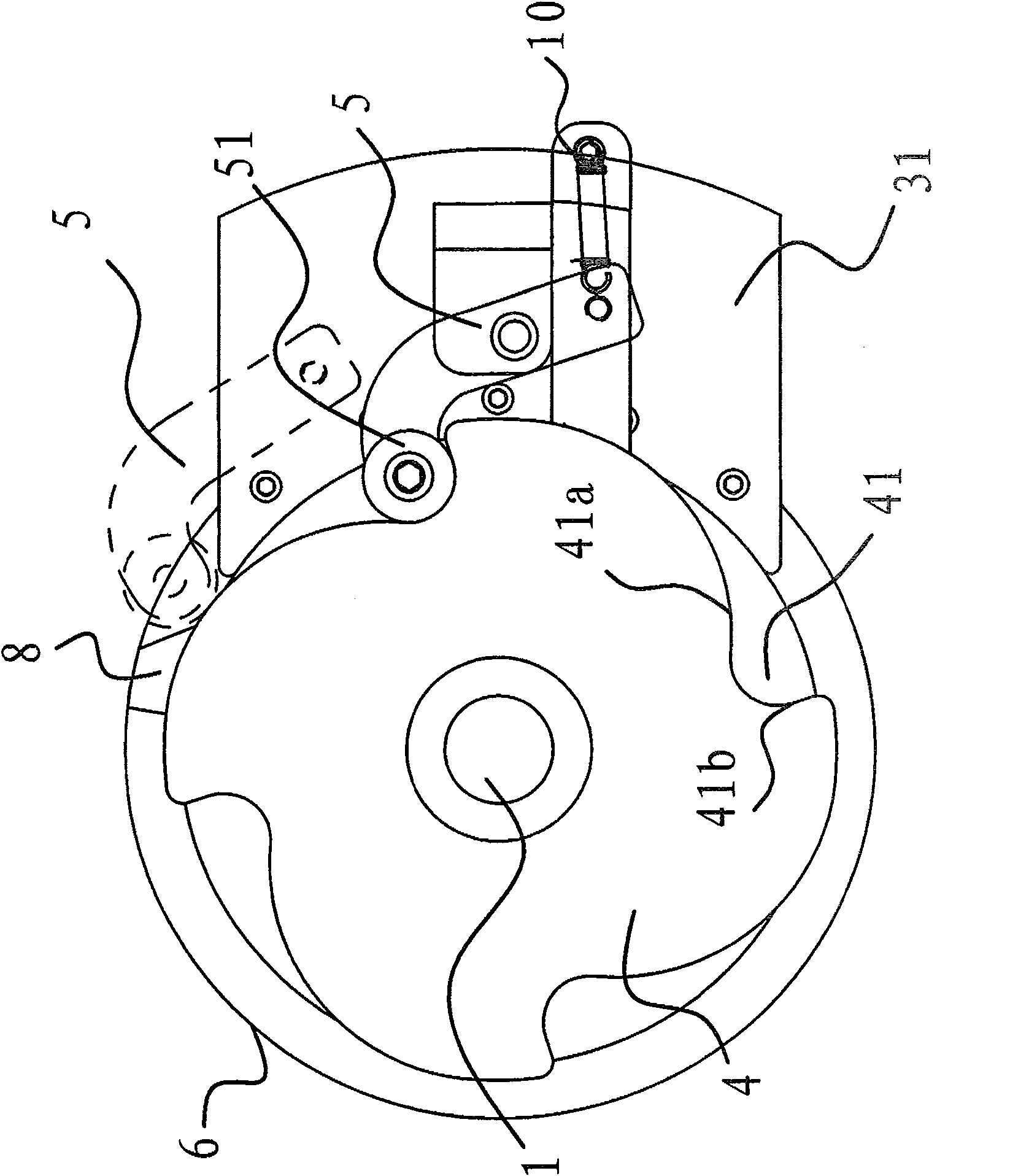

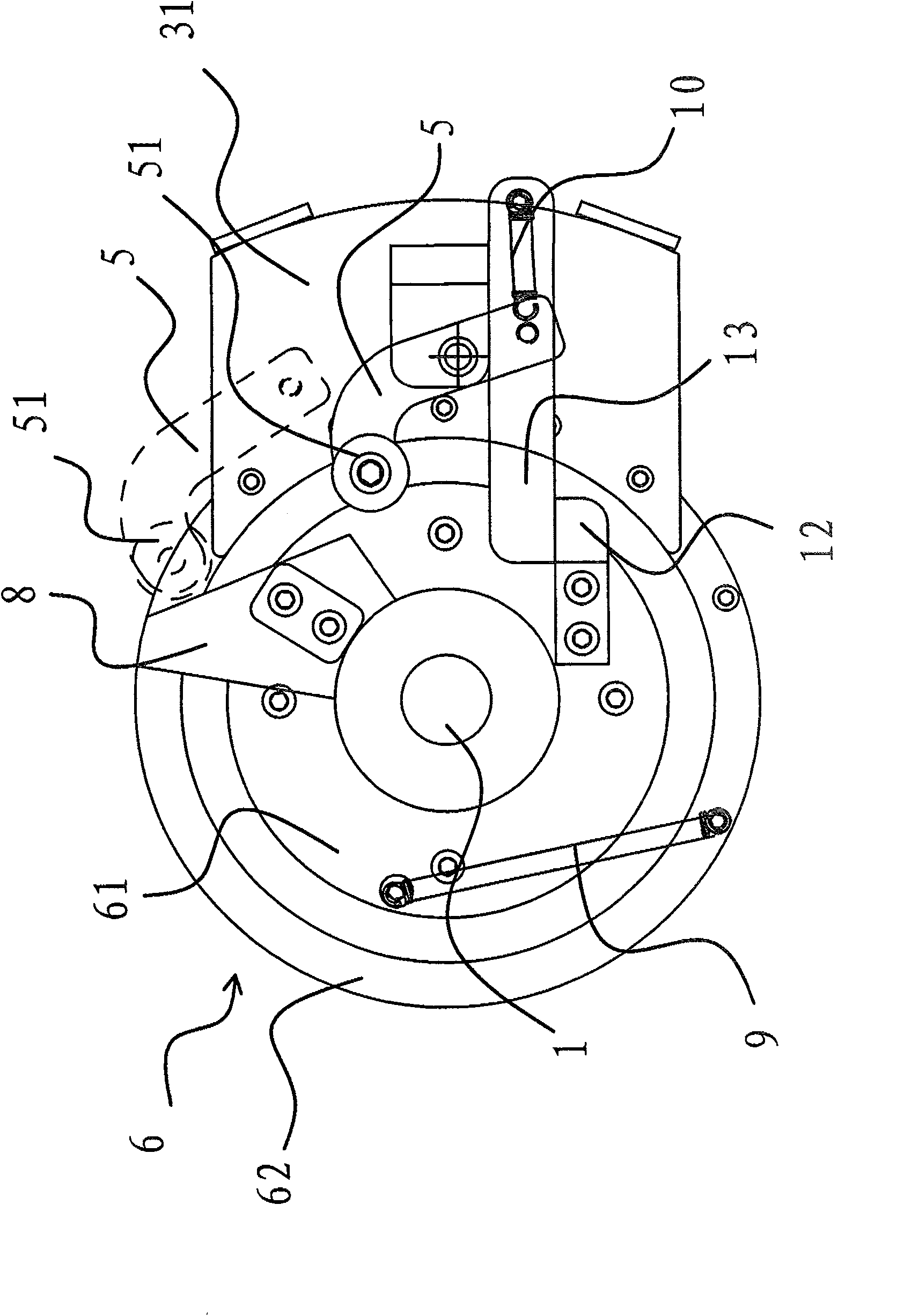

[0027] Such as figure 1 As shown, the barrel tracking oil injection device of this syringe assembly machine is composed of a rotating shaft 1, a feeding tray 2, a spray gun frame 3, a transmission wheel 4, a swing rod 5 and a large bearing 6, etc. A device for spraying oil in the cylinder.

[0028] Such as figure 1 and Figure 4 As shown, the above-mentioned feeding tray 2 is fixed on the rotating shaft 1 and can rotate together with the rotating shaft 1 , and twenty notches 21 for fixing the cylinder 11 are evenly distributed on its edge. Spray gun group frame 3 is arranged on the side of feeding tray 2, comprises base plate 31, support 32 that is connected with base plate 31 and the pressure regulating spray gun group 33 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com