Automatic production line of sealant

An automatic production line and sealant technology, applied in emulsification, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of overheating production of quantitative cylinder hydraulic system, interruption of production line production, increase of scrap rate, etc., to ensure continuous production , Ensure the performance of liquid materials and reduce the effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

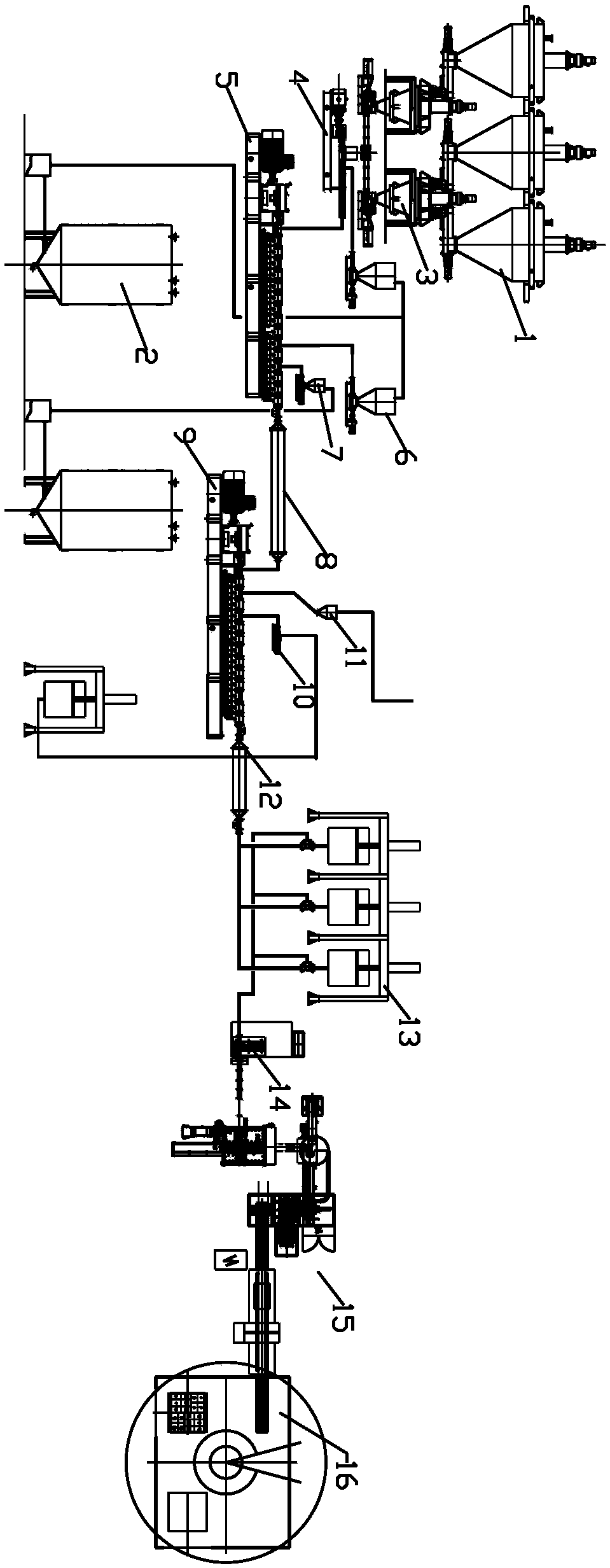

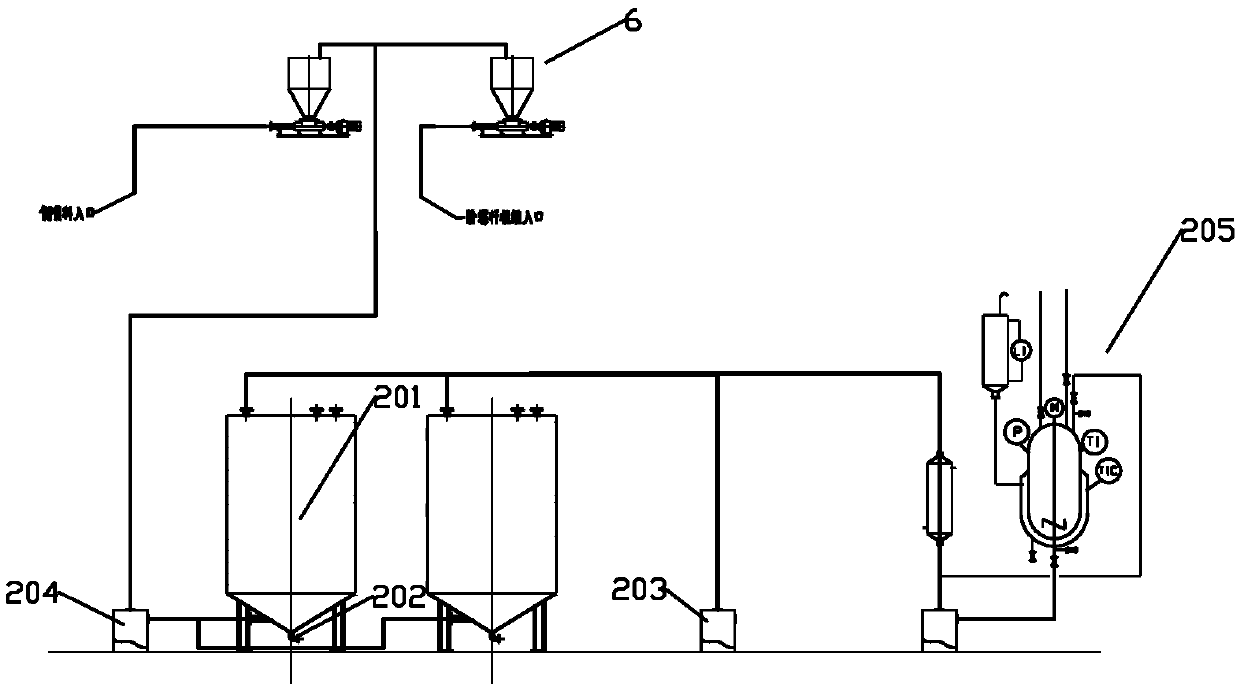

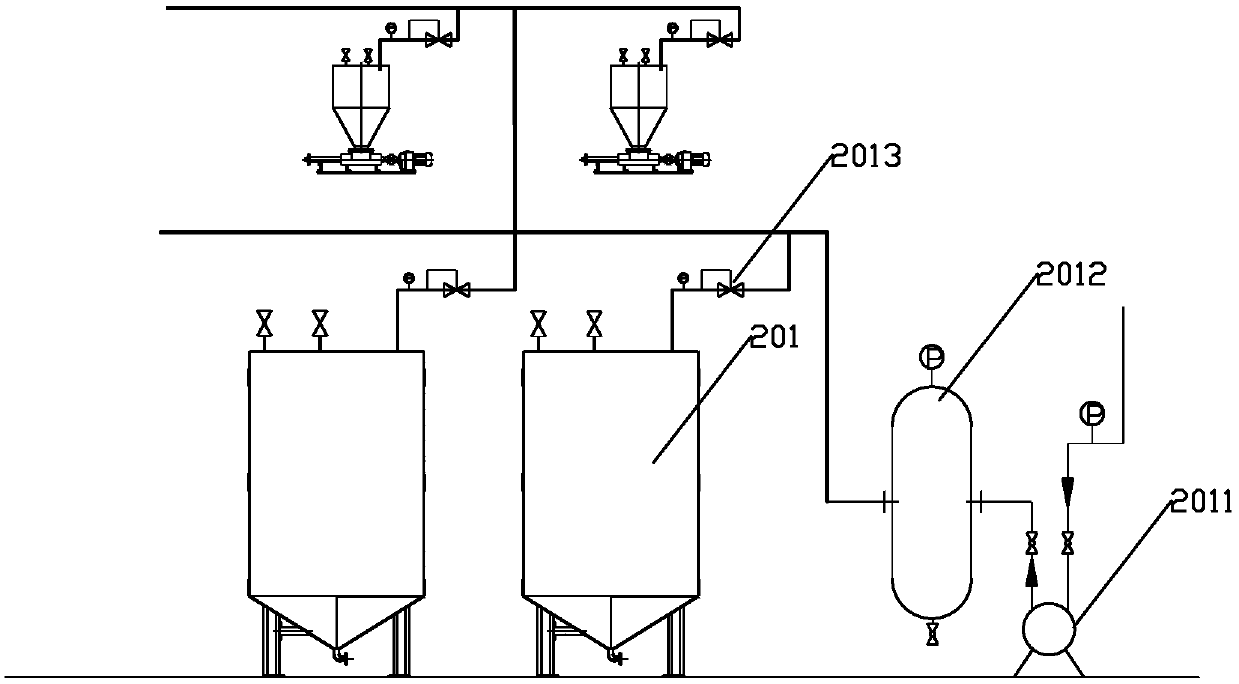

[0035] like figure 1 As shown, in this embodiment, an automatic sealant production line according to the present invention includes glue making equipment and packaging equipment. Glue making equipment includes material storage device 1, liquid storage device 2, feeding device 3, side feeding device 4, first-stage screw unit 5, liquid feeding device one 6, liquid feeding device two 7, cold and heat exchanger 8, second stage Screw unit 9, color material feeding device 10, cooler 12 and buffer tank device 13. Among them, the storage device 1, the feeding device 3, the side feeding device 4, the first-stage screw unit 5, the cold and heat exchanger 8, the second-stage screw unit 9, the cooler 12 and the buffer tank device are sequentially connected from upstream to downstream. Liquid feeding device one 6 includes a metering hopper and a metering pump, which can be accurately metered through weight loss. The liquid storage device 2 is respectively connected to the side feeding de...

Embodiment 2

[0043] In yet another embodiment of the present invention, the rest of the structure is basically the same as the above embodiment, the difference is that: downstream of the buffer tank device 13, a filling device 14, an automatic packing device 15 and an automatic palletizing device 16 are also provided. The sealant is output from the buffer tank device 13 to the filling device 14 for quantitative filling to form bottled sealant. The bottled sealant is packaged through the automatic packing device 15, and the bottled sealant is packed in a carton. Finally, the bottled sealant after packing is transported to the automatic palletizing device 16 for automatic palletizing and waiting for transportation.

[0044] Wherein, the automatic packing device 15 includes a carton folding device, a packing manipulator, a certificate putting device, a case sealing device and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com