Antibacterial polypropylene composite material, preparation method thereof and plastic tile

An antibacterial polypropylene and composite material technology, which is applied in the field of building materials, can solve environmental protection and energy saving problems, and achieve the effect of convenient transportation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

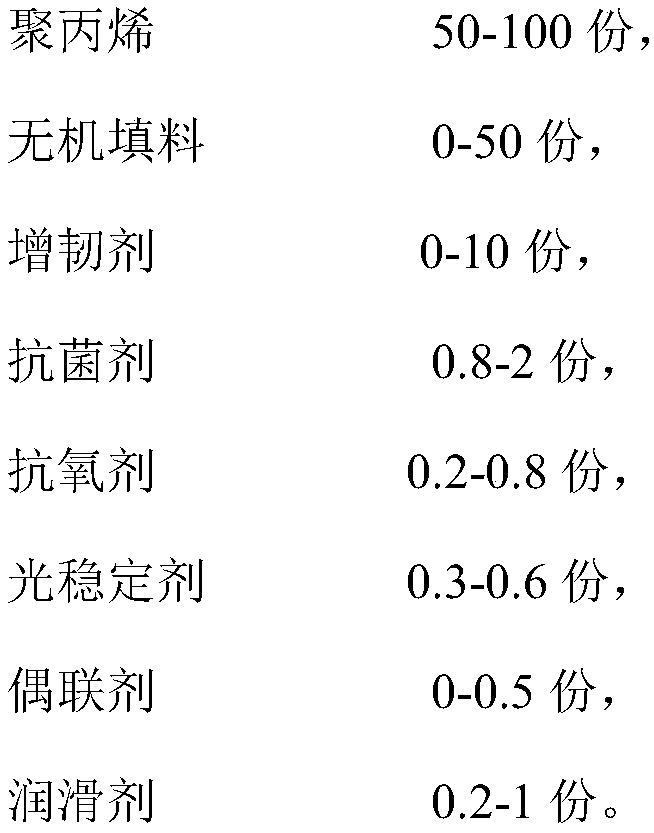

Method used

Image

Examples

Embodiment 1

[0032] In the present embodiment, the toughening agent is ethylene-octene copolymer, and the antibacterial agent is acyl pyrazolone, montmorillonite, and nano-silver with a particle diameter of 10-50 nm is dispersed in the middle of ethanol according to a mass ratio of 30:20:50 at 300 It is obtained by drying after stirring for 5 minutes at rpm. The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, and the light stabilizer is 2-(2 -Hydroxy-5-tert-octylphenyl) benzotriazole, the coupling agent is a silane coupling agent, and the lubricant is PE wax.

[0033] Weigh the raw materials according to the ratio (parts by weight) of each component in Table 1, add the weighed materials together into the high mixer and mix for 15 minutes; extrude the mixed blend through a twin-screw extruder to granulate , the temperature of each zone of the extruder is 170°C, 180°C, 185°C, 185°C, 200°C, 200°C, 200°C, 200°C, 200°C, 200°C from the feeding sec...

Embodiment 2

[0035] In the present embodiment, the toughening agent is an ethylene-propylene copolymer, and the antibacterial agent is acylpyrazolone, montmorillonite, and nano-silver with a particle diameter of 10-50nm dispersed in ethanol at 300 rpm according to a mass ratio of 30:20:80. It is obtained by drying after stirring for 5 minutes per minute. The antioxidant is tri-(2,4-di-tert-butylphenyl) phosphite, the light stabilizer is triacetone amine, and the coupling agent is a silane coupling agent. The lubricant is calcium stearate.

[0036] Weigh the raw materials according to the ratio (parts by weight) of each component in Table 1, add the weighed materials together into the high mixer and mix for 8 minutes; extrude the mixed blend through a twin-screw extruder to granulate , the temperature of each zone of the extruder is 180°C, 185°C, 195°C, 195°C, 210°C, 210°C, 210°C, 210°C, 210°C, 220°C from the feeding section to the die head. The length-to-diameter ratio is 44, and the rota...

Embodiment 3

[0038]In this embodiment, the toughening agent is ethylene-octene copolymer and ethylene-propylene copolymer, and the antibacterial agent is acyl pyrazolone, montmorillonite, and nano-silver with a particle size of 10-50nm according to the mass ratio of 30:20:50 The compound antibacterial agent that is mixed and equipped, the antioxidant is dioctadecyl thiodipropionate, and the light stabilizer is poly[[6-[(1,1,3,3-tetramethylbutyl)amine] -1,3,5-triazine-2,4-diyl][(2,2,6,6-tetramethyl-4-piperidine)imine]-1,6-dihexanediyl[( 2,2,6,6-tetramethyl-4-piperidine) imine]], the coupling agent is a silane coupling agent, and the lubricant is EVA wax and ethylene distearate amine.

[0039] Weigh the raw materials according to the ratio (parts by weight) of each component in Table 1, add the weighed materials together into the high mixer and mix for 8 minutes; extrude the mixed blend through a twin-screw extruder to granulate , the temperature of each zone of the extruder from the feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com