Ultrahigh pressure cylinder valve of hydrogen energy vehicle

An ultra-high pressure, hydrogen energy technology, applied in the field of valves, can solve problems such as large pressure variation range, output flow fluctuation, increase troubles and leakage points, etc., to avoid overpressure explosion, reduce output pressure and flow fluctuations, and integrate functions Accuracy and high monitoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

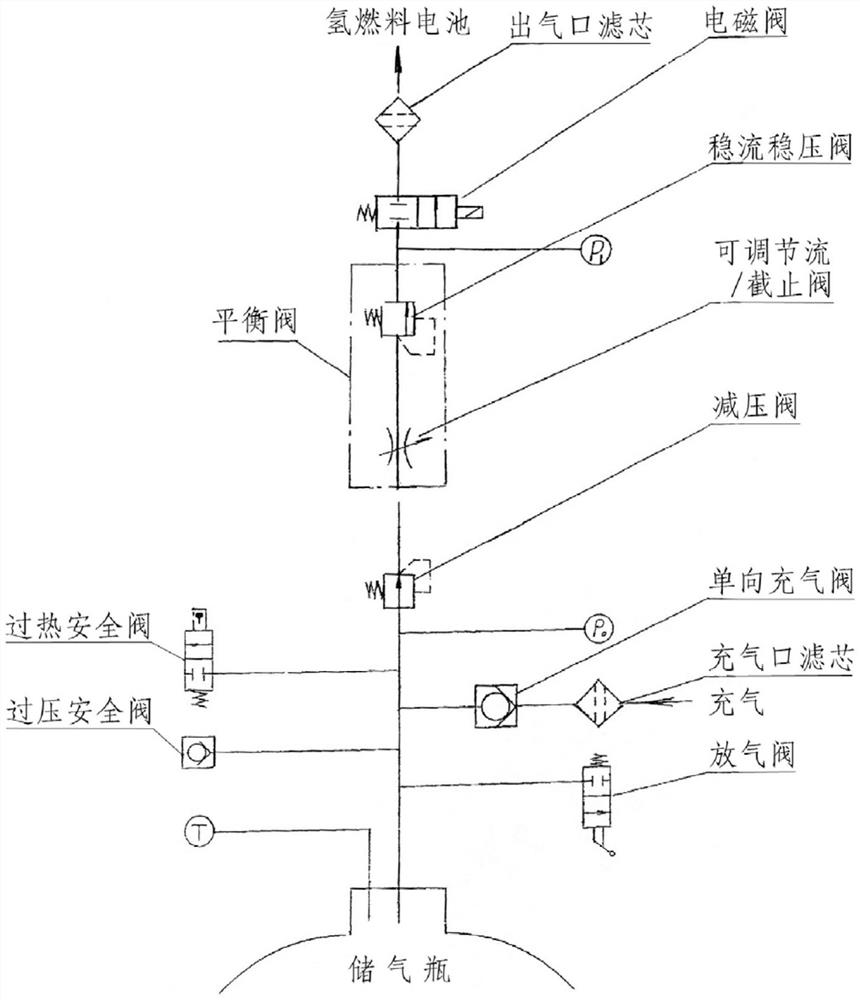

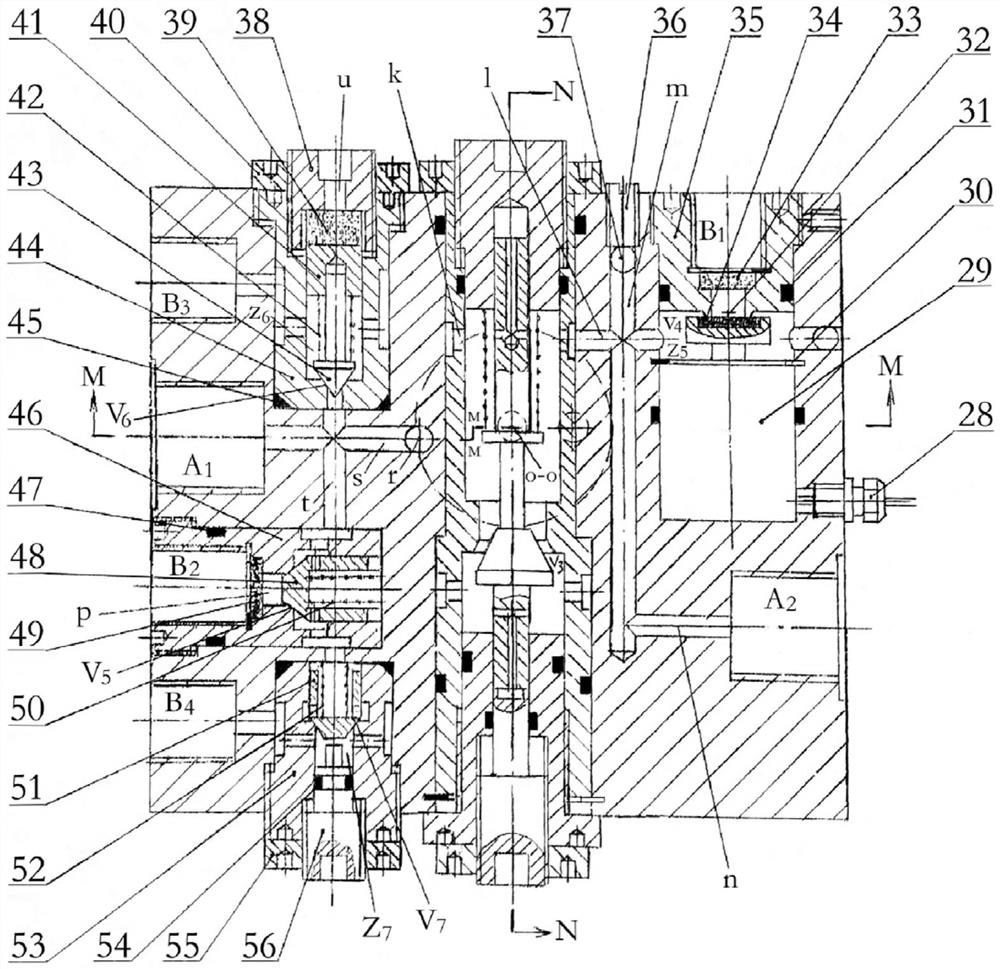

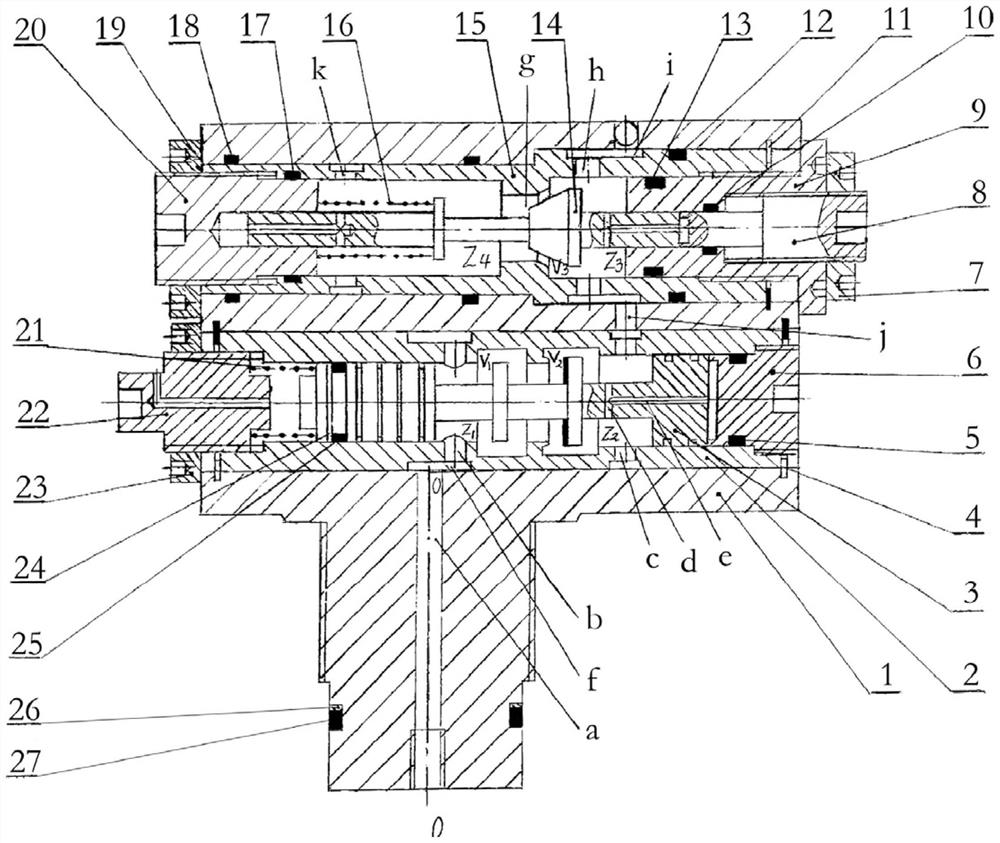

[0022] Construction of the hydrogen energy vehicle super high pressure bottle valve figure 2 , image 3 with Figure 4 , By the valve body 1, the inflatable port 49, the airfral filter 33, the pressure reducing valve, the balance valve, the solenoid valve, the inflatable single-direction valve, an overvoltage safety valve, an overheating safety valve, a gas valve, and is used to connect the air pressure in the bottle. The bottle pressure sensor interface A1 and the output pressure sensor interface A2, the air hole B1, the air hole B2, the vent hole B3 and the discharge hole B4 are collected, and each component is mounted in the valve body 1, and there is The relevant channels within the valve body 1 are connected in accordance with the design requirements. The material of the valve body 1 is a high strength aluminum alloy, so the weight is light, the valve body is composed of two parts perpendicular to each other, and the upper portion is a t-length square, in order to reduce the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com